Fitting/balancing tyres/wheels

|

SERVICE INFORMATION

|

|

Bulletin Nbr:

|

771-1425

|

|

Date:

...........

|

NOVEMBER 1993

|

|

Market:

|

ALL

|

|

|

Fitting/balancing tyres/wheels

|

Well-balanced and perfectly round wheels are essential for avoiding vibration

caused by tyres and wheels.

Unbalanced and out-of-round tyres caused by flat spots could be one of the causes of

vibration occurring in the steering wheel or seats. They can also be the cause of what is called

low-frequency infrasound.

This SI deals with the measures that are necessary to achieve the best possible results

when fitting and balancing tyres and wheels.

Always begin with a general inspection which covers the following points before

taking the car out on the road for testing:

|

1.

|

Check that the correct types of

tyre and wheel are fitted to the car.

|

|

2.

|

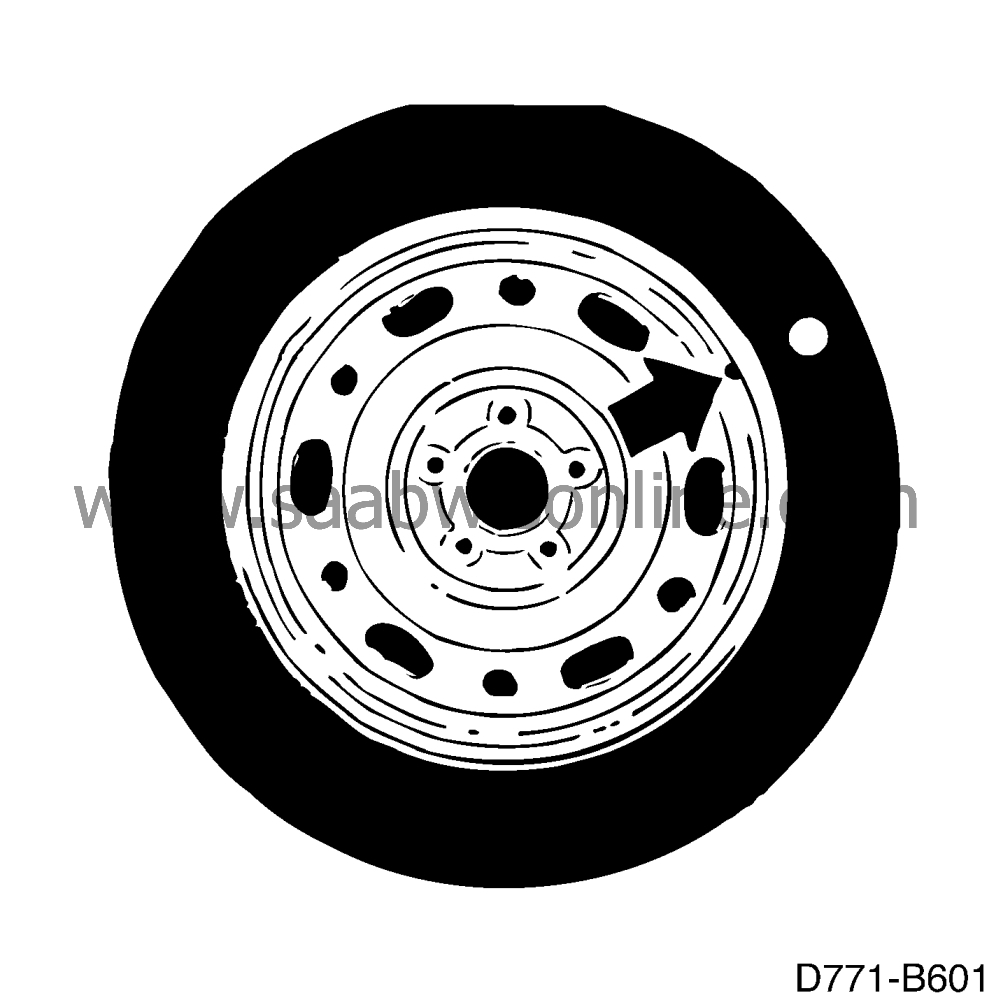

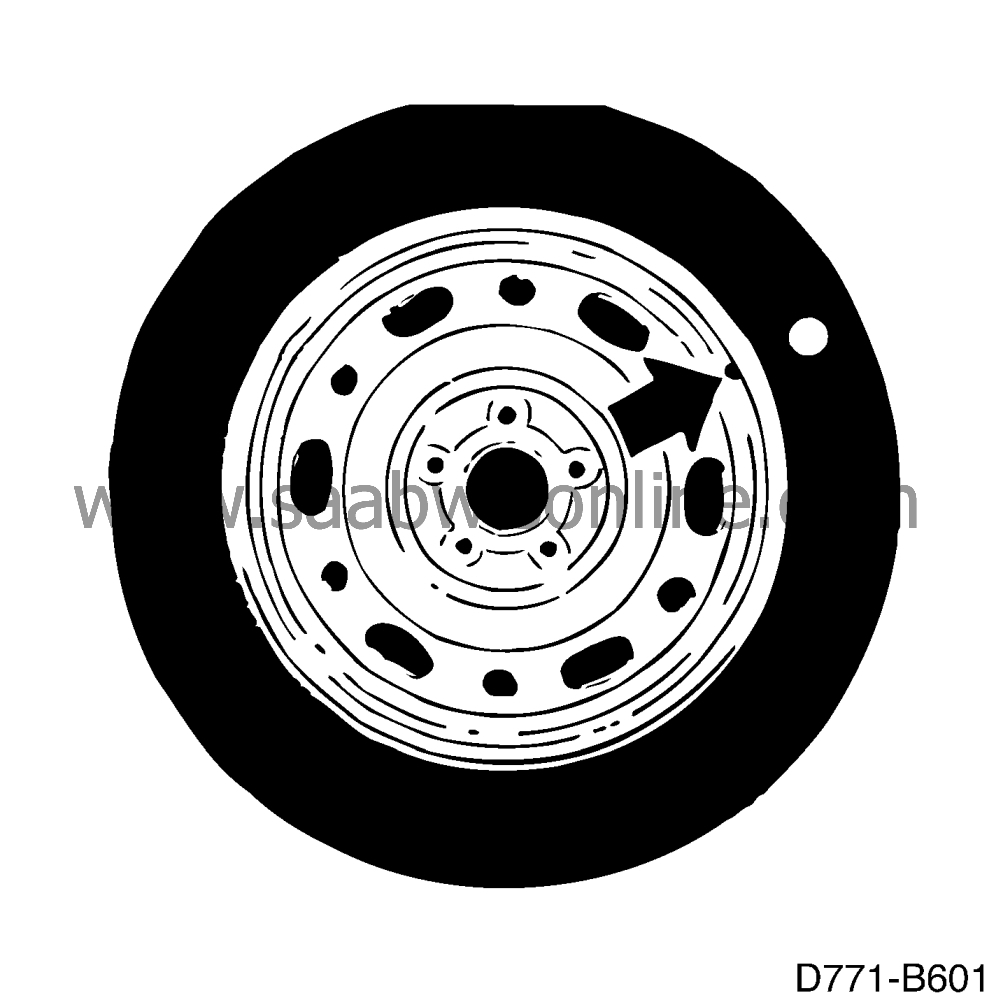

On cars with matched (pressed steel) wheels (chassis numbers up to

R2010422), check that the paint dot on the tyre is situated opposite the mark on the wheel.

The maximum permissible misalignment in the position of these marks is about

50 mm.

On cars with chassis numbers from R2010422, inclusive, matching by means

of a dot of paint on tyres and wheels is not used.

|

|

3.

|

Inspect the tyres and wheels for visible damage.

|

|

4.

|

Make sure that tyre pressures are correct and the same as those specified in the

owner's manual.

|

|

5.

|

Check that there are no flat areas on the tyre treads.

|

Important

|

|

Flat spots which occur when the car is parked and the tyres cool down after long and

hard driving will disappear by themselves if the car is driven for about 20-25 kilometres at a

speed of at least 90 km/h.

|

|

|

Test drive instructions

When the above inspection points have been carried out and any faults have been

rectified, the car should be taken out on the road for testing. The following instructions should

be followed:

|

|

6.

|

To get rid of flat-spots on the tyres, the car must be driven for at least 20-25

kilometres (in cold weather a somewhat longer distance) at normal highway speeds (90-110

km/h) so that the tyres will attain a sufficiently high temperature to regain their normal shape.

Not until then can assessment commence.

If balancing is judged to be necessary, it is extremely important to finish the test drive

by driving smoothly and unhurriedly so that the tyres will have time to cool down before the car

is returned to the garage. To avoid fresh flat-spots occurring, take the weight off the wheels or

remove them as soon as the car has been brought to a stop (max. 10 sec) at the end of the

road test.

Centring tyres

|

|

7.

|

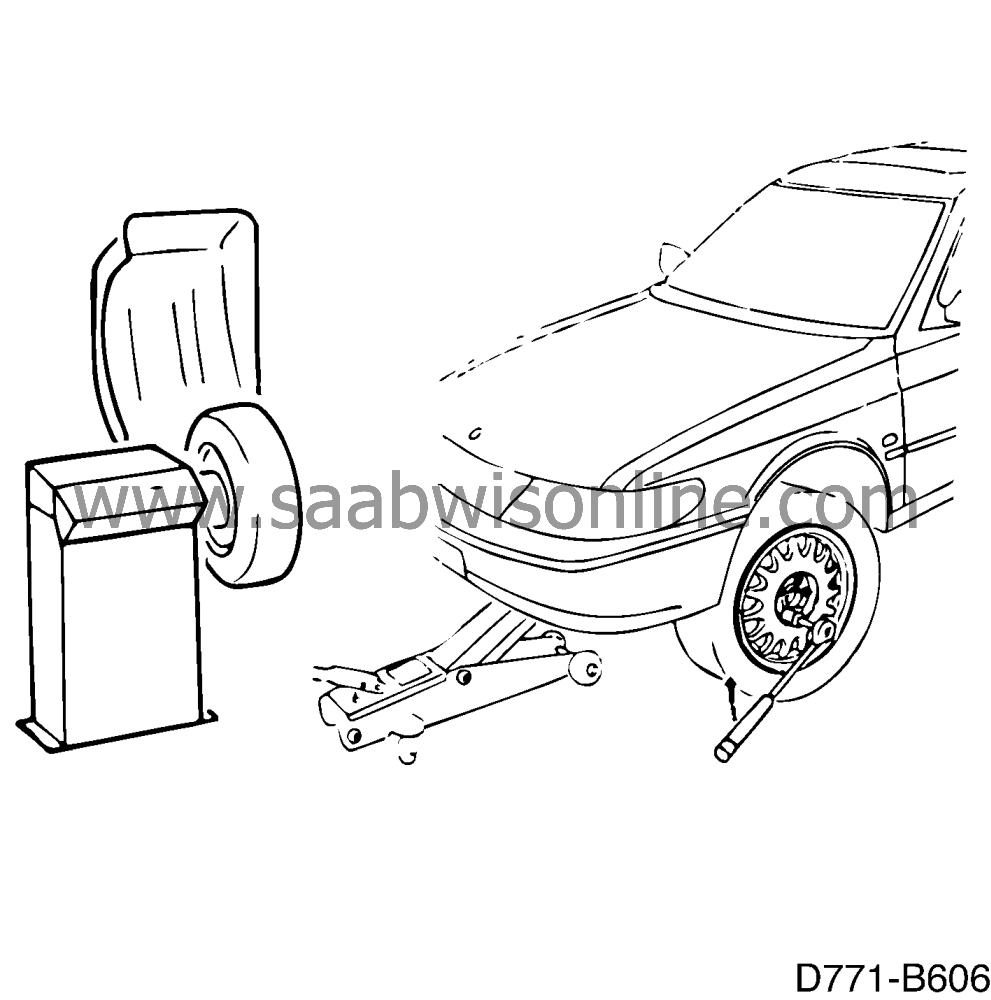

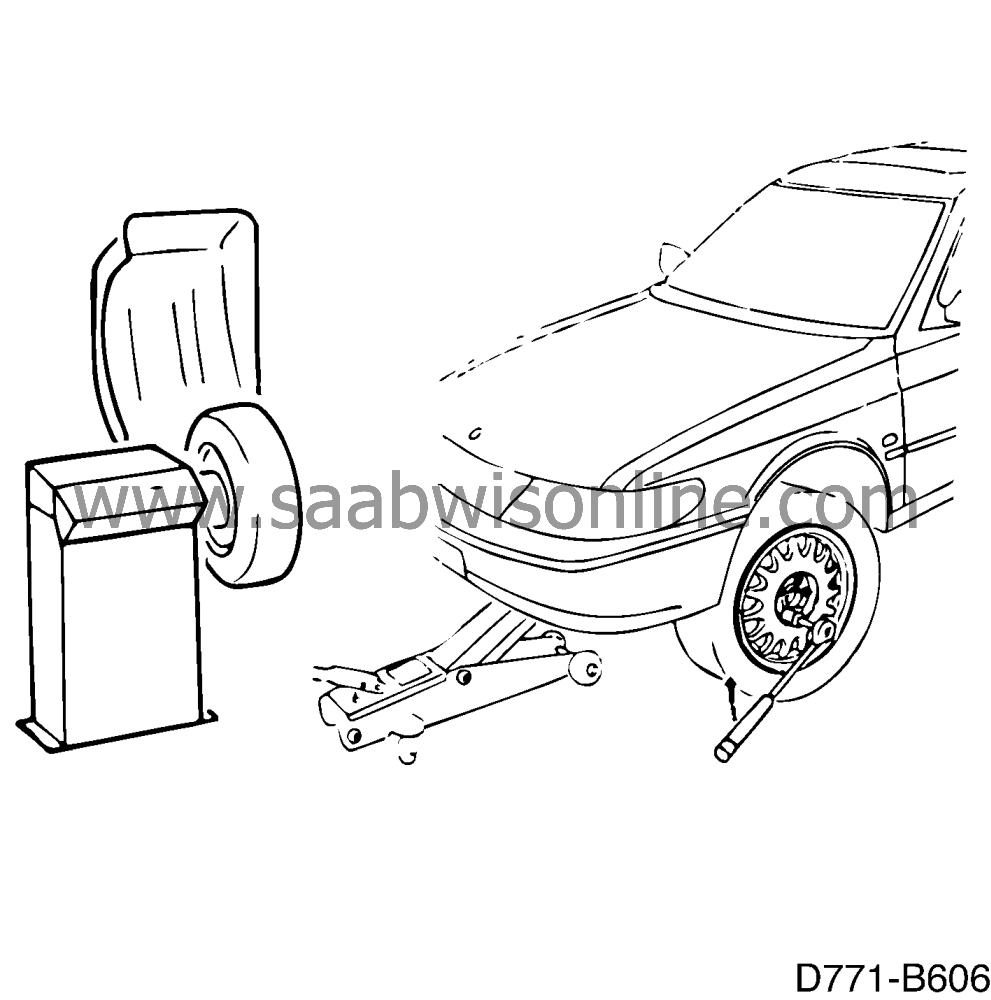

Thoroughly clean the wheel and place it in a wheel balancing machine that has

been inspected and approved.

For best results, the balancing machine's retaining device for the wheel should

consist of a

Saab hub

corresponding to the wheel mounting

on a 900 or 9000 model. Such wheel retaining equipment is normally provided by the

manufacturer of the balancing machine.

|

|

8.

|

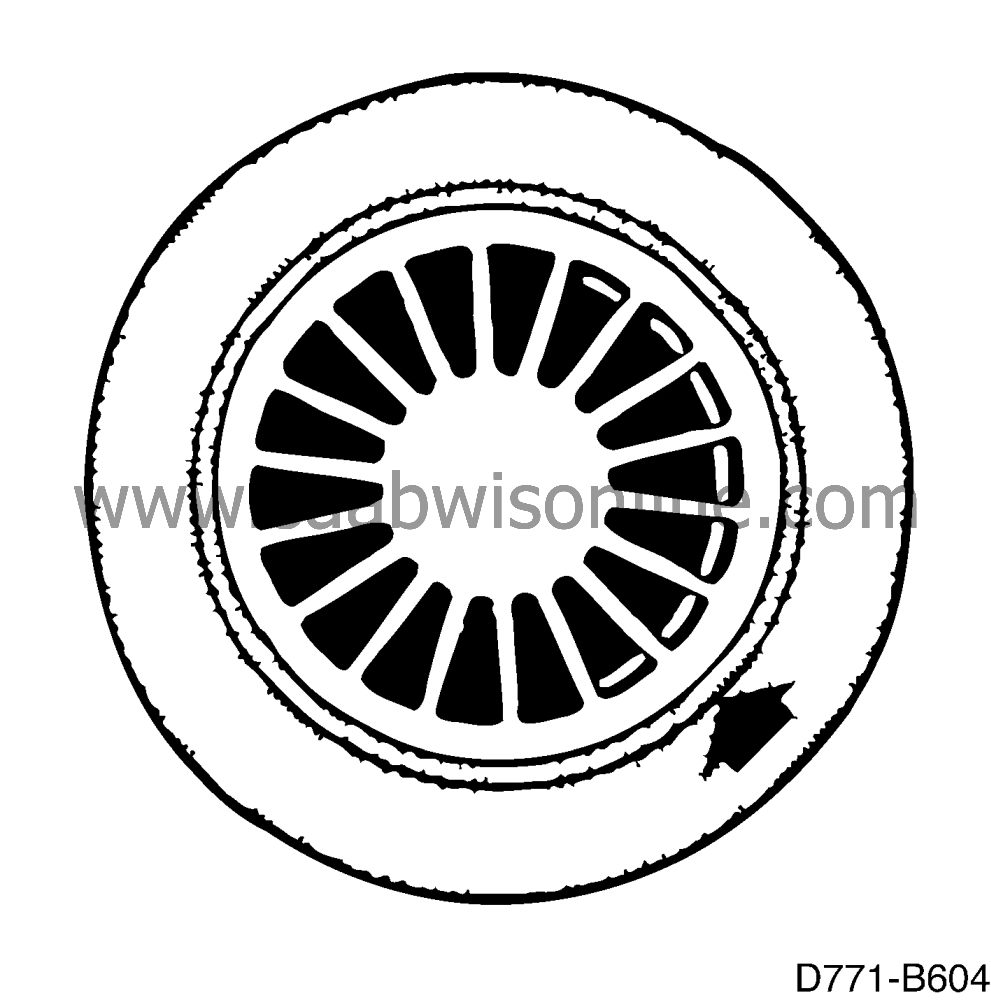

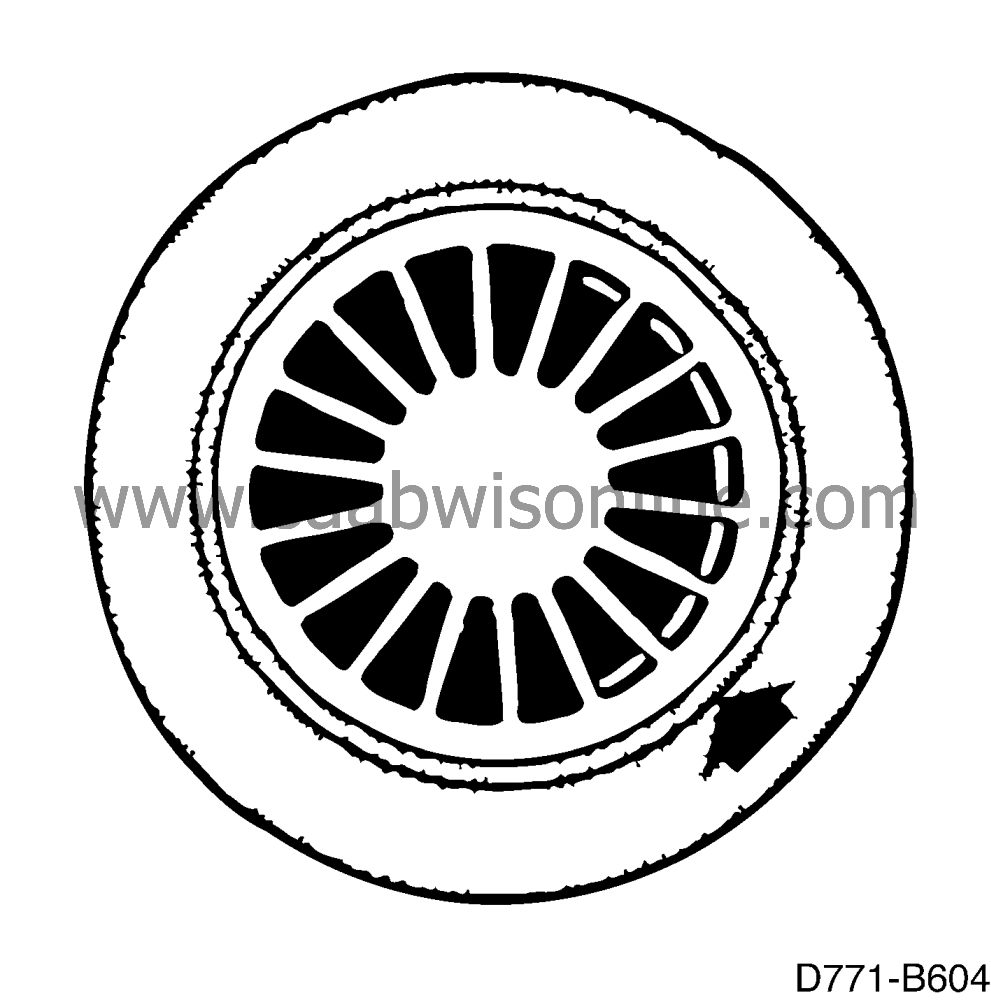

To check that the tyre's centring stripe moves in an even circular path,

start the machine and then open the cover before the machine's brake is applied.

|

|

9.

|

Also check the wheel's radial and axial throw in a similar manner. Neither

radial nor axial throw should exceed 1 mm.

|

|

10.

|

If the centring strip moves "up and down" because the tyre bead has not

"popped" out to the inside edge of the wheel rim, or if either radial or axial throw exceeds 1

mm, this can be remedied as follows:

|

|

|

•

|

lubricate the tyre and wheel as described in point 11

|

|

|

•

|

refit the tyre and inflate it to a pressure of 3.5 bar (51 psi) without a valve having

been fitted

|

|

|

•

|

then remove the compressed air line

|

|

|

•

|

fit the valve and inflate the tyre to the correct pressure. Then repeat points 8 and

9 above.

|

|

11.

|

Clean and lubricate the tyre bead and the inside of the wheel rim with a liquid

lubricant or, better still, mounting paste (part No. 45-30 21 169). If paste is used, avoid heavy

acceleration and braking before the wheel has become warm so that the tyre will not move on

the wheel rim.

|

Important

|

|

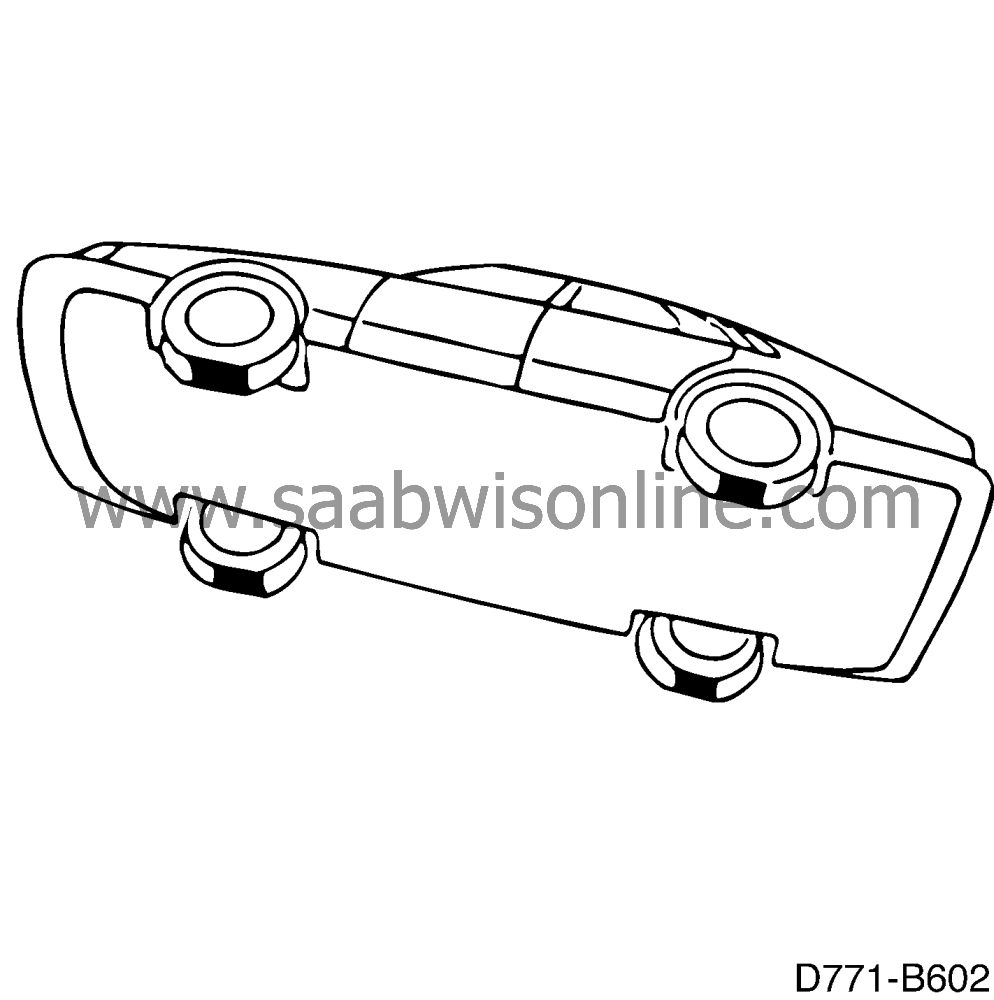

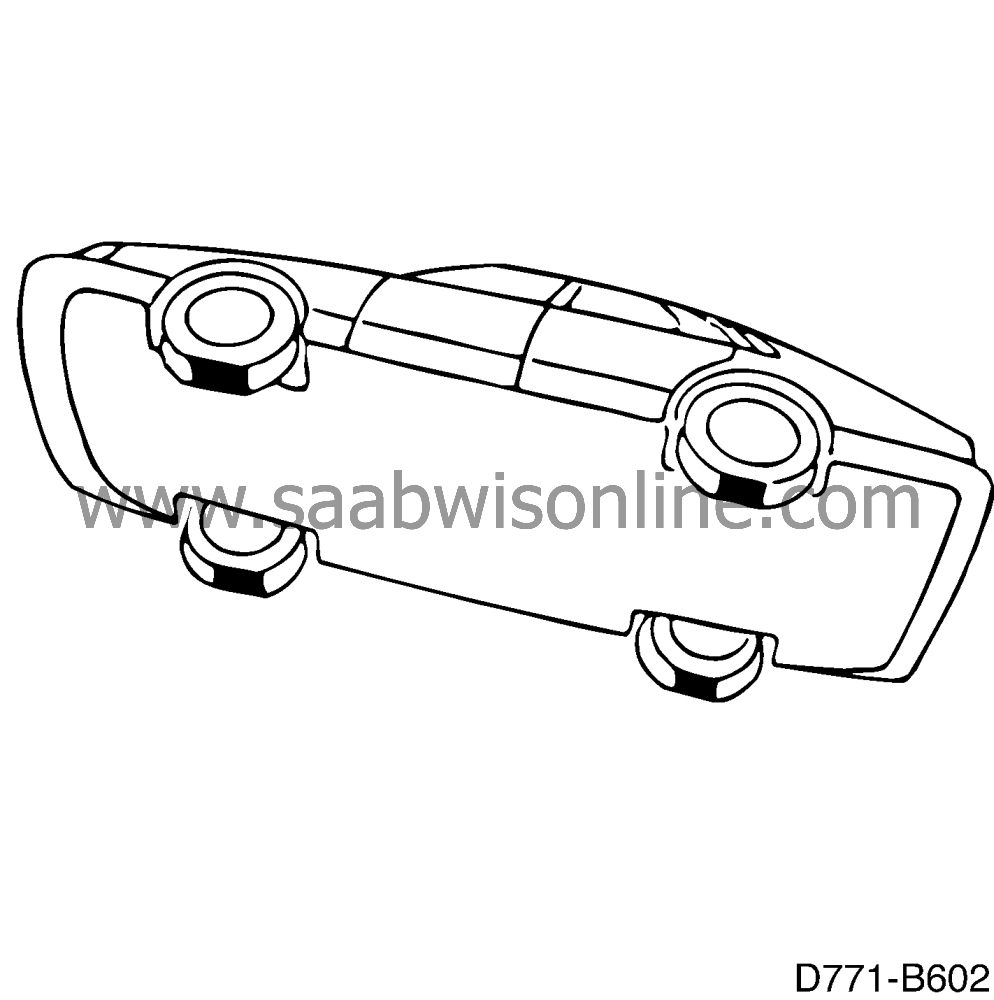

If the tyre has not "popped" over the hump (A) at a pressure of 2.5 bar (35 psi), remove

the tyre and repeat the lubricating procedure.

|

|

|

|

|

12.

|

Again check the position of the centring stripe as well as radial and axial throw

on the balancing machine. If centring and both axial and radial throw are OK, balance the

wheel as described in point 13 below.

If centring is not OK, repeat points 10 to 12. Should centring and radial and/or axial

throw remain unacceptable in spite of this, the tyre and wheel will have to be changed.

|

Important

|

|

Fit the wheels, those with the best centring at the front.

|

|

|

Balancing

|

|

13.

|

Balance all wheels on stationary wheel-balancing equipment so that residual

imbalance is reduced as much as possible.

|

|

|

•

|

The weights used, not more than one per wheel side,

must not exceed 40 grammes per wheel side or a total of 80 grammes per wheel. If they do,

remove the tyre, rotate it through 180° and repeat points 8-12.

|

|

|

•

|

Fit the wheel and tighten the wheel bolts to the correct torque see table below.

|

Important

|

|

When tightening the wheel bolts using a torque wrench, the car should be raised from

the floor (an assistant will be needed to apply the brakes).

|

|

|

Tightening torque, wheel bolts:

900 M94-: 105-130 Nm (78-96 lbf ft) alloy

900 M94-: 90-110 Nm (67-81 lbf ft) steel

|

|

14.

|

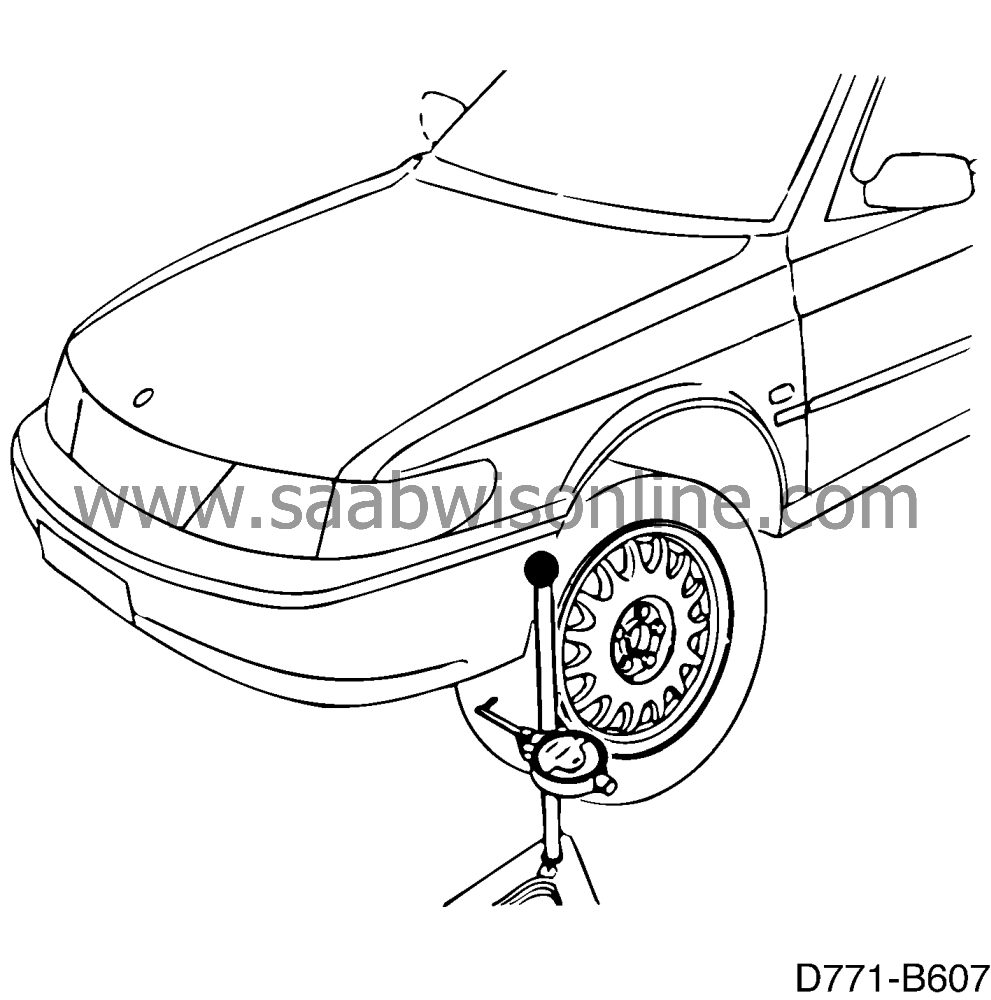

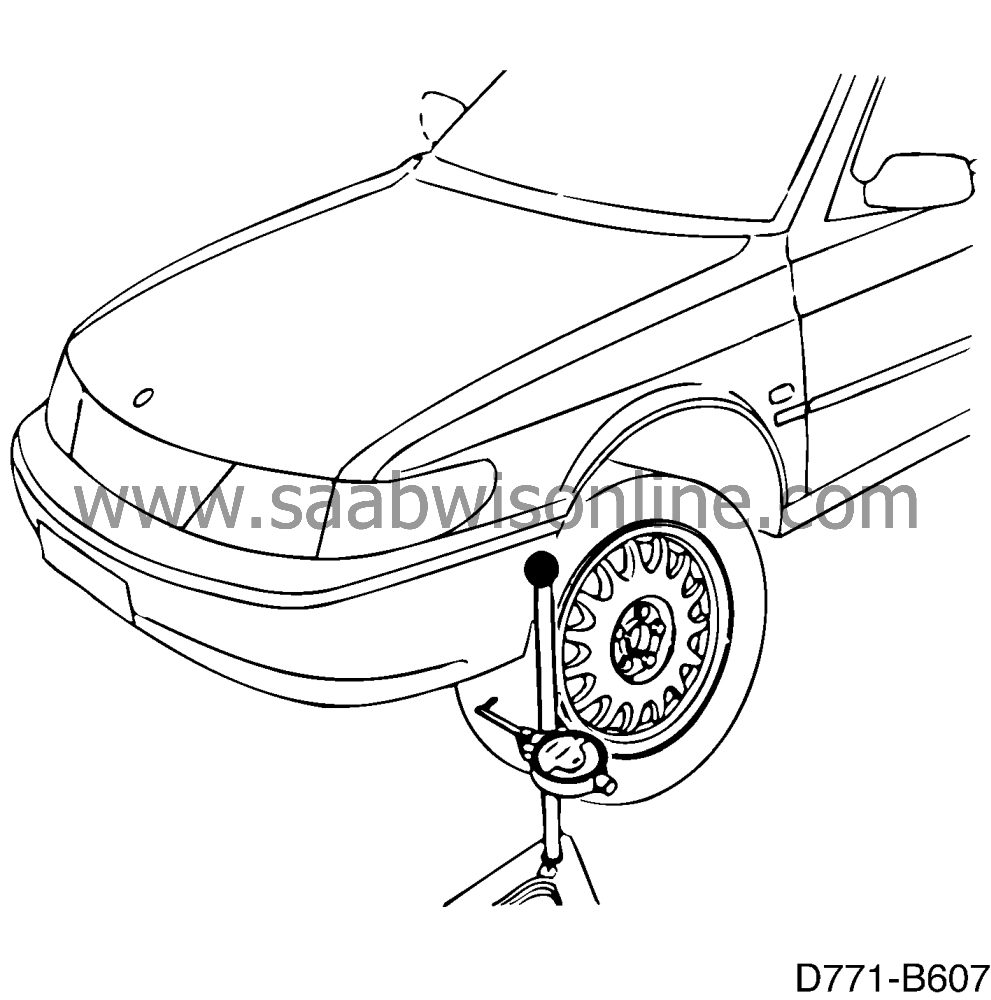

When the wheels have been fitted, check them for ovality (out-of-roundness) or

radial throw which, like axial throw, should not exceed 1 mm. If this figure is exceeded,

remove the wheel, rotate it through 180° on the hub and tighten it to the correct torque

again according to the table in point 13. Radial throw and axial throw should then not exceed 1

mm. If such should be the case, proceed to point 16 "Measuring wheel throw".

|

|

15.

|

Test drive the car at speeds between 70 and 90 km/h (110 km/h where possible

and allowed).

Measuring wheel throw

|

|

16.

|

Mount the wheel (without tyre) in a stationary wheel-balancing machine. Fit a dial

gauge in a stand and measure radial and axial throw on both sides of the wheel rim.

Maximum permissible throw:

|

A

|

B

|

Type of wheel

|

Radial (mm)

|

Axial (mm)

|

Pressed steel wheel

|

0.6

|

0.8

|

Light alloy wheel

|

0.5

|

0.5

|

|

|

17.

|

Change wheels having excessive throw.

|

Important

|

|

Also check new wheels for rim damage (damage in transit) before fitting the tyres.

|

|

|

|

|

18.

|

Fit the tyre on the wheel.

|

|

19.

|

Centre and balance the wheel as described in points 7-13.

Spinner or finish balancing

|

|

20.

|

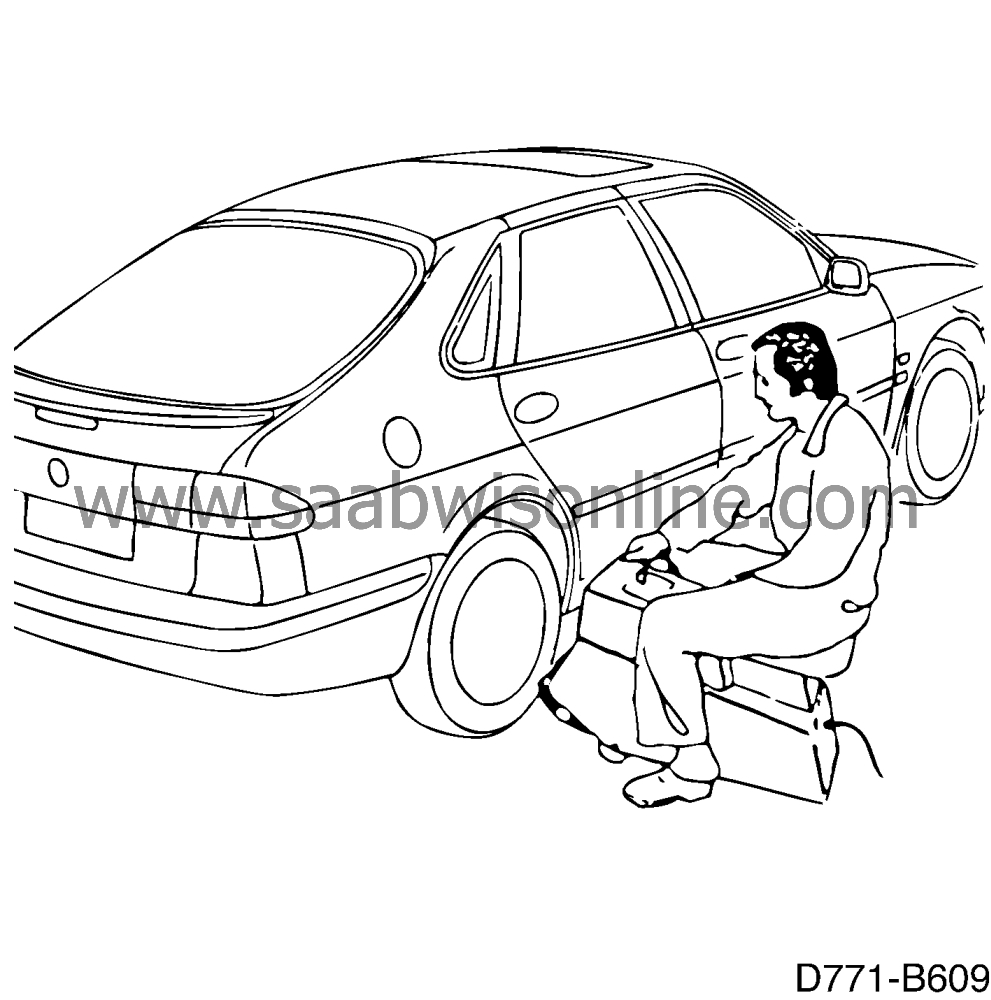

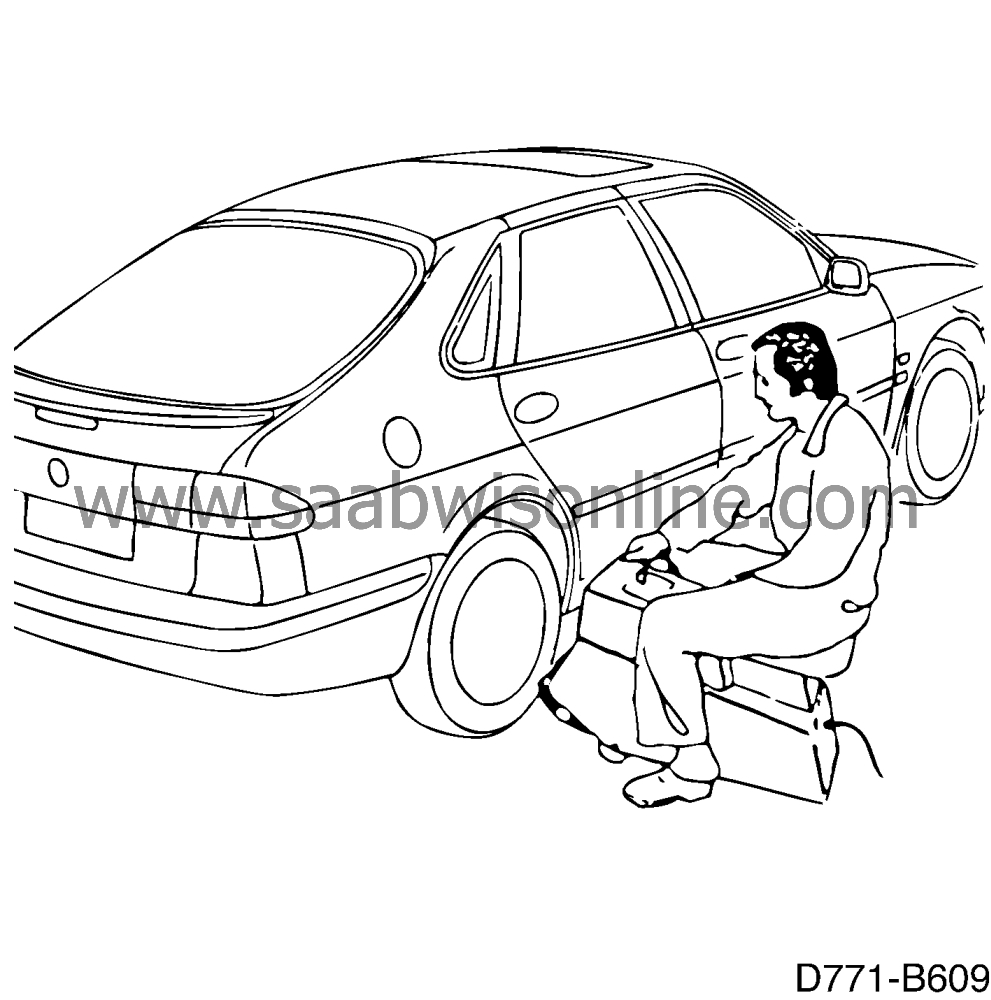

This type of balancing is recommended for the non-driven rear wheels only.

|

|

21.

|

As an absolutely last resort, spinner balancing can be carried out on the driven

front wheels. In this case, the car's own power transmission system is used.

|

|

22.

|

On cars equipped with TCS, the TCS must be disabled by means of the TCS

button.

|

|

23.

|

Test drive the car at speeds between 70 and 90 km/h (110 km/h where possible

and allowed).

|

Important

|

|

To avoid damaging the differential, the wheels must rotate at the same speed.

Therefore, make sure that the brakes are fully released on all wheels. On rotation, the highest

gear should be engaged. Recommended speed: 90-120 km/h. For more detailed instructions,

refer to the instructions for the equipment concerned.

|

|

|

|

|

Standard time information

|

Object code: 77110

Fault code: 11

Localization: 09

Action: 05

Time: 1.4 hours (Saab 9000) 1.3 hours (Saab 900)