Fuel injection

| Fuel injection |

| Injectors |

The injectors are of solenoid type with needle and seat. They open when current flows through the coil and are closed by a powerful spring when the current is cut off.

For optimal combustion and so cleaner exhaust gases, the spray nozzles are of twin-jet type (with four holes).

The jets of fuel are set within extremely tight limits, each jet individually and between the two jets (one jet for each inlet valve) This also makes big demands on the positions of the injectors and to ensure their precise location they are fixed in position by means of special guide rails.

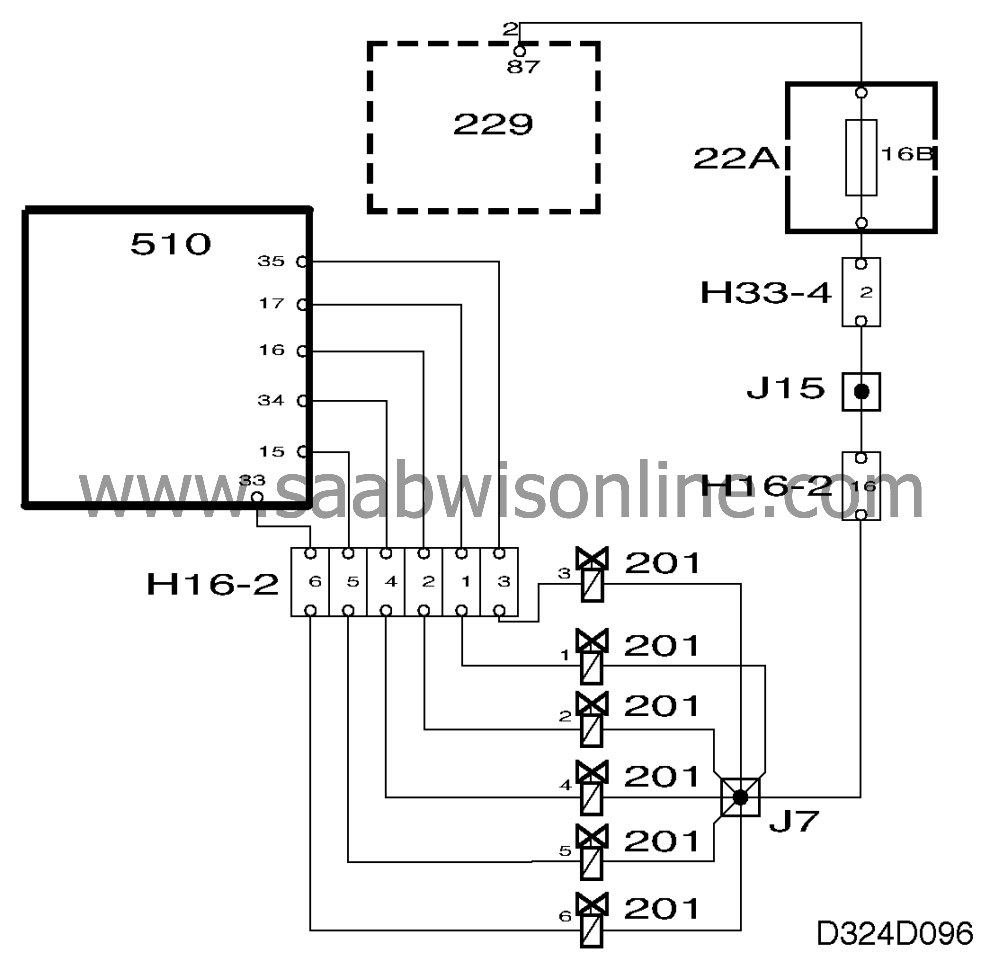

All the injectors receive operating current from the main relay while the control module grounds them individually as follows.

| • |

Injector 1 is grounded via pin 17

|

|

| • |

Injector 2 is grounded via pin 16

|

|

| • |

Injector 3 is grounded via pin 35

|

|

| • |

Injector 4 is grounded via pin 34

|

|

| • |

Injector 5 is grounded via pin 15

|

|

| • |

Injector 6 is grounded via pin 33

The exact amount of fuel to be injected into the cylinders is calculated on the basis of the control module's input signals from the oxygen sensors, mass air flow sensor, crankshaft position sensor and other sensors. This is done by varying the length of the grounding signals between about 3 and 15 ms. In conditions of extreme cold (< -30°C), the duration of the signals may increase to 300 ms. The system has no cold-starting valve. While the starter motor turns the engine over, the control module sends signals to all the injectors more or less simultaneously to facilitate starting (after only four pulses from the crankshaft position sensor). During engine braking, all injectors close to reduce the amount of HC (fuel shut-off), provided that certain engine speed conditions are met. With the engine idling, readings of about 7 Hz and 3 ms should be obtained with a pulse meter on pins 15, 16, 17, 33, 34 and 35. |

|

| Fuel consumption |

The signal to the instrument indicating fuel consumption is not a separate output signal from the control module. Instead, the signal is obtained from pin 35 of the control module. This signal is also sent to injector No. 3. With the engine idling, a reading of about 7 Hz for this signal can be obtained on a pulse meter.