Throttle lever sticking

| MODIFICATION INSTRUCTION | |

| Bulletin Nbr: | 270-1735 |

| Date: ........... | APRIL 1997 |

| Market: | ALL |

| Throttle lever sticking |

| Safety-related campaign 10705 |

Cars in stock should be rectified before delivery.

Owners of cars already delivered must be informed of the fault by means of a personal communication requesting them to get in touch with their nearest Saab garage as soon as possible to have the fault rectified.

| Cars concerned |

Saab 900 M94-97 with 4-cylinder engines within the following chassis-number range:

R2000001-V2019663 (3-d/5-d)

or

S7000001-V7003647 (Convertible)

| Background |

The throttle may be sluggish as a result of the throttle lever sticking. To rectify, fit a new spindle and bush.

| Materials |

46 13 246 Kit containing spindle and bush

| Action (non-turbo) |

Before starting work, check box D1 (M94, not US/CA) (see SI 801-1747) or B2 (M94, US/CA only), B2 (M95-96) or B1 (M97) on the modification identity plate. If the box has not been marked, proceed as follows.

| 1. |

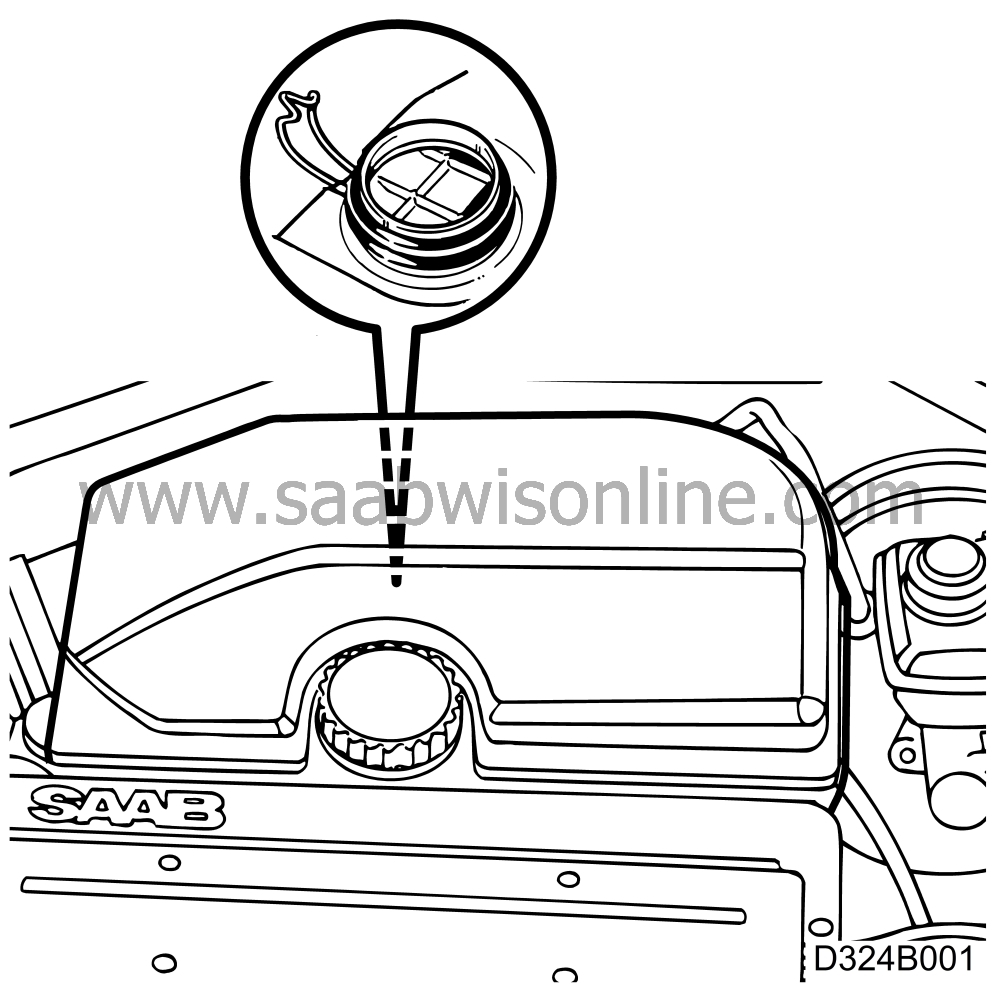

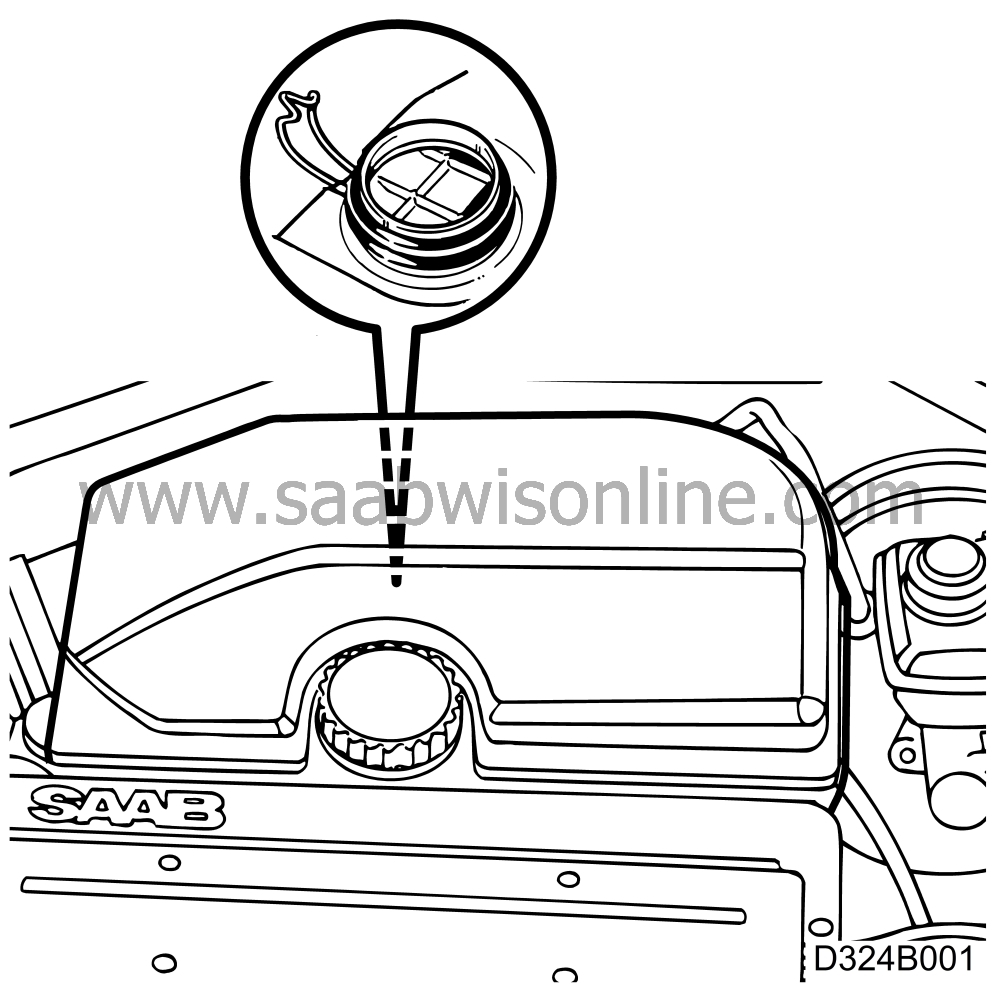

Remove the resonator from the throttle body.

|

|

| 2. |

Move the resonator aside, so that it is not blocking the throttle body.

|

|

| 4. |

Move the lever aside and use a screwdriver or other tool to push out the bush from behind.

|

|

| 5. |

Fit a new bush into the throttle lever.

|

|

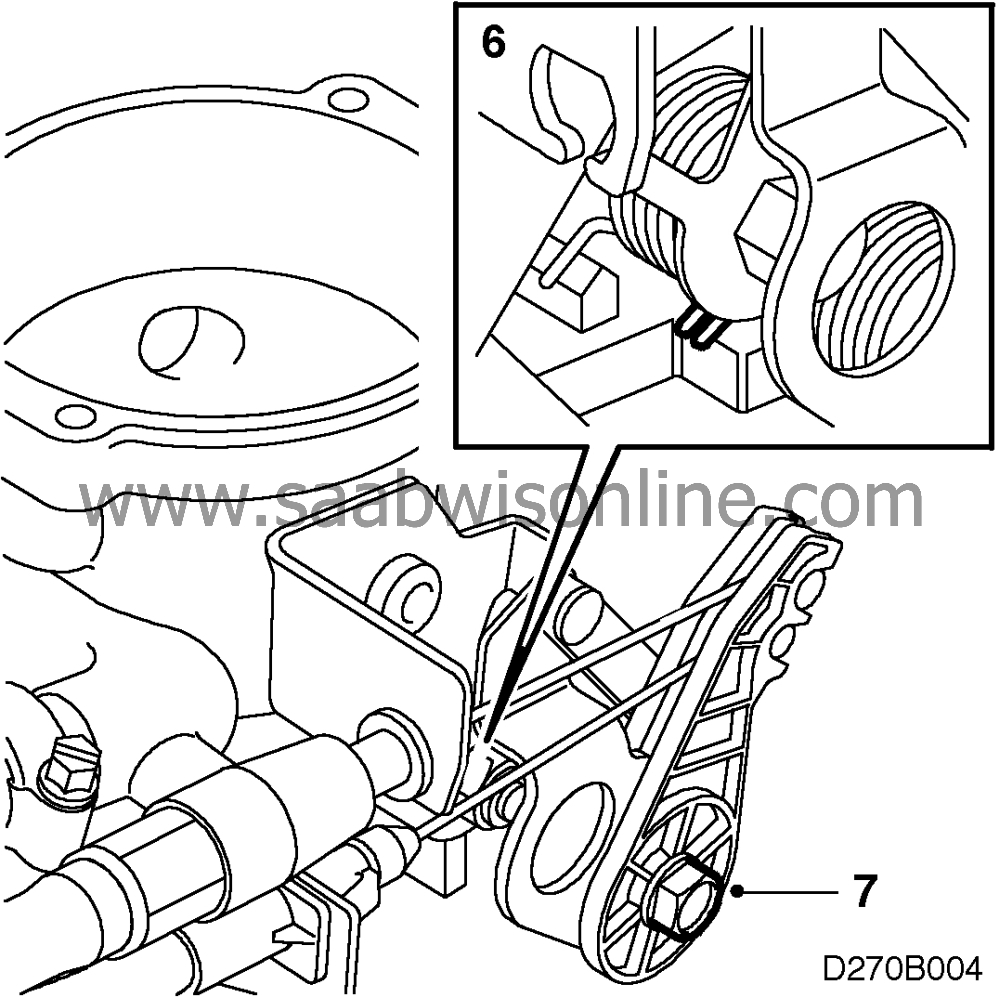

| 6. |

Fit the throttle lever, ensuring that the ends of the springs are locked against the stops on the throttle body (as shown).

Open the throttle lever slightly and screw in the new spindle. |

|||||||||

| 7. |

Tighten the spindle to the specified torque.

Tightening torque 8 Nm (6 lbf ft). |

|

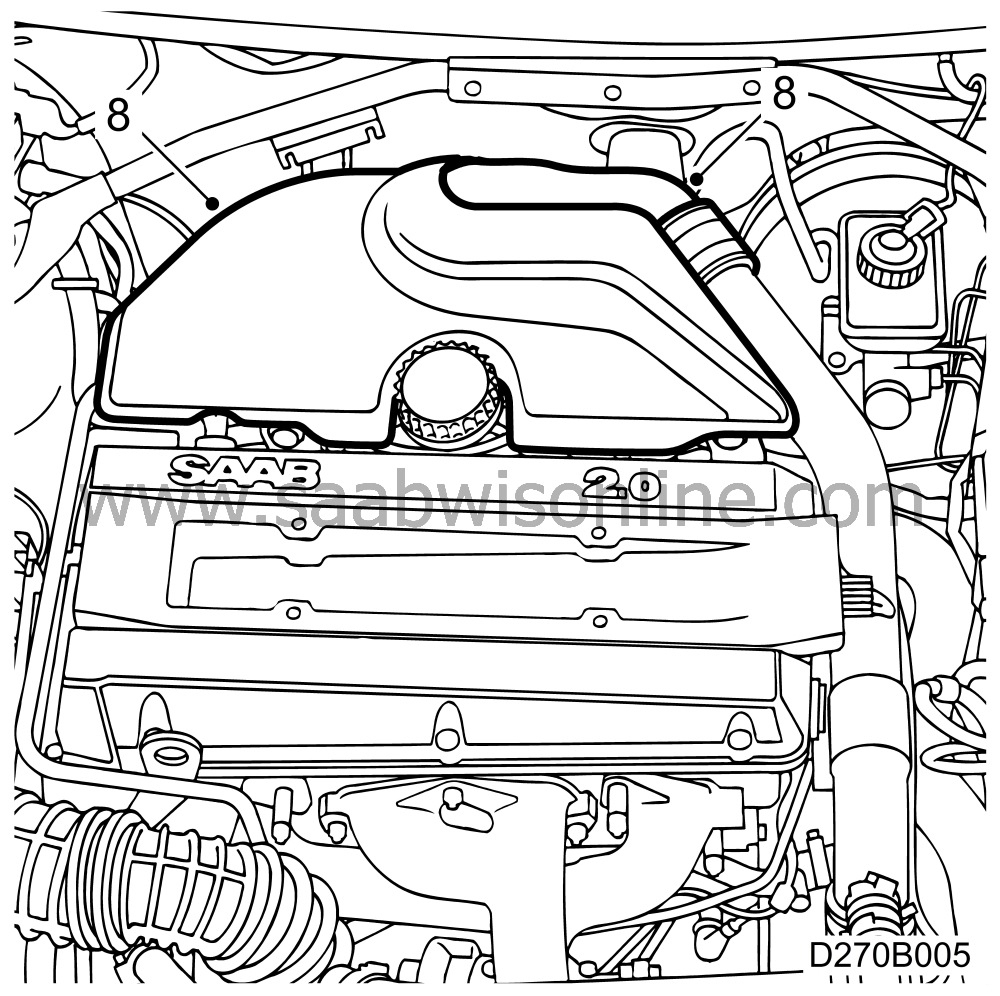

| 8. |

Check that the ’O’ rings on the resonator are intact and correctly seated. Lubricate the rings with acid-free petroleum jelly and refit the resonator. Ensure that the hose clip is correctly positioned.

|

|

| Action (turbo) |

Before starting work, check box D1 (M94, not US/CA) (see SI 801-1747) or B2 (M94, US/CA only), B2 (M95-96) or B1 (M97) on the modification identity plate. If the box has not been marked, proceed as follows.

| 1. |

Remove the cover.

|

|

| 2. |

Disconnect the pressure pipe (between the charge-air cooler and the throttle body) from the throttle body: unplug the electrical connector from the sensor body, remove the hose clip and undo the two screws holding the pipe to the throttle body.

|

|

| 3. |

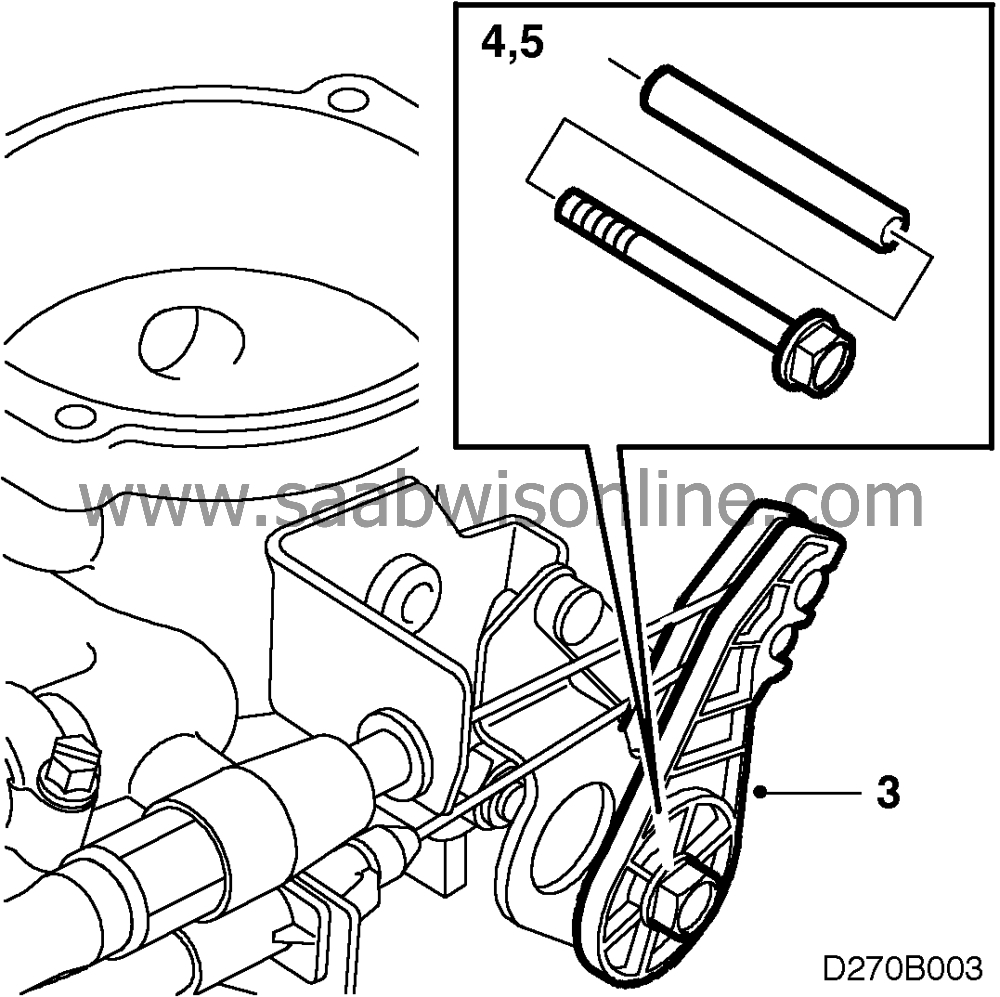

Unscrew the throttle-lever spindle.

|

|||||||||

| 4. |

Move the lever aside and use a screwdriver or other tool to push out the bush from behind.

|

|

| 5. |

Fit a new bush into the throttle lever.

|

|

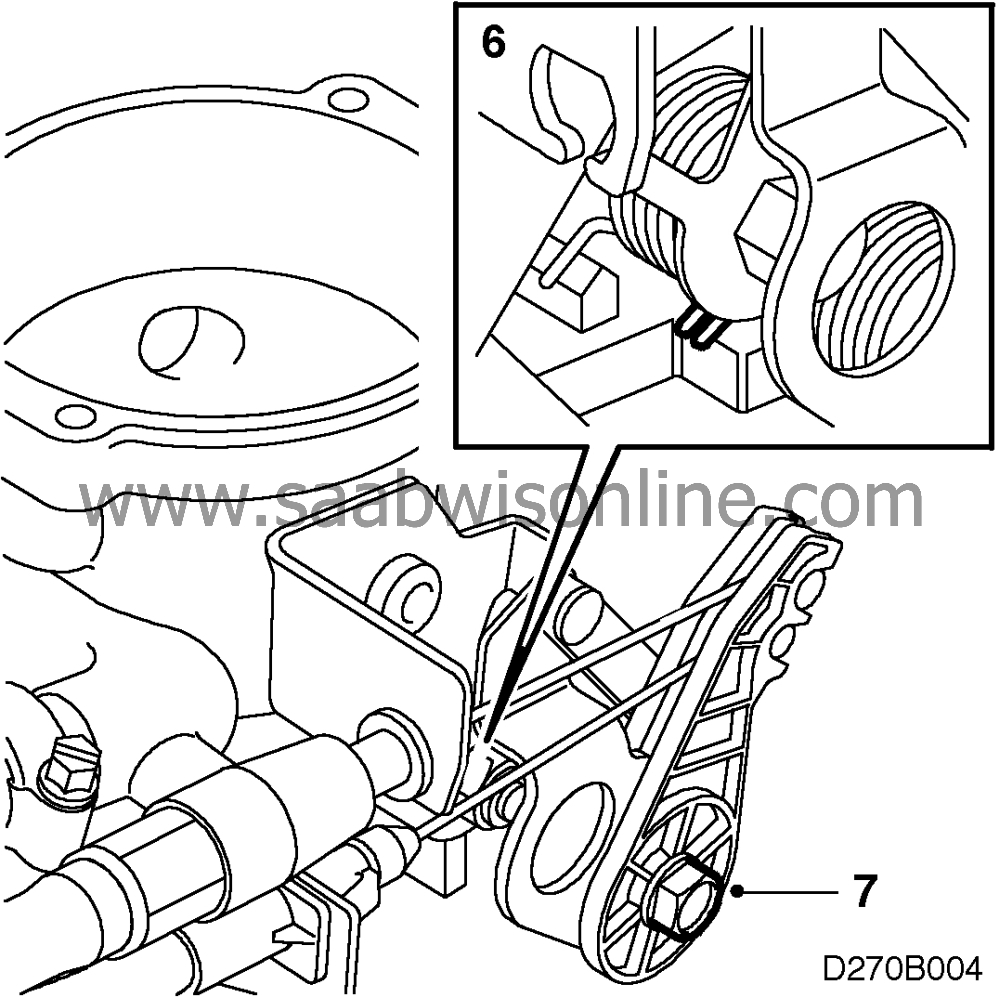

| 6. |

Fit the throttle lever, ensuring that the ends of the springs are locked against the stops on the throttle body (as shown).

Open the throttle lever slightly and screw in the new spindle. |

|||||||||

| 7. |

Tighten the spindle to the specified torque.

Tightening torque 8 Nm (6 lbf ft). |

|

| 8. |

Check that the ’O’ ring on the pressure pipe is intact and correctly seated. Lubricate it with acid-free petroleum jelly, refit the pipe and plug in the connector. Refit the cover.

|

|

| Marking the modification identity plate |

After completing the work, mark box D1 (M94, not US/CA) (see SI 801-1747) or B2 (M94, US/CA only), B2 (M95-96) or B1 (M97) on the modification identity plate: put a ’7’ in the box if done by the importer or an ’8’ if done by a dealer.

| Standard-time information |

See separate literature.

Warning

Warning