Adjustment of bearing tension

|

SERVICE INFORMATION

|

|

Bulletin Nbr:

|

471-1544

|

|

Date:

...........

|

JANUARI 1995

|

|

Market:

|

ALL

|

|

|

Adjustment of bearing tension

|

Saab 900 M1994- and 9000 M1985- with manual gearbox.

A new method has been developed to set output shaft bearing tension more

precisely. This means that the service life of affected bearings is increased. The method is

based on measuring the output axle turning torque using a torque meter in the range 0-300

N/cm. Measurement is made after normal setting of bearing tension, but before the nut is

locked.

Driver 87 91 428

Torque meter 16-87 92 483 (MKM-536)

M8 hexagonal socket with 1/2 attachment

M8 fuel line (approx. 100 mm long)

2 Hose clamps for fuel line

|

1.

|

Adjust bearing tension as

described in SI 471-1358 (-M1993) or Service Manual 4:1 "Manual gearbox" (M1994-)

.

.

|

|

2.

|

The following must done before taking measurements:

Input shaft bearing fitted (axial clearance 0.04-0.16 mm).

Differential fitted (axial clearance 0.05-0.20 mm).

All bearings oiled.

The

gearbox must be in the same position as in the car (horizontal).

|

|

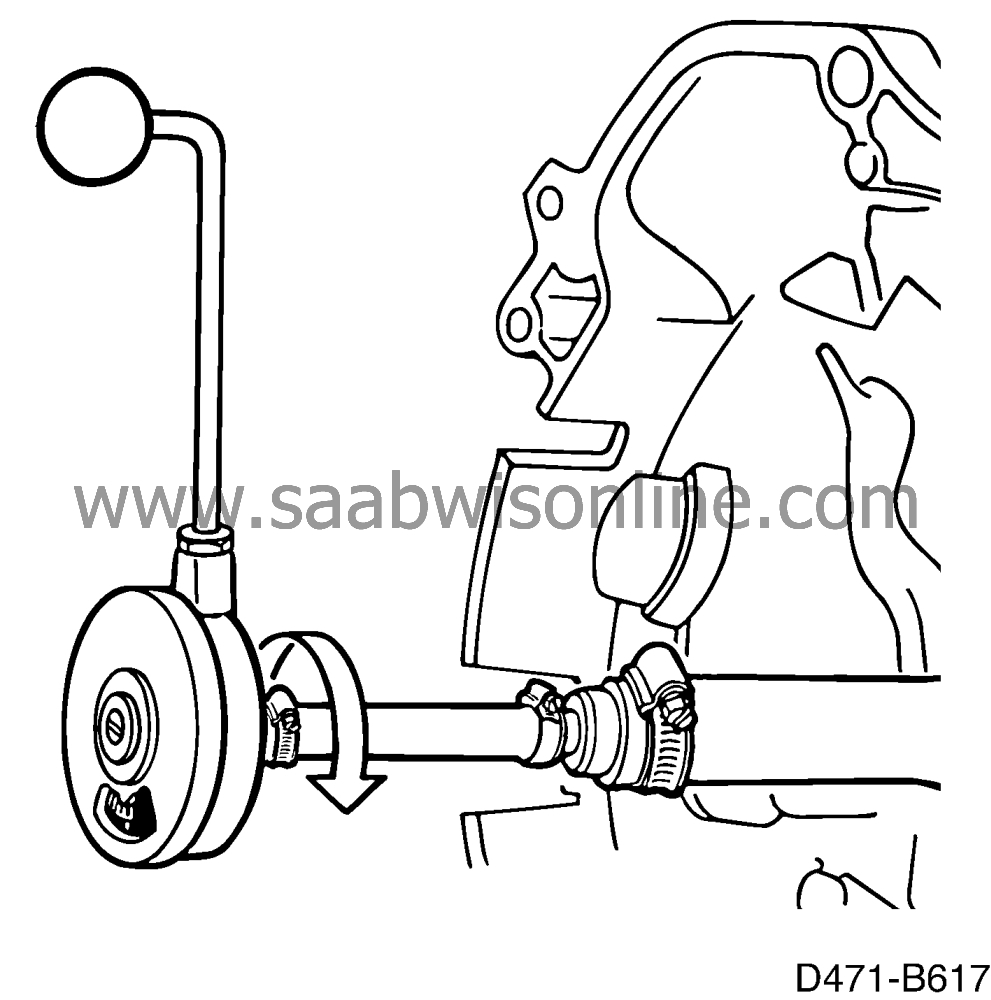

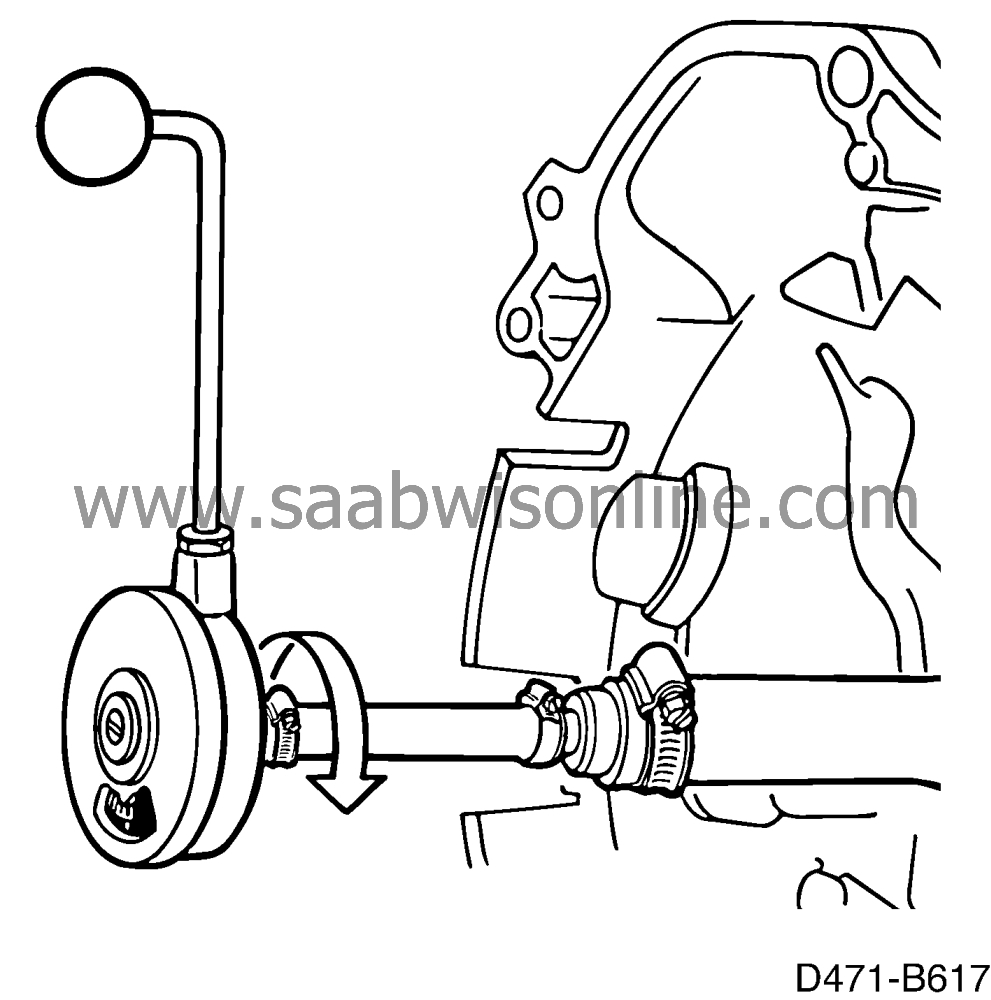

3.

|

Fit the hose between tool 87 91 428 and the hexagonal socket. Make sure that

no gear is engaged.

|

|

4.

|

Quickly rotate the input shaft back and forth. Measurement can start when the

shaft moves freely.

|

Important

|

|

Torque meters are extremely sensitive to impact, overload or heavy handling. If your are

in the slightest doubt about the setting of the torque meter, have it calibrated immediately.

|

|

|

|

|

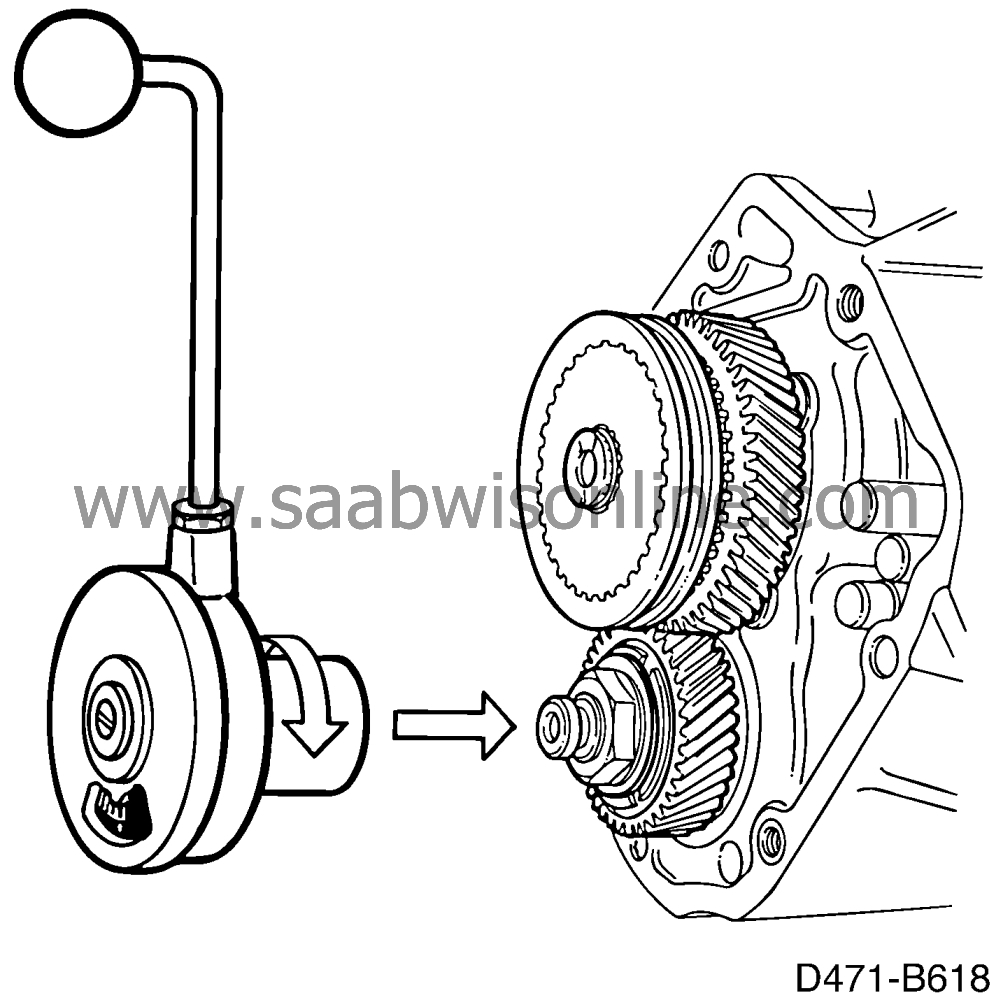

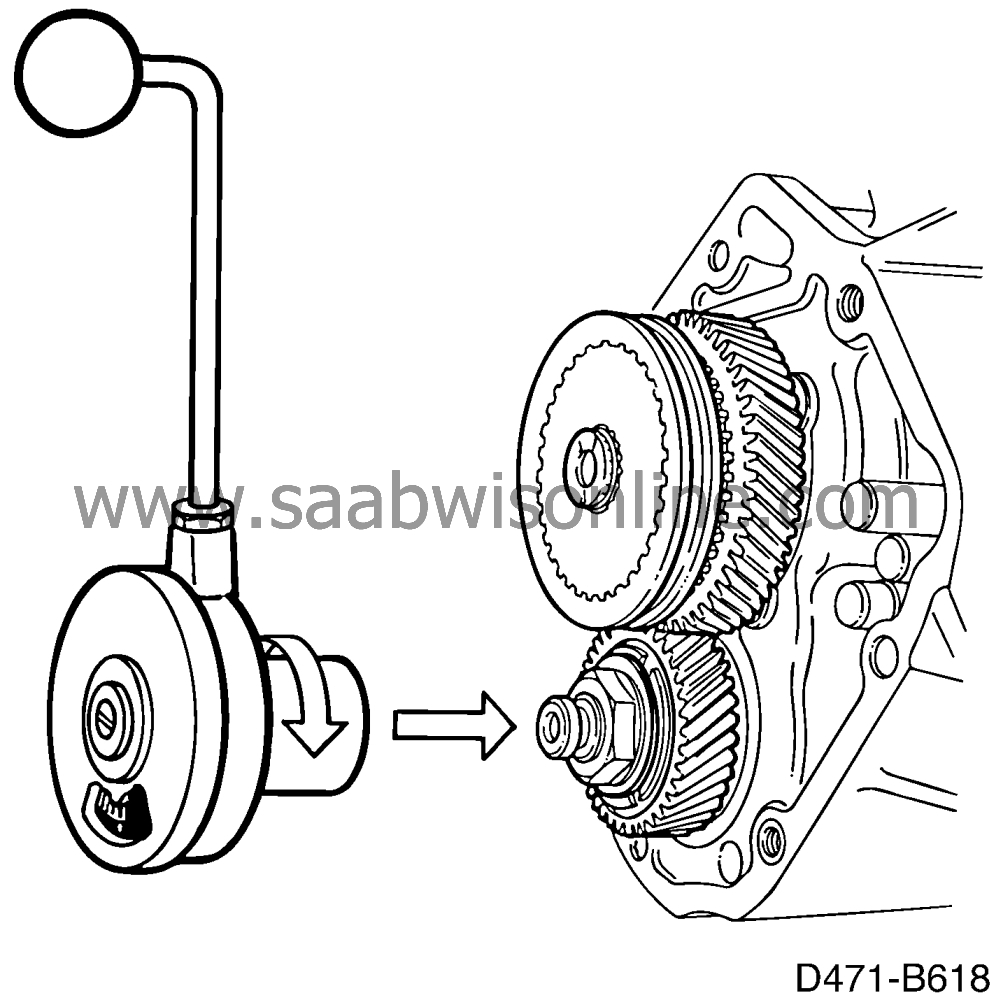

5.

|

Attach the torque meter and rotate it several turns clockwise with even speed.

Take the average reading from the meter during rotation, normally 10-30 N/cm.

|

|

6.

|

If the reading is higher, or varies significantly during rotation, the synchromesh

sleeves or dirt or particles are preventing free movement. Dismantle the gearbox and

establish the cause. It can sometimes help to mechanically rotate the shaft back and forth

under load, but the bearings must be oiled afterwards.

|

|

7.

|

Move the torque meter to the output shaft on the 5th gear nut, but 5th

gear must not be engaged. Rotate the torque gauge several times clockwise with even speed.

Take the average reading from the gauge during rotation.

|

|

8.

|

Subtract the average reading for the input shaft from the average reading for the

output shaft. The calculated tension is a measure of the output shaft turning torque, normally

50-100 N/cm. Example: reading on output shaft = 110 N/cm and reading on input shaft = 30

N/cm gives 110 - 30 = 80 N/cm.

If average torque is higher, or if it varies significantly, the synchromesh sleeves or dirt or

particles can be preventing free movement. Dismantle the gearbox and establish the cause.

If you suspect that the bearings are too tight, over 100 N/cm, the gearbox must be

dismantled, and the collapsable spacer be changed, see Service Manual 4:1 "Manual

gearbox"

. The bearings should then be tensioned and test readings should be repeated.

. The bearings should then be tensioned and test readings should be repeated.

If the calculated value is less than 50 N/cm, the bearings are too loose. If this is the

case, tighten the output shaft bearing further in small steps until the desired reading is

achieved.

|

|

Standard time information

|

See standard time list.

Regular warranty rules apply.

.

.