Oxygen sensor

| Oxygen sensor |

The oxygen sensor is mounted in the exhaust pipe after the turbo unit and measures the oxygen content of the exhaust gases.

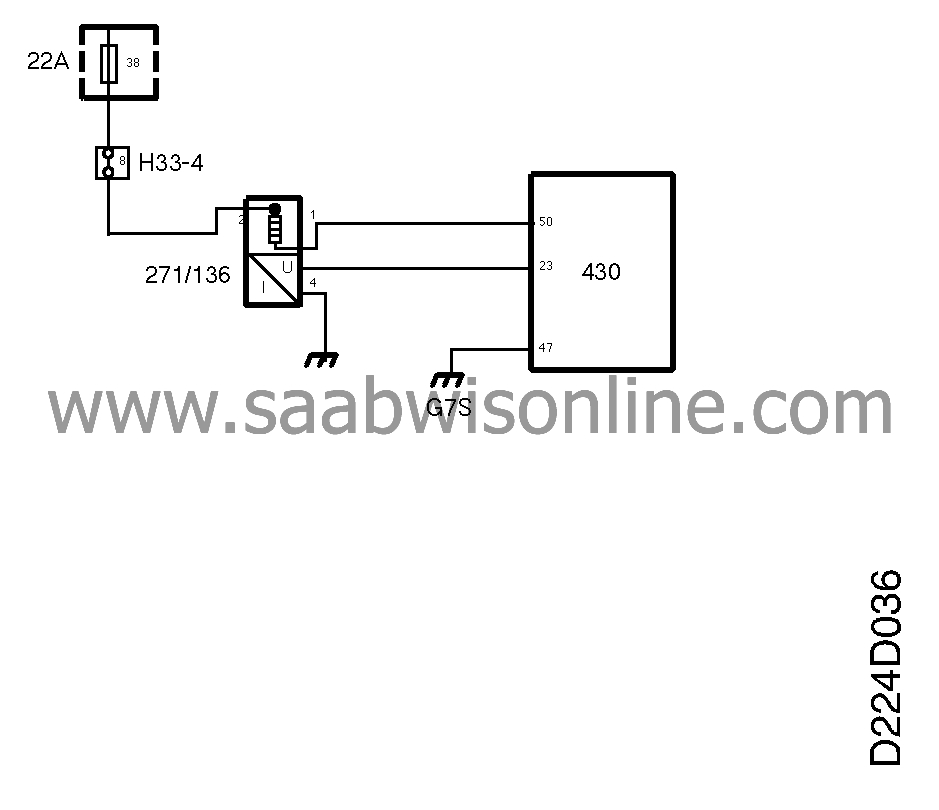

The oxygen sensor receives reference oxygen from the surrounding air via the connecting pipes. For this reason, contact spray or grease must not be used in the sensor connector.

The oxygen sensor has to be heated to be able to supply a voltage after the engine has been started. The heater is supplied with Batt+ from the fuel pump relay via fuse 38 and is grounded from ECM pin 50. The ECM estimates the exhaust gas temperature on the basis of load and engine speed. The preheater is switched off if the exhaust temperature is high.

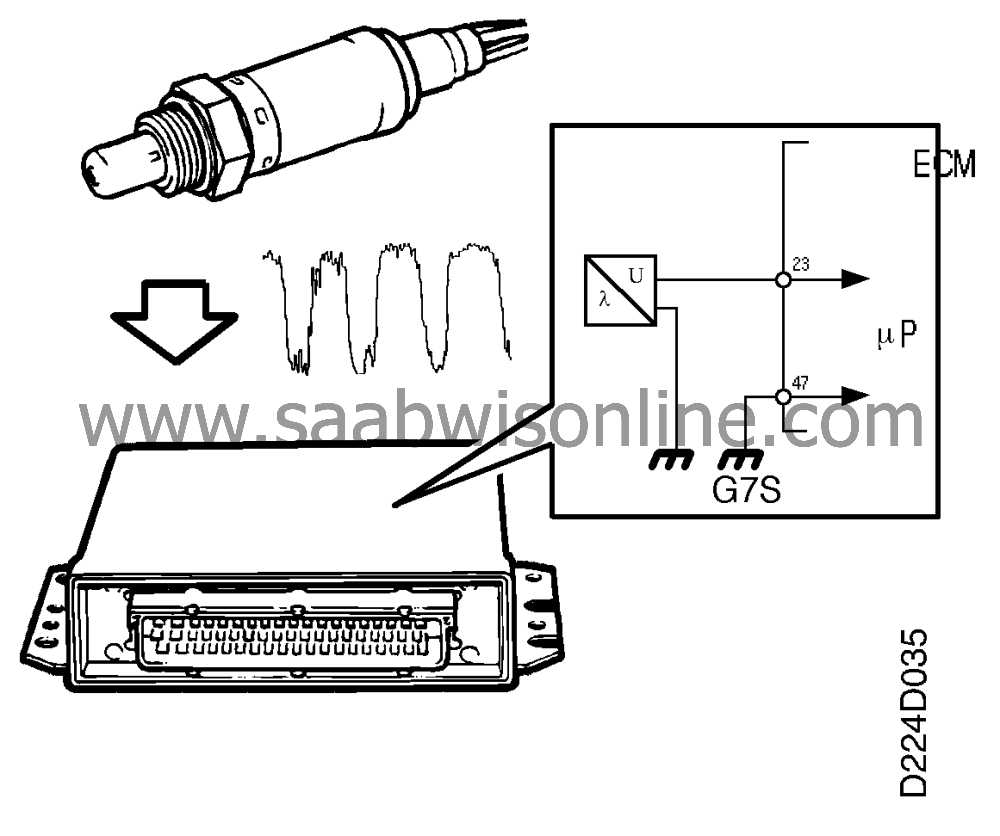

In the case of a lean fuel/air mixture the oxygen sensor supplies approx. 0.1 V and in the case of a rich fuel/air mixture approx. 0.9 V.

The ECM receives the voltage from the oxygen sensor on pin 23. This voltage is used to correct fuel injection times continuously so that lambda=1.0 is always maintained. This is important for optimum operation of the three-way catalytic converter.

The ECM continuously stores a correction factor for the fuel injection times at different engine loads and speeds. The ECM receives reference ground at pin 47 from ground point G7S on the engine in order to be able to measure the sensor voltage.

If the oxygen sensor does not work or if there is an open circuit, the value most recently entered is used to correct the fuel injection times and the malfunction indicator lamp (CHECK ENGINE) in the main instrument lights up.