Procedure before replacing ECM

|

|

Procedure before replacing ECM

|

When all the checks have been carried out in accordance with the diagnostic

procedures programme under the diagnostid trouble code concerned or through manual fault

diagnosis without any fault having been detected, it is natural to assume that the ECM is

faulty.

You should therefore run through the following points carefully before finally identifying

the Trionic ECM as the cause of the fault.

|

1.

|

Check once more that all the

items for checking in the fault diagnosis routine for the relevant diagnostic trouble code have

been carried out.

|

|

2.

|

Study the wiring diagram of the relevant circuit and examine its operation. If

necessary, consult the relevant parts of the technical description and the description of

electrical operation in Service Manual "3:2 Wiring diagrams".

|

|

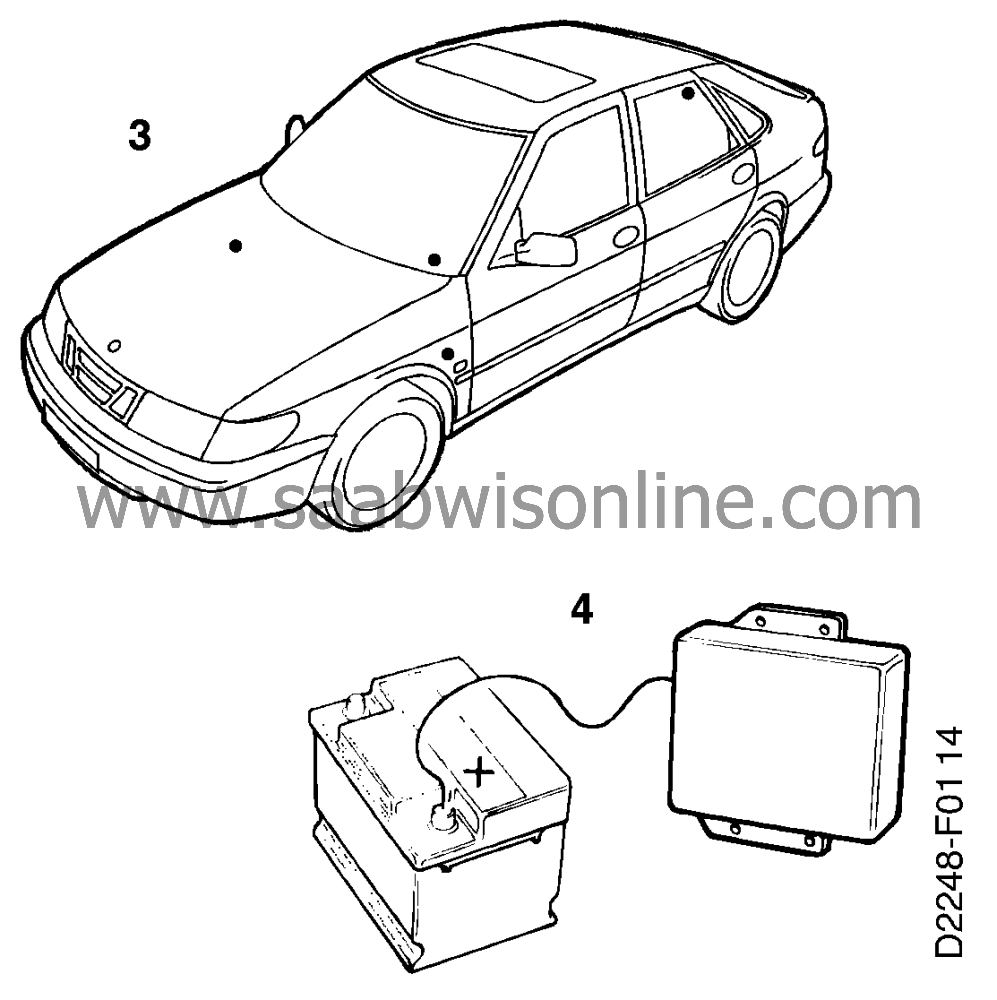

3.

|

Check all grounding points. If you have done this previously, do it once

more. Check the power ground and sensor are mechanically and electrically

separated.

|

|

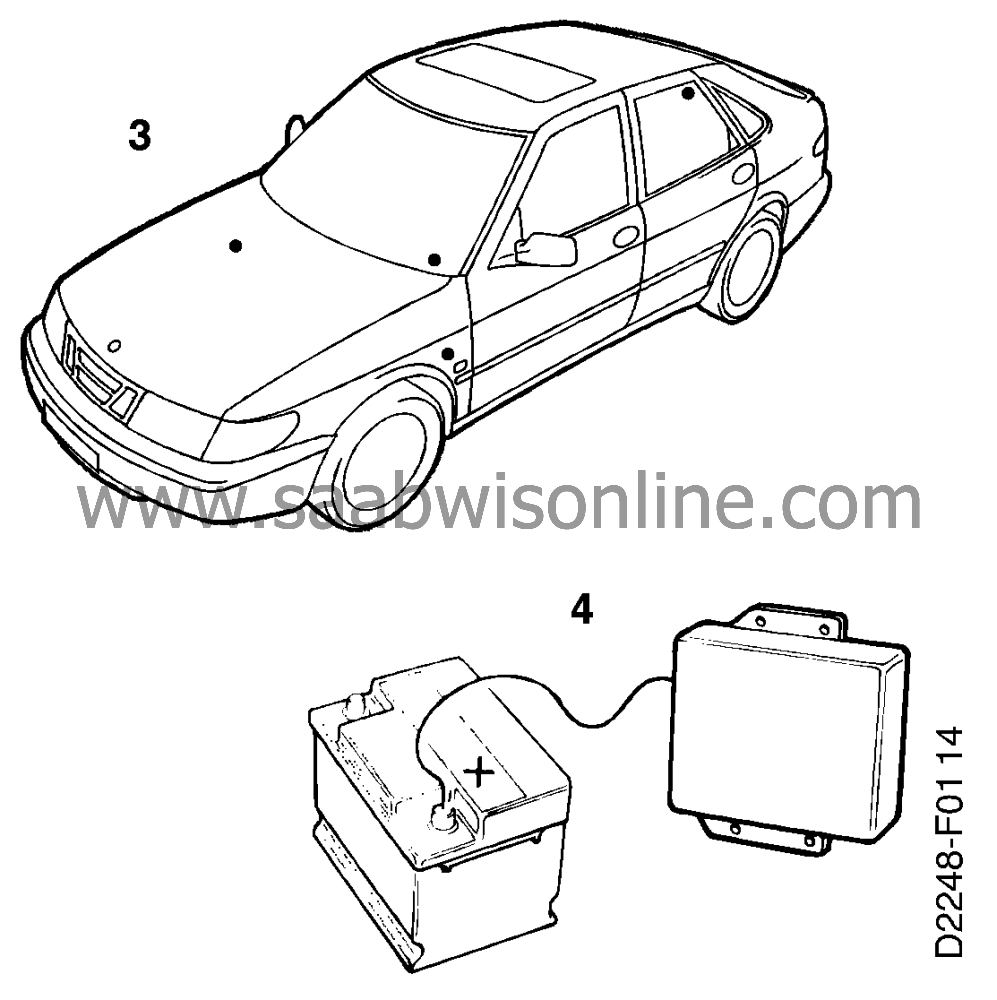

4.

|

Check the voltage supply to the ECM.

|

|

5.

|

Experience from the 1993 model shows that 80 %% of all Trionic ECMs returned

for repair under warranty were OK. Do not replace the ECM unnecessarily. ECMs replaced

without reason represent a large cost item for Saab Automobile and its dealers. Think through

likely causes for the fault before replacing the ECM. When replacing for test purposes, always

refit the correct ECM.

|

|

6.

|

If the origional fault nevertheless persists, the Trionic ECM must be replaced.

|