Tachometer (rev counter) (MIU2)

|

|

Tachometer (rev counter) (MIU

2)

|

Tachometer needle does not move.

|

2.

|

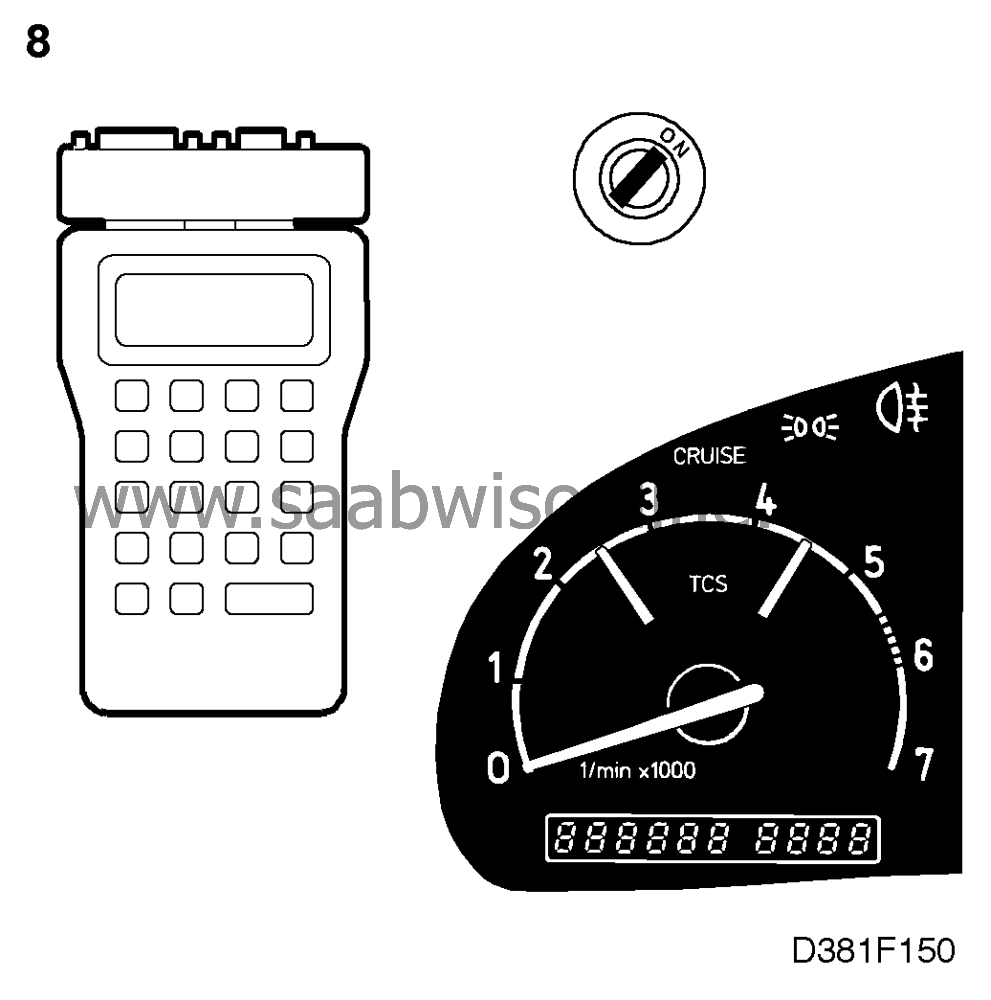

Connect the Scan Tool and select "READ VALUES" followed by "ENGINE RPM".

|

|

3.

|

Increase and decrease engine speed. If the rpm signal is OK, a corresponding

increase and decrease (in rpm) should be shown on the Scan Tool's display. If this is

the case, continue with point 7.

|

|

4.

|

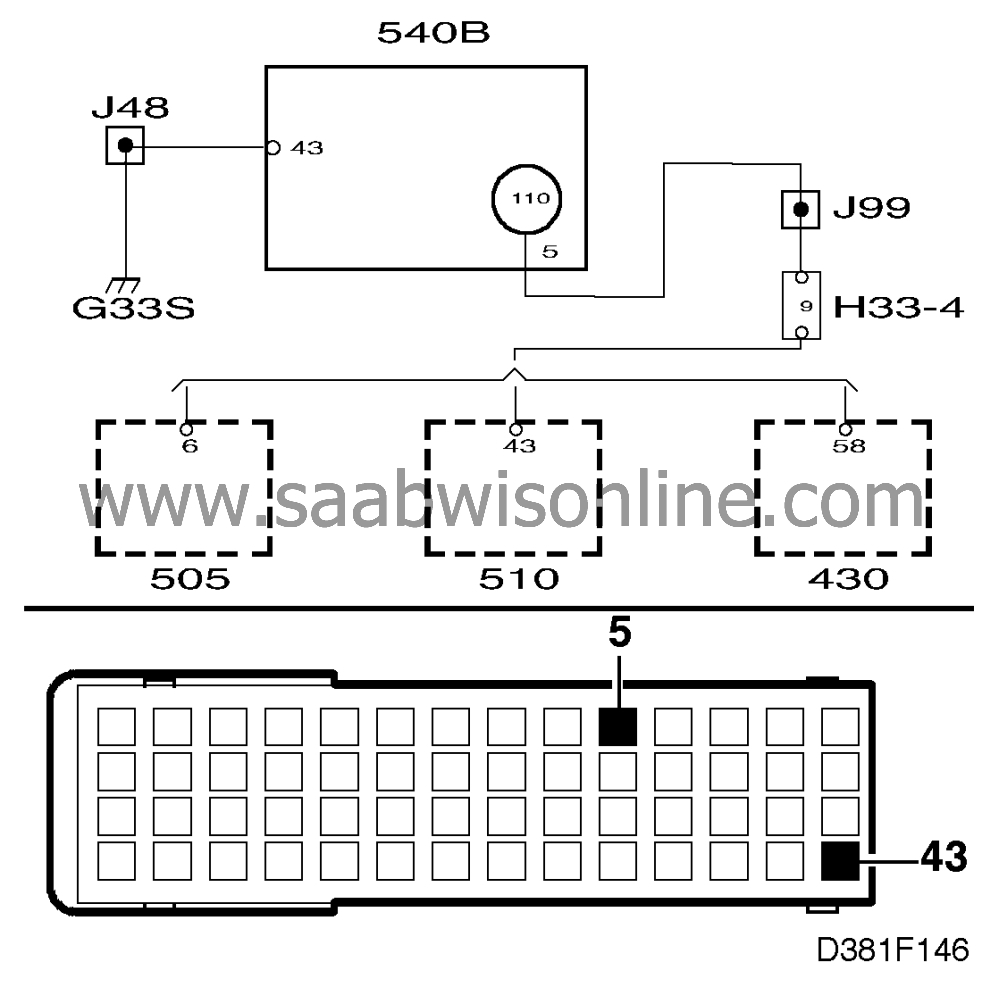

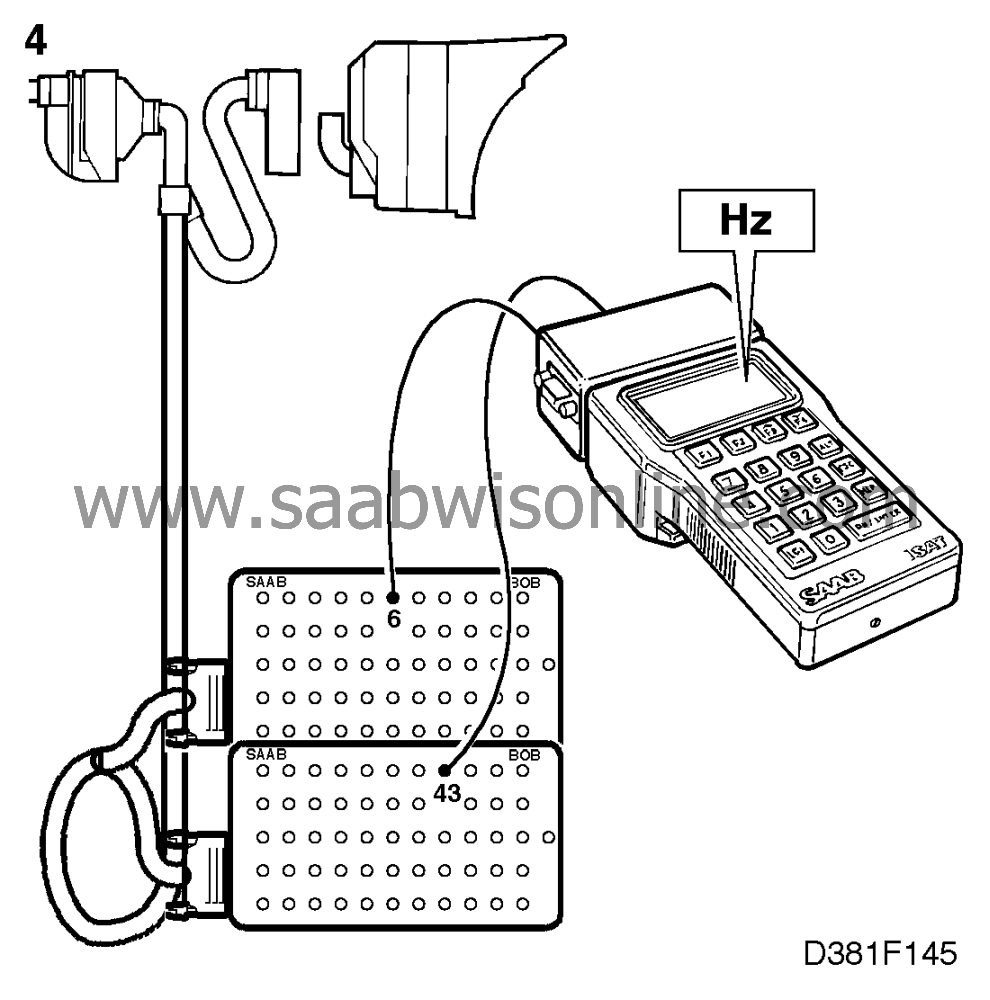

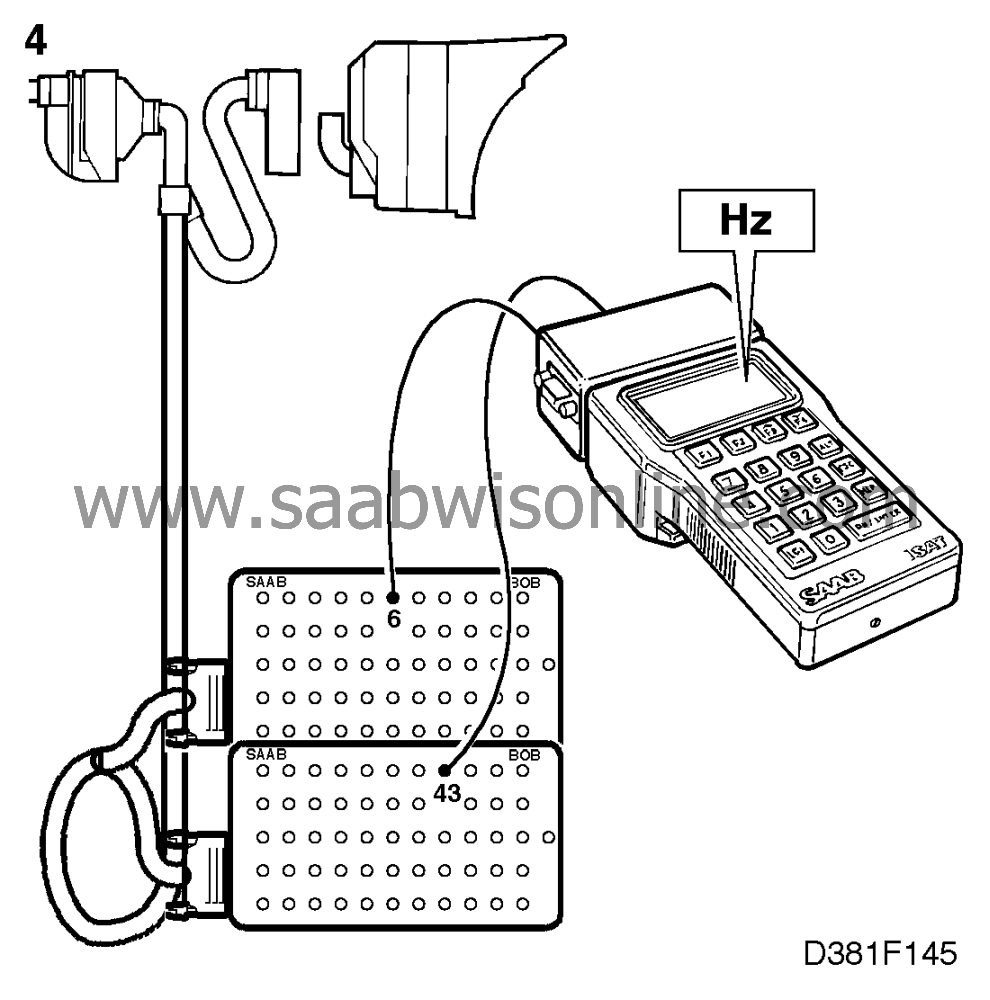

If no rpm signal is present, check the signal sent to the main instrument display

panel by connecting a BOB to the 56-pin connector behind the main instrument display panel

(which should not be connected).

Connect the Scan Tool's test leads to pin 6 and ground. Then select "MEASURE"

followed by "PULSE". Start the engine and check whether any pulses are generated.

About 40 Hz (4-cyl.) at idling speed. About 30 Hz (6-cyl.) at idling speed. If pulses are

generated, continue with point 8.

|

|

5.

|

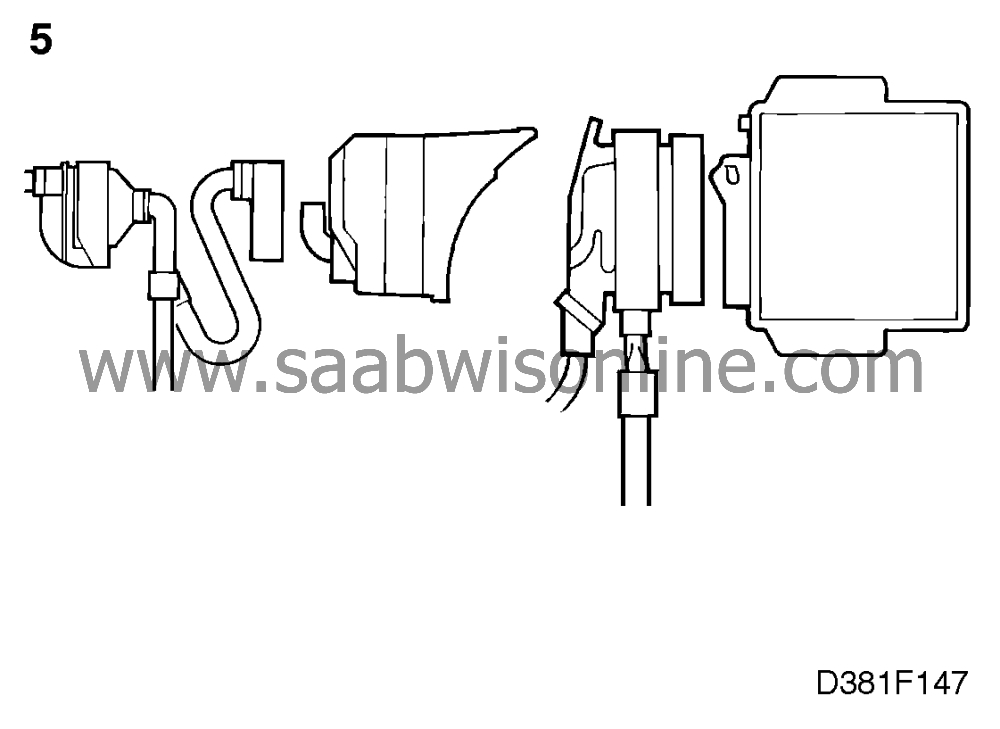

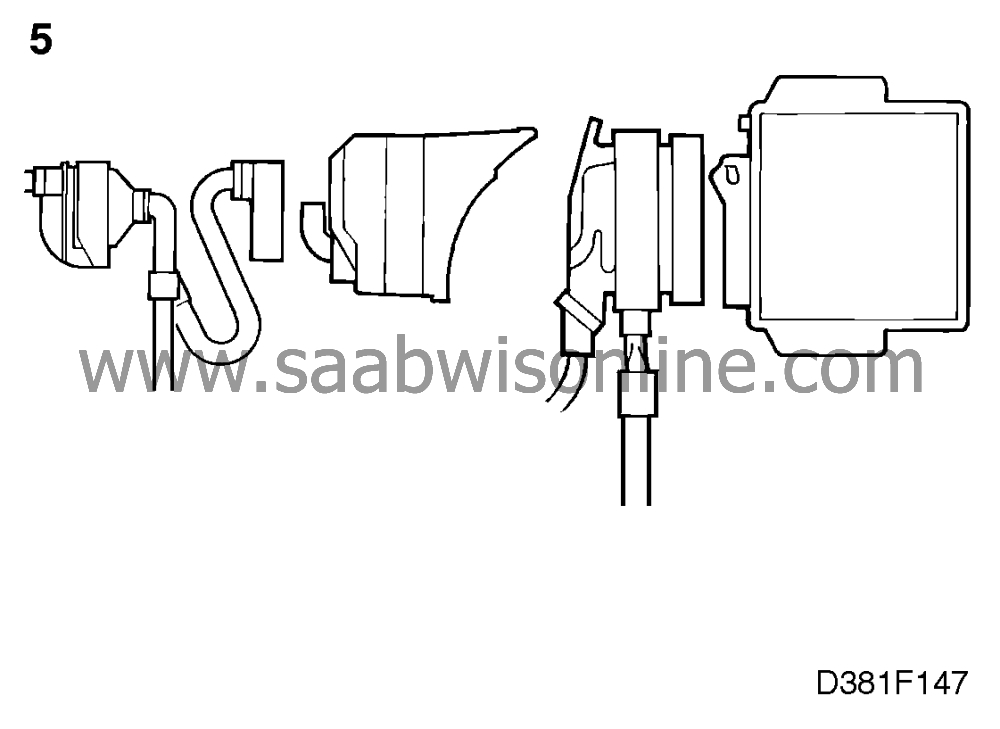

If no pulses are generated, check the wiring by connecting another BOB to the

connector of the engine management system's control module.

The control module should not be connected.

|

|

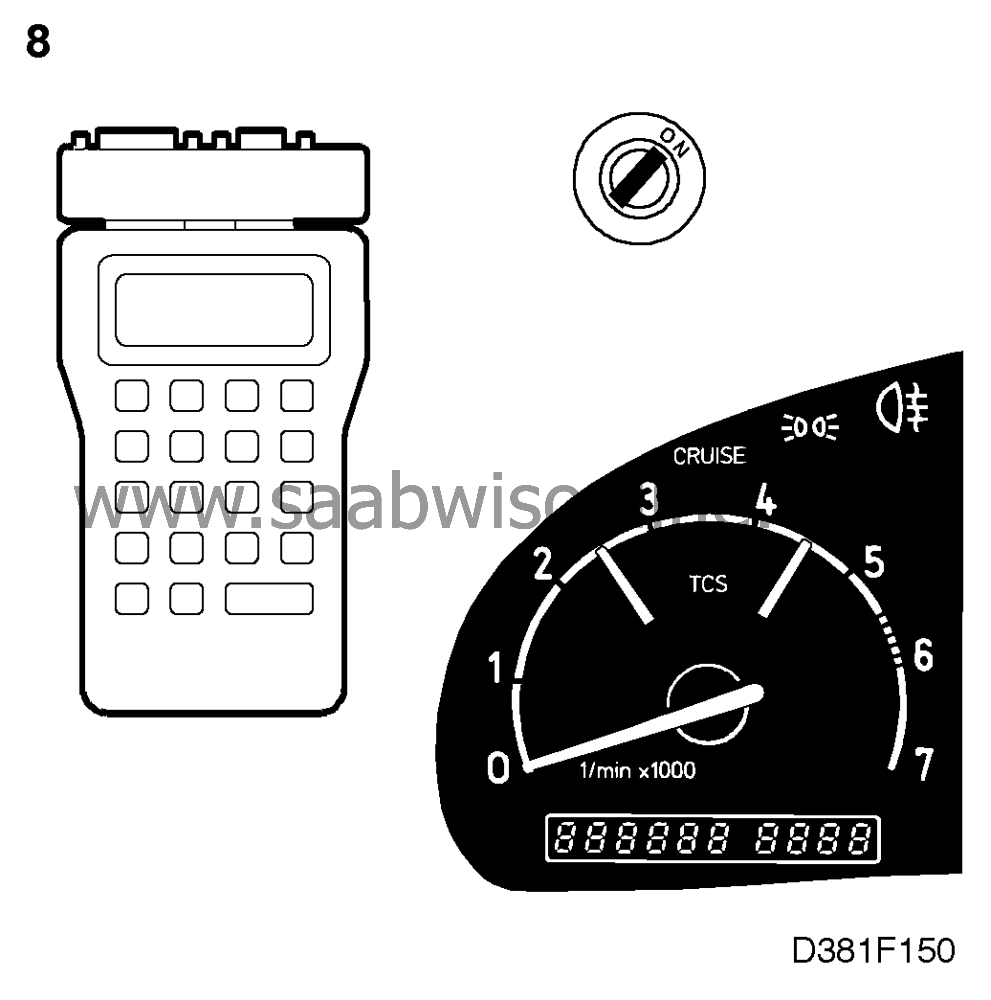

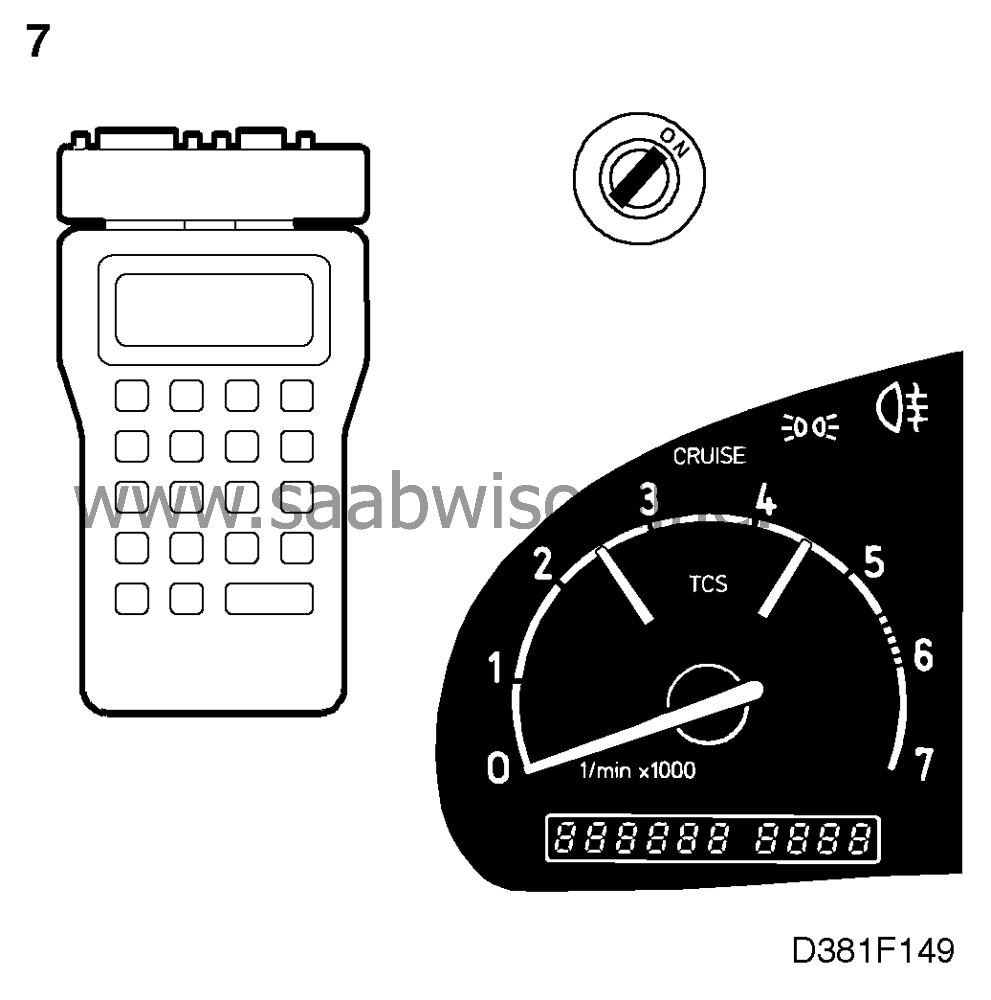

7.

|

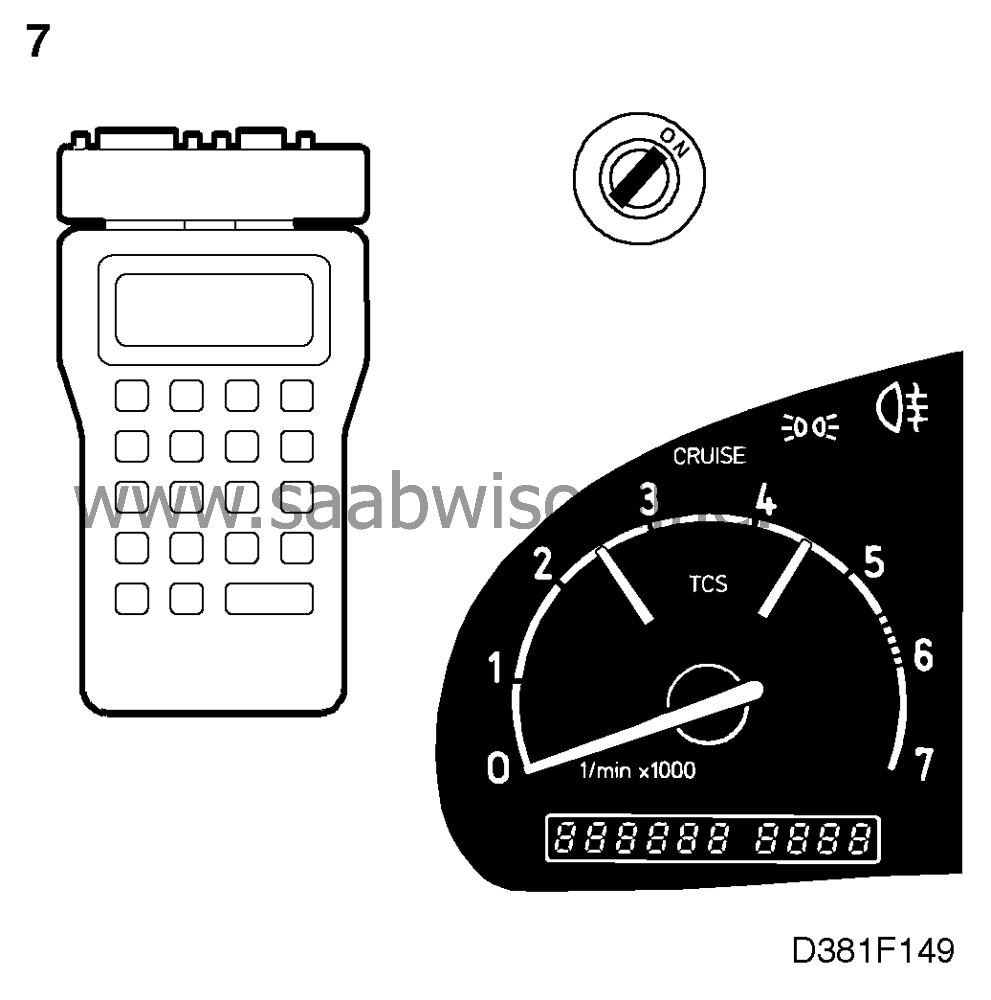

Select "TEST FUNCTIONS" followed by "TACHOMETER TEST" on the Scan

Tool.

If in proper working order, the rev counter needle should rise to 7000 rpm and then

return to 0.

If the tachometer does not work, it could be due to an open circuit in the connection

between the processor card and the intermediate part of the main instrument display panel.

Remove the main instrument display panel's rear section complete with

processor card and check that all leads connected to the connector marked CN3 are securely

located. If any lead has come loose or is broken, continue on

.

.

If the leads connected to the connector are all OK, the fault is probably in the

intermediate part with the indicating instruments. Continue on

.

.

|

|

8.

|

Select "TEST FUNCTIONS" followed by "TACHOMETER TEST" on the Scan

Tool. If in proper working order, the rev counter needle should rise to 7000 rpm and then

return to 0.

If the tachometer works, there is probably an open circuit between the connector and

the processor on the processor card in the main instrument display panel. Continue on

.

.

|