Front wheel housing and front frame member

|

|

Front wheel housing and front frame member

|

|

1.

|

Remove the door frame, see

Part of door frame, three-door body,

Part of door frame, three-door body,

Door frame, three-door body or

Door frame, three-door body or

Part of door frame, five-door body.

Part of door frame, five-door body.

|

|

2.

|

Mount the car on an aligning bench and realign to the correct measurements if necessary.

|

|

3.

|

Place a door aperture stay between the roof and the floor to prevent the roof from sagging when the wheel housing is removed.

|

|

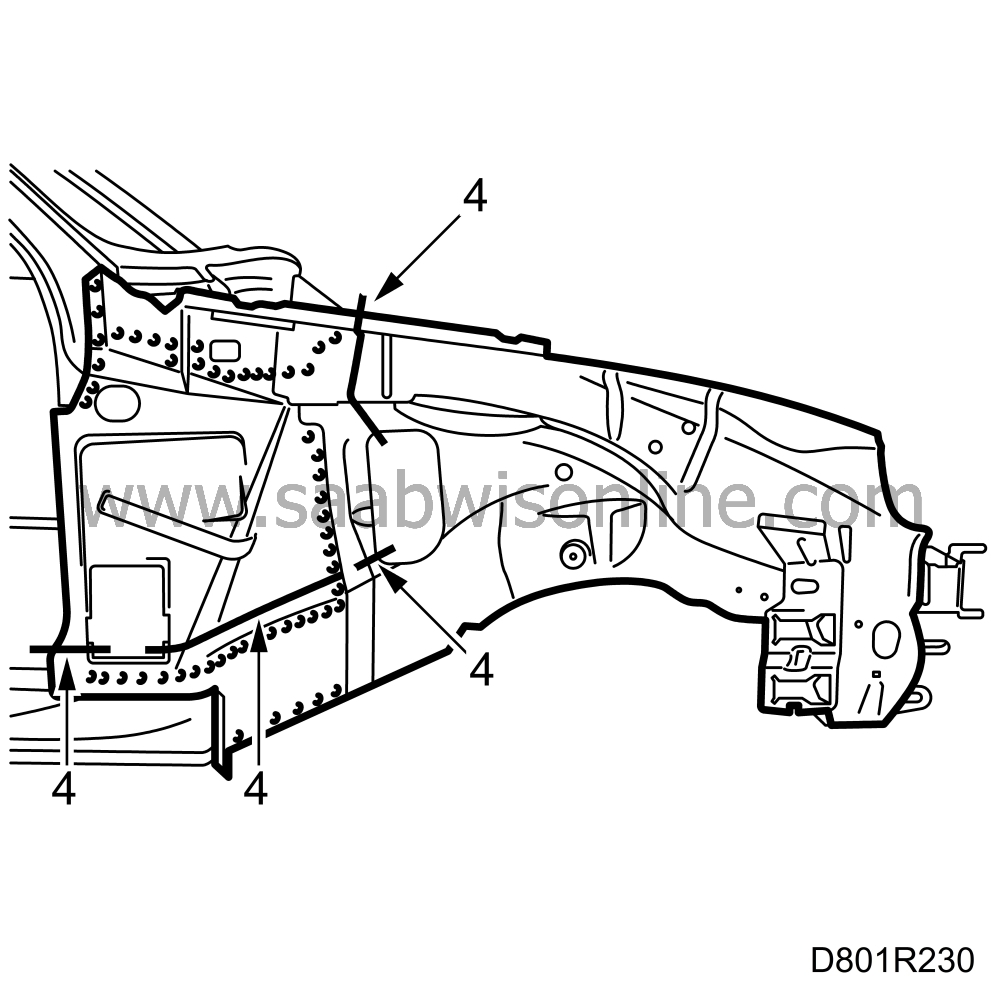

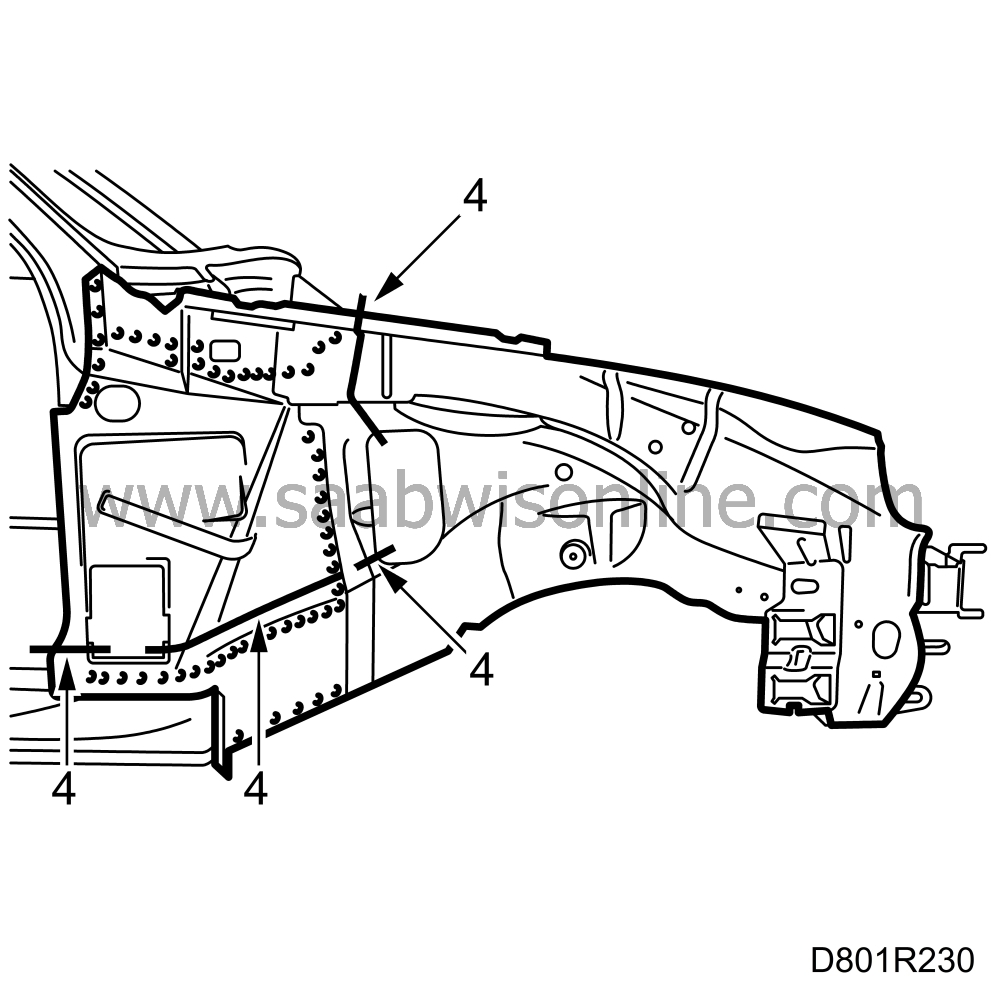

4.

|

Roughly cut the wheel housing so that it will be possible to reach the spot welds with a spot-weld drill.

|

|

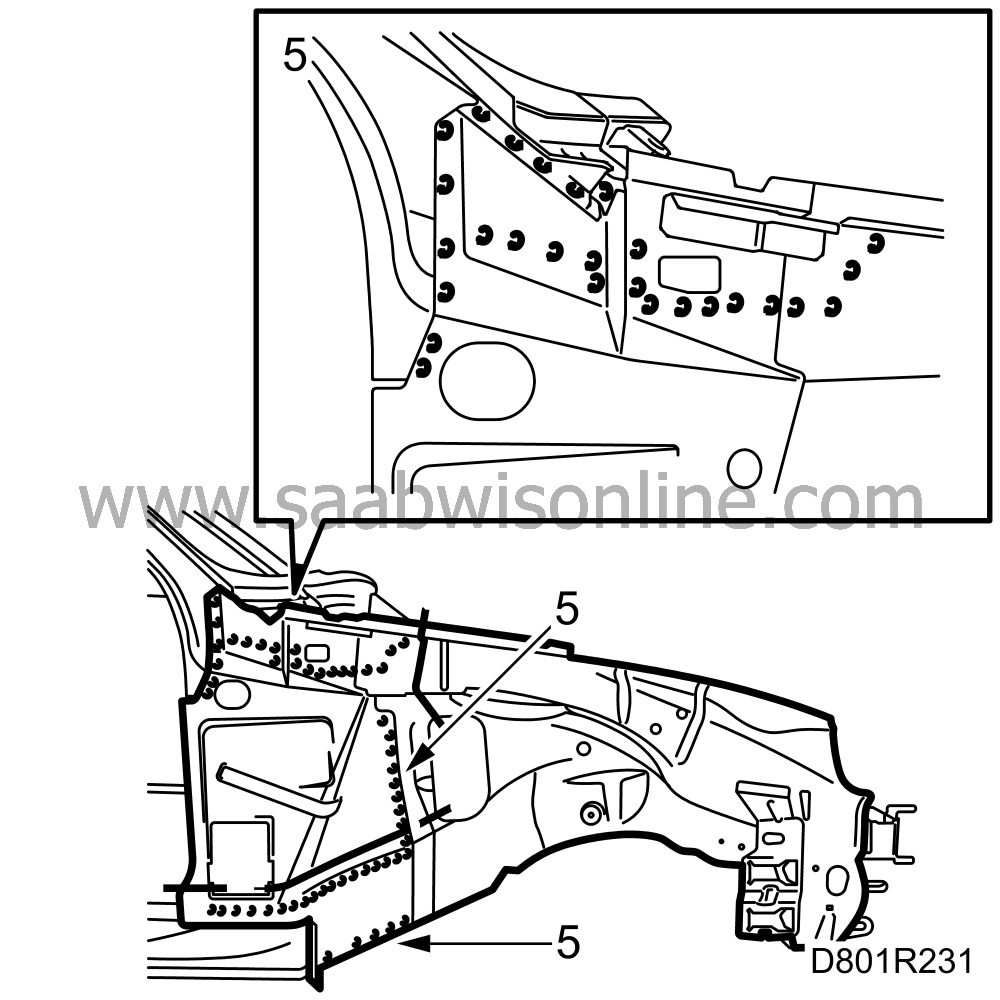

5.

|

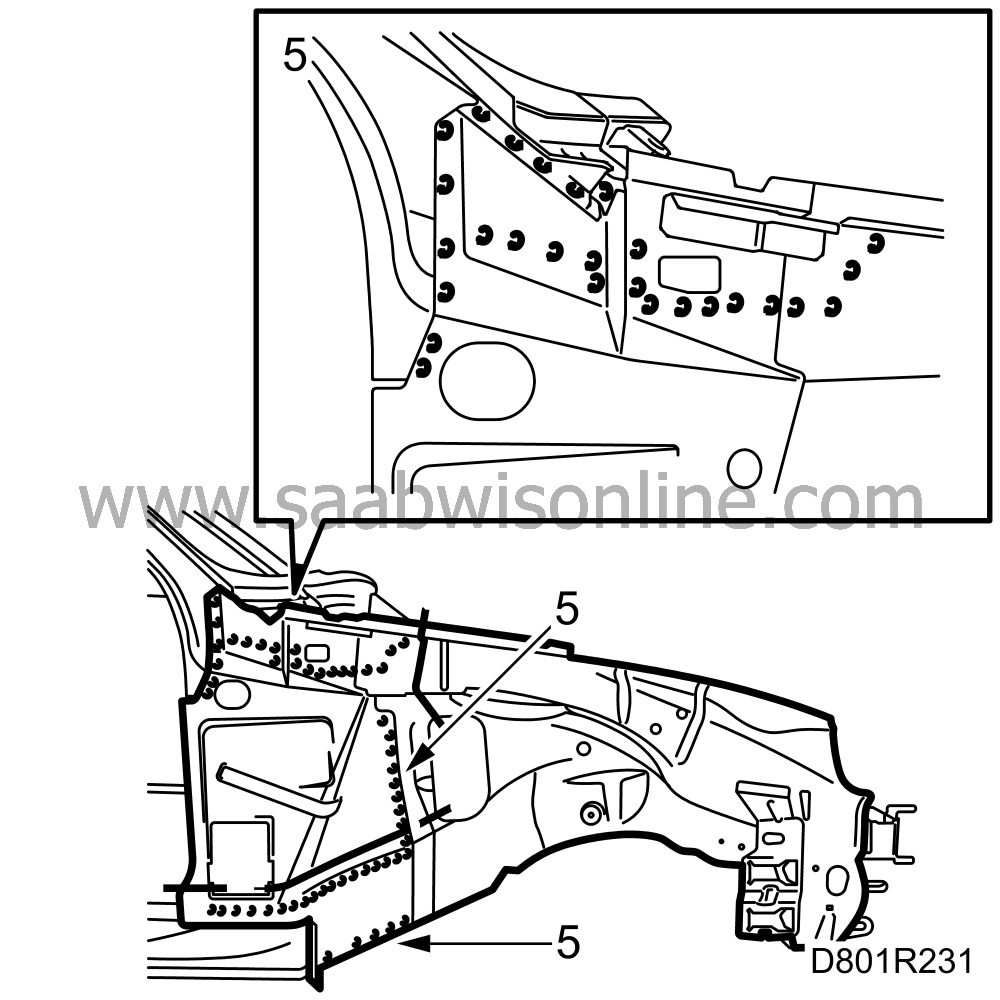

Drill out the spot welds and knock loose the remaining parts of the wheel housing.

|

|

6.

|

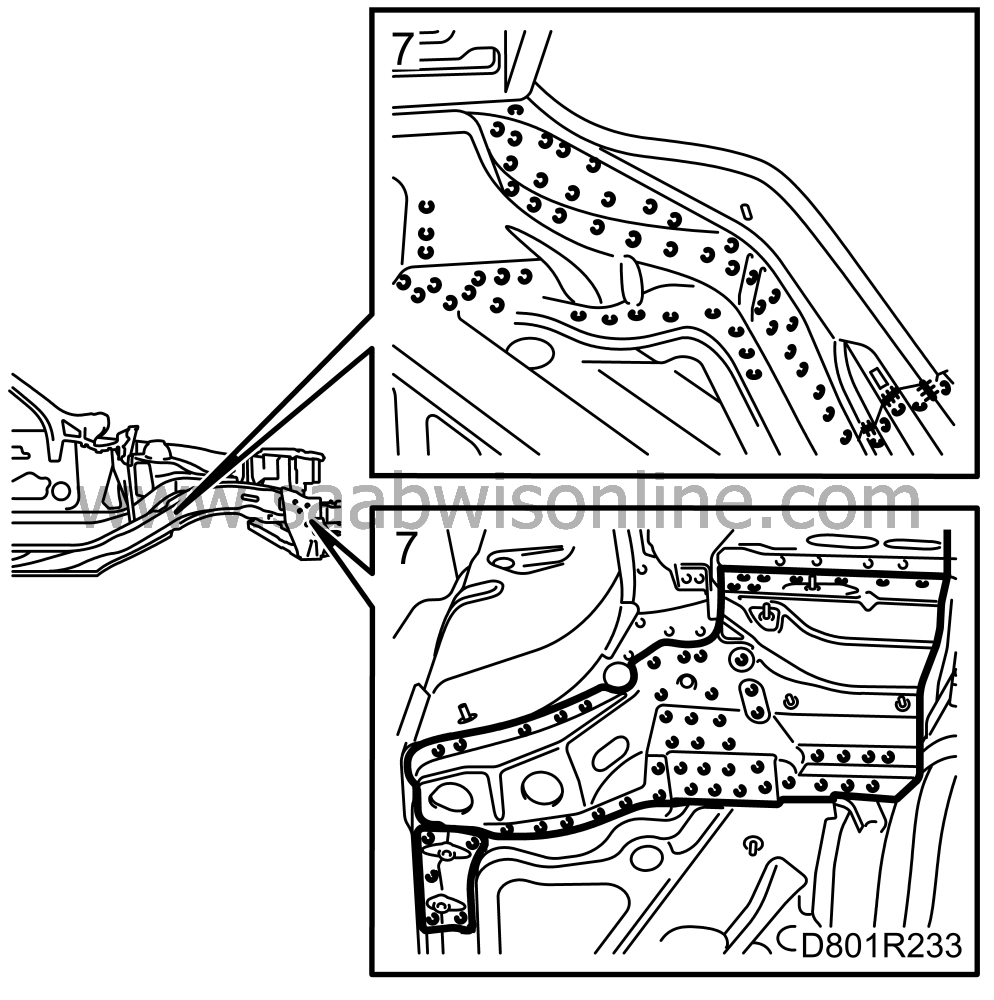

Cut the cross member according to the marking, as shown.

|

Important

|

|

The cross member should be welded only according to the marking, as shown. If the damage extends beyond the marking, the entire cross member must be changed.

|

|

|

|

|

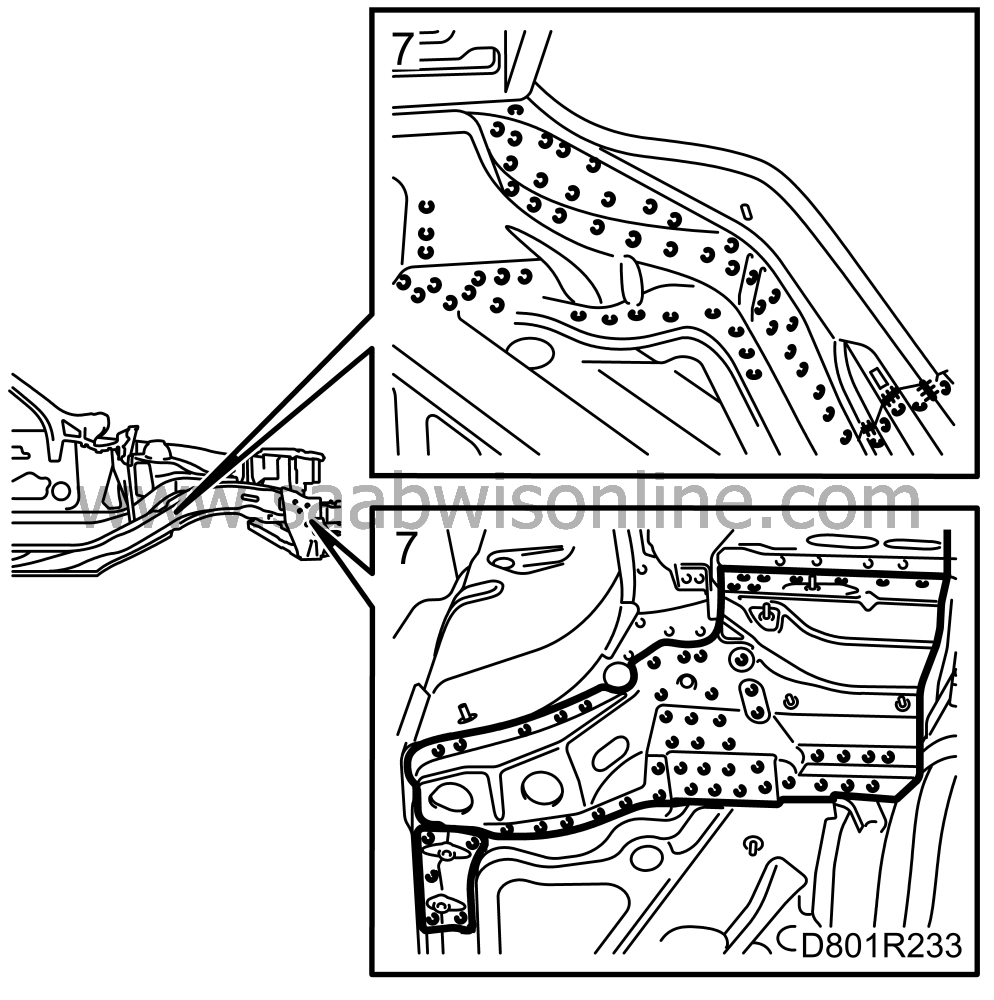

7.

|

Drill out the spot welds that secure the frame member and the cut off part of the cross member. Drill through all the sheet metal layers including the floor. Grind away the seam welding.

|

|

8.

|

Remove the frame member and the cut part of the cross member and realign any deformed metalwork.

|

|

9.

|

Drill holes in the body where the new frame member is to be plug-welded in place.

|

|

10.

|

Use a grinder to clean the areas on the frame member and body that are to be welded.

|

|

11.

|

Remove the grinding dust inside the frame member as this dust increases the likelihood of corrosion.

|

|

12.

|

Apply welding primer to the surfaces which are to be plug welded. Use Teroson Zinkspray.

|

|

13.

|

Position the frame member and fix it with a few welding clamps. Adjust its position exactly, checking the alignment by means of the aligning bench's coordinate measuring system.

|

|

14.

|

Plug and seam weld the frame member.

|

|

15.

|

Cut the cross member and position it.

|

|

16.

|

Put the cross member in place and fix it with a few welding clamps.

|

|

17.

|

Remove the cross member and drill holes for plug welding it.

|

|

18.

|

Use a grinder to clean the areas on the cross member and body that are to be welded.

|

|

19.

|

Apply welding primer to the surfaces which are to be plug welded. Use Teroson Zinkspray.

|

|

20.

|

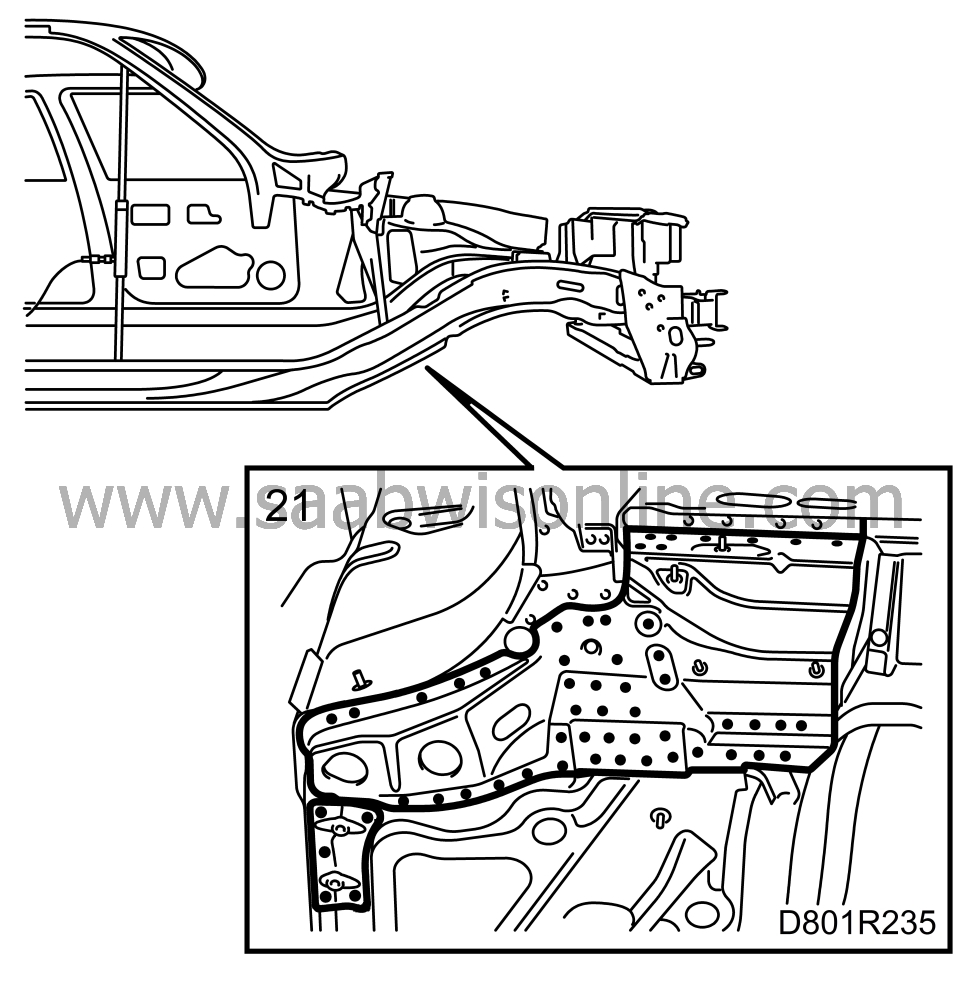

Position the cross member and fix it with a few welding clamps.

|

|

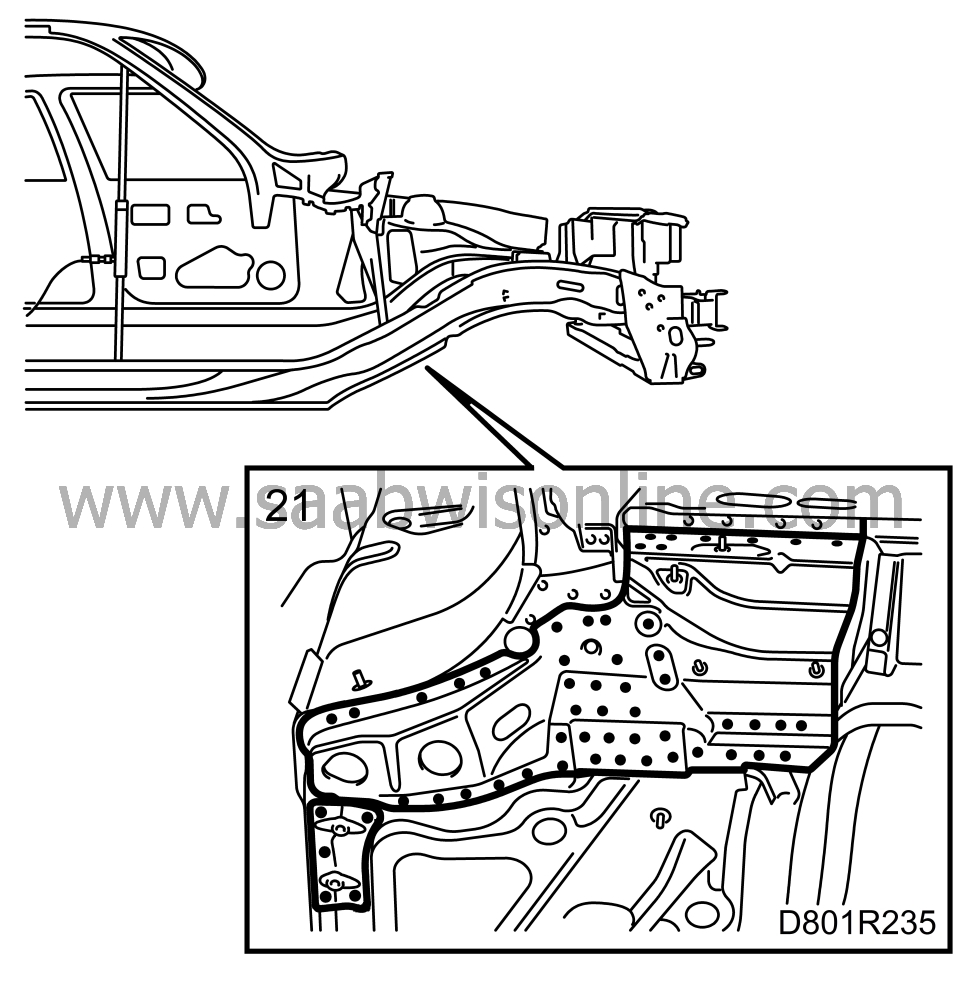

21.

|

Plug weld the cross member in place.

|

|

22.

|

Weld the joint on the cross member.

|

|

23.

|

Drill holes for plug welding in the new wheel housing at places which cannot be reached with a spot welding equipment.

|

|

24.

|

Use a grinder to clean the areas on the body and the new wheel housing that are to be welded.

|

|

25.

|

Apply welding primer to the surfaces which are to be spot and plug welded on the wheel housing and body. Use Teroson Zinkspray.

|

|

26.

|

Position the new wheel housing and fix it with a few welding clamps.

|

|

27.

|

Adjust its position exactly, checking the alignment by means of the aligning bench's coordinate measuring system.

|

|

28.

|

Fix the wheel housing by means of a couple of tack welds.

|

|

29.

|

Fit the front wing and bonnet in place, checking their fit and the alignment of the wheel housing.

|

|

30.

|

Remove the front wing and bonnet.

|

|

31.

|

Fit the wheel housing in place, securing it with spot welds and plug welds.

|

|

32.

|

Grind the welds clean.

|

|

33.

|

Grind clean the surfaces to be welded on the body and reinforcements that are to be fitted on the outside of the wheel housing.

|

|

34.

|

Apply welding primer to the surfaces which are to be spot welded. Use Teroson Zinkspray.

|

|

35.

|

Weld the reinforcement to the outside of the wheel housing.

|

|

36.

|

Wash off surplus welding primer. Welding primer makes for poorer adhesion of paint, filler and sealant.

|

|

37.

|

Apply primer to all surfaces which have been ground clean. Use Standox 1K Füllprimer.

|

|

38.

|

Seal joints and metal folds with putty. Use Terostat 1K-PUR.

|

|

39.

|

Apply underseal to the undersides of the frame member and cross member. Use Terostat 9320.

|

|

40.

|

Apply anti-corrosion agent to inside surfaces after painting. Use Terotex HV 400 or Mercasol 1.

|

Part of door frame, three-door body,

Part of door frame, three-door body,

Door frame, three-door body or

Door frame, three-door body or

Part of door frame, five-door body.

Part of door frame, five-door body.