Input shaft

| Input shaft |

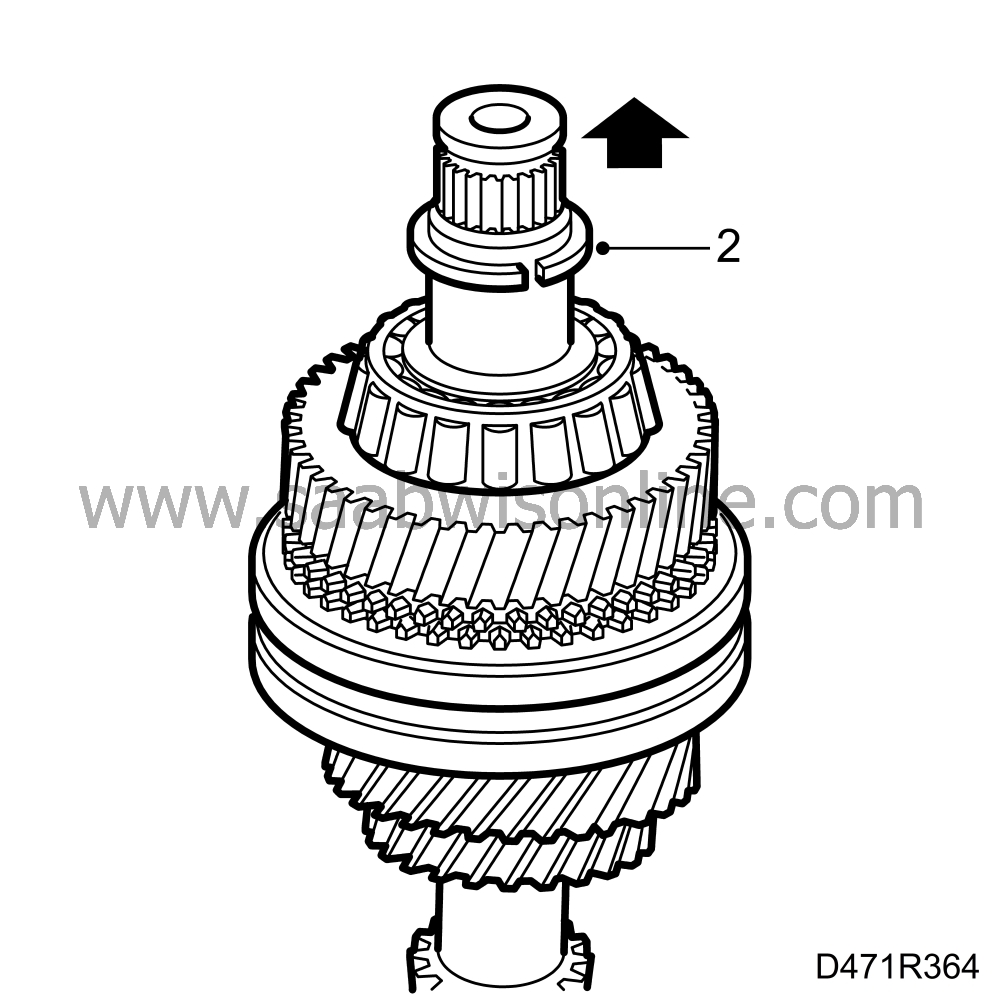

| 1. |

Mount the shaft in a vice with protective jaws.

|

|

| 2. |

Remove circlip.

|

|

| 3. |

Press the bearing off the shaft. Use puller 87 92 152

and basic tool 87 91 642

and basic tool 87 91 642

.

.

|

||||||||||

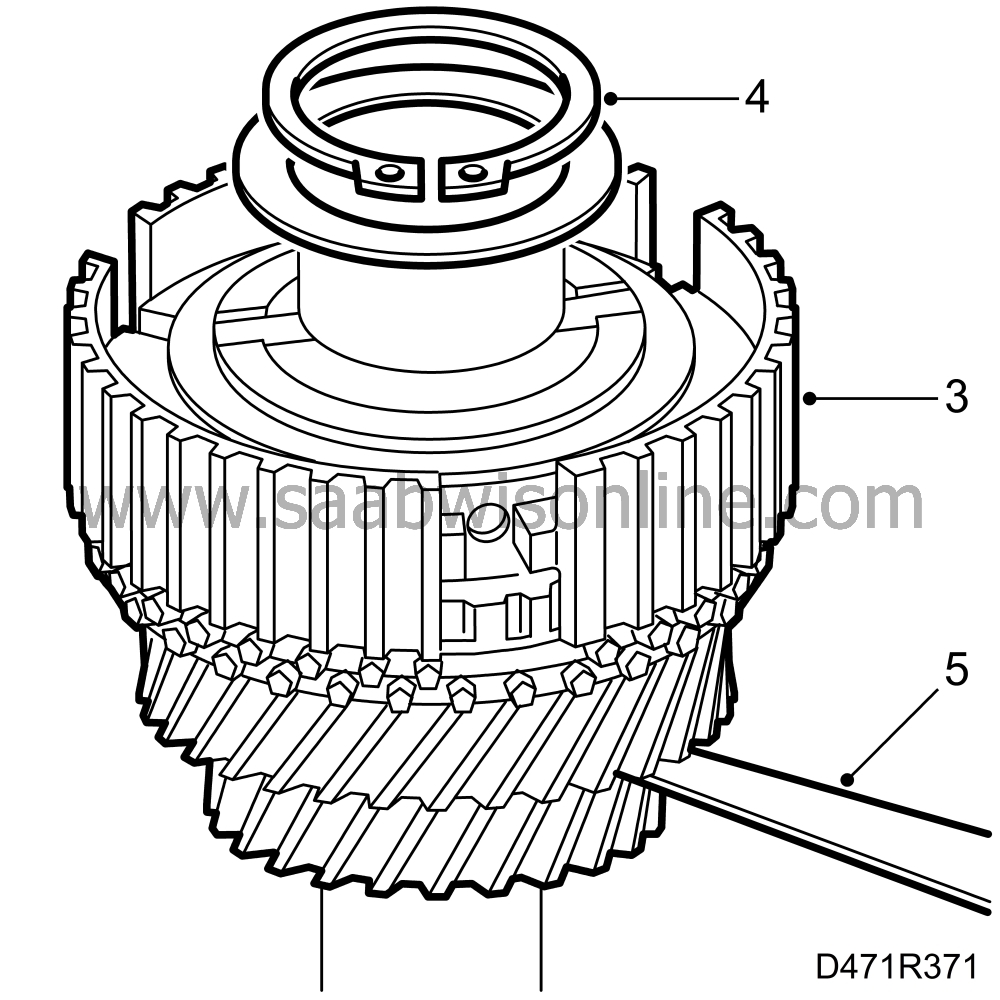

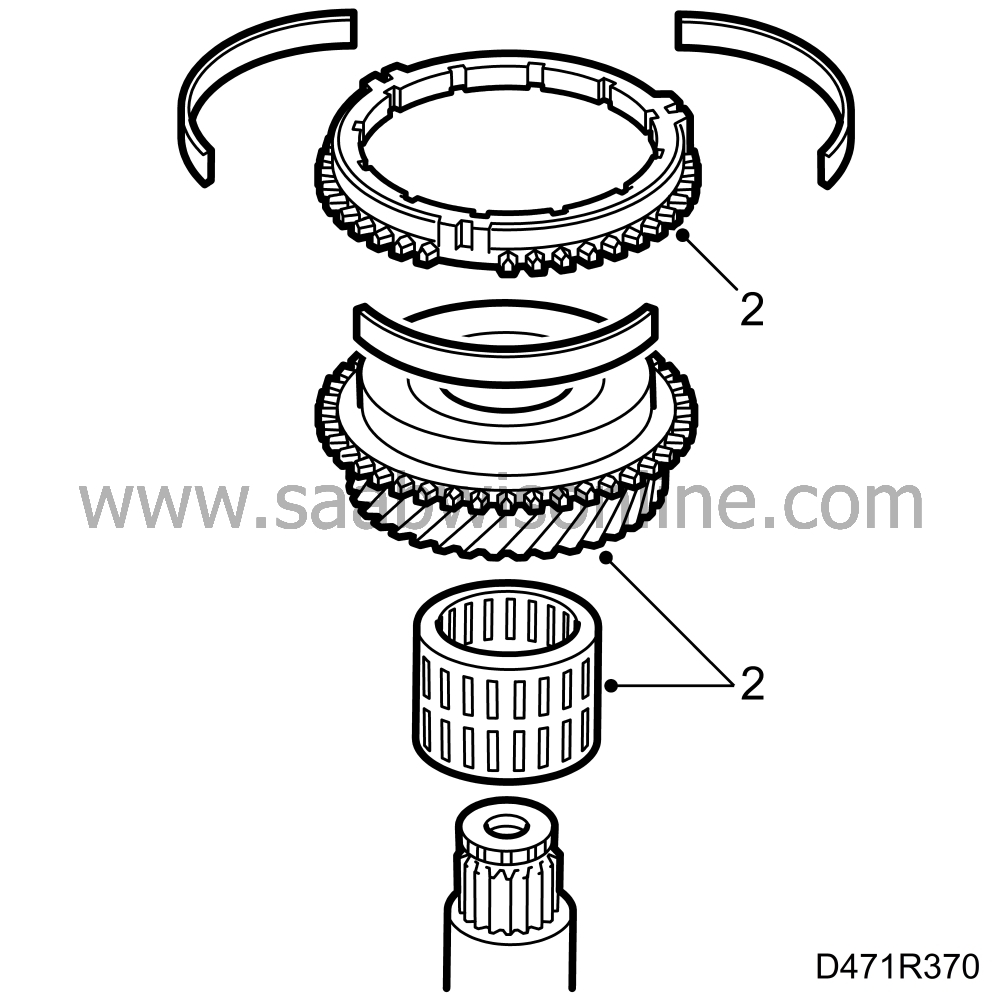

| 4. |

Lift off the pinion for 4th gear, synchromesh and needle bearing. Collect the leaf springs, if fitted.

|

|

| 5. |

Slightly lift the synchromesh sleeve and hold with your hand so that the spring-loaded rollers do not come out. Keep the rollers in a safe place.

|

|

| 6. |

Lift off the synchromesh sleeve.

|

||||||||||

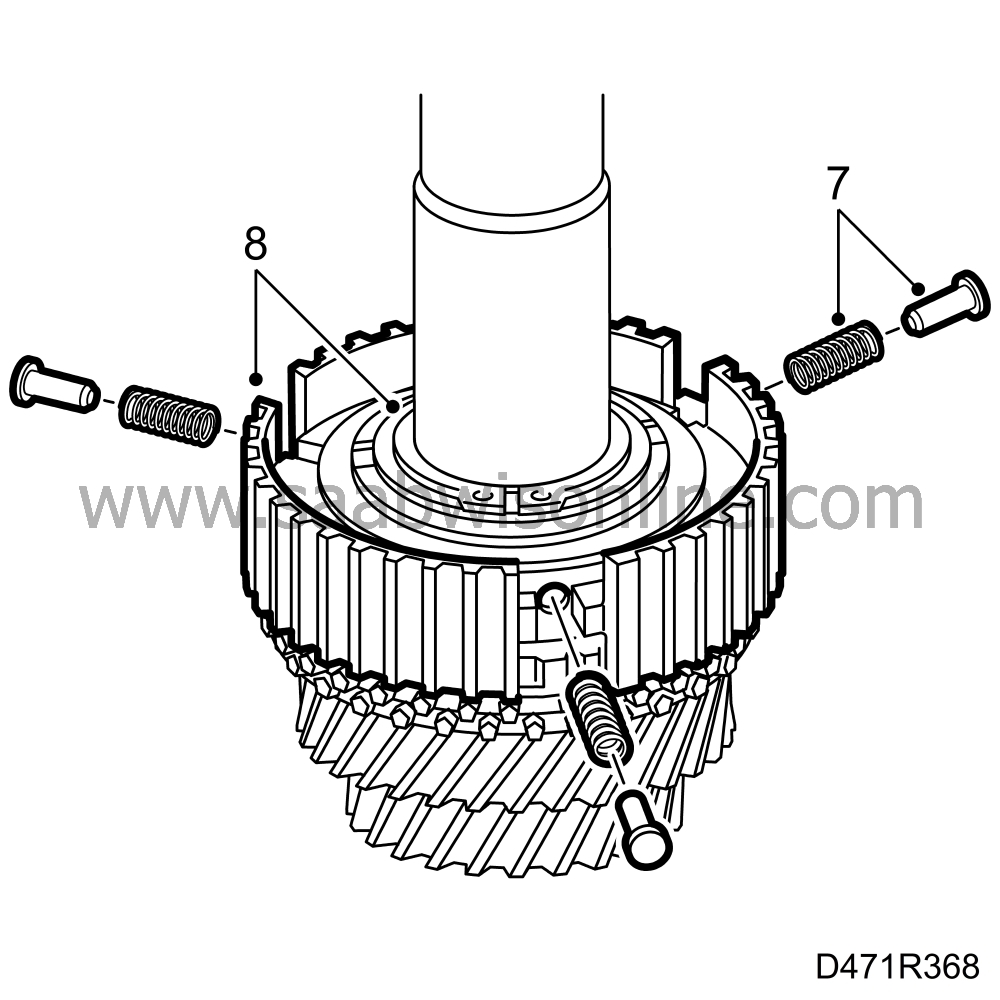

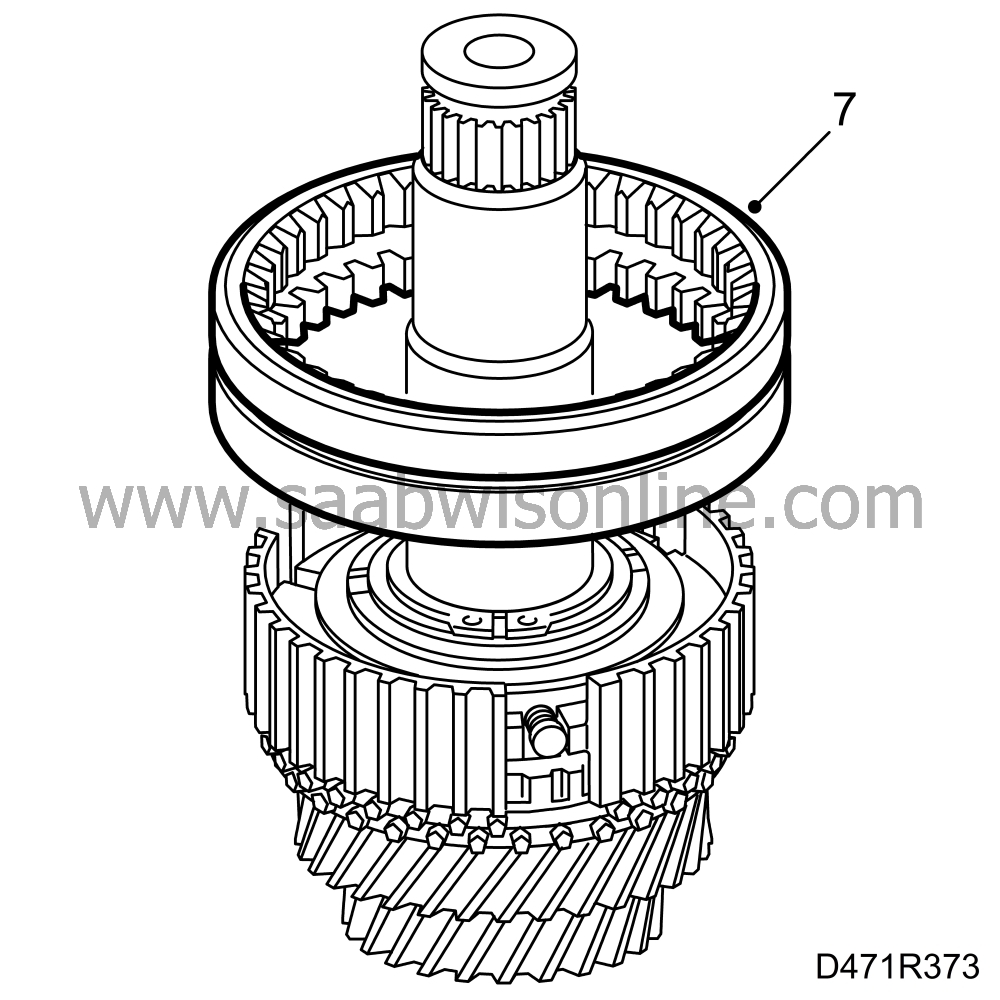

| 7. |

Keep springs and plungers.

|

|

| 8. |

Remove the circlip and, if fitted, the washer (only present on more recent gearboxes) holding the synchromesh hub in place. Remove the hub and collect the leaf springs, if fitted.

|

|

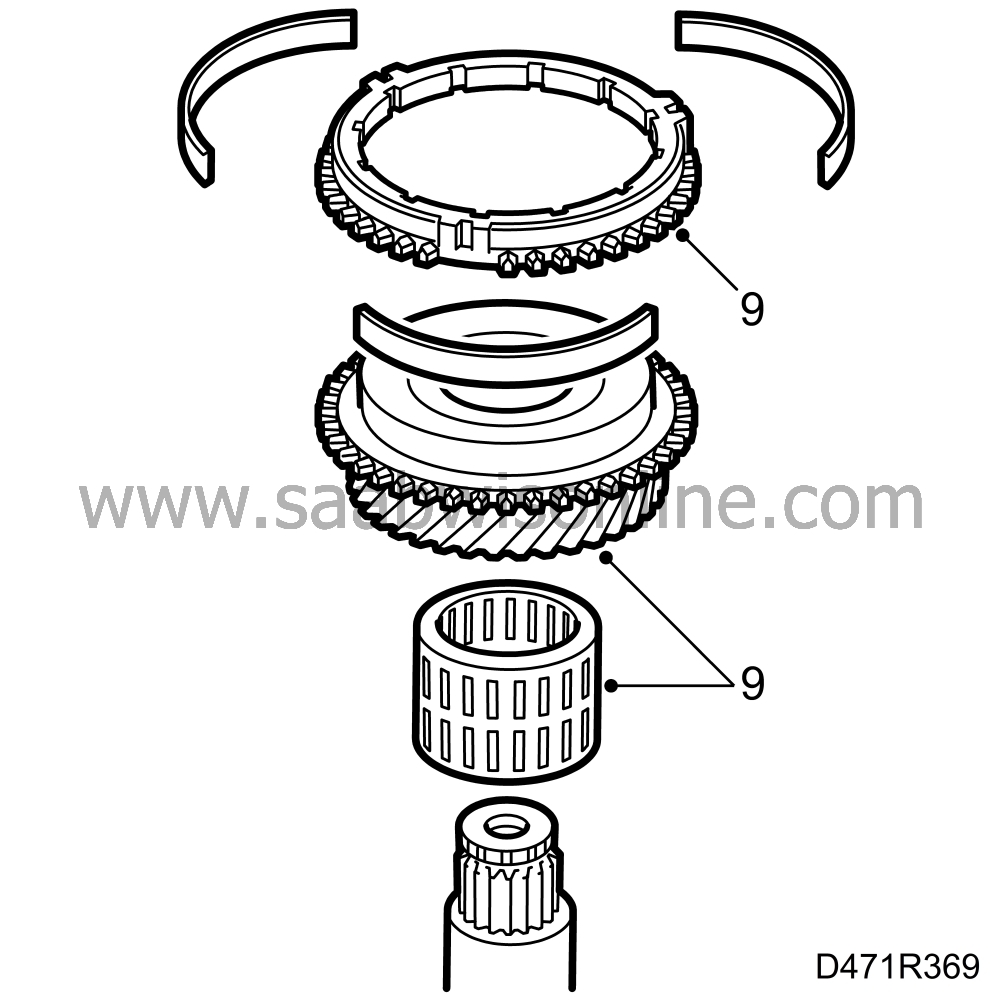

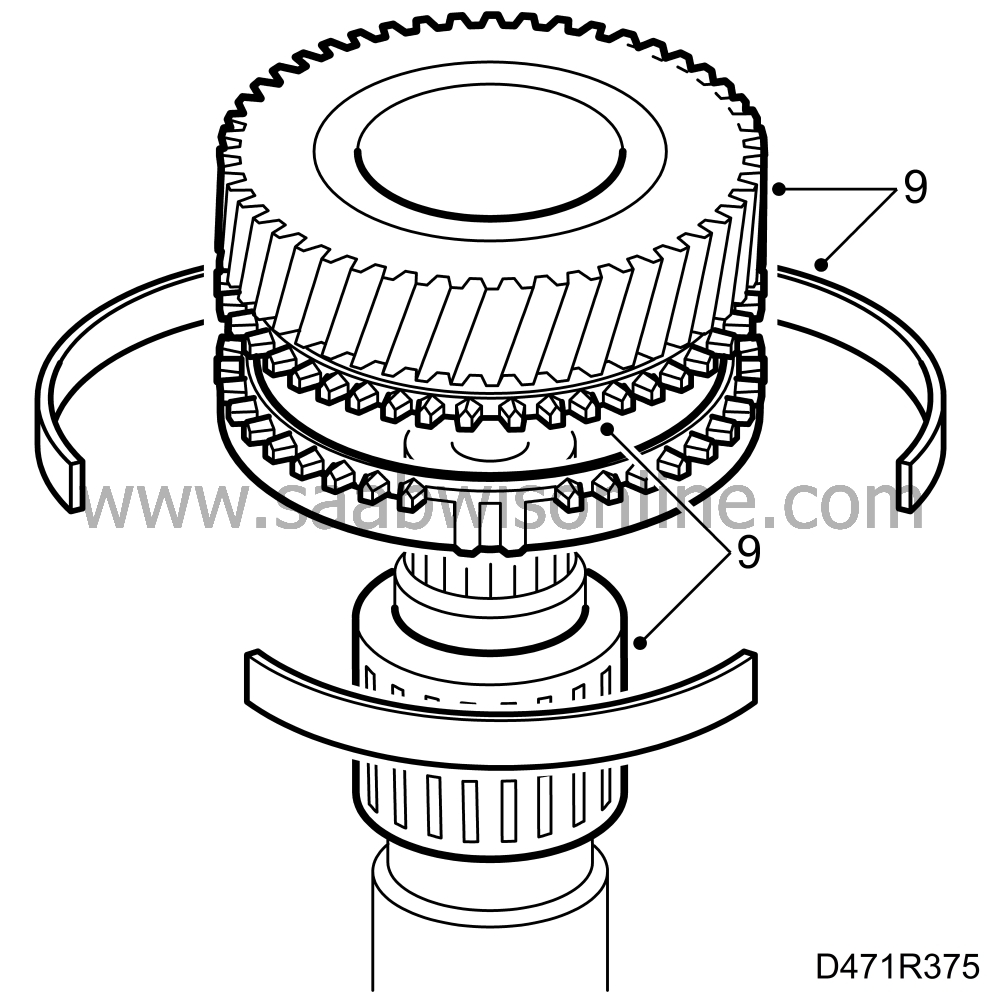

| 9. |

Lift off the 3rd synchromesh, pinion and needle bearing.

|

|

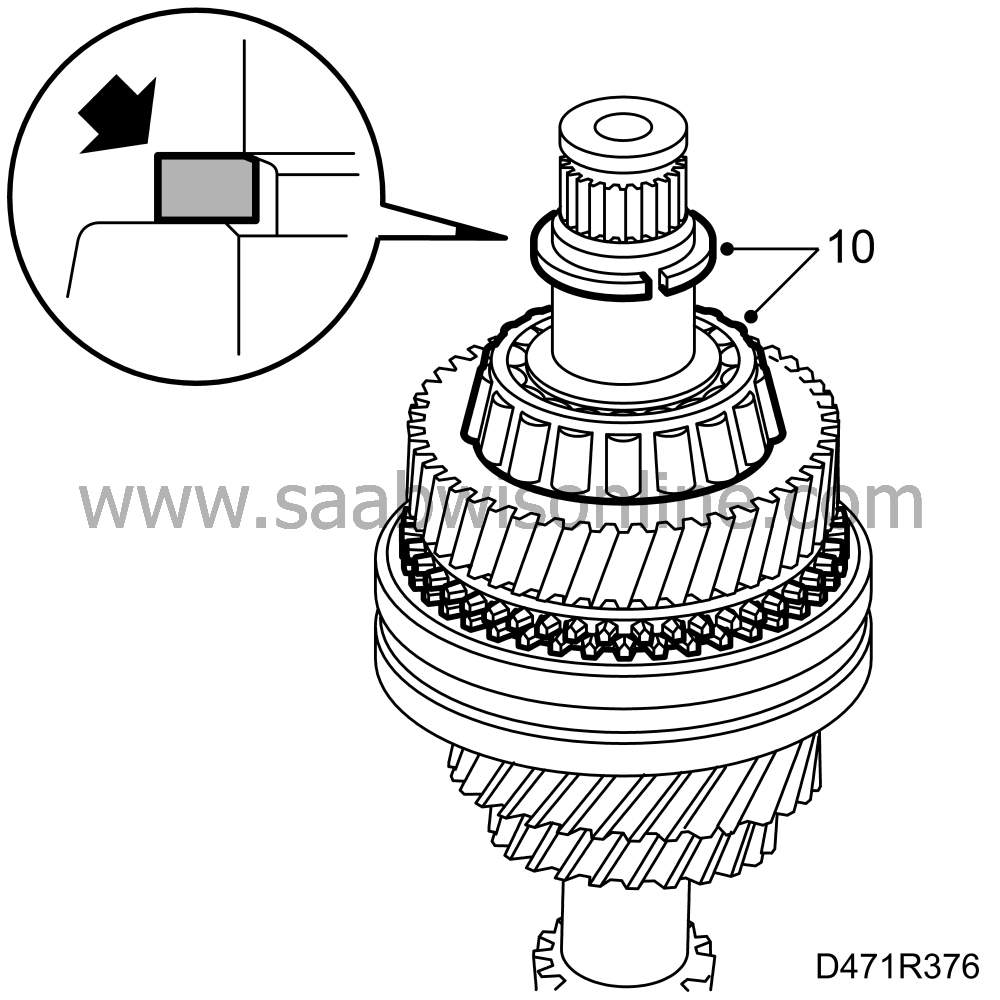

| 10. |

Check the condition of all parts as regards wear. Replace damaged or defective parts. Measure the wear on the synchromesh by fitting it in place. Measure with a feeler gauge in three places between the baulk ring and the pinion. Calculate an average of the readings. New synchromesh 0.8-1.1 mm. Min dimension is 0.5 mm. If the dimension is less, the synchromesh is worn out and must be replaced.

|

|

| To assemble |

Fit all the parts oiled with Saab synthetic manual gearbox oil, see

.

.

| 1. |

Mount the input shaft in a vice with protective jaws.

|

|

| 2. |

Fit the 3rd gear pinion with needle bearing, baulk ring and, if fitted, leaf springs.

|

|

| 4. |

Fit the washer (if used) and a new circlip. Fit the circlip with the sharp edge facing up.

|

|

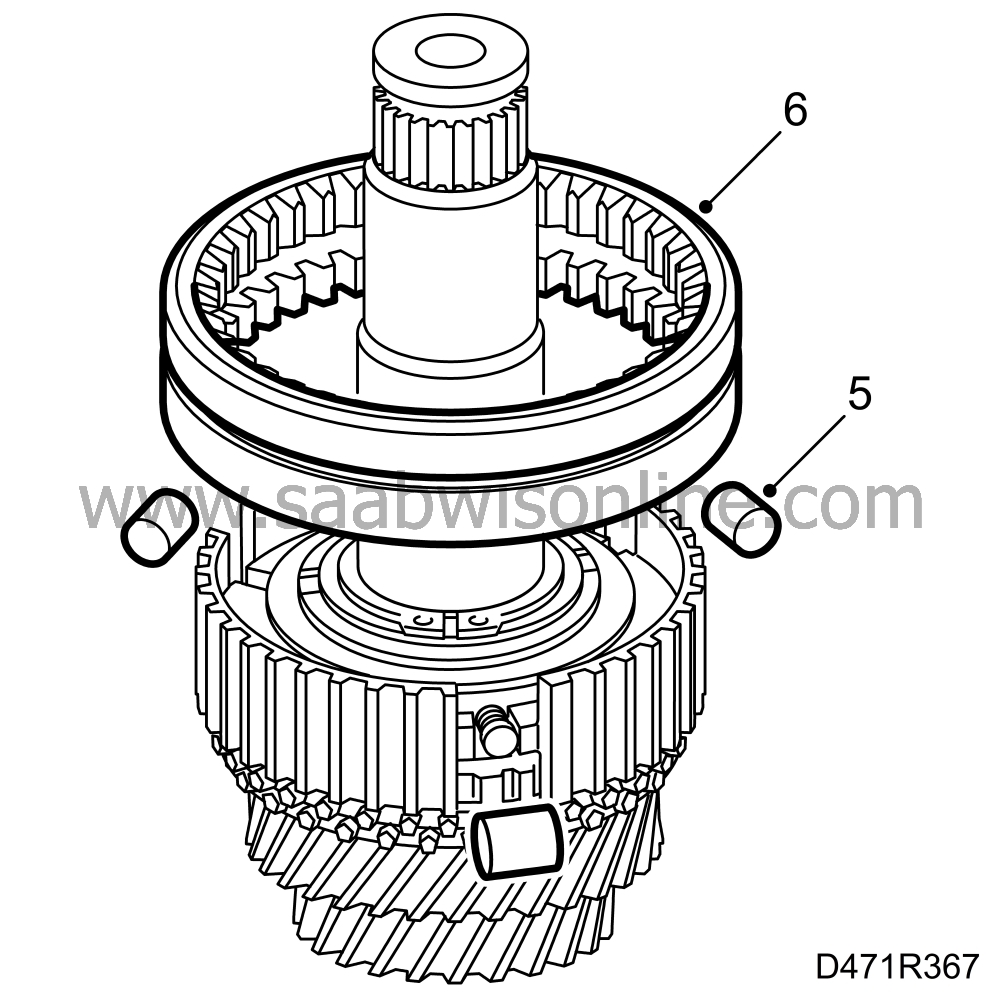

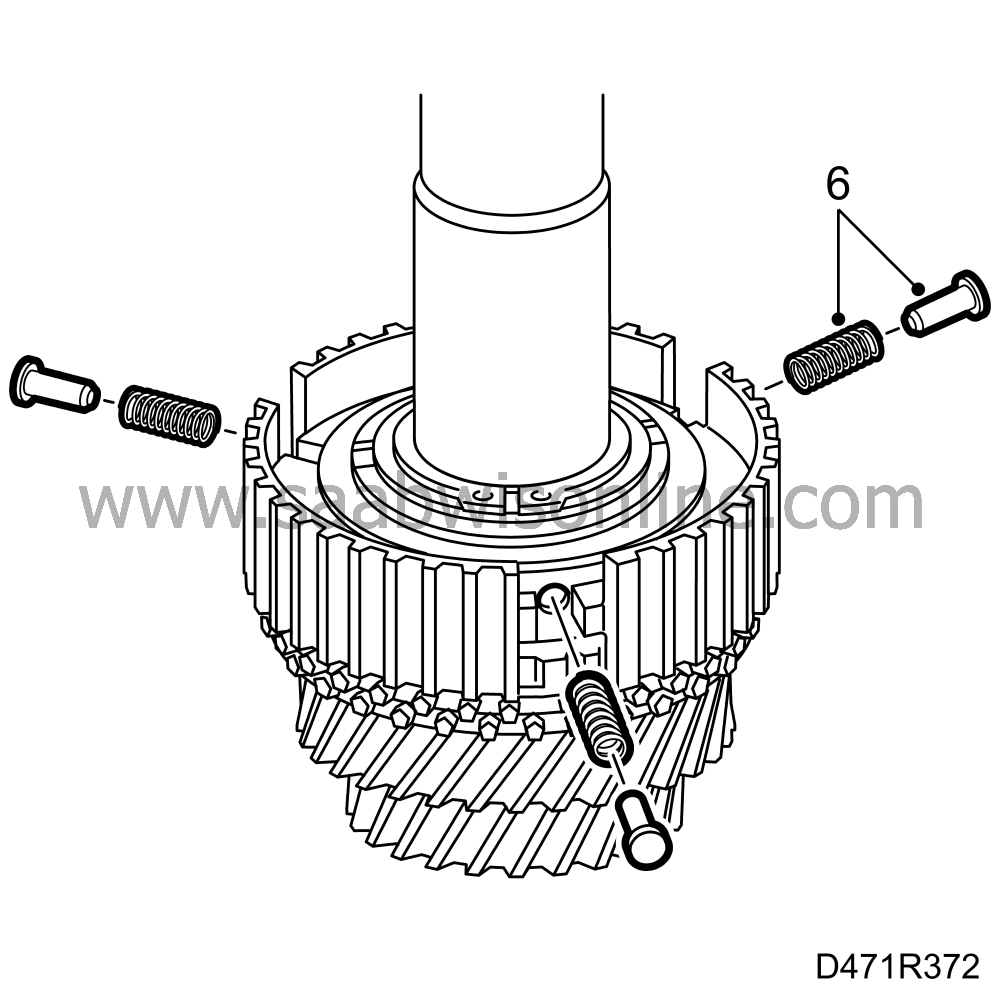

| 5. |

Check the end float between the 2nd and 3rd gear pinions. The play should be 0.05-0.40 mm.

|

|

| 6. |

Fit springs and plungers.

|

|

| 7. |

Fit the synchromesh sleeve.

|

||||||||||

| 8. |

Fit the rollers. They are fitted by pressing in the springs. A small screwdriver can be used to press in the springs.

|

|

| 9. |

Fit the 4th baulk ring, leaf springs, needle bearing and pinion.

|

|

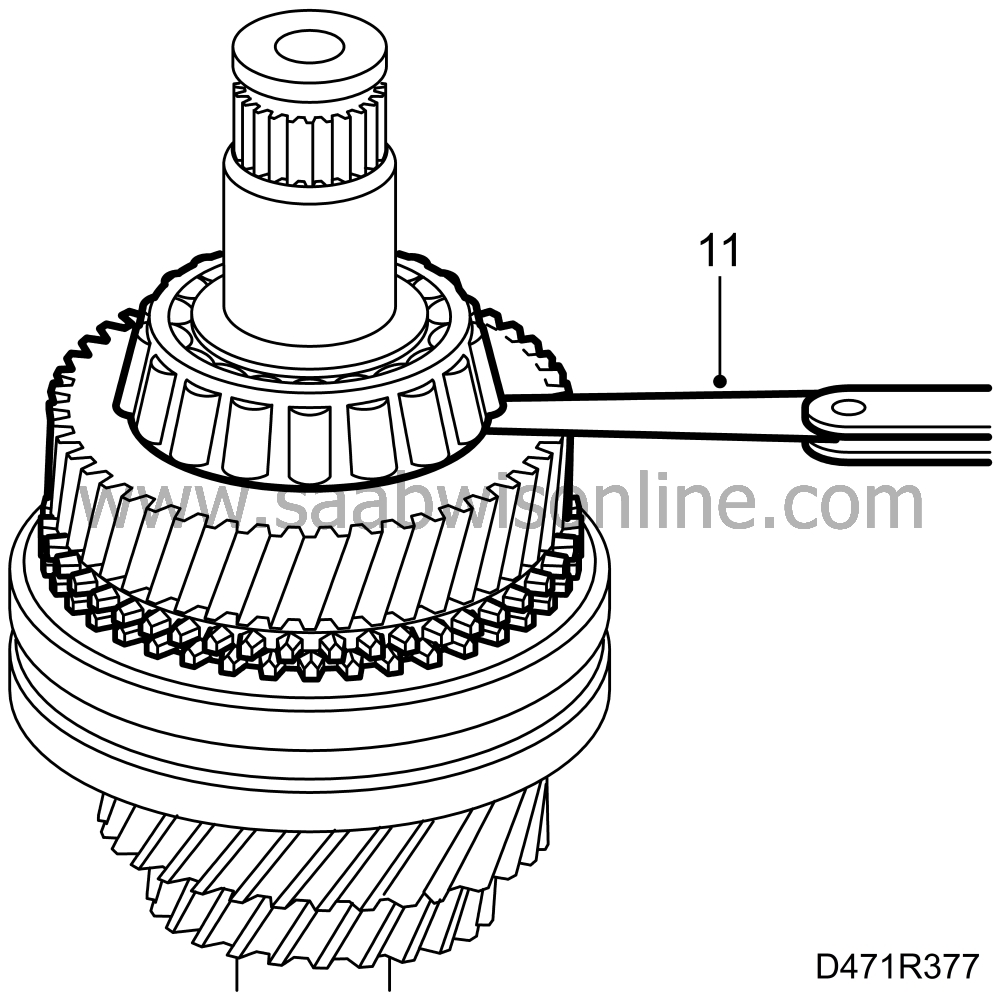

| 11. |

Check the play between bearing and 4th pinion to ensure that the input shaft is correctly fitted. Play should be 0.05-0.40 mm.

|

|