Gear selector position sensor

| Gear selector position sensor |

| To remove |

| 1. |

Move the selector lever to position P.

|

|

| 2. |

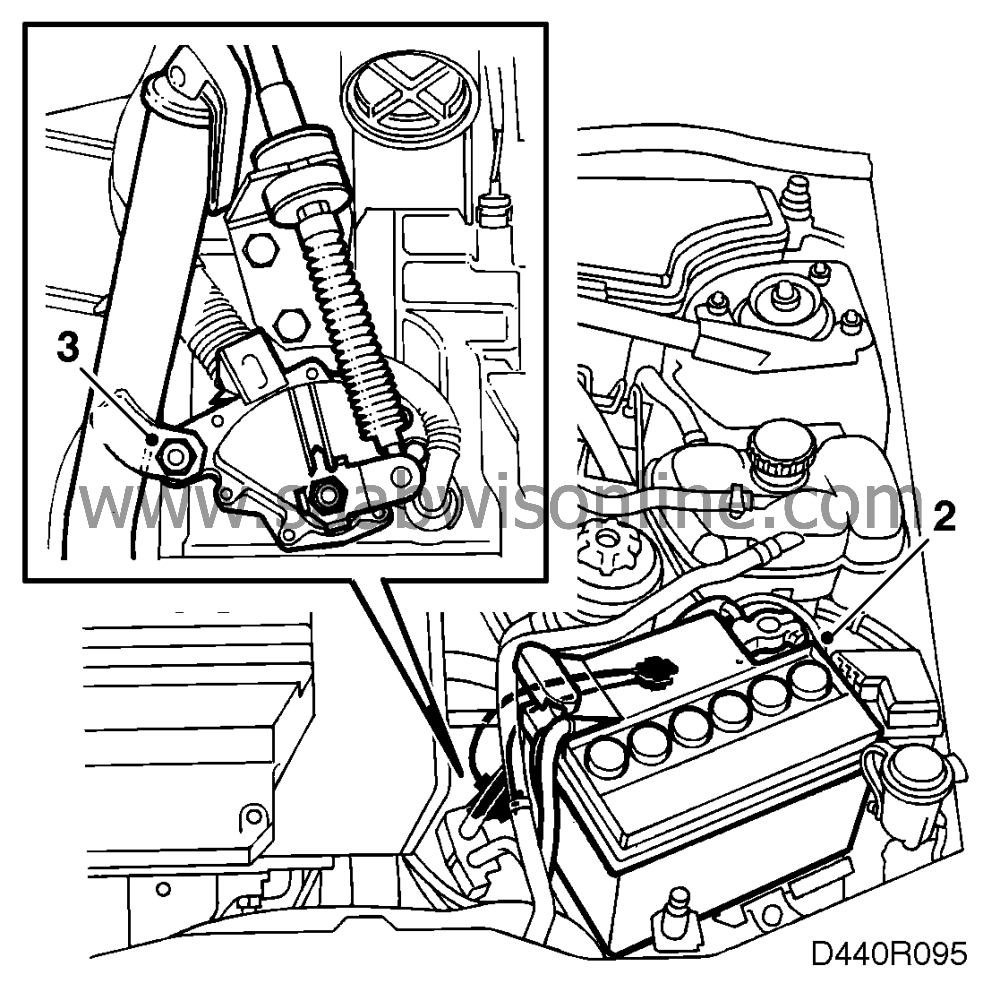

Remove the battery.

|

|

| 3. |

Remove the dipstick.

|

|

| 4. |

Remove the servo pump pipe's mounting bracket to expose the gear selector position sensor.

|

|

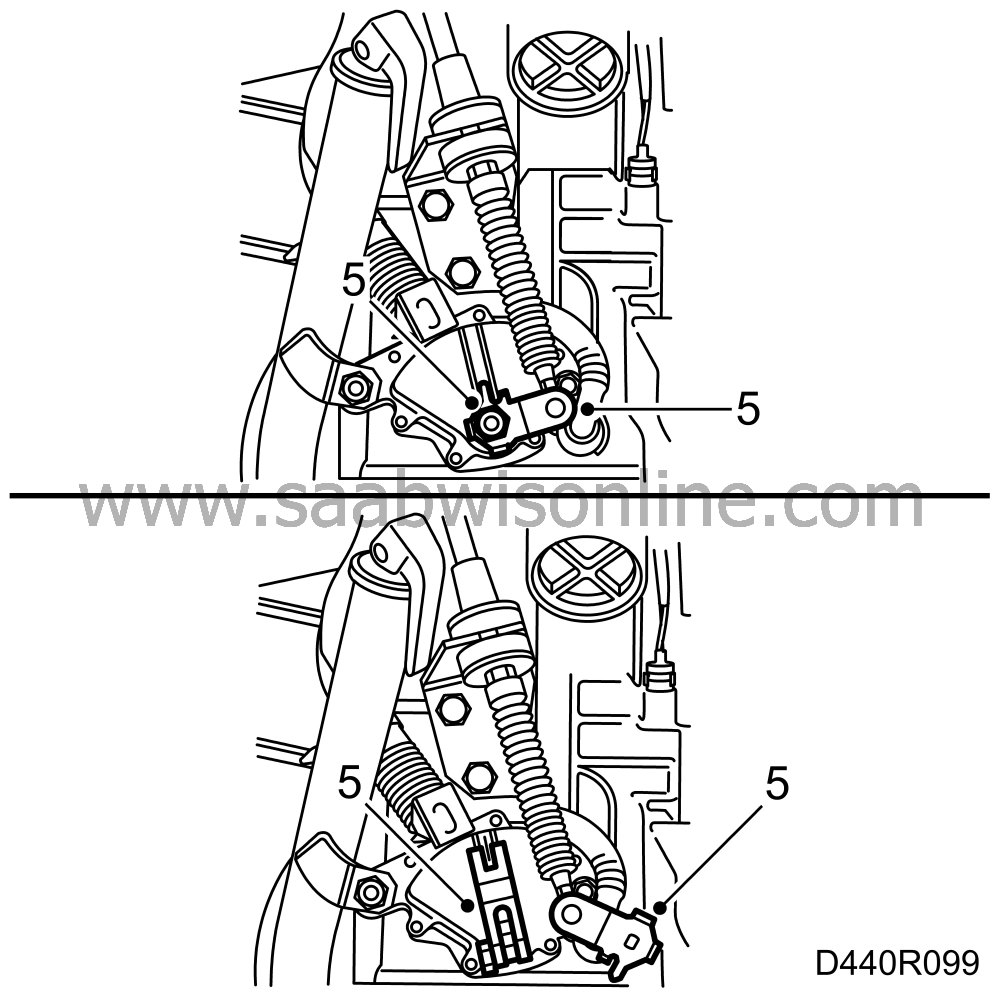

| 5. |

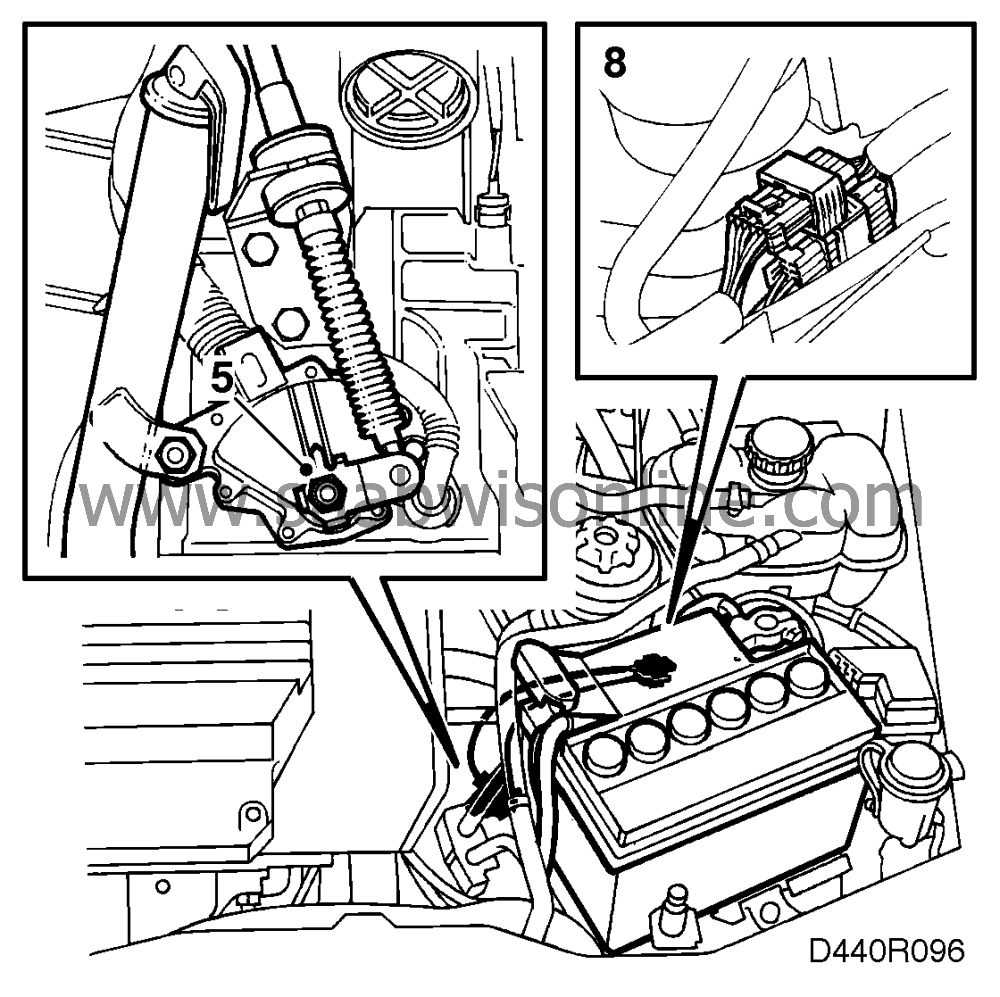

Remove the lever.

|

|

| 6. |

Remove the gear selector position sensor's bolt.

|

|

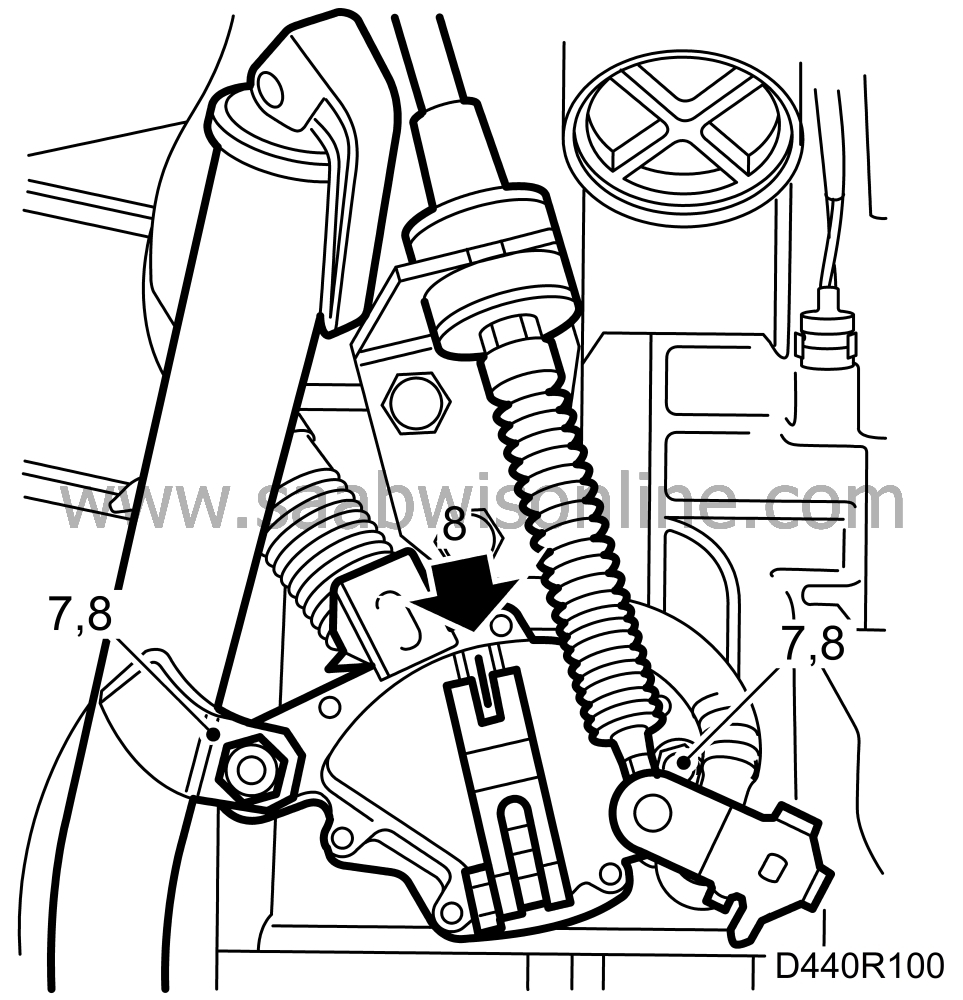

| 7. |

Remove the gear selector position sensor's nut.

|

|

| 8. |

Unplug the electrical connector and lift the sensor off the shaft.

|

|

| Fitting |

| 1. |

Plug in the connector and mount the sensor on the shaft.

|

|

| 2. |

Fit the gear selector position sensor's nut.

Tightening torque: 8 Nm (6 lbf ft). |

|

| 3. |

Refit the lever but do not tighten it and move the selector lever to position N. Lift off the lever and check the position of the gear selector position sensor, see points 5-10.

|

|

| 4. |

Tighten the bolt(s).

Tightening torque: 25 Nm (18.5 lbf ft). |

|

| 5. |

Check that the engine starts with the selector lever in positions P and N and that the reversing light comes on only in position R.

|

|

| 6. |

Clean and lubricate the fluid filler pipe's O-ring with acidfree vaseline (petroleum jelly) and refit the fluid filler pipe.

Tightening torque: 25 Nm (18.5 lbf ft). |

|

| 7. |

Fit the servo pump pipe's mounting bracket.

|

|

| 8. |

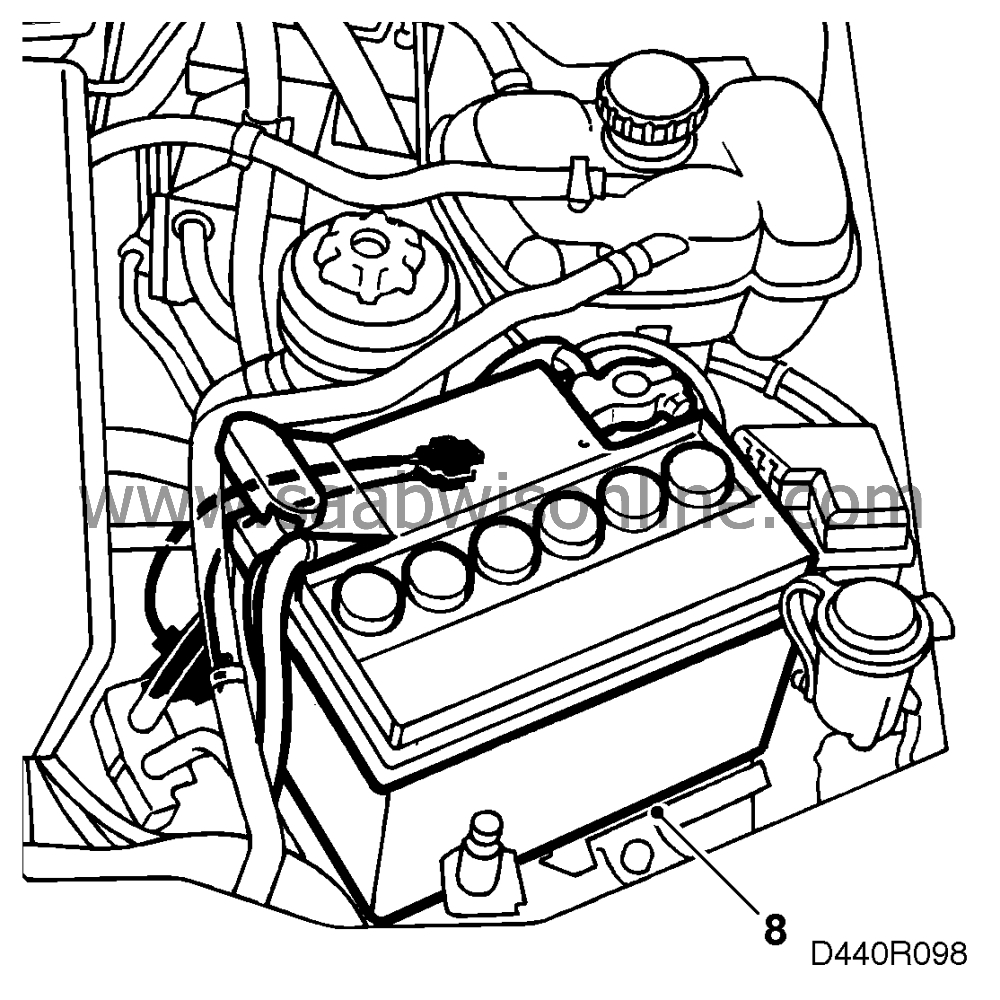

Refit the battery.

|

|

| Checking and adjusting |

| 1. |

V6:

Remove the engine covers.

|

|

| 2. |

Disconnect the battery and lift it out.

|

|

| 3. |

Remove the servo pump pipe's mounting bracket.

|

|

| 4. |

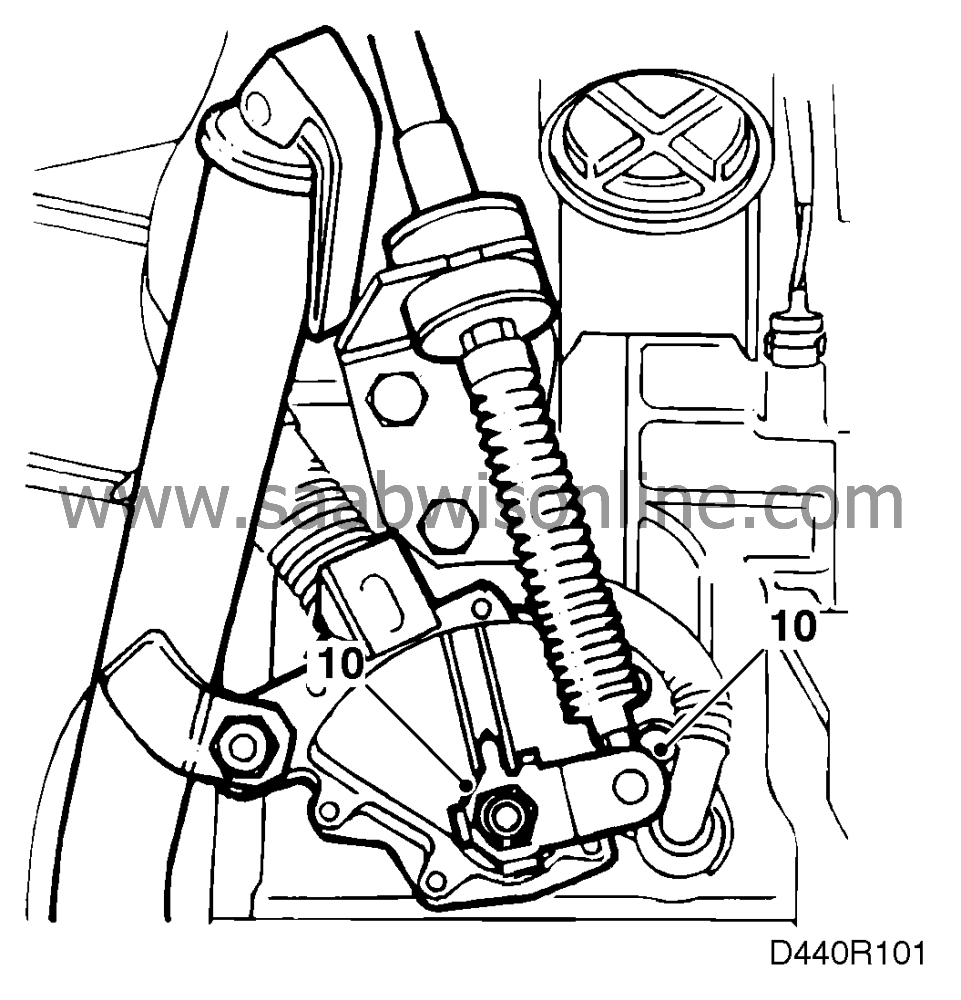

Move the selector lever to position 1 (to relieve the cable of tension) and undo the lever's nut.

|

|

| 5. |

Move the selector lever to position N, remove the selector lever cable's lever and fit tool 87 92 467. Check that the line marked on the gear selector position sensor is visible in the centre of the tool's notch. - If it is not, the sensor should be adjusted. Continue with point 6. - If it is, proceed to point 10.

|

|

| 6. |

Remove the fluid filler pipe's nut and remove the pipe.

|

|

| 7. |

Remove the gear selector position sensor's bolt(s).

|

|

| 8. |

Turn the sensor so that the line marked on it is visible in the centre of the tool's notch and then tighten the bolt(s).

Tightening torque: 25 Nm (18.5 lbf ft). |

|

| 9. |

Clean and lubricate the fluid filler pipe's O-ring with acidfree vaseline (petroleum jelly) and refit the fluid filler pipe.

Tightening torque: 25 Nm (18.5 lbf ft). |

|

| 11. |

Fit the servo pump pipe's mounting bracket, put the battery back in place and connect the cables.

|

|

| 12. |

V6:

Fit the engine covers.

Important

|

||||||||||