PWM signals

| PWM signals |

| Background |

In modern cars, it is often necessary to send information between different systems, sometimes between systems of different makes. Analogue transmissions have proved to be unreliable. Voltage drops in leads and connectors as well as tolerances in the various control modules and sensors are the cause of this unreliability.

| PWM (Pulse Width Modulation) |

The solution to the problem is to use PWM signals. PWM stands for pulse width modulation, which means that it is the period during which the lead is energized that is of importance, not the voltage level.

PWM signals can also be described as a square wave in which the width of the voltage pulses correspond to the information. As voltage can only have two states, on or off, the signal is said to be digital.

| Example |

A position sensor for the throttle sends a voltage to the Motronic control module. The level of the voltage depends on how much the throttle is open; at idling speed, the voltage may be about 0.2 V and at full throttle about 4.5 V. The voltage is therefore proportionate to the opening angle of the throttle and the value is said to be analogue.

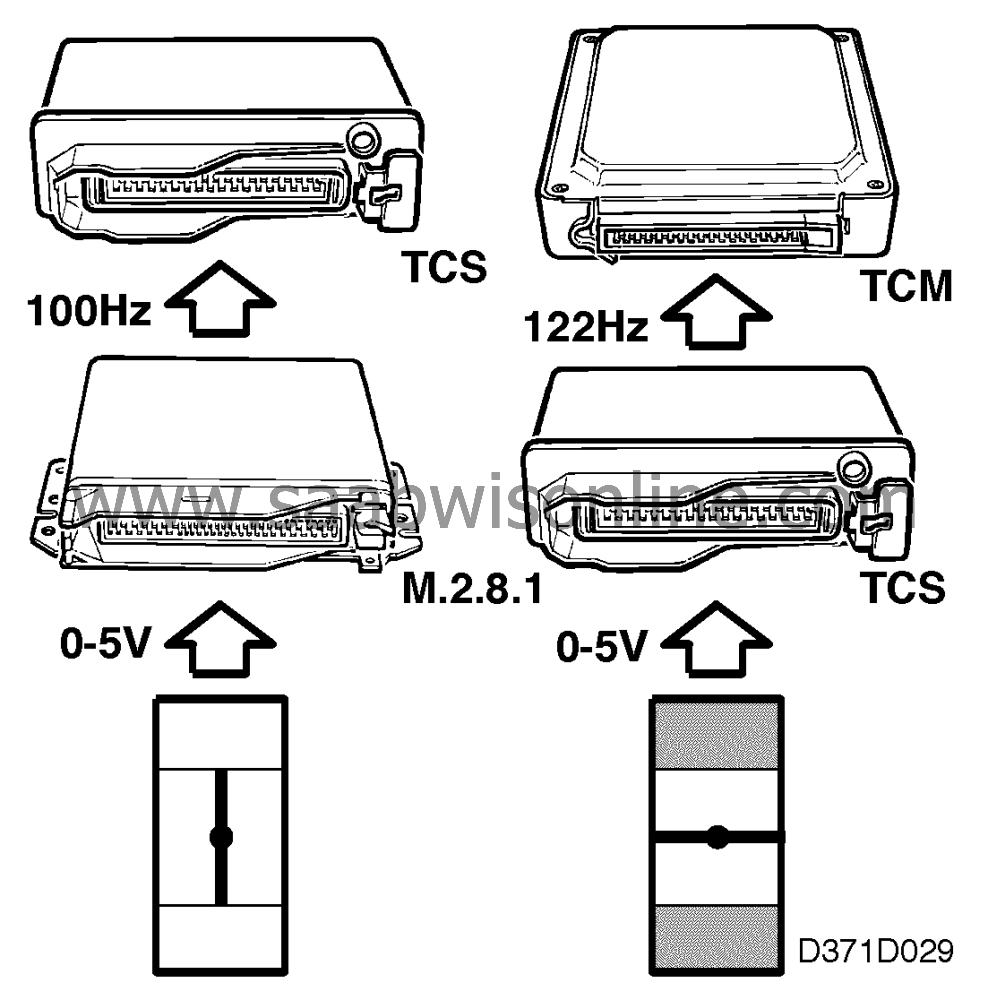

Information on the throttle position can then also be sent to other systems, e.g. TCS, TCM, etc. but not as an analogue voltage but as a PWM signal.

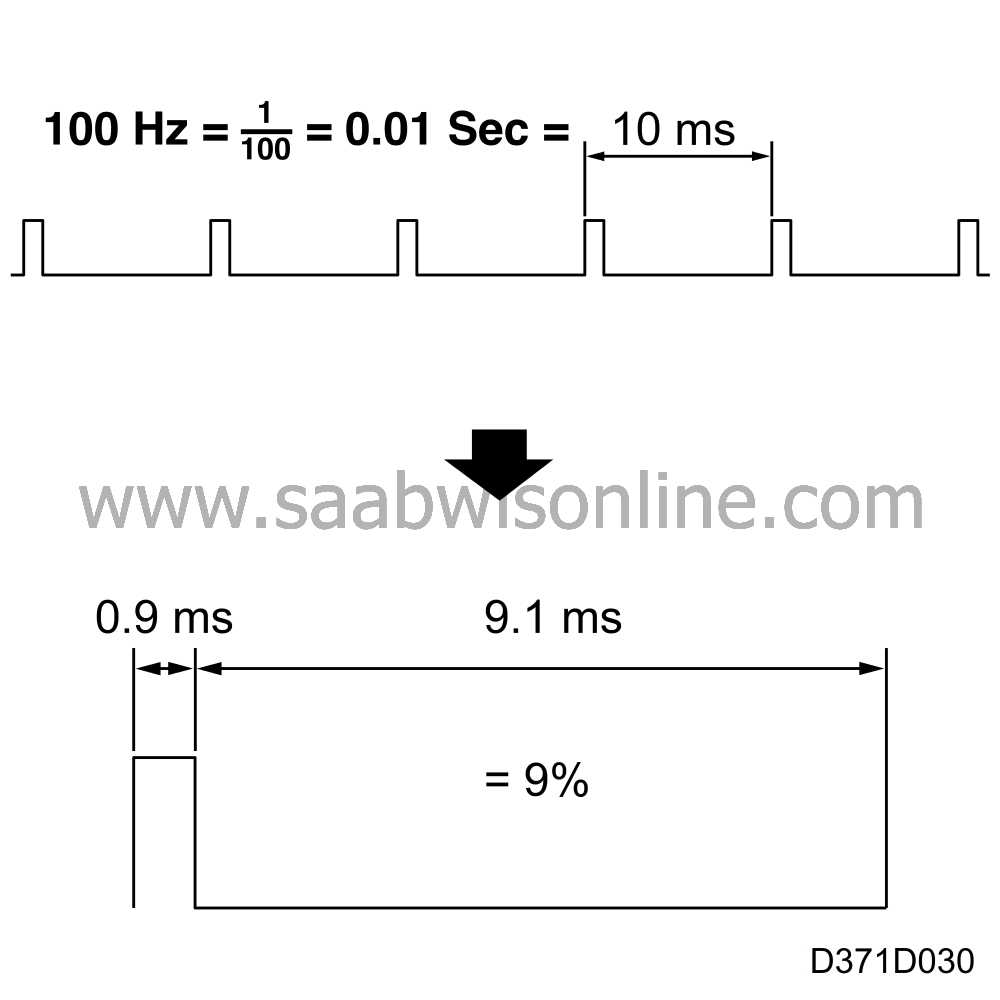

In this case, the PWM signals always have a pulse ratio of 9%% at idling speed (higher during acceleration), irrespective of voltage drops and tolerances.

| PWM signal frequency |

Information from one control module to another often changes very rapidly, which means the pulse width must also change very rapidly.

This means that the pulses must be sent very often, i.e. the signal must have a high frequency.

A PWM signal often has a fixed frequency of between 75 and 225 Hz, which means that the pulses occur 75 to 225 times every second. *)

Normal frequencies in cars are 100, 122 and 200 Hz for the transmitter control module, while the receiver control module often accepts relatively large deviations from these values. A very reliable communication is ensured in this way.

*) In exceptional cases, the frequency is not fixed, i.e. the load signal Tq from Trionic, whose frequency depends on the engine speed but whose pulse width reflects the engine load.

| PWM signal characteristics |

Frequency

The actual frequency does not say anything about the value of the information on the lead but it does confirm that there is contact with the transmitter control module and it is possible to check that the frequency is within reasonable limits.Pulse length

At 100 Hz, there will be 100 pulses during 1 second, which means that the maximum pulse length can only be 1/100 of a second, i.e. 10 milliseconds. The pulse length at 100 Hz is therefore between 0 and 10 milliseconds.Pulse ratio

If the pulse length at 100 Hz is 0.9 ms, the pulse ratio is said to be 9%% (as the pulse exists for 0.9 ms of a possible 10). When transmitting information, the pulse ratio is between 8 and 92%%.| When a PWM signal is not a signal |

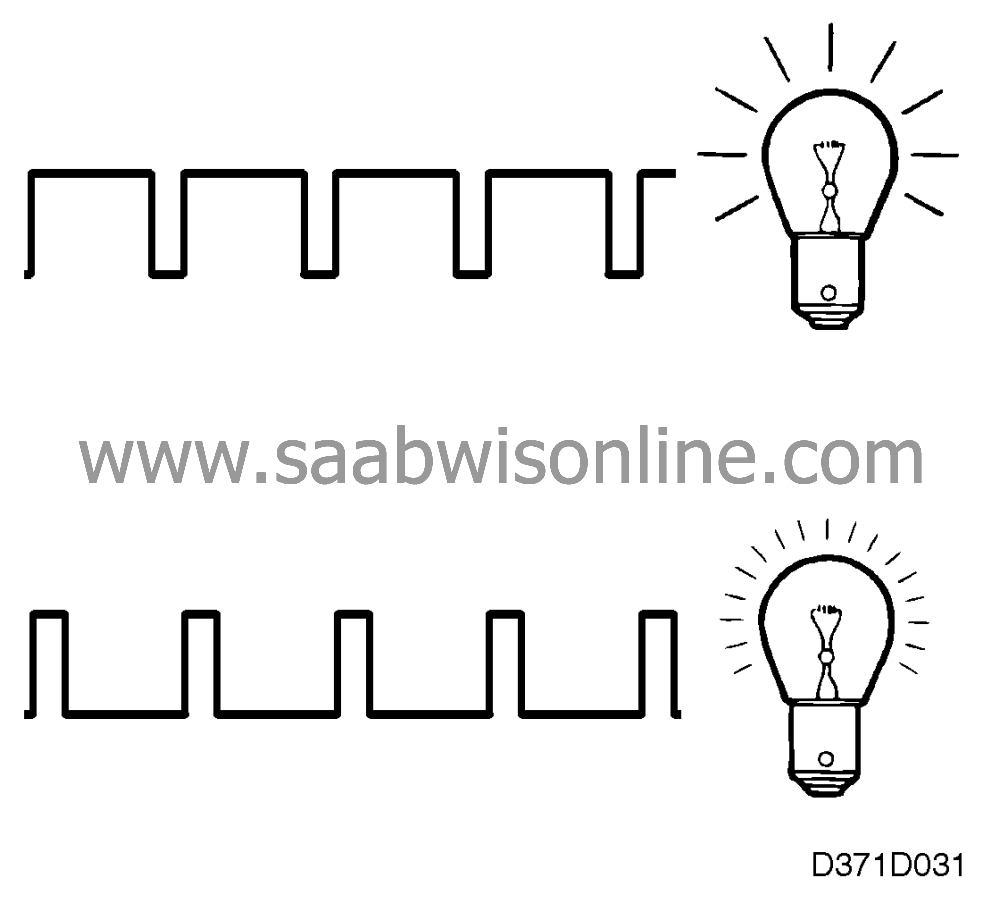

PWM can be used for other purposes than just transmitting information between control modules. It can also be sent directly to a consumer in the system, when it is no longer referred to as a PWM signal as it is not carrying information as such.

One example of this is the instrument lighting, which is supplied with a PWM voltage where a low pulse ratio lights the lamps dimly and a higher pulse ration increases the illumination. As the frequency is so high, the human eye will not detect the lamps "flashing". Other examples are the throttle motor in the TCS system, the IAC valve, the APC control valve and the EVAP purge valve.

The supply to the injectors can also be referred to as being pulse width modulated as the pulse width corresponds with the opening duration of the injectors.

In the examples above, we referred to PWM outputs (transmitter) and PWM inputs (receiver), for which the system manufacturer is free to designate frequencies and pulse ratios. Some common frequencies are e.g. the APC control valve in TRIONIC 70-90 Hz, instrument lighting 56-90 Hz and TCS throttle motor 500 Hz.