Checking for lateral runout andvariation in thickness

|

|

Checking for lateral runout and

variation in thickness

|

|

1.

|

Lift the car and remove the front

wheels.

|

|

2.

|

Start performing the check measurement on one side. Press in the brake piston

using a pair of grips.

|

|

3.

|

Remove the brake caliper and bind it to the spring strut using a cable tie.

|

|

4.

|

Fit the five wheel studs with the four washers on each wheel studs. The washers

have part no. 80 73 124.

|

|

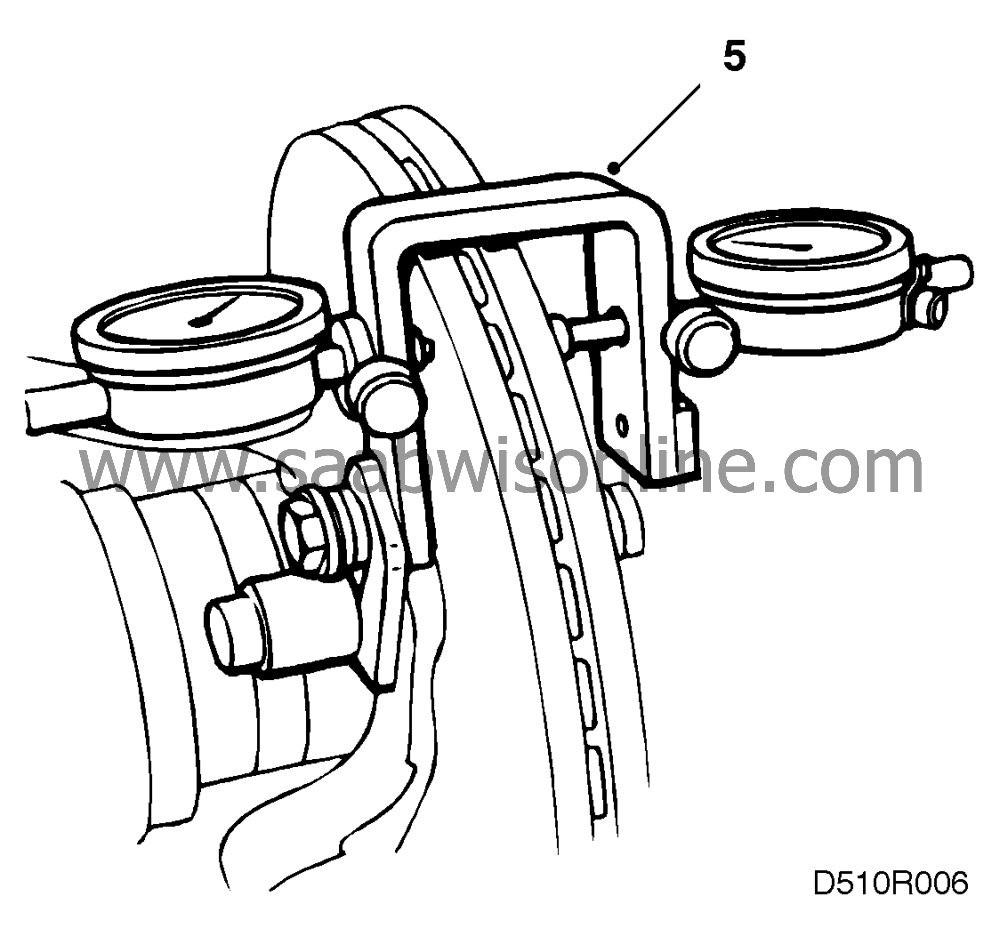

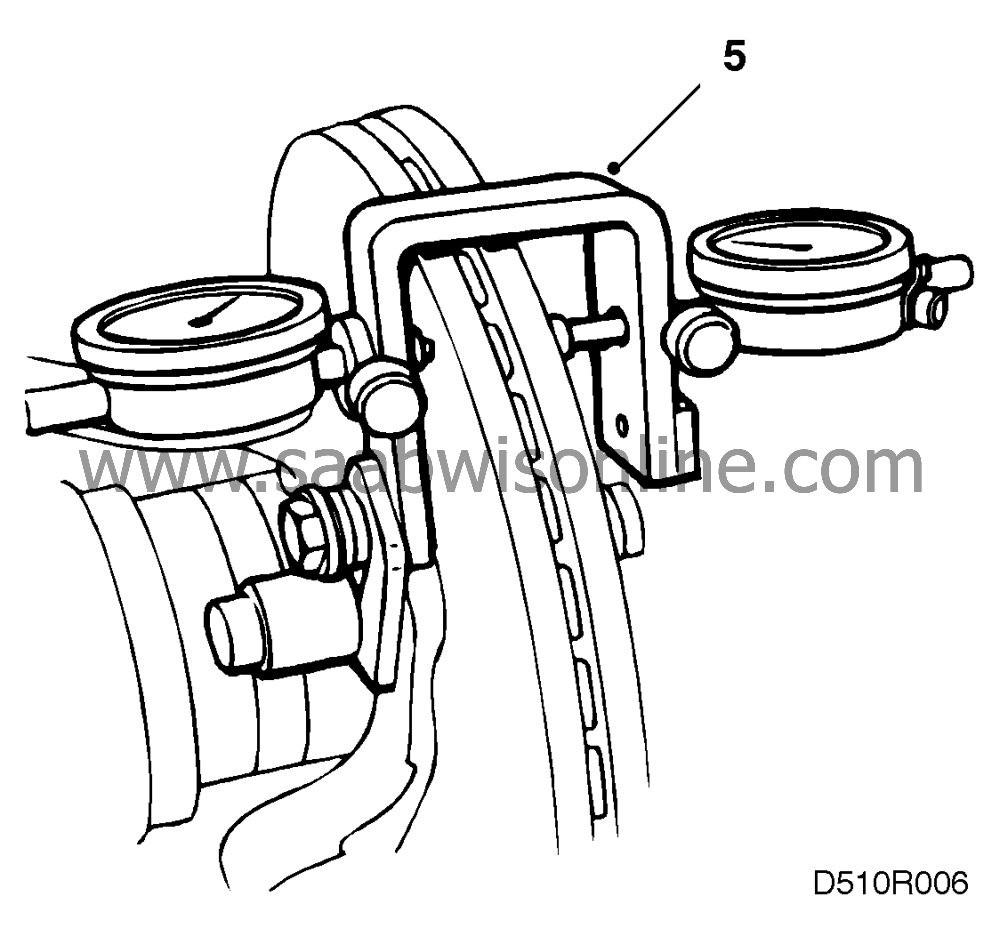

5.

|

Fit the measuring clamp on the lower securing lug for the brake caliper. Secure

the measuring dials. The measuring dials have part no. 78 40 622.

|

|

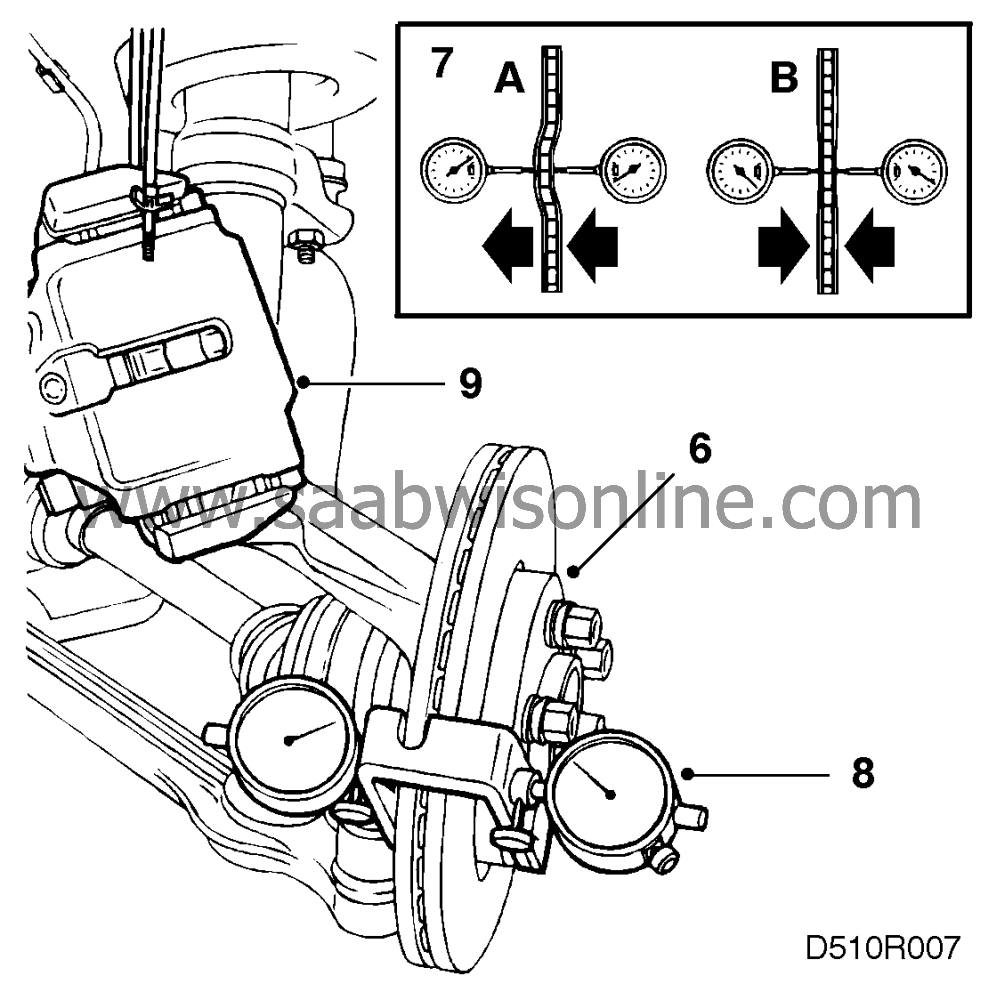

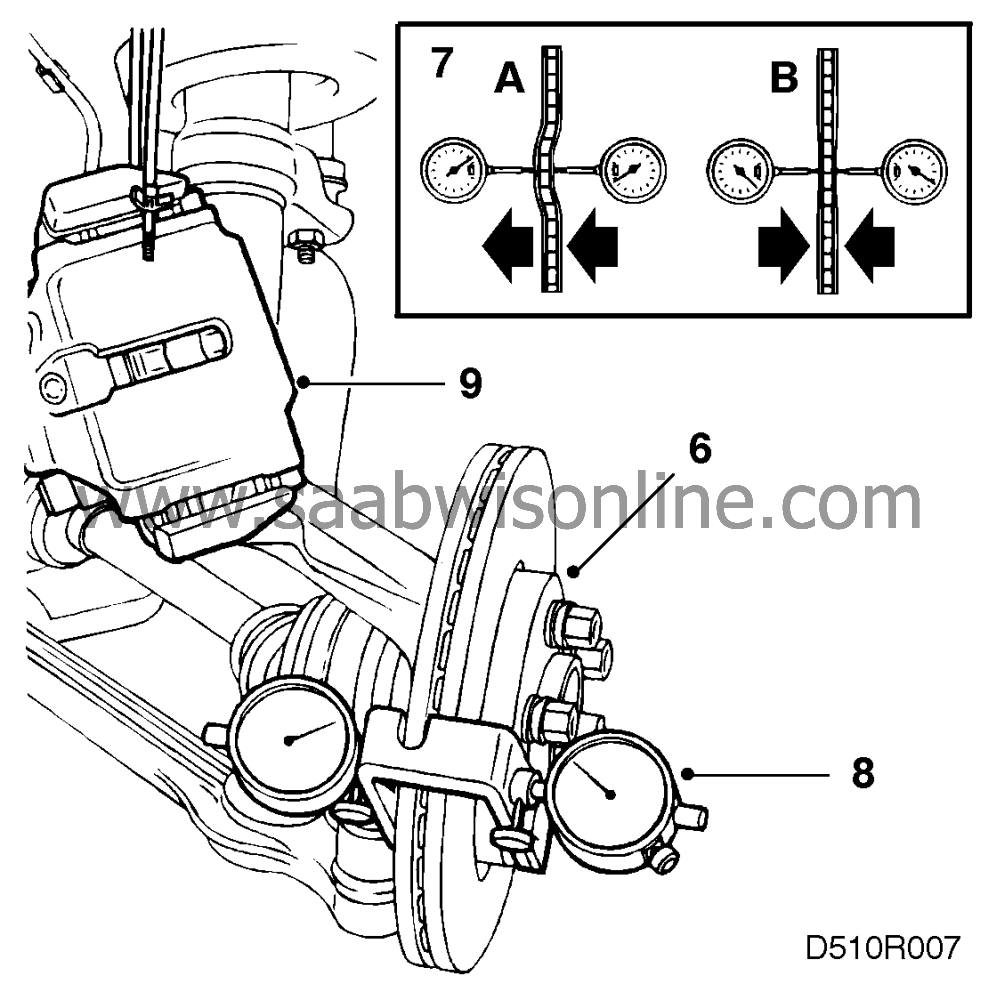

6.

|

Rotate the brake disc and at the same time watch the outer measuring

dial. Reset both dials when the outer shows the maximum negative effect.

|

|

7.

|

Rotate the disc and read of the dials. Note the runout (A) and the variation in

thickness (B).

|

|

8.

|

Remove the dials, measuring clamp and wheel studs with washers.

|

|

9.

|

Fit the brake caliper, lock the stud threads with Locktite and tighten.

Tightening torque 80 Nm (59 lbf ft)

|

|

10.

|

Fit the wheels and tighten the wheel studs.

Tightening torque

- light alloy wheels 117 Nm (86.6 lbf ft)

- pressed steel wheels 100 Nm (74 lbf ft)

|

|

11.

|

Repeat this method of measurement on the other front wheel.

|

|

12.

|

When the measurements have been completed, lower the car and press the

brake pedal to press out the brake pads.

|