Fuel Rail and Injectors Cleaning and Inspection (LDK, LHU)

|

|

Fuel Rail and Injectors Cleaning and Inspection (LDK, LHU)

|

Special Tools

EN-48266

Injector Seal Installer and Sizer

For equivalent regional tools, refer to

Special Tools (LDK, LHU)

.

|

1.

|

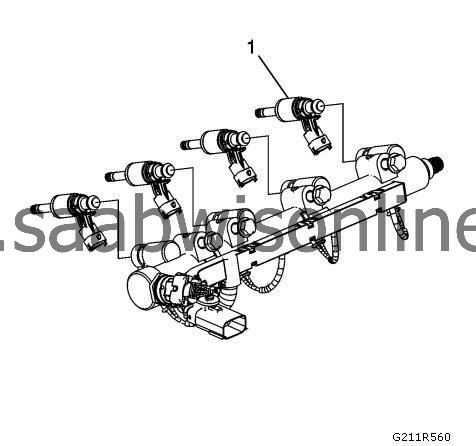

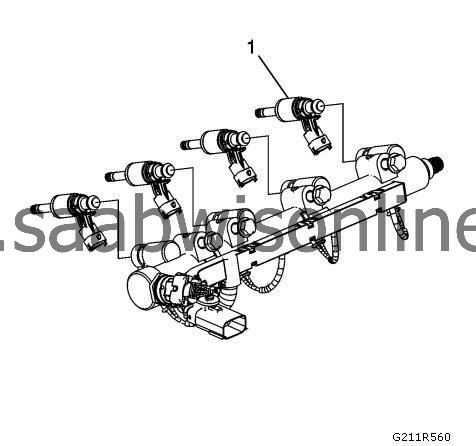

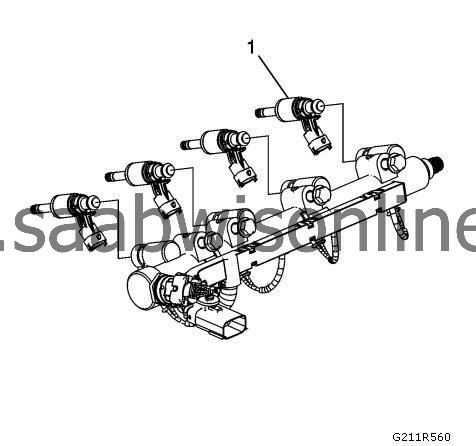

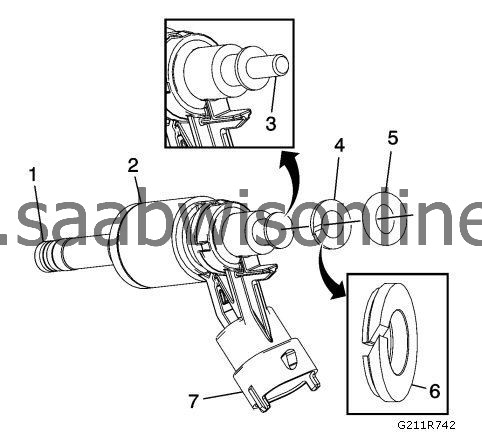

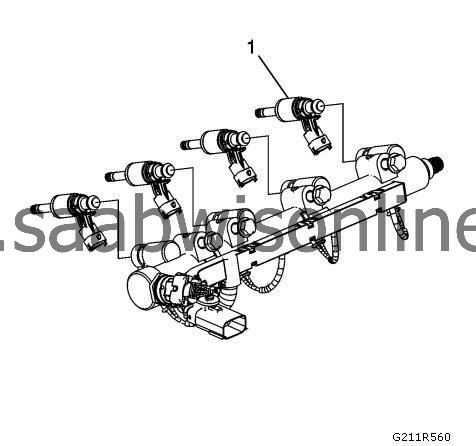

Unplug the electrical connections from the fuel injectors (1).

|

|

2.

|

|

Note

|

|

DO NOT tilt or twist the injector during removal.

|

Remove the injectors from the fuel rail by pulling straight out along the fuel injector axis.

|

|

3.

|

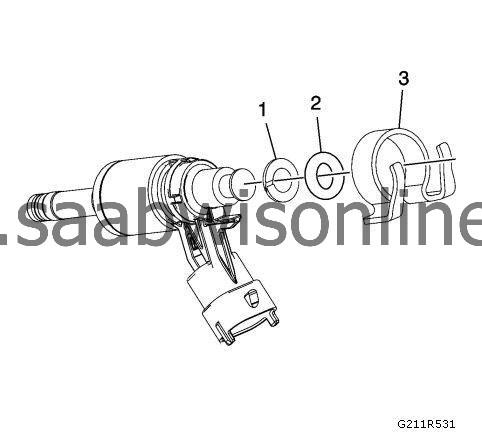

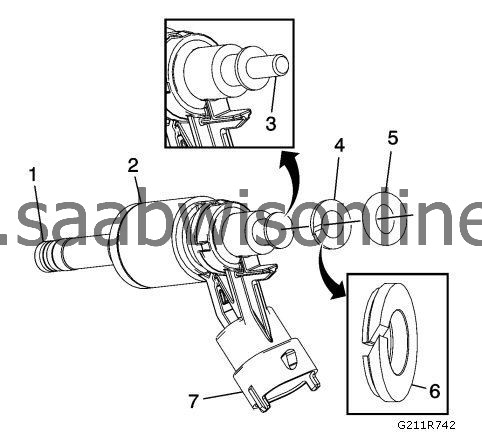

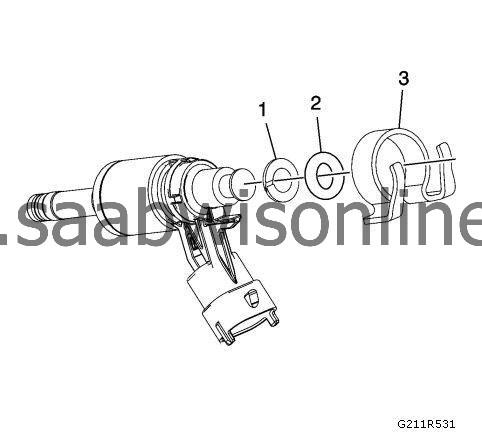

Remove and discard the fuel injector hold-down clamp (3).

|

|

4.

|

Remove and discard the fuel injector O-ring (2) and plastic spacer (1).

|

|

5.

|

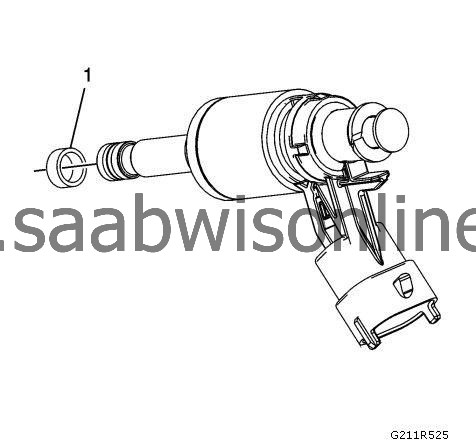

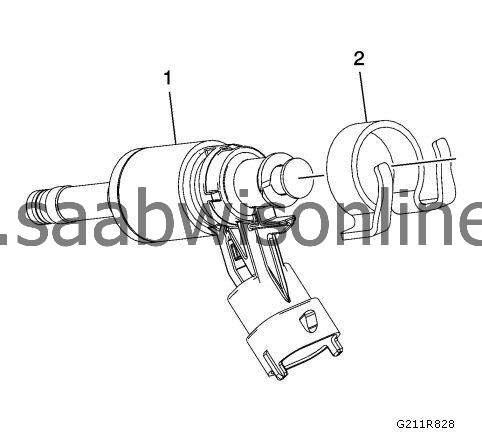

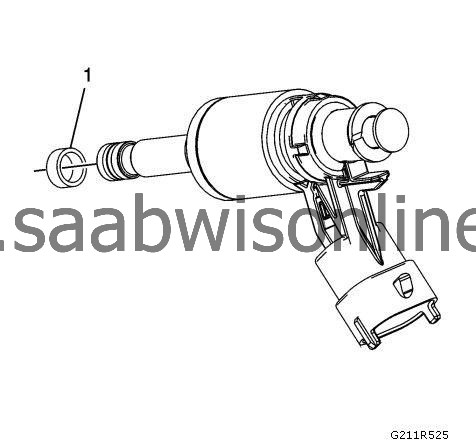

Remove and discard the fuel injector seal (1).

|

|

6.

|

|

Note

|

|

Do not soak or submerge the fuel rail or injectors in solvent.

|

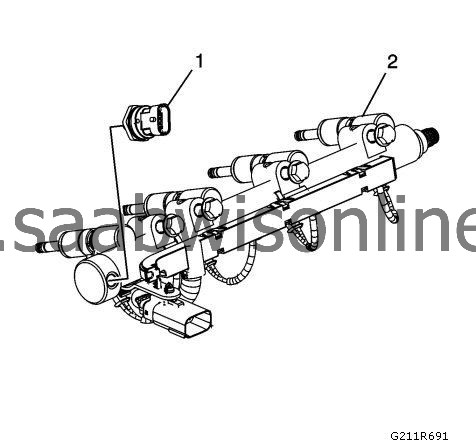

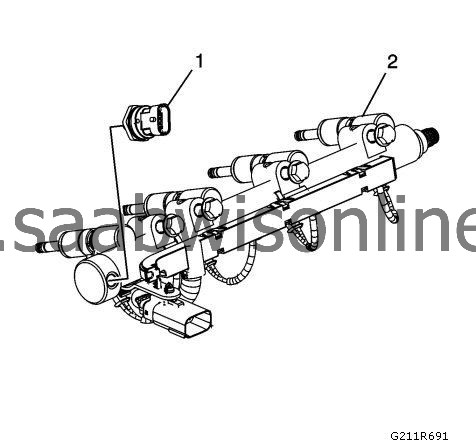

Clean the exterior of the fuel rail (2) and injectors in solvent.

|

|

7.

|

Refer to

Fastener Caution

.

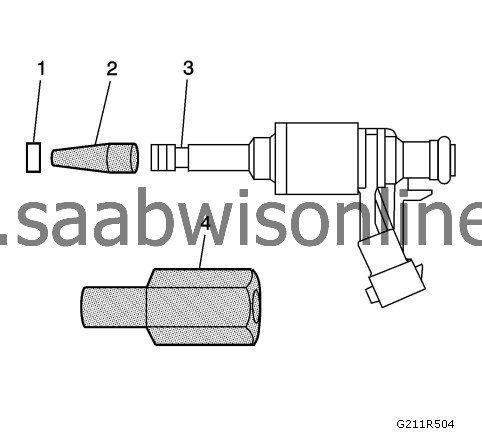

Inspect the high pressure fuel sensor (1) for damage.

|

|

|

7.1.

|

If replacing, dry the fuel pressure sensor bore in the fuel rail with a lint free cloth.

|

|

|

7.2.

|

The bore should be free of fuel, debris, and burrs.

|

|

|

7.3.

|

Lubricate the fuel pressure sensor bore, in the fuel rail, with clean engine oil.

|

|

|

7.4.

|

Lubricate the threads and sealing area on the fuel pressure sensor with clean engine oil.

|

|

|

7.5.

|

Install the fuel pressure sensor hand tight.

|

|

|

7.6.

|

Remove the fuel pressure sensor and re-lubricate the bore, threads, and sealing area.

|

|

|

7.7.

|

Re-install the fuel pressure sensor. Tighten the high pressure fuel sensor to

33 Nm (25 lb ft)

.

|

|

8.

|

Inspect the fuel rail and components for the following conditions:

|

|

|

•

|

Damage, debris, or restrictions to the fuel rail

|

|

|

•

|

Damage, debris, or restrictions to the fuel ports in the fuel rail

|

|

|

•

|

Damage to the mounting area for the fuel rail

|

|

|

•

|

Damage to the fuel rail mounting bolts

|

|

|

•

|

Damage to the threads on the fuel rail fuel feed fitting

|

|

9.

|

Inspect the fuel injectors for the following conditions:

|

|

|

•

|

Damage to the fuel injector connector (7)

|

|

|

•

|

Damage to the fuel injector harness connector

|

|

|

•

|

Damage to the fuel injector tip (1)

|

|

|

•

|

Damage to the tolerance ring (2)

|

|

|

•

|

Damage to the wave guide (3), if equipped

|

|

10.

|

Replace the fuel rail or injector if any damage is found. Do not attempt to repair a fuel rail or injector.

|

|

11.

|

Lubricate the NEW O-ring (5) with 5W30 engine oil.

|

|

12.

|

Install a NEW O-ring and plastic spacer (4) on the injector. The plastic spacer has a top (6) and a bottom. The top, O-ring sealing area, is wider.

|

|

13.

|

|

Note

|

|

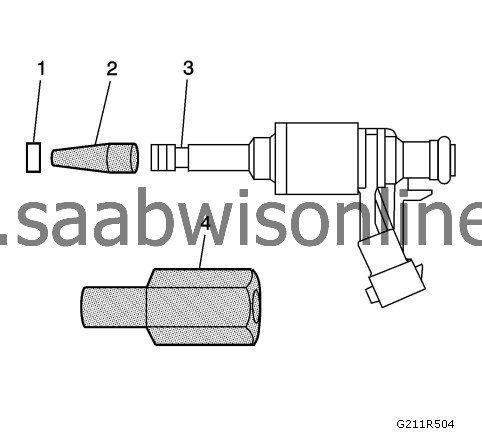

Do not use any type of lubricant when installing the NEW seal (1) on the fuel injector tip.

|

Install

EN-48266

installer (2) onto the fuel injector tip. Install a NEW seal (1) over

EN-48266

installer on the injector. The seal must be installed/slid into the recessed area (3) of the fuel injector. Compress the seal with your fingers before resizing the seal using the

EN-48266

sizer.

|

|

14.

|

Using the

EN-48266

sizer (4) , resize the seal.

|

|

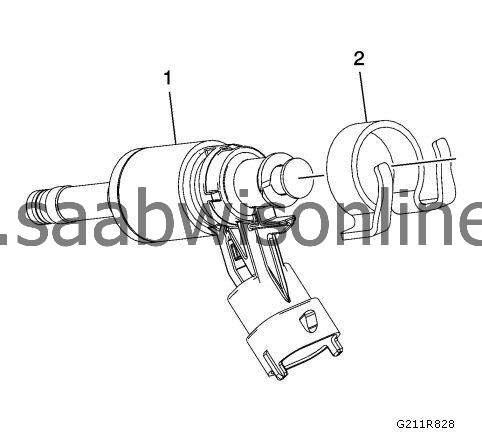

15.

|

Install a NEW fuel injector hold-down clamp (2) on the fuel injector (1).

|

|

16.

|

Repeat the fuel injector cleaning and inspection process for all 4 fuel injectors.

|

|

17.

|

|

Note

|

|

DO NOT tilt or twist the injector during installation.

|

Install the fuel injectors (1) by pushing the injectors straight into the fuel rail along the fuel injector axis.

|

|

18.

|

Connect the electrical connection to the fuel rail for each injector.

|