Adjusting gear position and gear positionsensor

|

SERVICE INFORMATION

|

|

Bulletin Nbr:

|

432-1545

|

|

Date:

...........

|

DECEMBER 1994

|

|

Market:

|

ALL

|

|

|

Adjusting gear position and gear position

sensor

|

Saab 900 M1994- with automatic transmission.

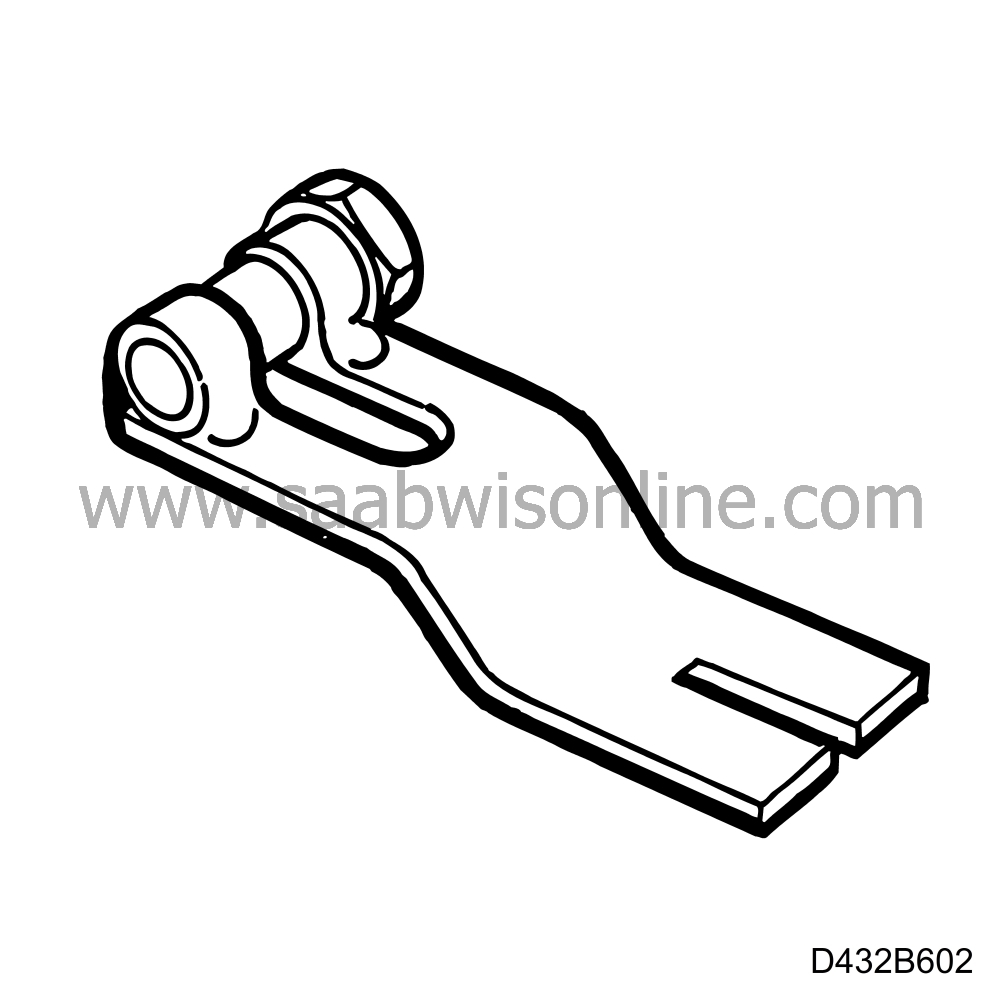

A new tool has been developed for adjusting the gear position sensor and

adjusting instructions are therefore changed.

87 92 467 Adjusting tool

Check gear selector lever positions when changing the gear position sensor,

gear selector cable or if the positions are not correct. It should only be possible to start the

engine in P and N, and the reversing light should only come on at R. Feel how much play

there is in the top of the gear selector lever. The play should be the same in N and D. If gear

position or play are not correct, adjust as described on pages 2 and 3.

|

Adjusting gear position sensor

|

Warning

Warning

|

|

There a danger of burn injury when working near the exhaust pipe.

|

|

|

|

|

|

|

1.

|

Wash the gearbox around the

fluid filler pipe.

|

|

2.

|

V6:

Remove the engine covers.

|

|

3.

|

Read any diagnostic trouble codes, make a note of the code for the radio code

lock (if this type of radio is fitted), disconnect and remove the battery.

|

|

4.

|

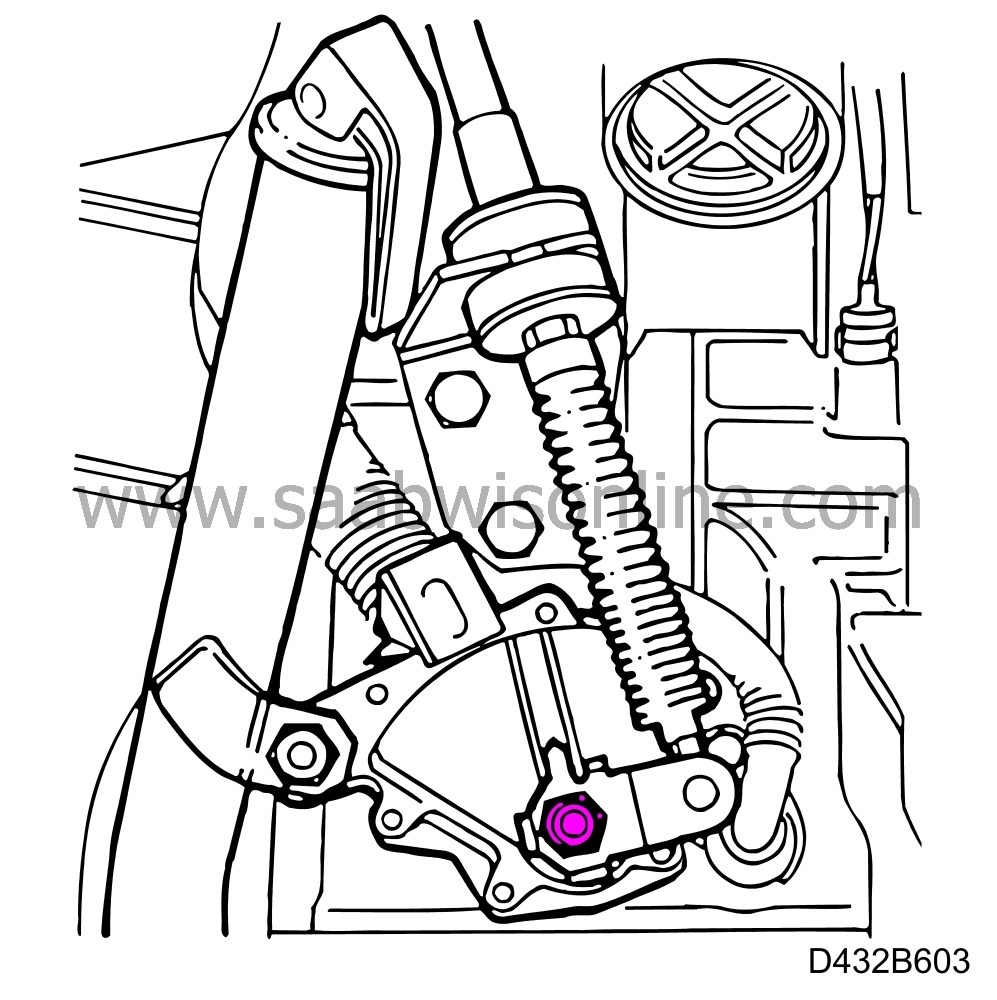

Remove the servo pump pipe attachment bracket.

|

|

5.

|

Set the gear selector lever to position 1 (to read the cable) and undo the lever

nut.

|

|

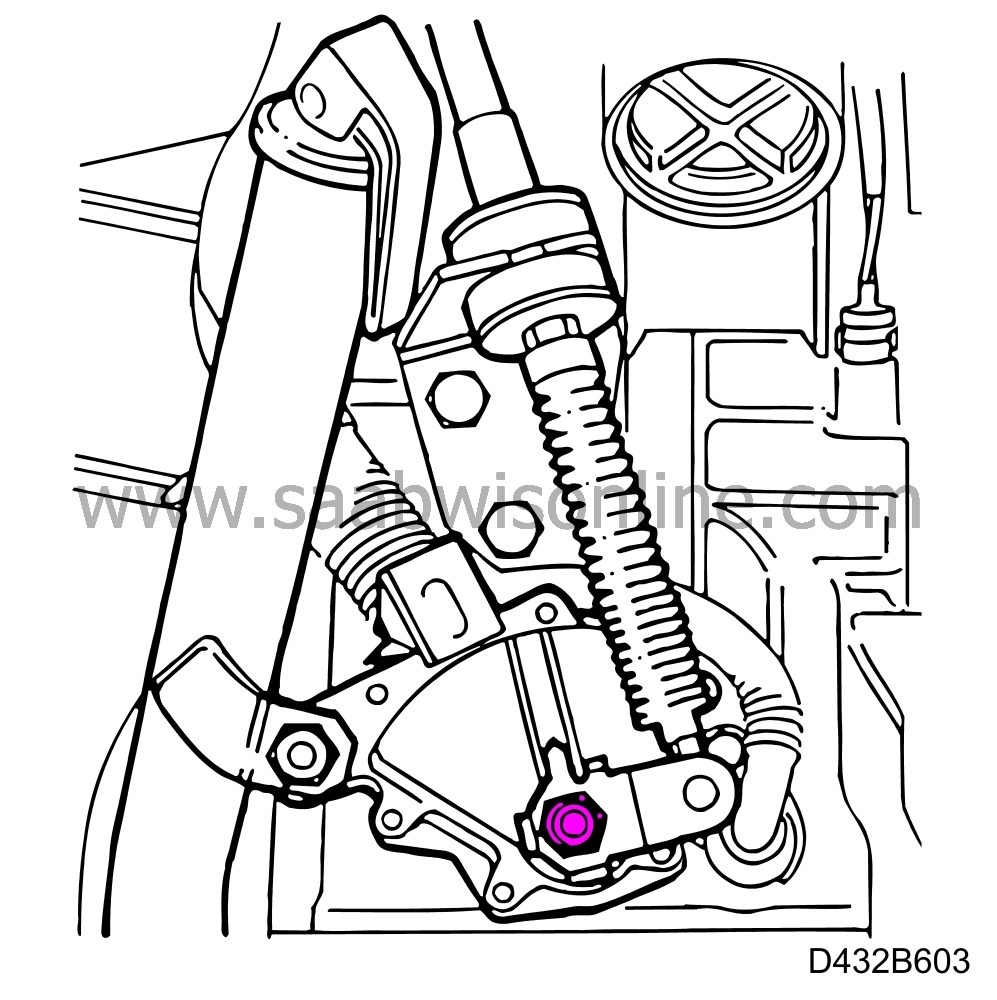

6.

|

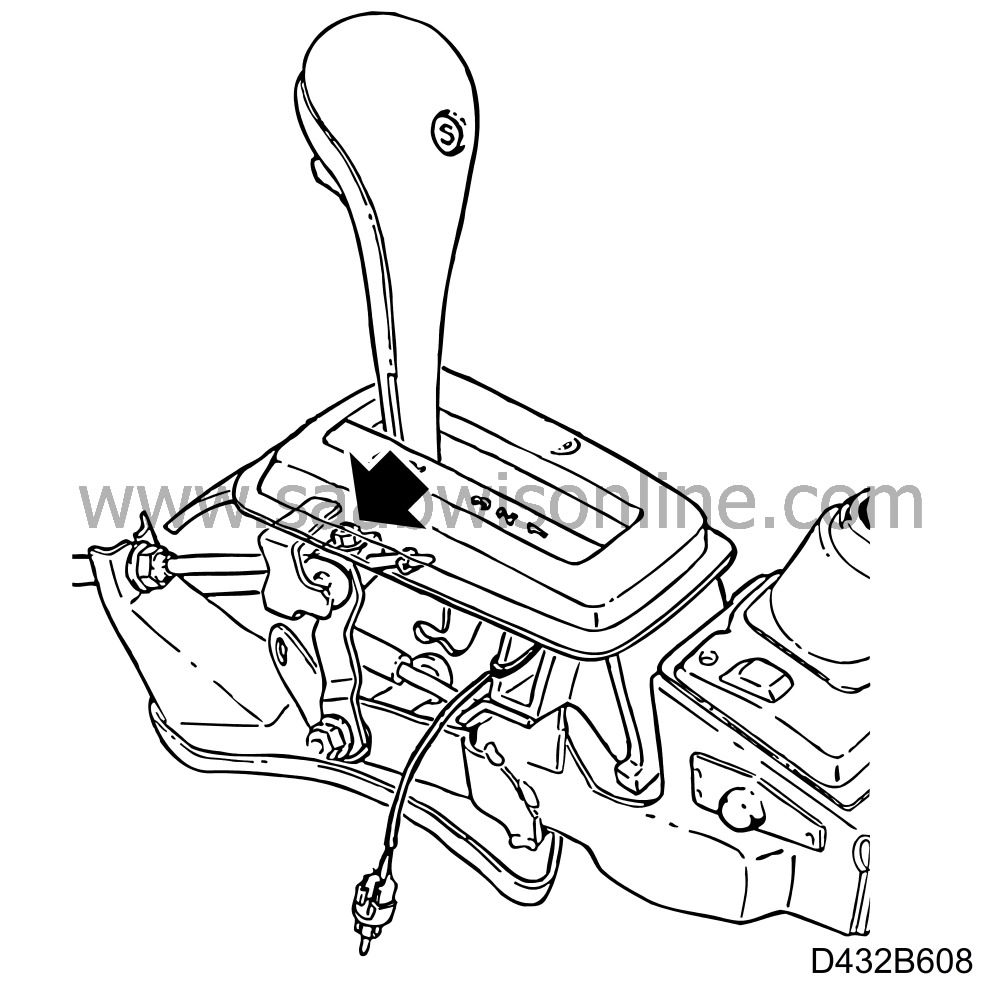

Move the gear selector lever to N, remove the gear selector wire lever and fit tool

87 92 467. Check that the line on the gear position sensor is visible in the center of the tool

groove.

|

|

7.

|

If this is not the case, the fluid filler pipe nut should be undone, the pipe turned

aside and the bolt or bolts securing the gear position sensor be undone.

|

|

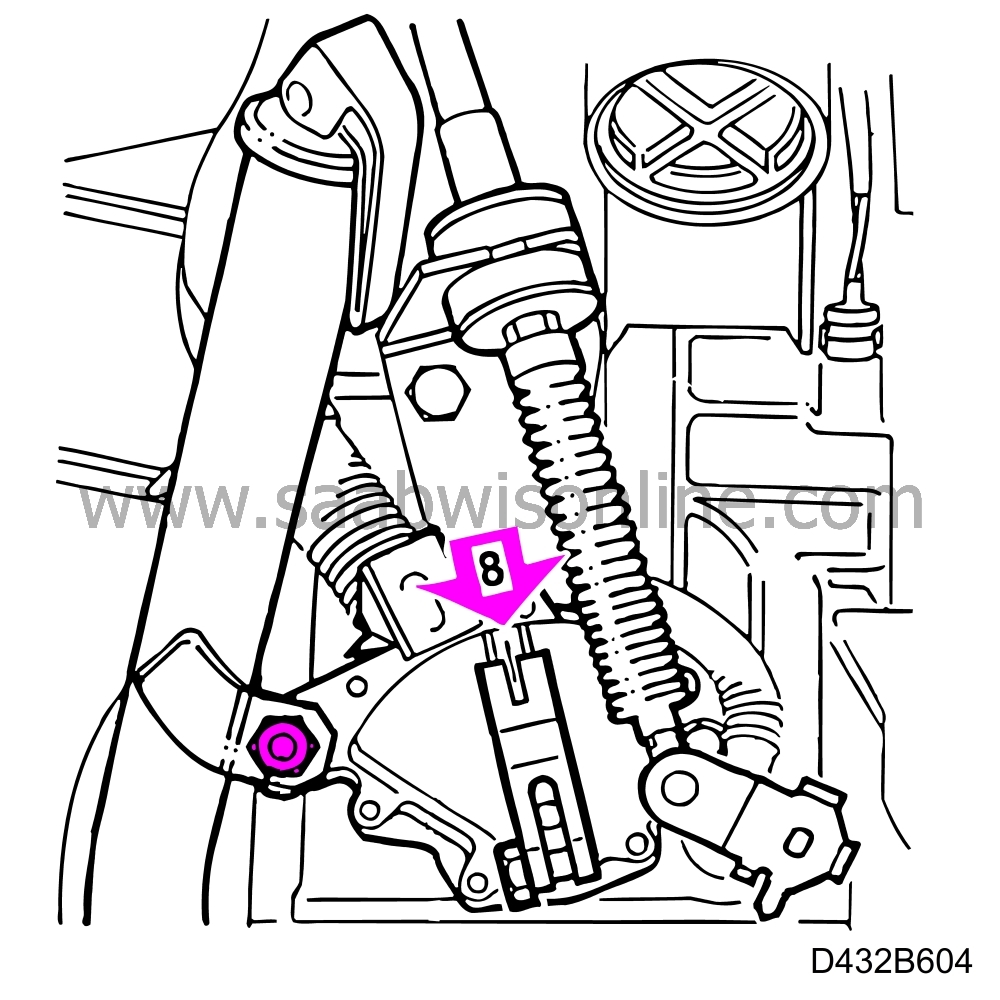

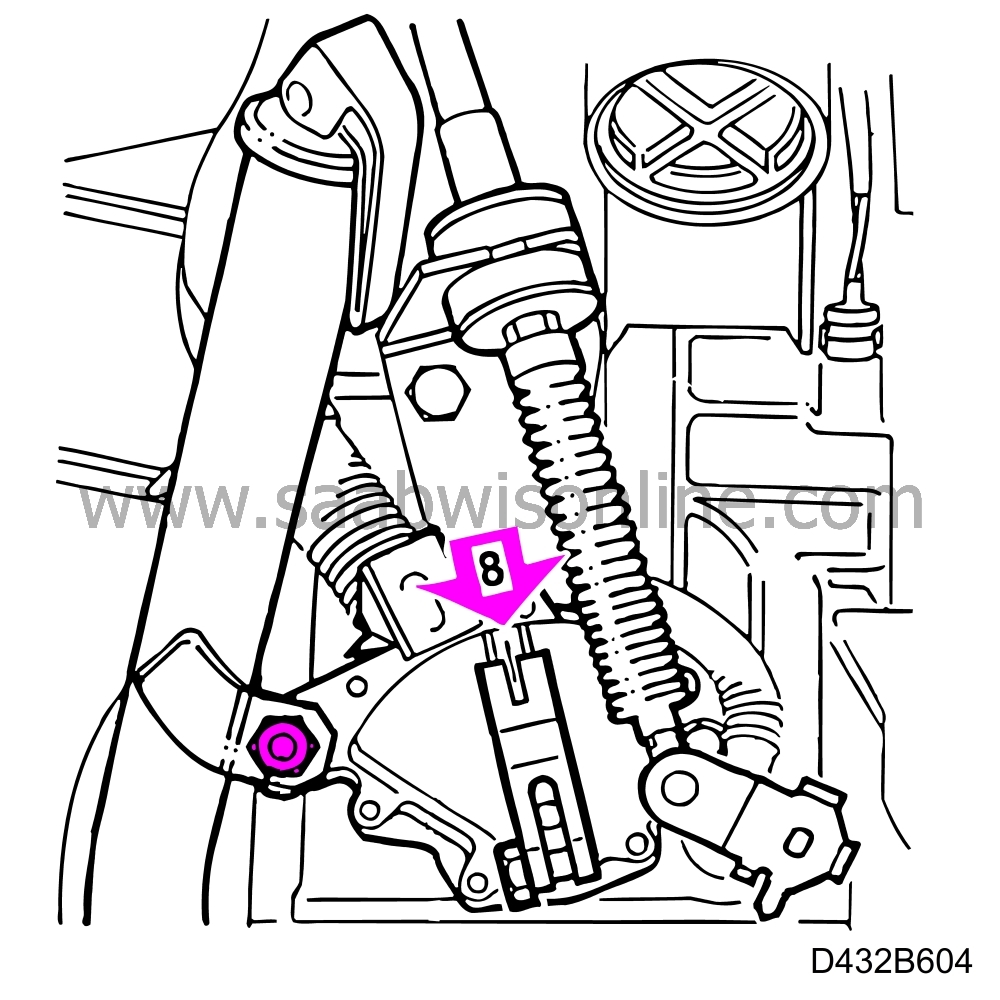

8.

|

Turn the sensor so that the line on it is visible in the center of the tool groove and

tighten the bolt(s).

Tightening torque 25 Nm (18.5 lbf

ft)

|

|

9.

|

Lubricate the fluid filler pipe O-ring using acid free petroleum jelly and refit the oil

filler pipe.

Tightening torque 25 Nm (18.5 lbf

ft)

|

|

10.

|

Remove the tool and fit the gear selector cable lever. Before tightening the nut,

the gear selector lever should be moved to P to relieve the load on the cable.

Tightening torque 25 Nm (18.5 lbf

ft)

|

|

11.

|

Fit the servo pump pipe attachment bracket, refit and connect the battery. Enter

the radio code (if this type of radio is fitted).

|

|

12.

|

V6:

Fit the engine covers.

|

|

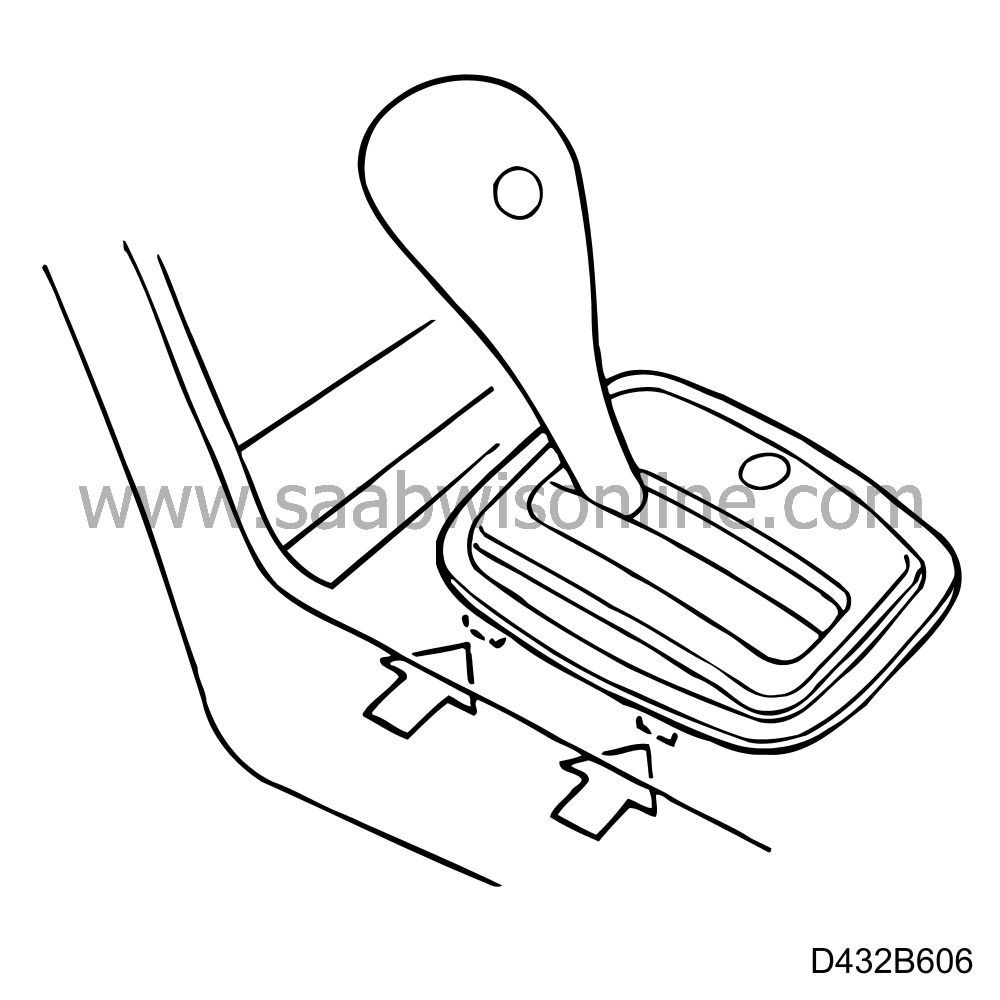

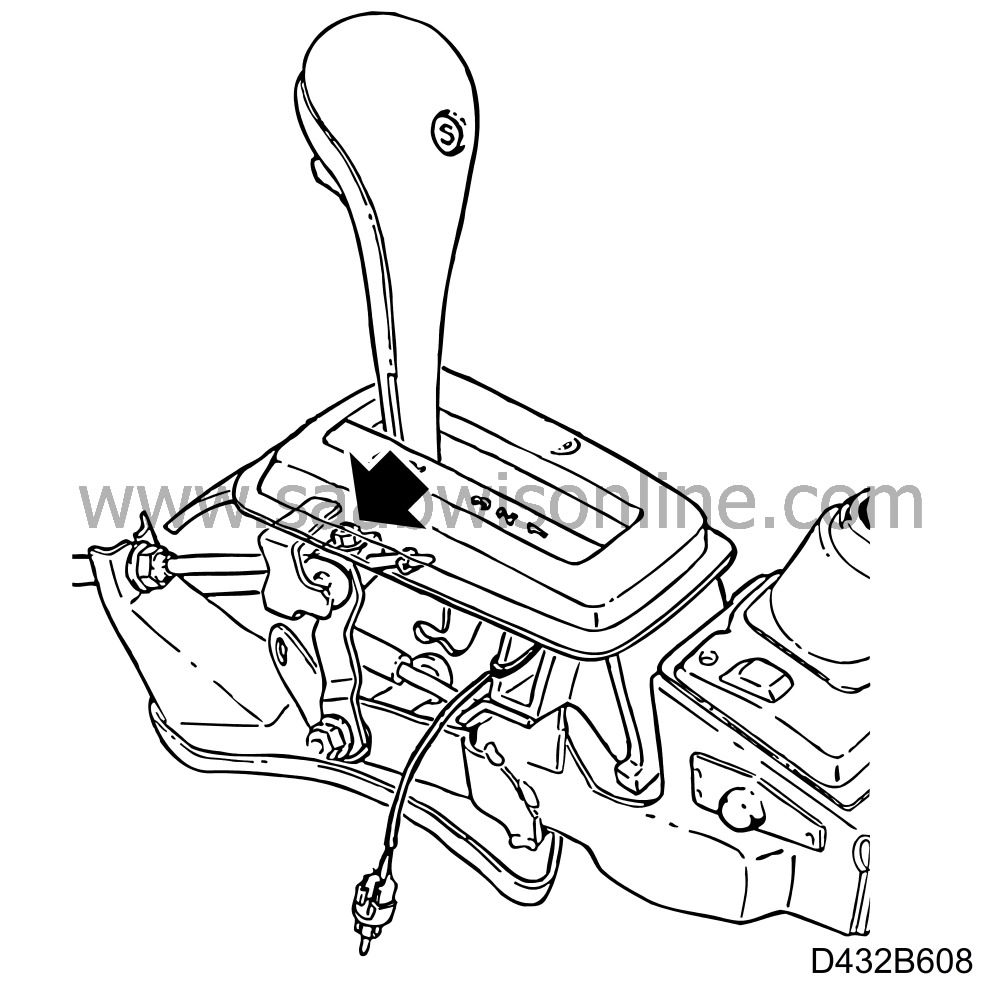

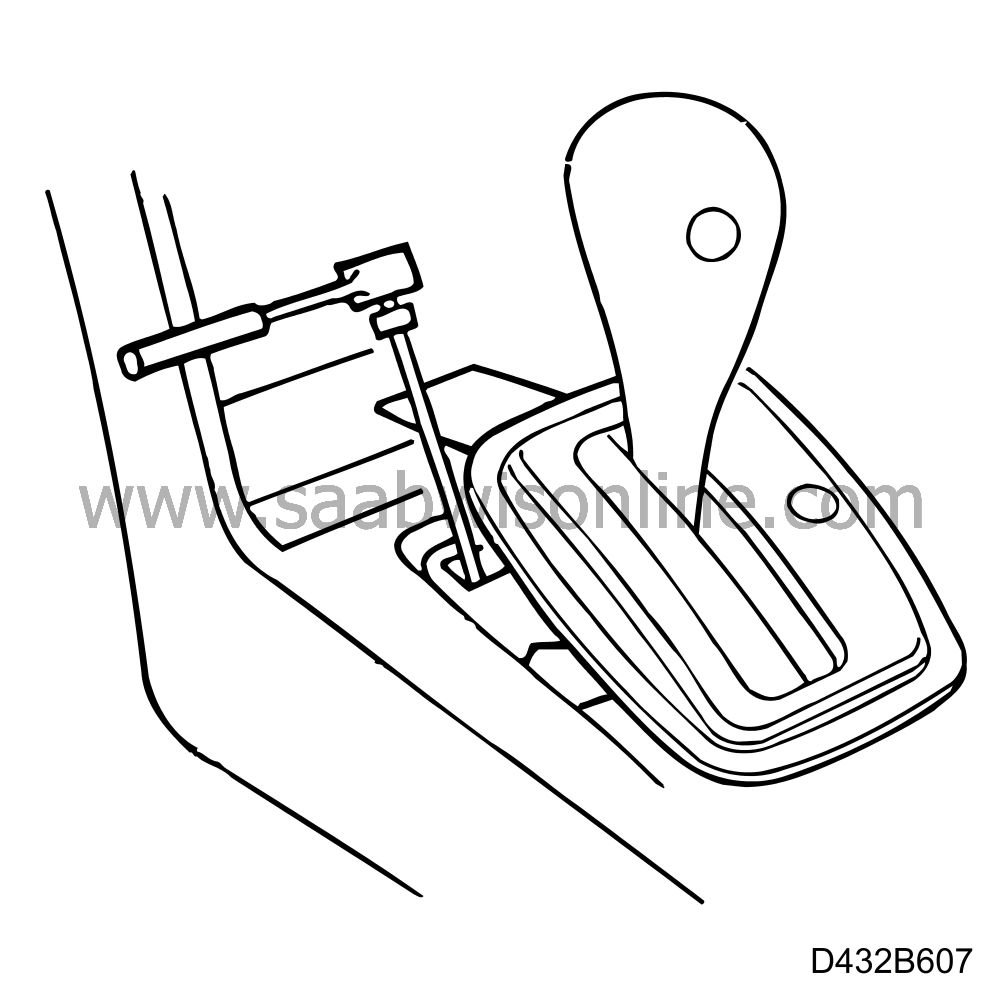

1.

|

Detach the cover beside the

gear selector lever, see drawing.

|

Important

|

|

Be careful of the WINTER switch and the cables under the cover.

|

|

|

|

|

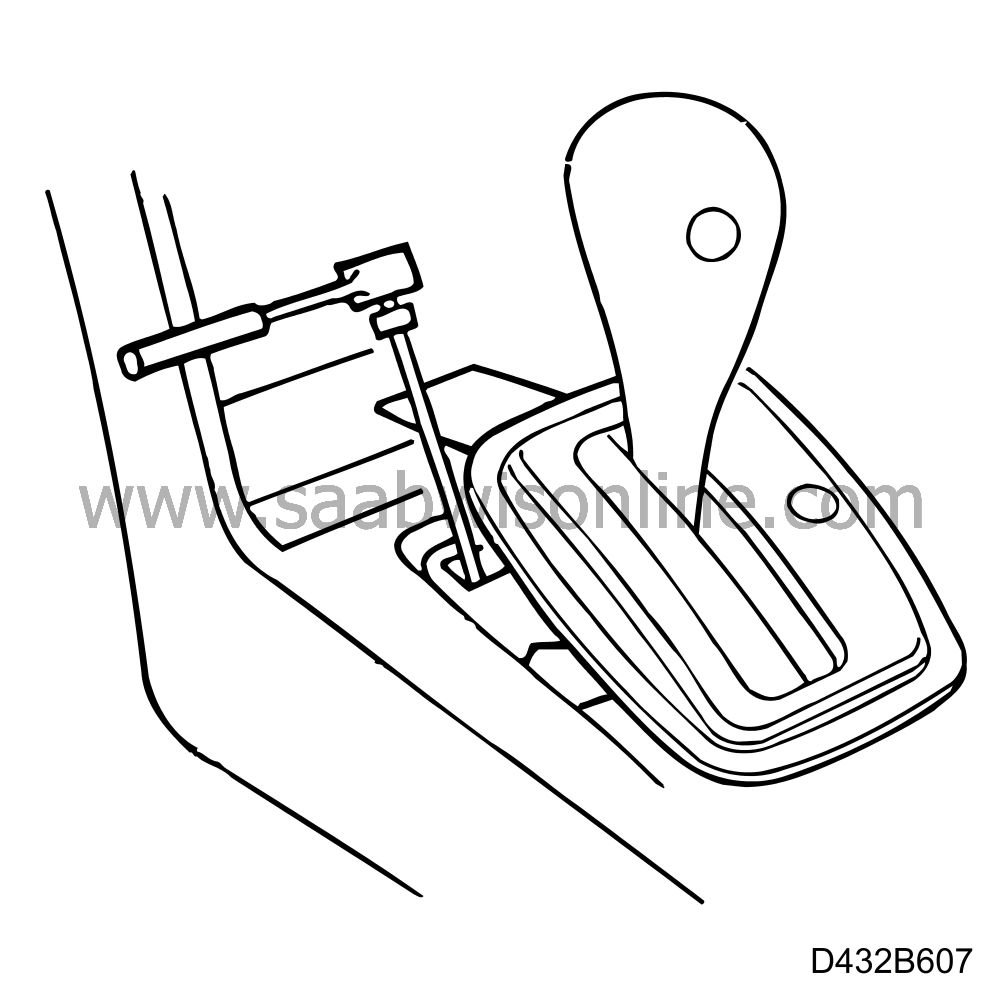

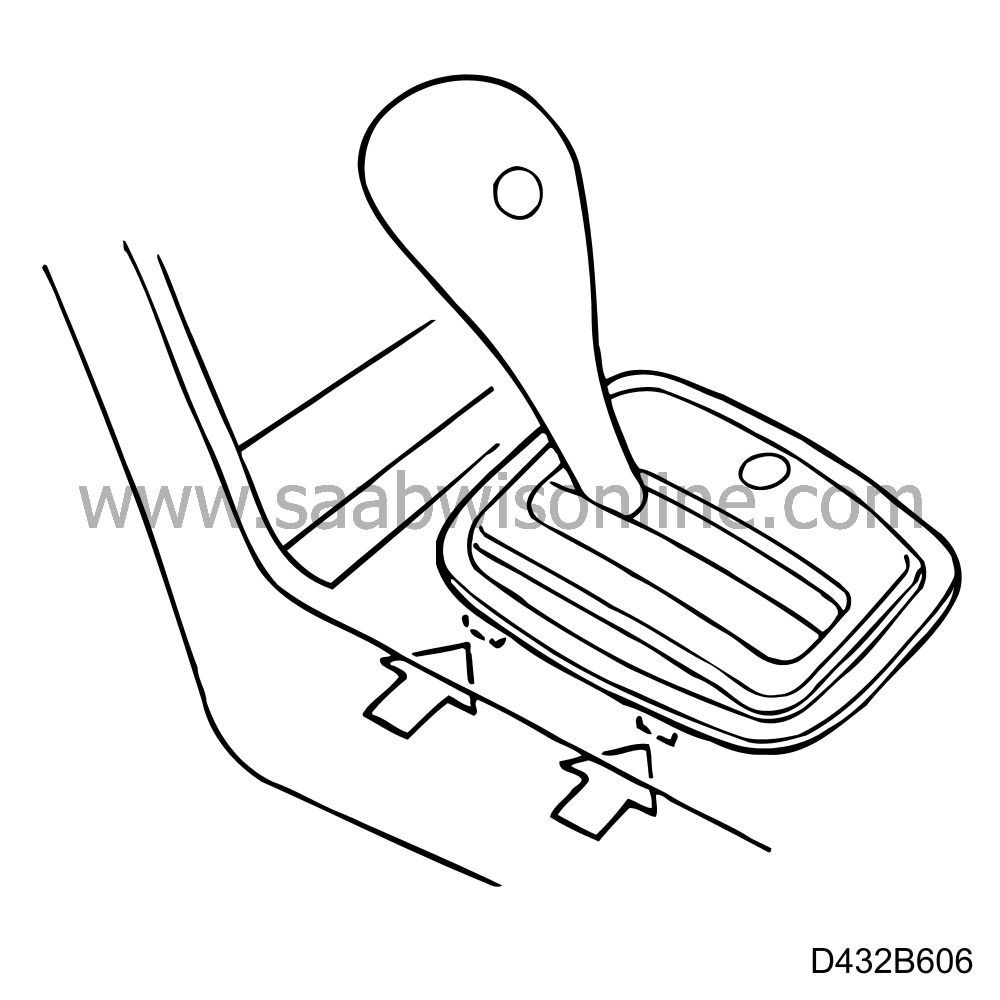

2.

|

Move the gear selector lever to 1, lift the front edge of the indicator plate and

move the lever to R.

|

|

3.

|

Using a 10 mm socket (with 1/4 attachment) on an extension, undo the nut

securing the gear selector cable, so that the ends of the cable are free.

|

|

4.

|

Check that the gear selector lever is at R and do up the nut.

Tightening torque: 8 Nm (6 lbf

ft)

|

|

5.

|

Feel the gear selector lever to make sure that the play is the same in N and D

and that all gear positions can be engaged. If this is not the case, repeat point 3 and 4.

|

|

6.

|

Move the gear selector lever to 1 and fit the indicator plate in position. Press

down the cover beside the gear selector lever.

|

|

Standard time information

|

Gear position sensor

Object code: 36439

Fault code: 67

Localization code: 00

Action code: 05 Time: 0,3

Gear position

Object code: 43271

Fault code: 79

Localization code: 00

Action code: 05

Time: 0.1

Regular warranty rules apply.

Warning

Warning