Ignition coil

Symptom: Engine misfires or fails to start

Fault symptom

Engine misfires or fails to start

|

1.

|

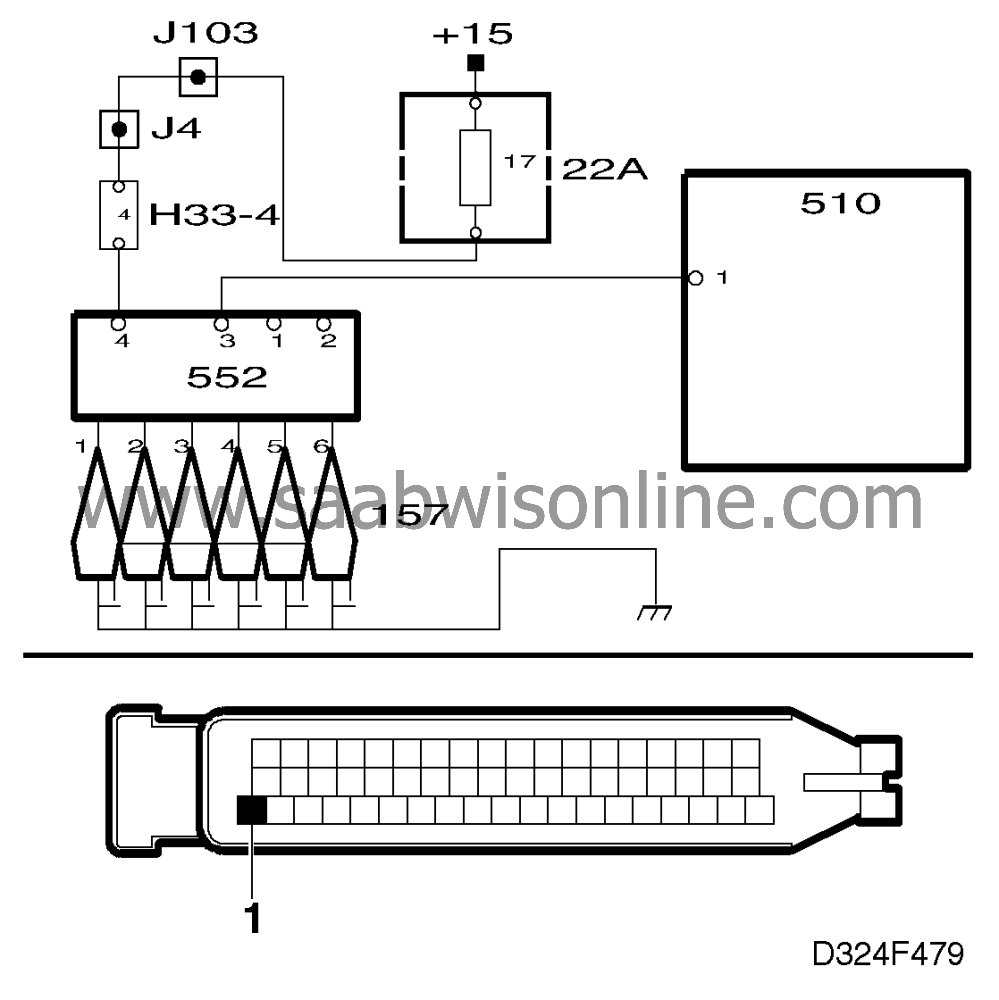

If possible, start the engine and

use the ISAT commands "IGNITION

COIL 1+4", "IGNITION COIL 2+5" AND "IGNITION COIL 3+6" in the

"READ ON/OFF" menu.

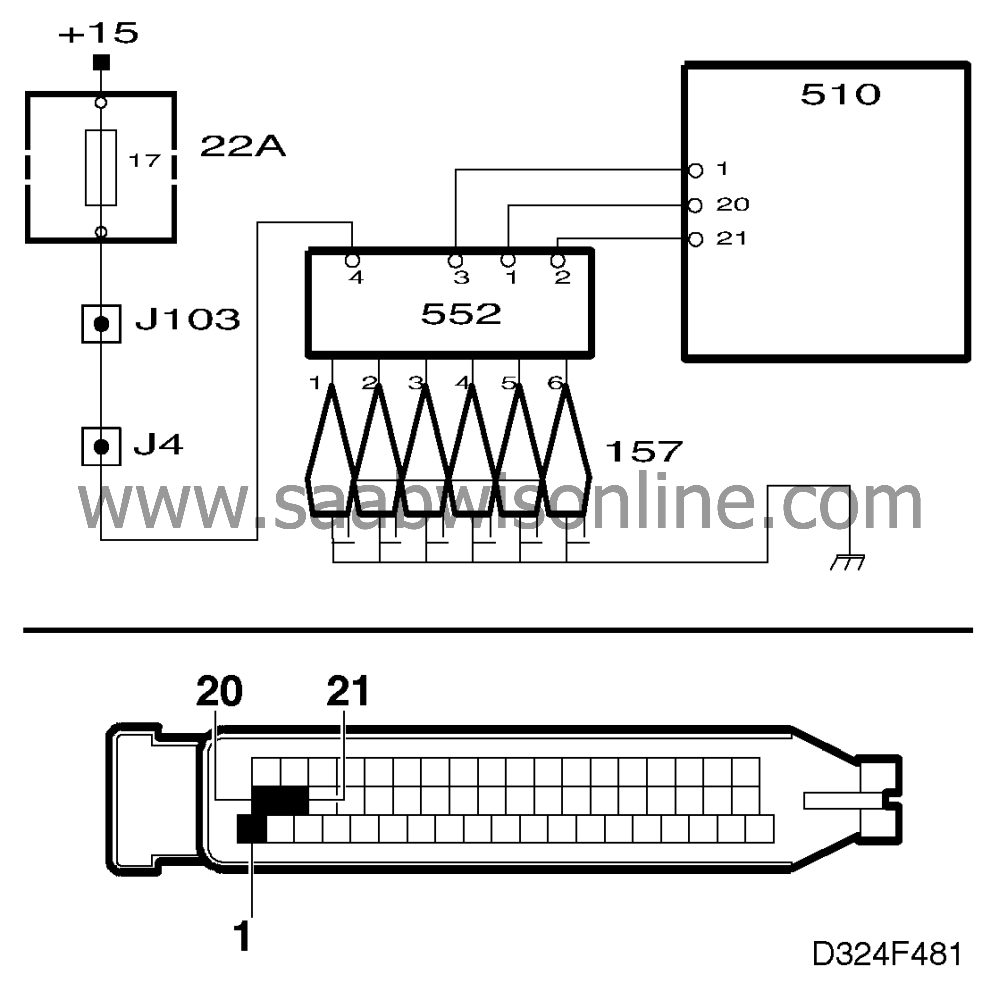

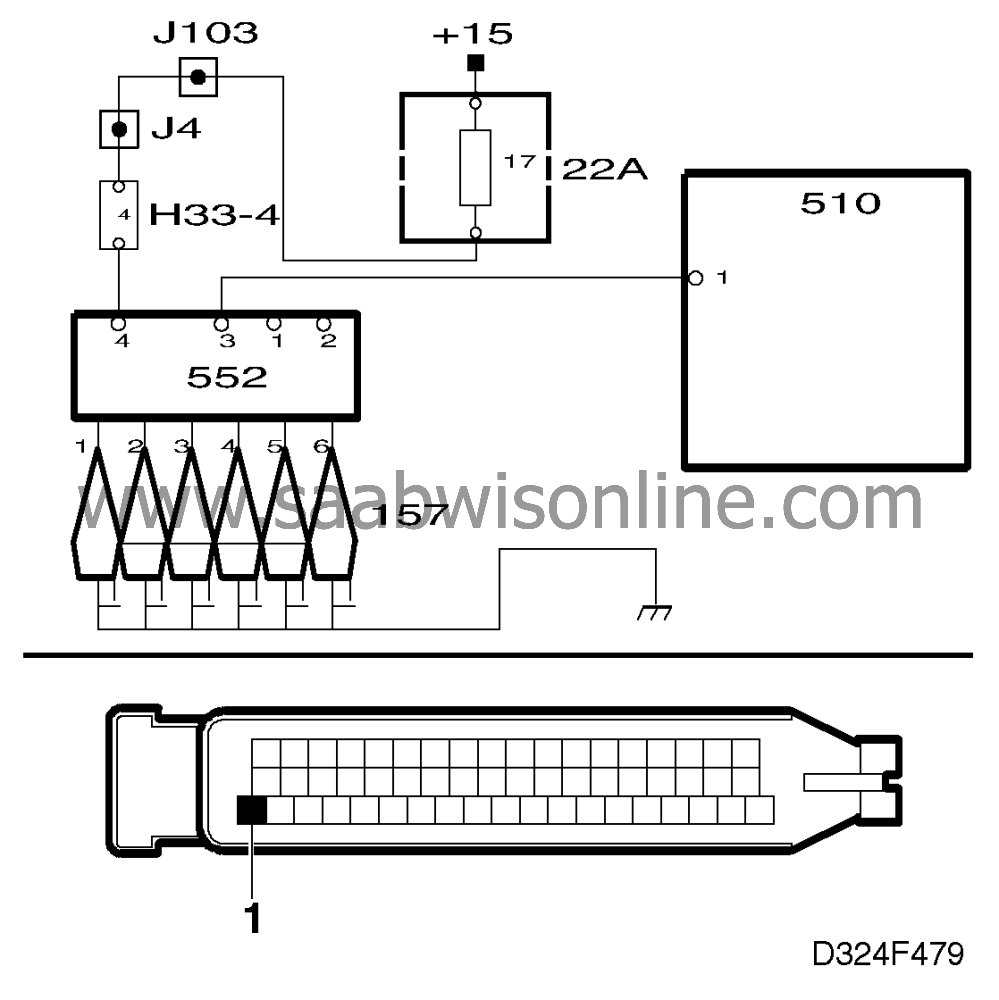

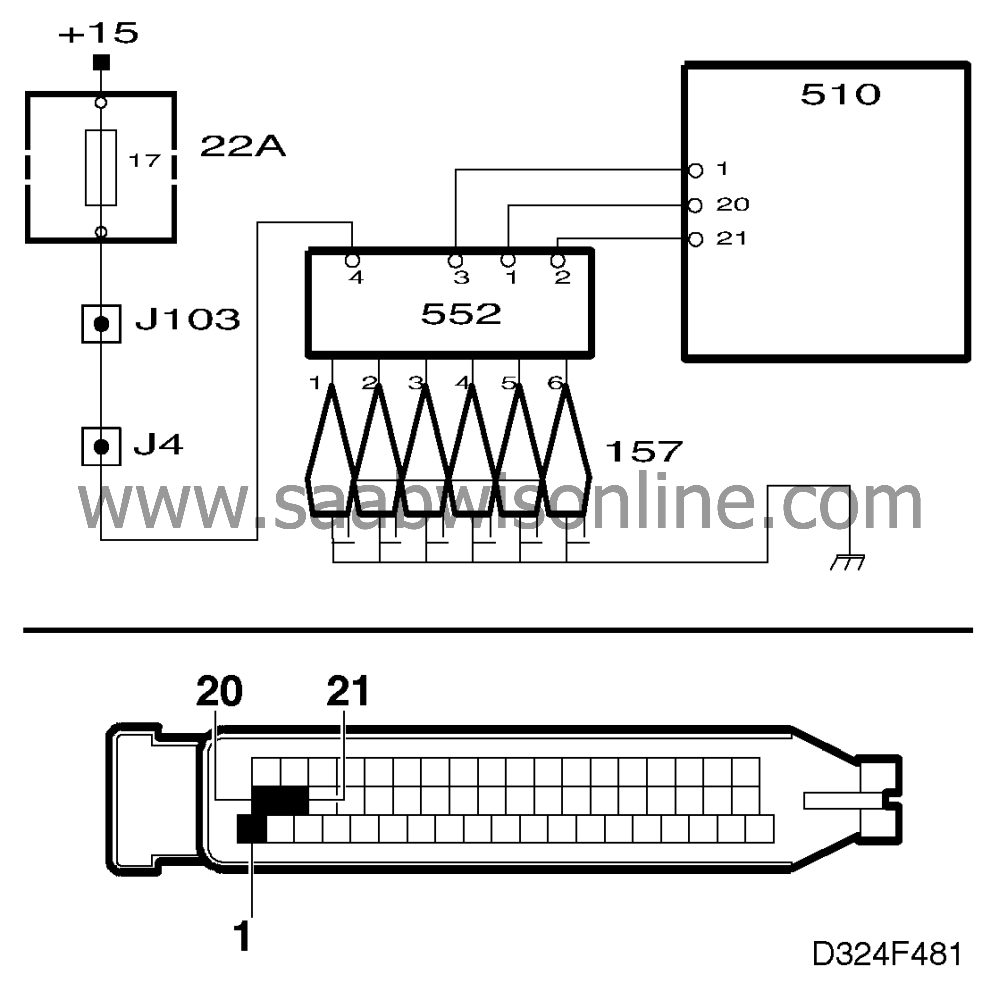

If the control module sends trigger signals from pin 1 (cyl. 1+4), pin

20 (cyl. 2+5) and pin 21 (cyl. 3+6), the ISAT should show "ACTIVE"

when each command is used.

If the ISAT shows "INACTIVE", turn to

for further

diagnostic instructions.

for further

diagnostic instructions.

|

|

2.

|

Remove the HT lead from any spark plug in cylinders 2, 4 or 6 and

connect it to a test spark plug with a wide gap. Ground the spark plug

and use the ISAT commands "FIRING CYL 1-4", "FIRING CYL 2-5"

and "FIRING CYL 3-6" in the "ACTIVATE" menu. The spark plugs

corresponding to the relevant commands should now produce a spark. If

they do not, the relevant ignition coil is not producing ignition

current. Check the leads between pins 1, 20 or 21 of the control unit

and pins 3, 1 or 2 of the ignition coils.

If none of the ignition coils produces ignition current, also check

whether pin 4 of the coils receives current from fuse 17.

|

|

3.

|

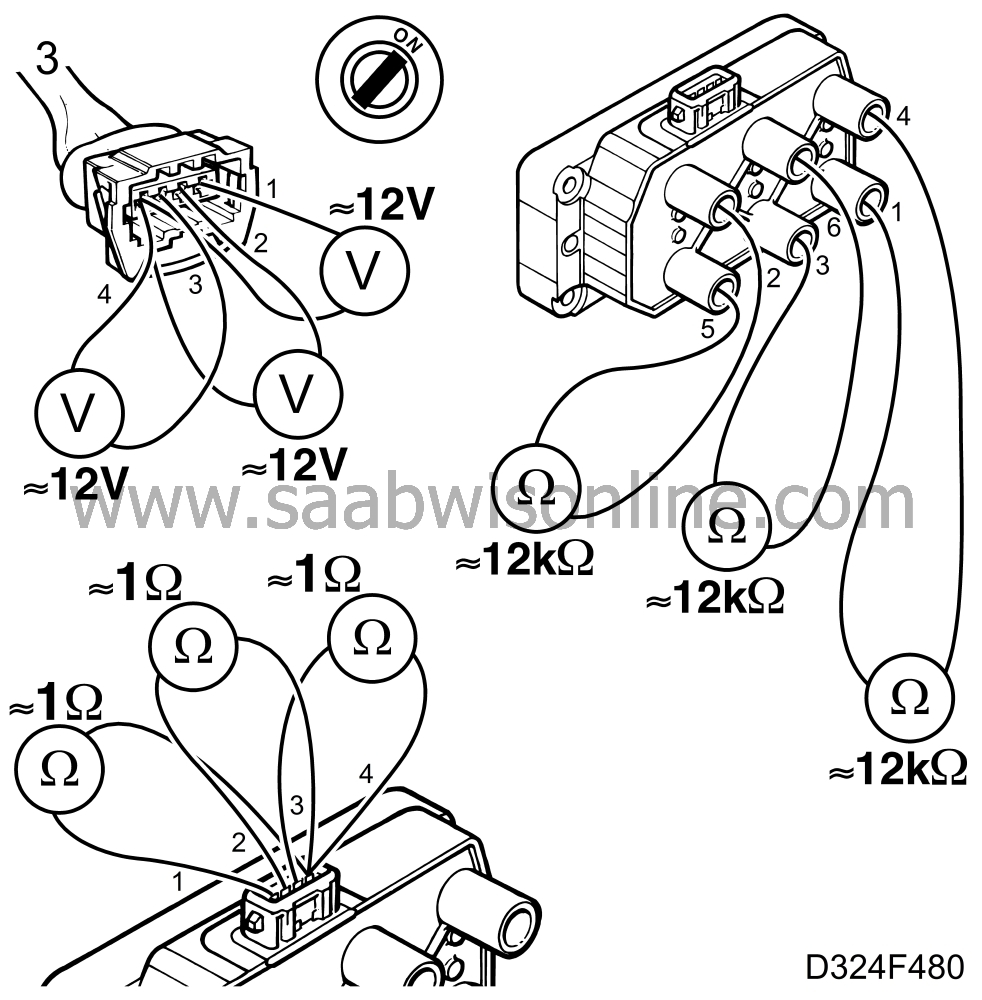

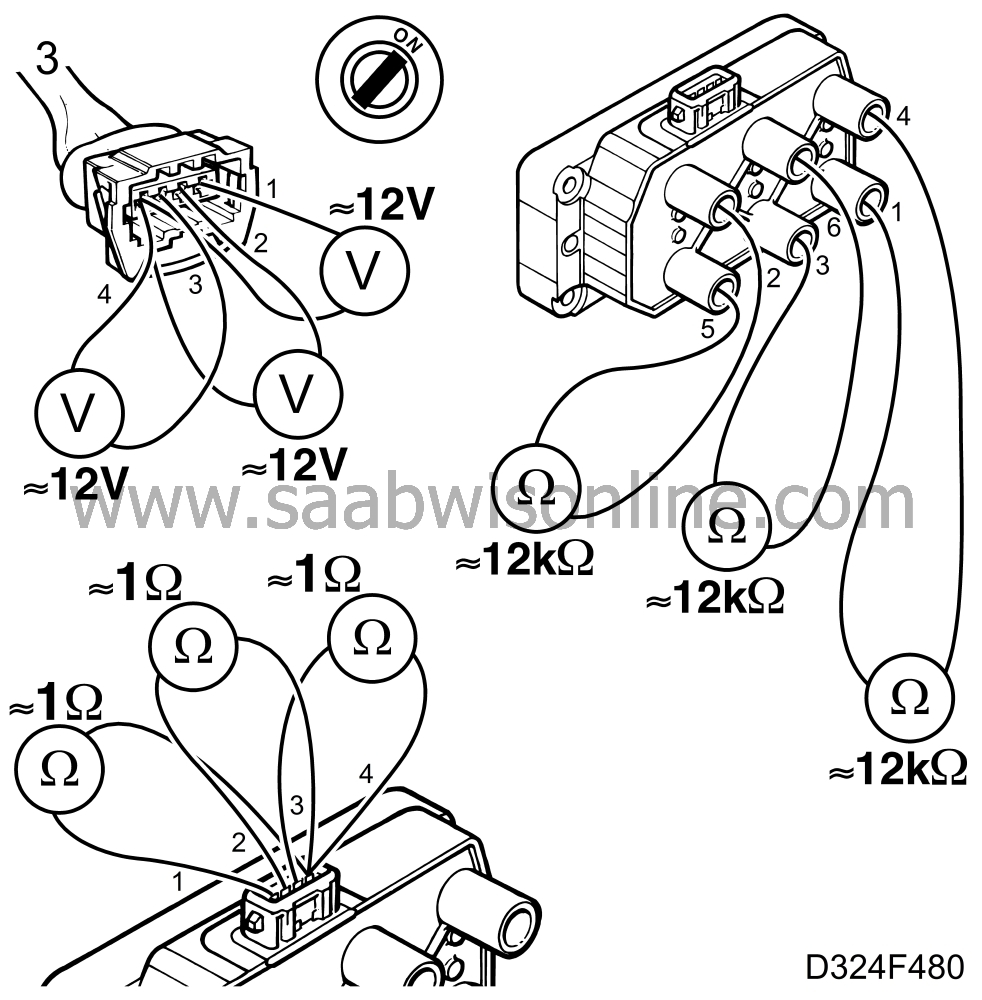

Unplug the ignition coils' 4-pin connector and use a voltmeter to

take readings across pins 4 and 1, 4 and 2, and 4 and 3. With the

ignition switch in the Drive position, the voltmeter should show about

12 V and on engagement of the starter motor it should fluctuate between

about 4 and 6 V.

If the readings are not OK, continue with the next point.

If the readings are OK, check the resistance of the primary circuit in

the ignition coils by taking a reading across pins 4 and 1, 4 and 2,

and 4 and 3. The correct resistance is about 1 ohm.

Also check the secondary windings by measuring the resistance across the

HT lead outlets for spark plugs 1+4, 2+5 and 3+6. The correct

resistance is about 12,000 ohms. If the resistance is not OK, change

the ignition coil.

|

|

4.

|

If no diagnostic trouble codes have been generated in the MOTRONIC

system, also check that the control module is supplied with the correct

voltage and that its ground connection is good.

Also check that the crankshaft position sensor is in satisfactory

working order, see

.

.

If no faults have been detected after carrying out the above checks,

change the control module.

|