Crankshaft and Bearing Installation

| Crankshaft and Bearing Installation |

Special Tools

EN 45059 Torque Angle Sensor KitFor equivalent regional tools, refer to Special Tools

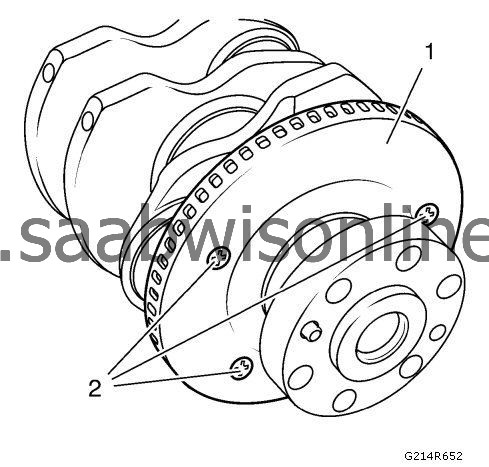

| 1. |

Install the increment wheel (1).

|

|

| 2. |

Refer to

Fastener Caution

.

Install the 3 sensor wheel bolts (2) and tighten to 12 Nm (107 lb in) . |

|

| 3. |

Clean the crankcase crank bore with a lint-free cloth.

|

|||||||

| 4. |

Clean all the oil from the backside of new bearing halves.

|

|

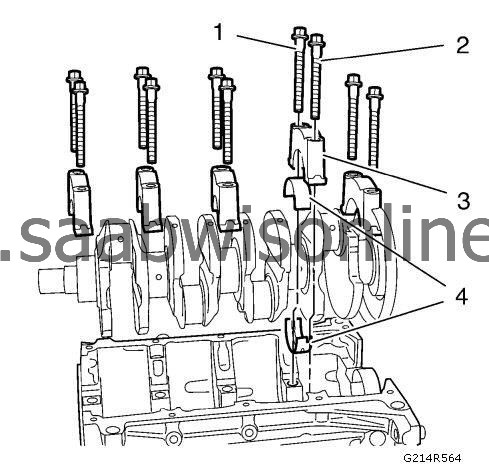

| 5. |

Install the 10 crankshaft bearing halves (4) into position. Ensure that the upper bearing insert contains the oil transfer hole and groove. Roll the bearing into position so that the lock tang engages the crank slot. The bearing must fit flush with the upper crankcase.

|

|

| 6. |

Using two hands, install the crankshaft straight up to the engine block.

|

|

| 7. |

Install the 5 crankshaft bearing caps (3).

|

|

| 8. |

Install the 10 crankshaft bearing cap bolts (1, 2).

|

|

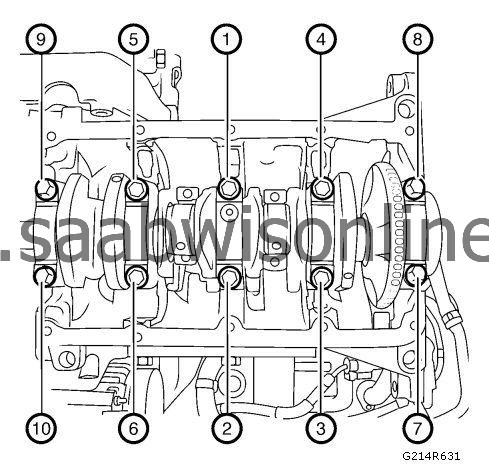

| 9. |

Tighten the 10 NEW crankshaft bearing cap bolts in sequence (1-10) in 2 passes:.

|

|

| • |

First pass in sequence to 25 Nm (19 lb ft).

|

| • |

Second pass in sequence to 100 degrees using the

EN 45059

angle sensor

|