Windscreen member (conv.)

|

|

Windscreen member (conv.)

|

|

1.

|

Mount the car in an alignment bench with measuring fixture and cross-measure as necessary.

|

|

2.

|

Cut the windscreen member along the edge of the inner section of the A pillar.

|

|

3.

|

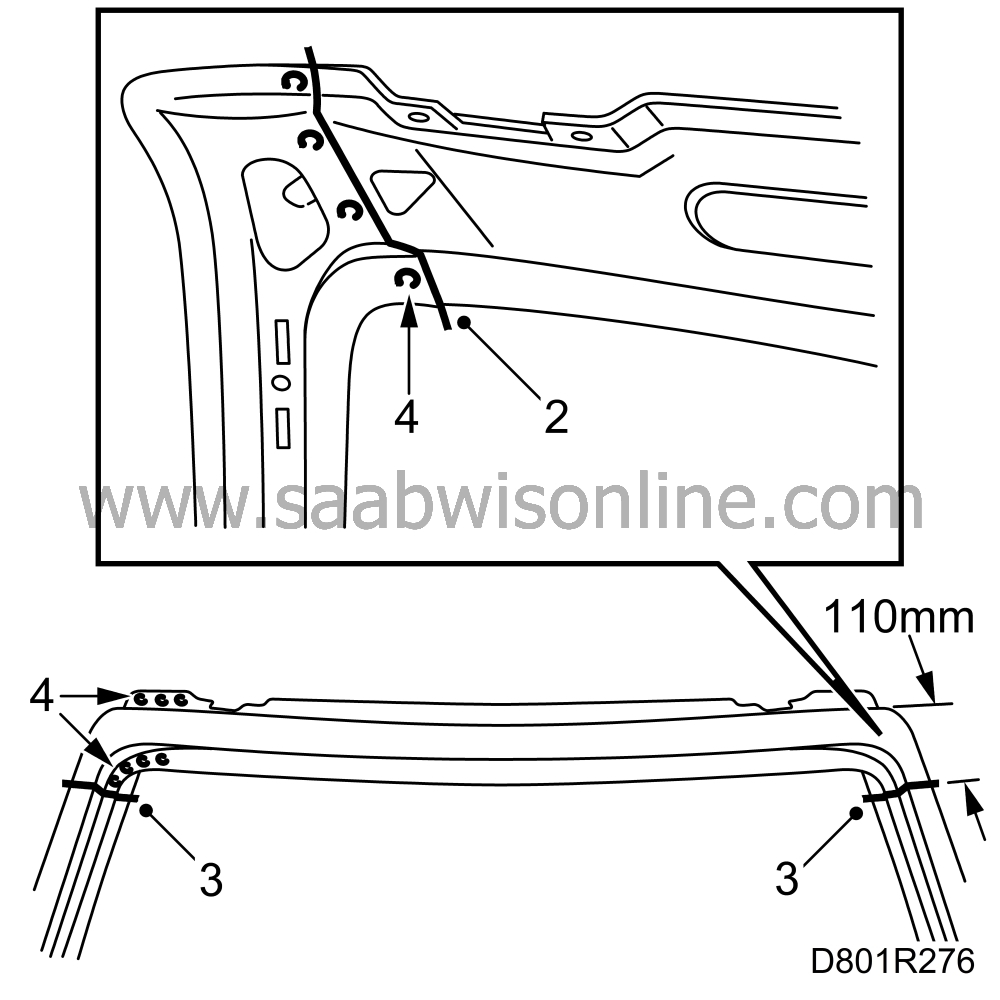

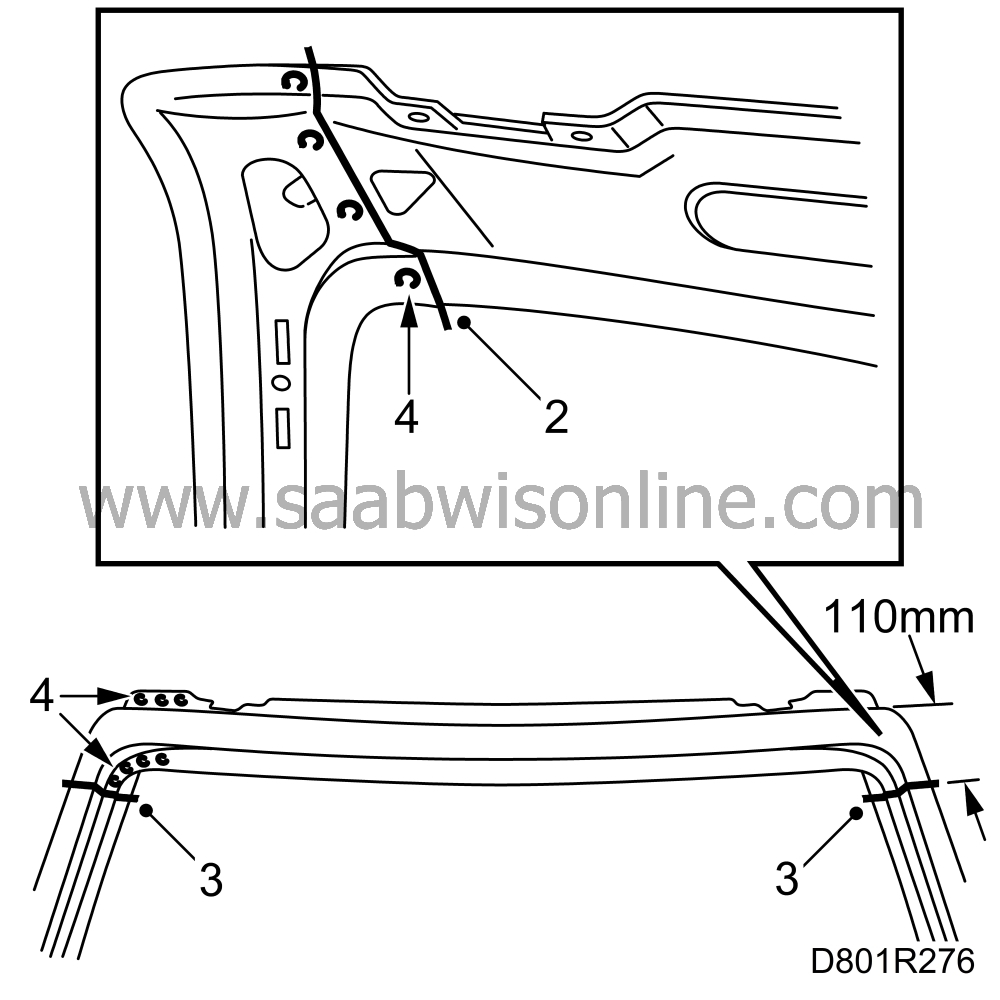

Cut the outer panel of the windscreen member 110 mm from the top edge.

|

|

4.

|

Drill out the spot welds securing the remaining sections of the windscreen member.

|

|

5.

|

Knock away the remaining sections and align any deformed metal.

|

|

6.

|

Grind the areas to be welded on the inner and outer panels of the new windscreen member and on the body.

|

|

7.

|

Apply welding primer to the surfaces which are to be spot welded. Use Teroson Zinkspray.

|

|

8.

|

Put the new inner and outer panels of the windscreen member in place and secure them with some welding clamps. Measure out the exact position with the measuring fixture.

|

|

9.

|

Cut through the outer panels of the windscreen member and the A pillar at the same time so that the joints can be butt welded.

|

|

10.

|

Tack on the outer panel of the windscreen member with a couple of welds on the joints.

|

|

11.

|

Put the windscreen and doors in place and check the fit. The door windows must be raised.

|

|

12.

|

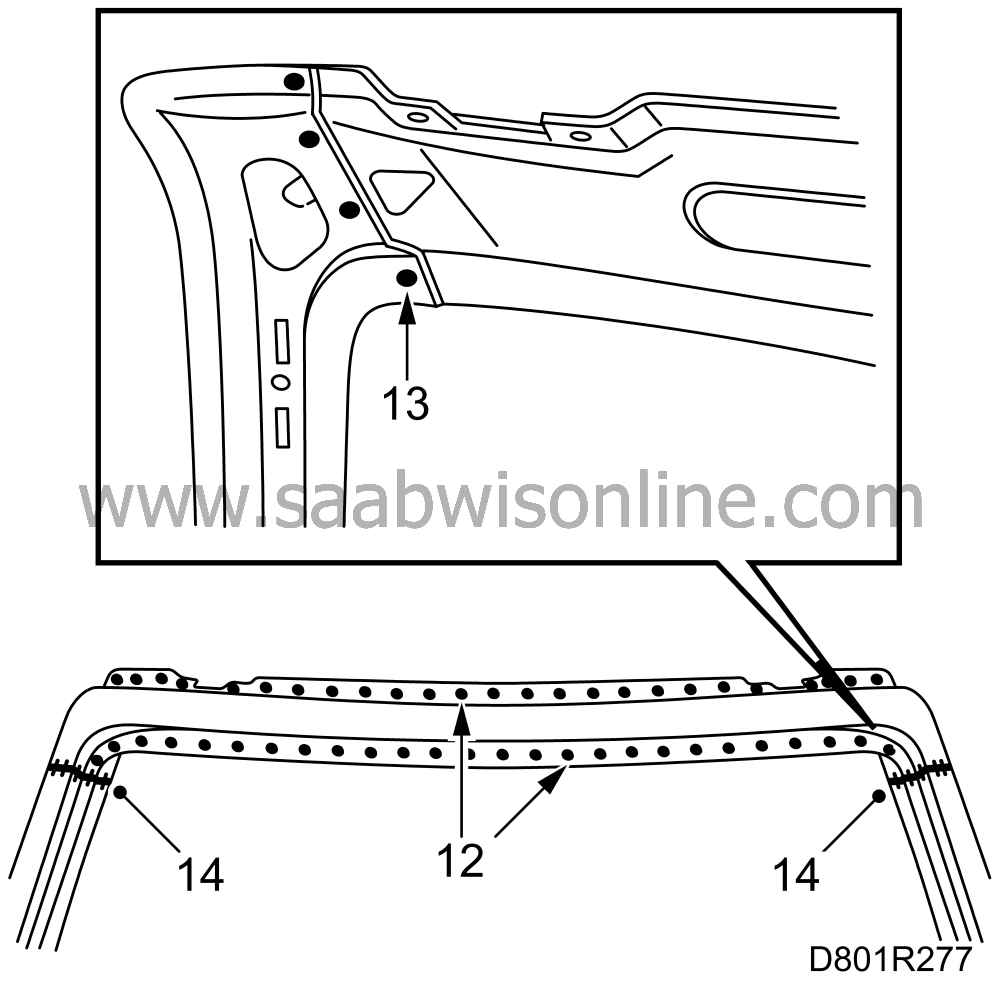

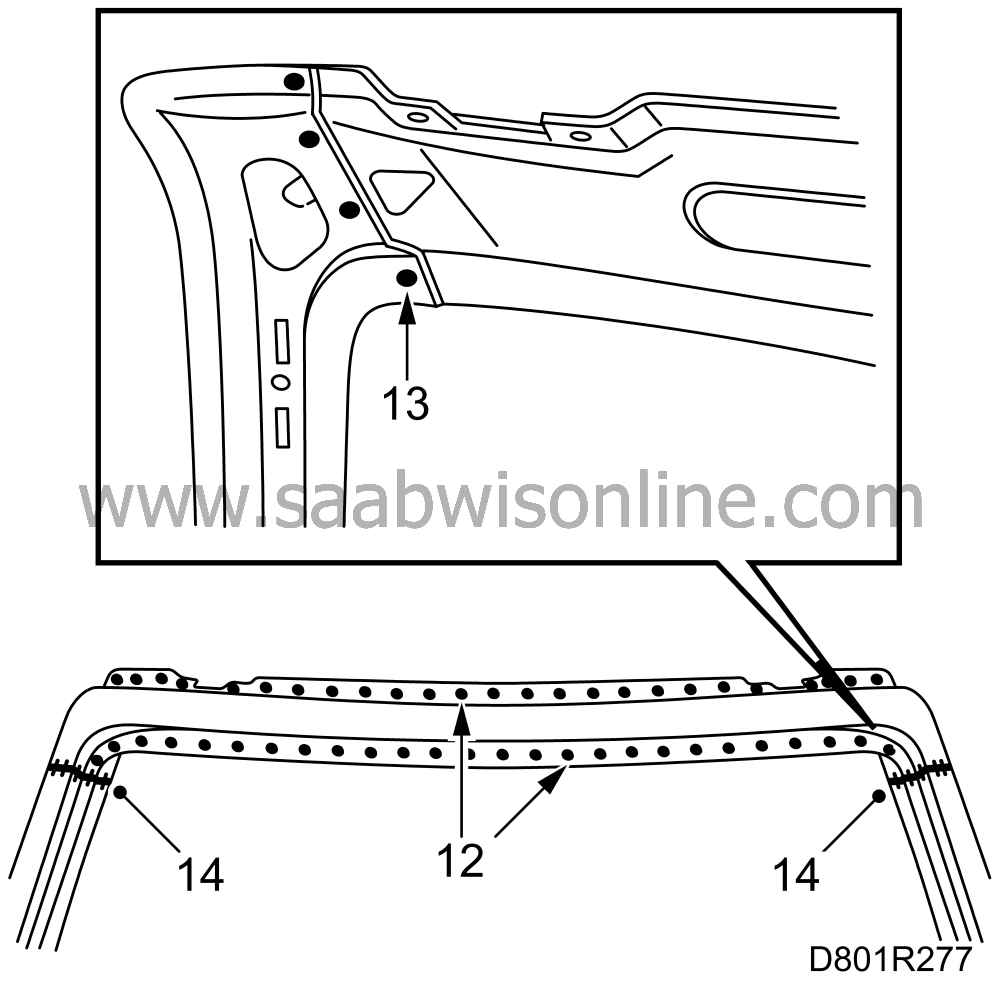

Spot weld the outer and inner sections of the windscreen member.

|

|

13.

|

Plug weld the inner section of the A pillar to the windscreen member.

|

|

15.

|

Grind the welds clean.

|

|

16.

|

Wash off surplus welding primer. Welding primer makes for poorer adhesion of paint, filler and sealant.

|

|

17.

|

Apply tin filler to the joints.

|

|

18.

|

Apply primer to all bare metal surfaces. Use Standox 1K Füllprimer.

|

|

19.

|

Seal joints and metal folds with putty. Use Terostat 1K-PUR.

|

|

20.

|

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400.

|