Cylinder Head Assemble (LDK, LHU)

| Cylinder Head Assemble (LDK, LHU) |

Special Tools

| • |

EN-8062

Valve Spring Compressor

|

|

| • |

EN-9666

Valve Spring Tester

|

|

| • |

EN-43963

Valve Spring Compressor (off car)

|

|

For equivalent regional tools, refer to Special Tools (LDK, LHU) .

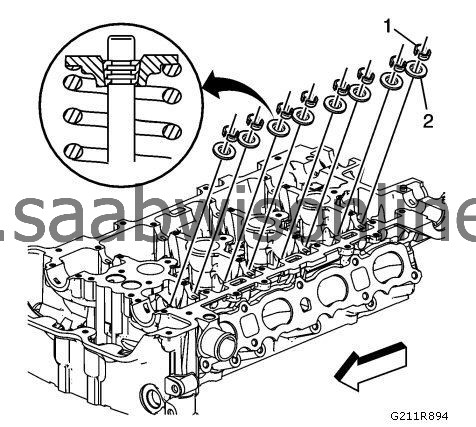

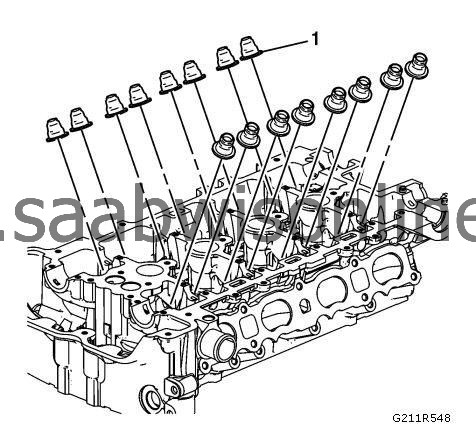

| 1. |

Install NEW cylinder head plugs (1). Coat the plugs with sealer. Refer to Adhesives, Fluids, Lubricants, and Sealers (LDK, LHU) .

|

|||||||||

| 2. |

Inspect the valve springs.

|

|

| 3. |

Look for the following conditions when inspecting the valve springs:

|

|

| • |

Expanded height

|

| • |

Unparallel spring ends

|

| • |

Spring tension using

EN-9666

tester

|

| • |

Any distorted springs should be replaced

|

| 4. |

Inspect the valves (1) and the valve seats. Refer to

Valve and Seat Grinding

.

|

|

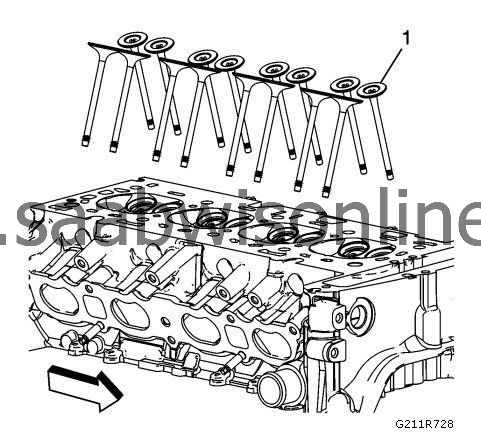

| 5. |

Install the valves (1). Replace any valves, if required.

|

|

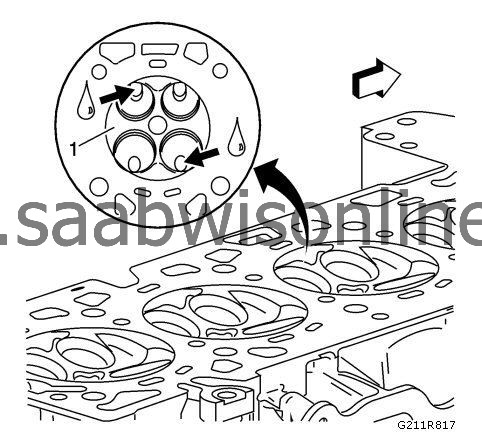

| 6. |

Install the new valve seals (1). Fully seat the seals on the valve guides.

|

|||||||

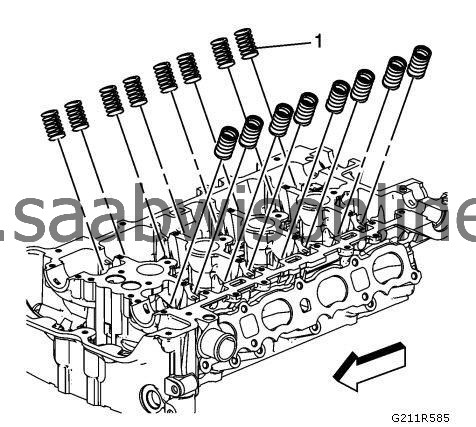

| 7. |

Install the springs (1).

|

|

| 9. |

Using the

EN-8062

compressor and the

EN-43963

compressor , compress the valve spring.

|

|

| 10. |

Install the valve keys (1).

|

|

| 11. |

Slowly release the

EN-8062

compressor and the

EN-43963

compressor from the valve/spring assembly.

|

|

| 12. |

Inspect for proper valve key seating.

|

|

| 13. |

Install the remaining valves, springs, and other components.

|

|

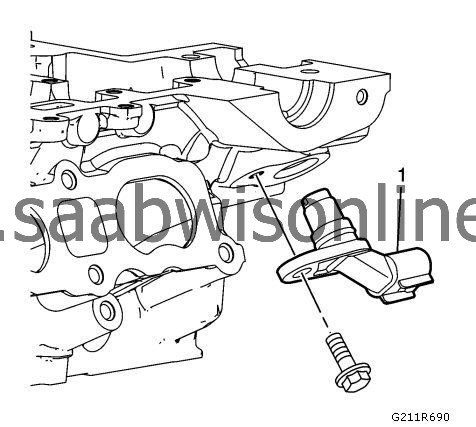

| 14. |

Lubricate the camshaft position sensor O-ring with clean engine oil.

|

|

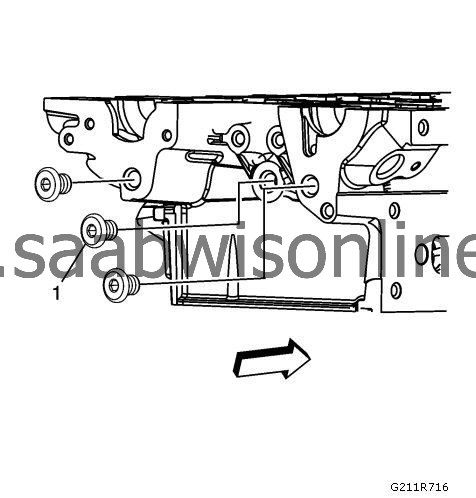

| 15. |

Refer to

Fastener Caution

.

Install the intake camshaft position sensor (1) and bolt. Tighten the intake camshaft position sensor bolt to 10 Nm (89 lb in) . |

|

Warning

Warning