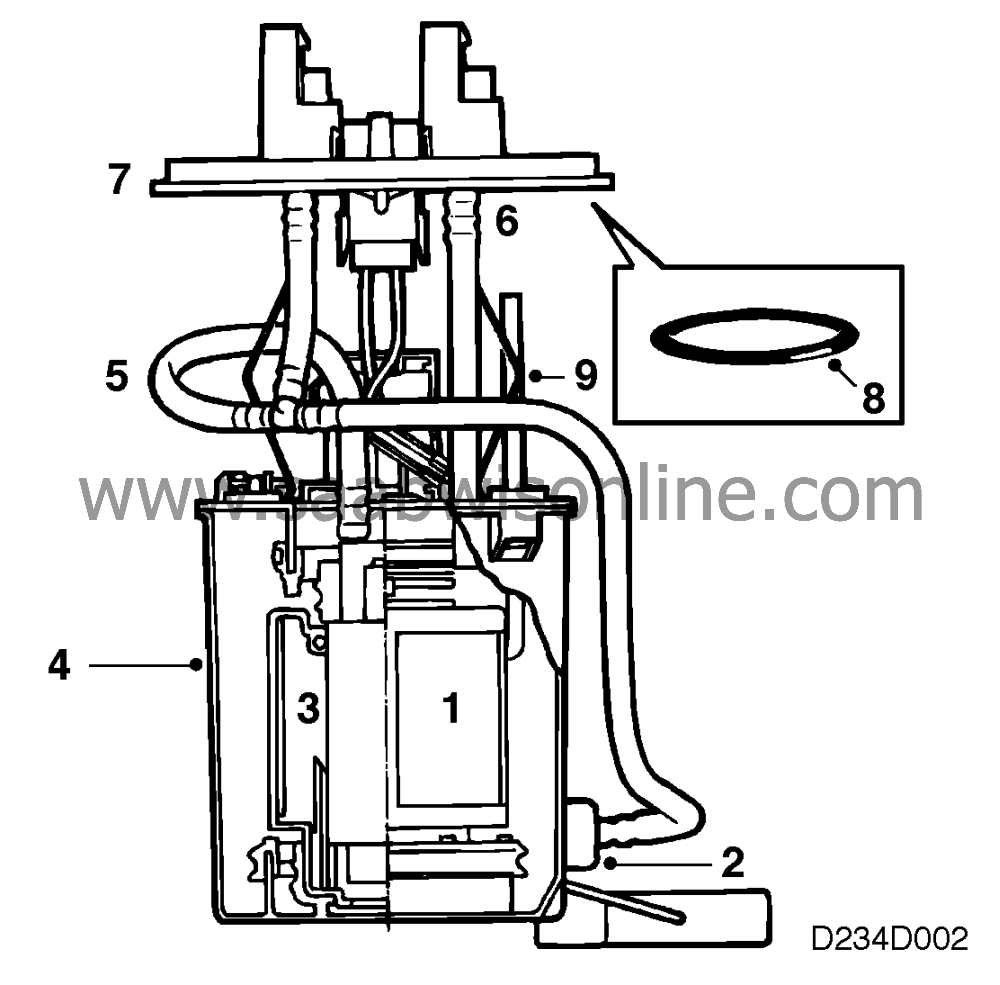

Fuel pump, components

| Fuel pump, components |

Fuel pump

| 1. |

Pump

|

|

| 2. |

Ejector

|

|

| 3. |

Filter

|

|

| 4. |

Reservoir

|

|

| 5. |

Pump delivery line

|

|

| 6. |

Return line

|

|

| 7. |

Screw ring

|

|

| 8. |

O-ring

|

|

| 9. |

Spring element

|

|

| Fuel pump |

The fuel pump is situated inside a plastic reservoir clamped between the top and bottom of the tank. It is located by ribs on the bottom of the tank and secured at the top by means of a screw ring (7).

Any flexing of the tank is absorbed by the fuel pump spring element (9). The design and principle of operation of the pump are basically the same as in earlier fuel pumps having a main pump and a feed pump. However, in the Wallbro pump the feed pump has been replaced by a positive ejector which is driven by the flow of fuel through the pressure line via a T-piece. The pump is an electric rotary pump.

Location of the fuel pump in the tank

The purpose of the ejector is to ensure that the pump is continuously supplied with fuel. Owing to the location of the pump in the reservoir, the supply of fuel to the engine is maintained during cornering and acceleration even when only a small quantity of fuel remains in the tank. Pump and motor form a single factory-sealed unit and cannot be dismantled for overhaul or repair.

A non-return valve on the pressure side of the pump, fitted in the connecting nipple on the pump cover, prevents the pressure in the fuel line from dropping immediately after the motor has stopped.

| Fuel filter |

The fuel filter is mounted in the pressure line between the fuel pump and the fuel injection manifold at the front right- hand side of the fuel tank.

The purpose of the filter is to strain out impurities and other foreign matter in the fuel and so prevent clogging of the injectors.

The filter contains a paper element having a mean porosity of 5 µ and after it a strainer to catch any paper fragments that may have worked loose. A support locates the filter element in the housing, which is made of metal. The efficiency of the filter is dependent on the impurity of the fuel.

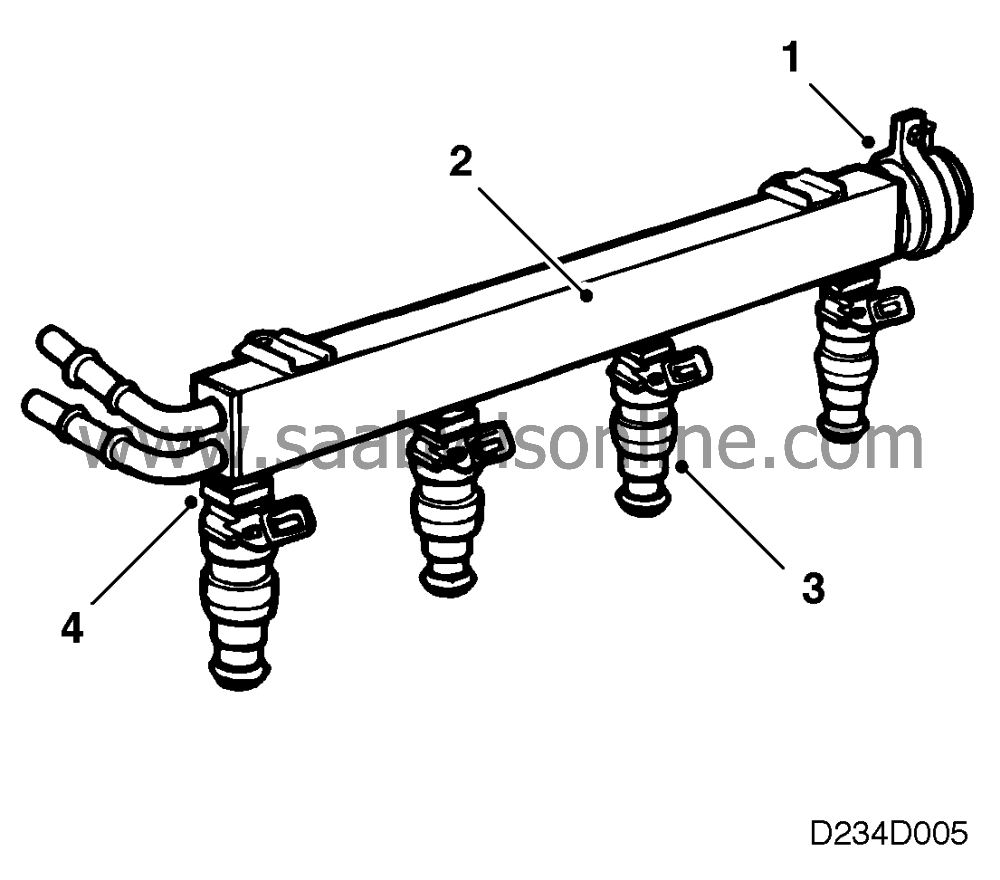

| Fuel injection manifold |

Fuel injection manifold, four-cylinder engine

| 1. |

Pressure

regulator

|

|

| 2. |

Fuel injection manifold

|

|

| 3. |

Injector

|

|

| 4. |

Clip

|

|

The fuel injection manifold meters equal amounts of fuel to all the injectors. It also acts as a fuel accumulator. In relation to the amount of fuel consumed during each working cycle, the manifold has sufficient capacity to prevent pressure variations. Since the injectors are connected to the injection manifold, they all receive fuel under the same pressure. The design and construction of the fuel injection manifold makes possible a simple method of fitting the injectors, which are in direct communication with it.

Also connected to the fuel injection manifold are the fuel line and fuel pressure regulator.

Fuel injection manifold, V6 engine

| 1. |

Pressure

regulator

|

|

| 2. |

Fuel injection manifold

|

|

| 3. |

Injector

|

|

| 4. |

Clip

|

|

| Pressure regulator |

Pressure regulator

The pressure regulator is mounted on the farther short side of the fuel injection manifold.

The pressure regulator maintains a constant ratio between the fuel pressure and the pressure in the air induction pipe. This ensures that the amount of fuel injected is determined exclusively by the opening duration of the electromagnetic injectors.

The pressure regulator is a diaphragm-controlled overflow valve set for 3.0 bar. It consists of a metal housing divided into two chambers by a press-fitted diaphragm. In one of the chambers a spiral spring presses against the diaphragm while fuel flows through the other chamber.

If the preset pressure is exceeded, a valve controlled by the diaphragm exposes an opening to the return line through which superfluous fuel can flow back to the fuel tank.

The spring-loaded chamber of the pressure regulator is connected by a hose to the engine's air induction pipe or throttle. In consequence, the pressure in the fuel system is affected by the absolute pressure in the air induction pipe, with the result that the pressure drop across the injectors is constant at all positions of the throttle butterfly.

Refer to "Technical data" for the relevant pressures.

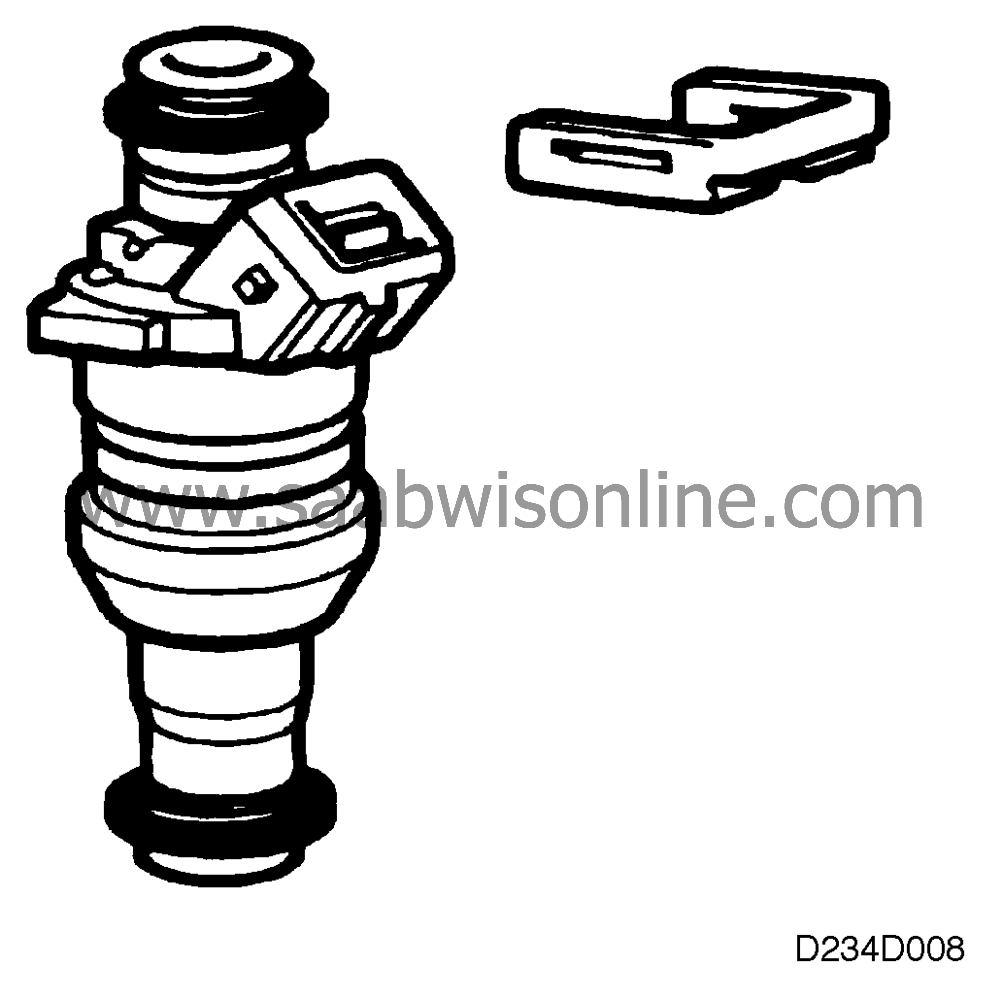

| Injectors |

Injector, four-cylinder engine

The injectors are in direct communication with the fuel injection manifold. They are fitted in the inlet manifold passages above the inlet valves.

The injectors consist of a valve body and spray nozzle with electromagnetic armature. The valve body contains a solenoid winding and actuator for the spray nozzle. The injectors are controlled electromagnetically, opening and closing by means of electric pulses from the control module.

Different injector versions may be used, depending on the engine variant.

For further information on injectors, refer to “Engine management system”.

| Temperature sensor (turbo and V6 engines) |

Temperature sensor

The temperature sensor is mounted between the air cleaner and the engine inlet manifold.

For further information on the temperature sensor, refer to “Engine management system”.

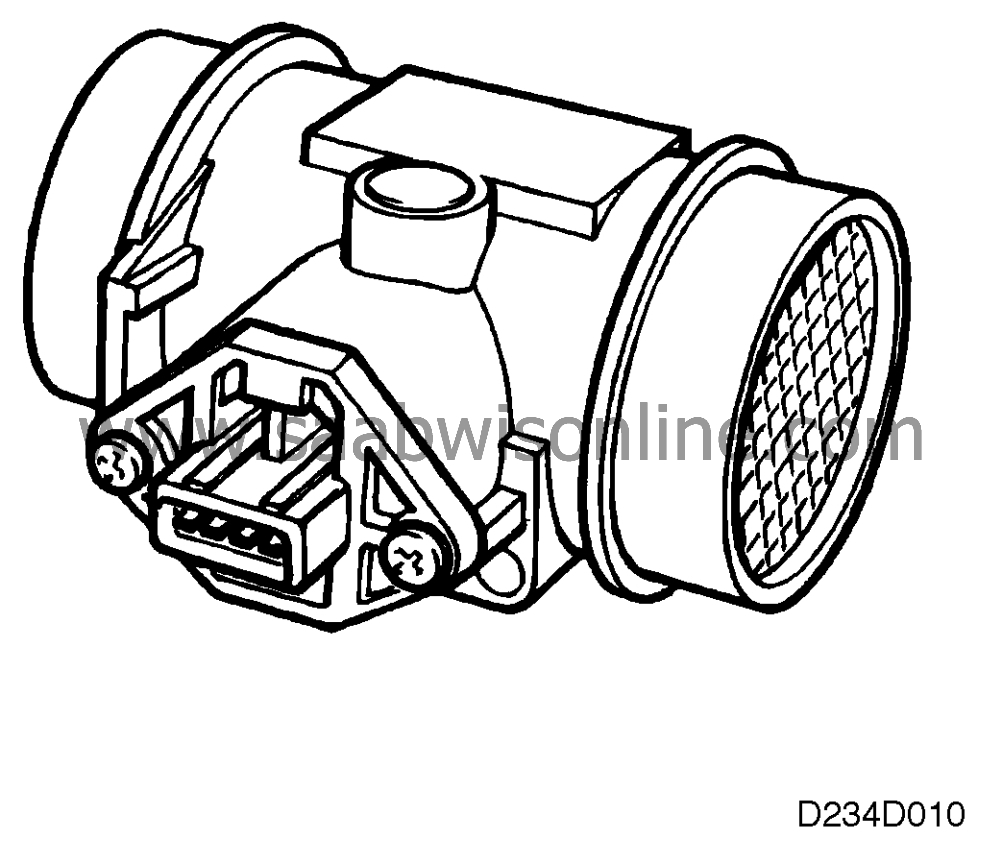

| Mass air flow sensor HFM (not turbo engine) |

Mass air flow sensor

The mass air flow sensor is mounted between the air cleaner and the engine intake manifold. It is of hot film type.

For further information on the mass air flow sensor, refer to “Engine management system”.

| Air cleaner |

Air cleaner

| 1. |

Cover

|

|

| 2. |

Filter element

|

|

| 3. |

Air chamber

|

|

| 4. |

Air intake pipe

|

|

| 5. |

Connecting duct for mass air flow

sensor

|

|

The air cleaner is situated in the engine bay, on the right- hand side.

The air cleaner consists of a rectangular casing (air chamber) containing an air filter element. A cover is fitted over the casing and secured by clamps. Fitted to the cover is a connecting duct for the mass air flow sensor (not on turbo engines). The duct is held in place by hose clips.

Intake air is admitted to four-cylinder engines via a straight air induction pipe pointing forwards. On the V6 engine, intake air is admitted through the air induction pipe, here facing rearwards, via a resonator (silencer) before passing through the air cleaner.