Principle of operation, idling compensation

| Principle of operation, idling compensation |

| DRIVE signal |

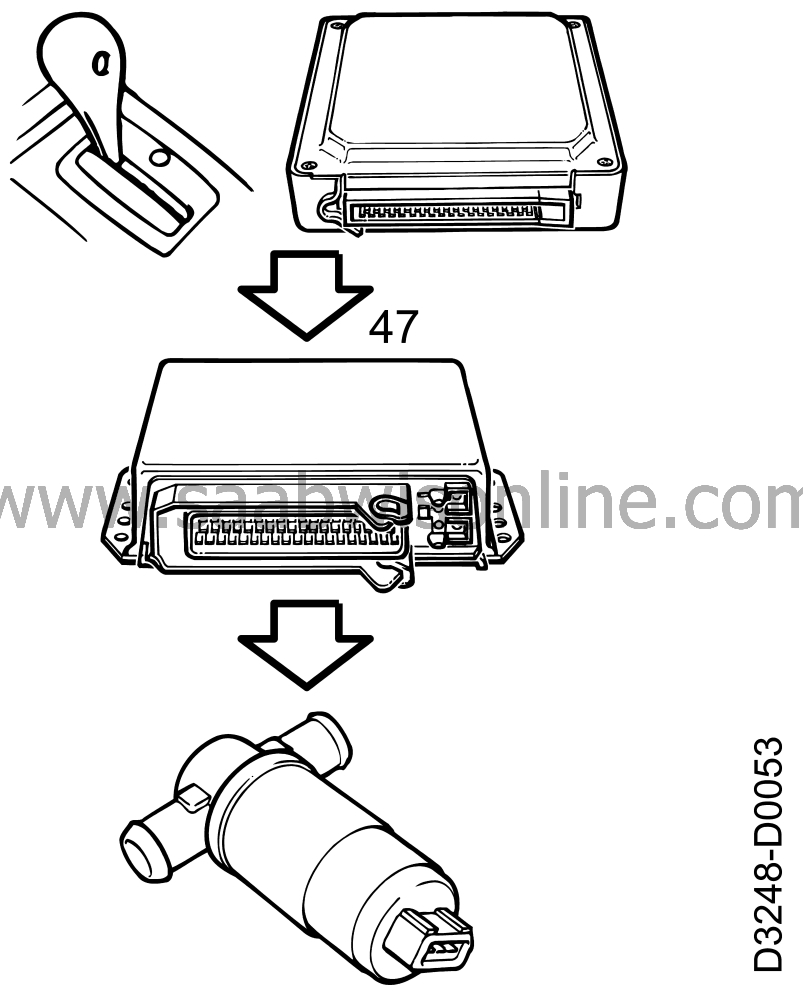

Pin 47 of the MOTRONIC control module is supplied with information on the current gear position, P-N or R-D-1-3 from pin 11 of the automatic transmission's control module.

When any of the gear positions R-D-1-2 or 3 is selected, a supply of about 12 V is applied to pin 47 of the control module, which then attends to idling compensation.

Idling compensation is achieved by the control module opening the IAC valve so that the mass air flow increases by about 1.8 grammes per second above normal.

If no signal is received, idling speed will drop below 850 rpm when the DRIVE position is selected.

| Secondary air injection pump |

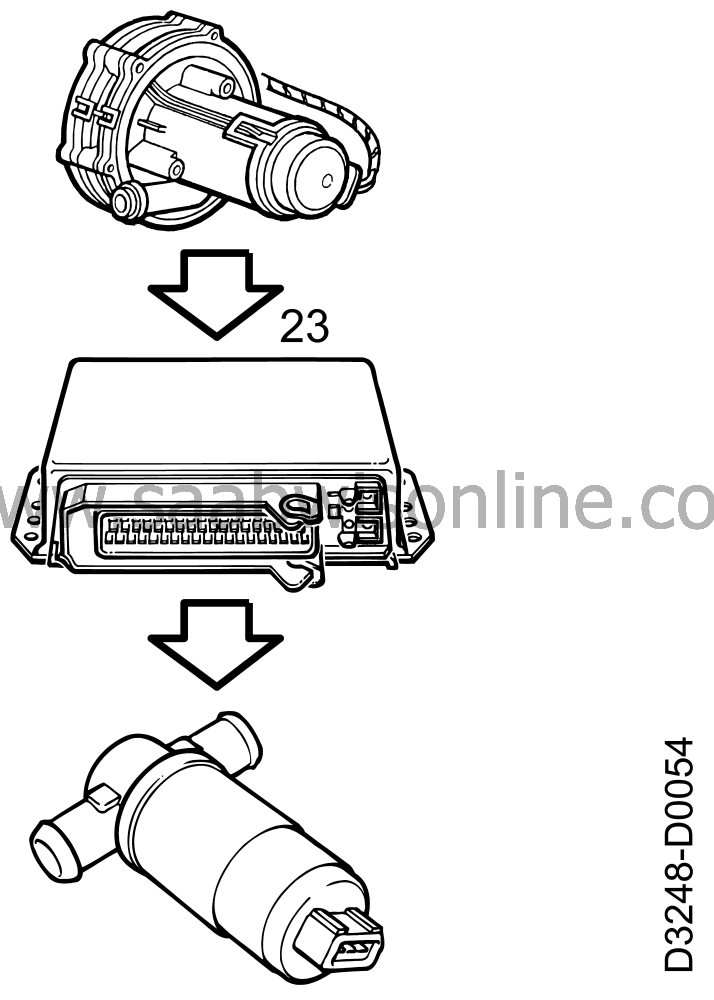

When the MOTRONIC control module grounds pin 23 and so starts the air pump, the IAC valve also opens at the same time for a mass air flow increase corresponding to about 0.8 grammes per second.

| Radiator fan |

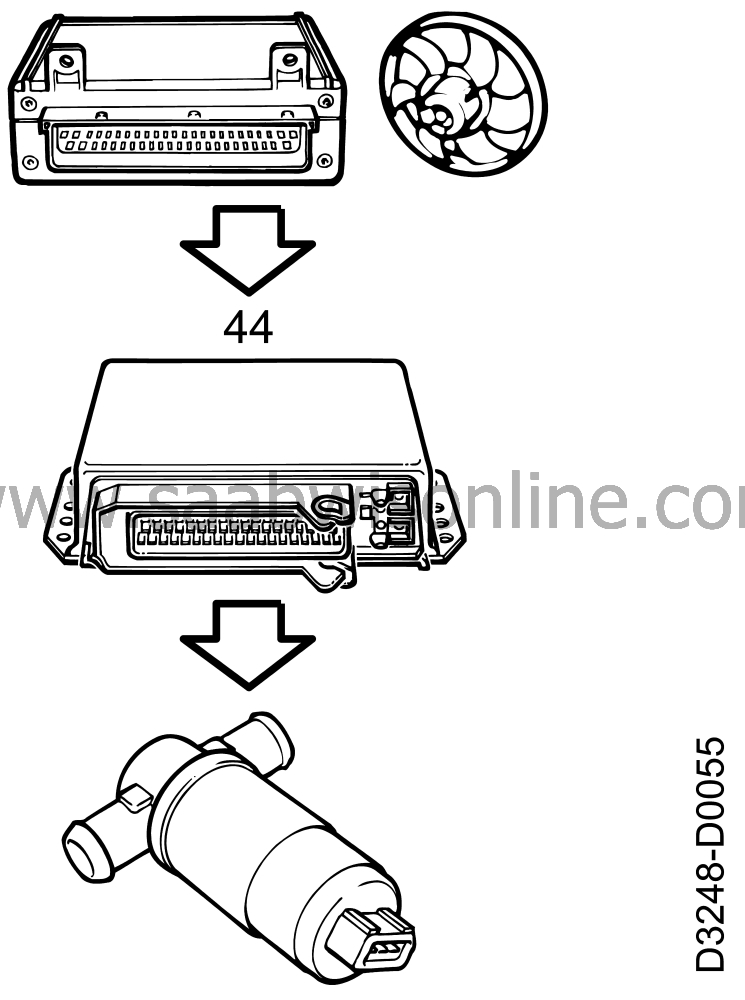

When the MOTRONIC control module is supplied with information on pin 44 (from ICE) to the effect that the radiator fan has started, the IAC valve opens for a mass air flow increase corresponding to about 0.4 grammes per second.

| Signal from A/C-ACC |

When the A/C-ACC is activated, either manually via the A/C switch or automatically via the ACC control module, a supply of about 12 V is applied to pin 41 of the MOTRONIC control module.

When the control module receives this voltage signal on pin 41 it increases idling speed before the compressor starts, which is done by the control module grounding pin 33 at the same time as relay 156 is grounded through the pressure monitor.

If the signal is absent, the A/C compressor will not start.

A delay and engine speed compensation are built into the control module.

Idling compensation is achieved by the control module opening the IAC valve so that the mass air flow increases by about 1.4 grammes per second above normal.

The control module always gives priority to the engine's need for maximum power so that at full throttle, such as when overtaking, the compressor is disconnected for the length of time that maximum power is required, but not for longer than eight seconds at most.

Should the coolant temperature climb to 120°C (250°F), the compressor will also be stopped by ICE (the control module for overriding electronic functions) breaking the connection to the anti-freeze thermostat.