Windscreen member

| Windscreen member |

| 1. |

Drill out the spot welds.

|

|

| 2. |

Grind down the welds securing the windscreen member to the lower end of the A pillar and cut the windscreen member.

|

|

| 3. |

Knock loose the windscreen member and align any damaged panels.

|

|

| 4. |

Use a grinder to clean the areas on the spare part and body that are to be welded.

|

|

| 5. |

Apply welding primer to the surfaces which are to be spot welded. Use Teroson Zinkspray.

|

|

| 6. |

Position the spare part and fix it with a few welding clamps.

|

|

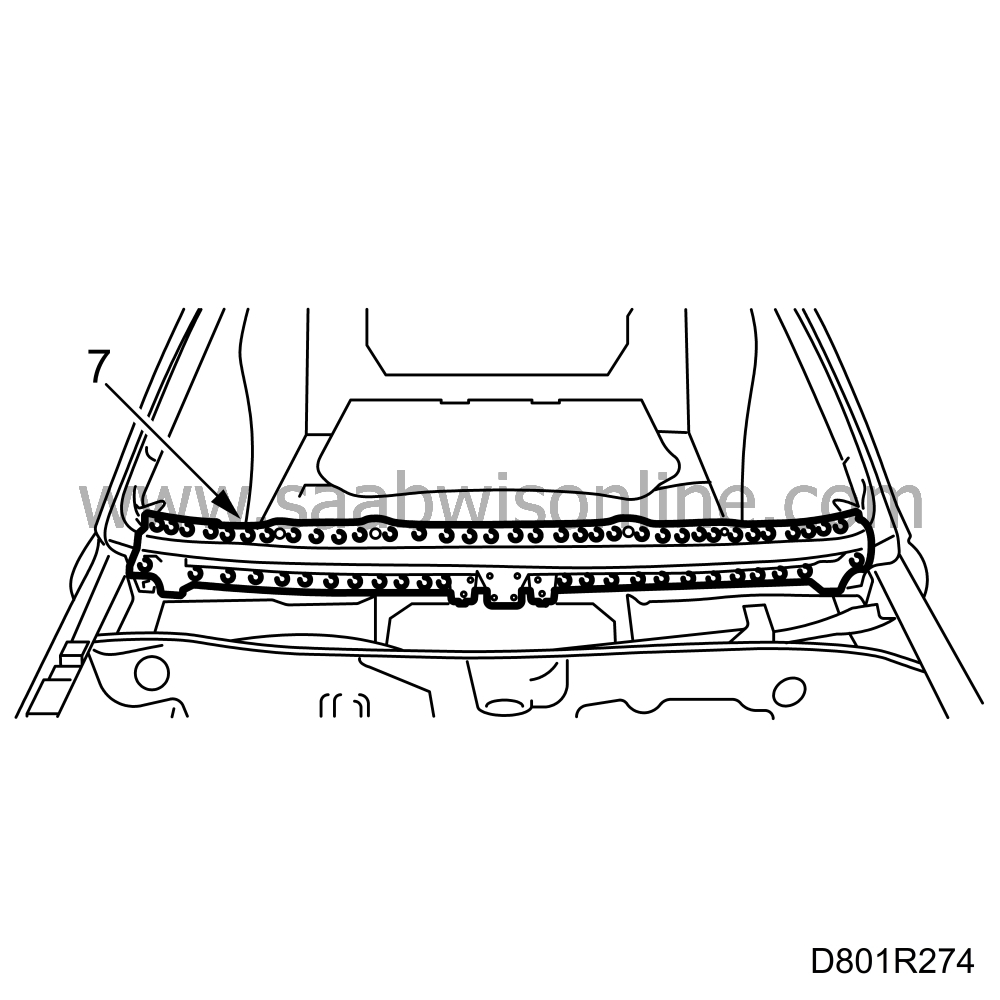

| 7. |

Spot weld the new windscreen member in place.

|

|

| 8. |

Weld the joints between the windscreen member and the lower ends of the A pillars.

|

|

| 9. |

Grind the welds clean.

|

|

| 10. |

Wash off surplus welding primer. Welding primer makes for poorer adhesion of paint, filler and sealant.

|

|

| 11. |

Apply primer to all surfaces that have been ground clean. Use Standox 1K Füllprimer.

|

|

| 12. |

Seal joints and metal folds with putty. Use Terostat 1K-PUR.

|

|