A pillar, lower part

| A pillar, lower part |

Both the A pillar and the sill are reinforced. This reinforcement must not be damaged when cutting the A pillar.

| Important | ||

|

Body reinforcement components should be cut and joined only if they are specifically covered in the description of methods. Unless otherwise stated, a damaged reinforcement component must be discarded and a new one fitted in its place. This is mandatory. |

||

| 1. |

Mount the car on an aligning bench and realign to the correct measurements if necessary.

|

|

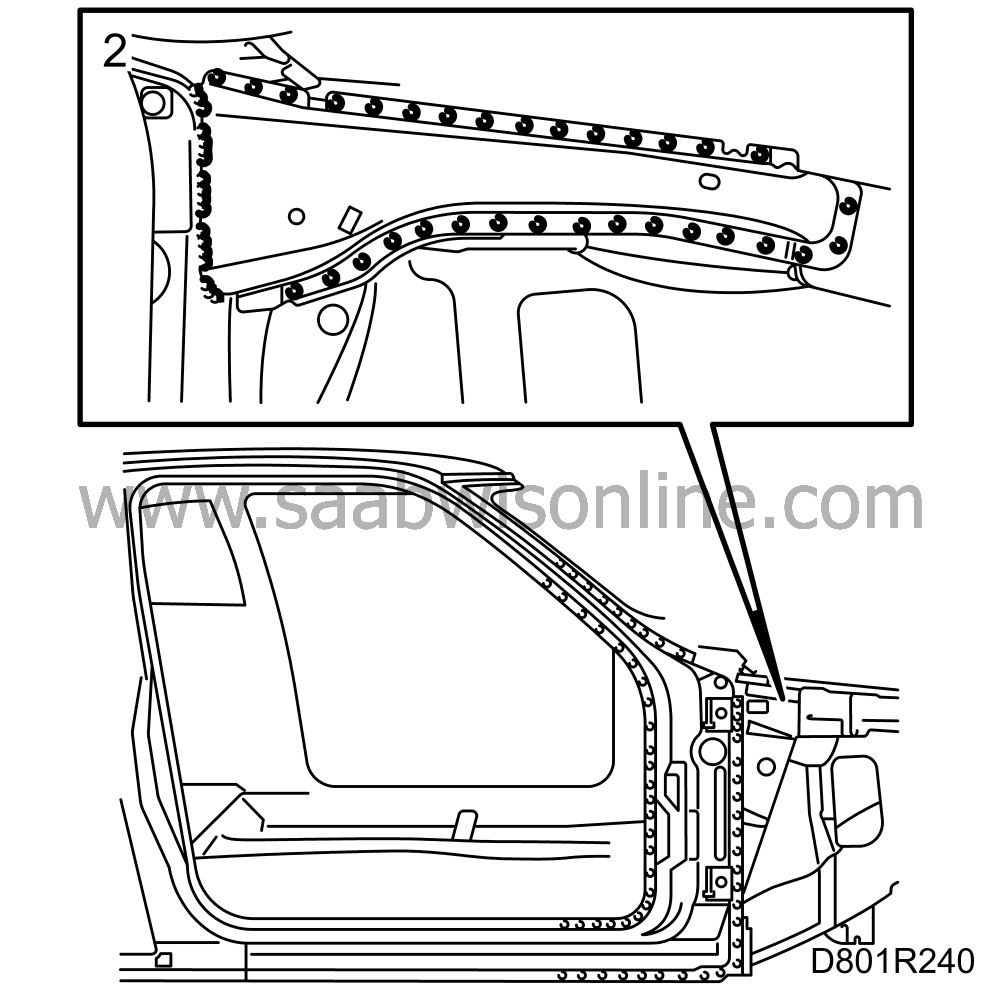

| 2. |

Remove the reinforcement on the outside of the wheel housing. If undamaged it can be used again on reassembly.

|

|

| 3. |

Roughly cut the A pillar and sill.

If the position of the hinge is unchanged, cut the outer panel around the hinges. Be careful that the underlying metalwork is not damaged. |

|

| - |

On five door cars, the upper part of the A pillar is cut in the middle of the marked groove.

|

| - |

On three door cars, the upper part of the A pillar is cut 70 mm above the marked groove.

|

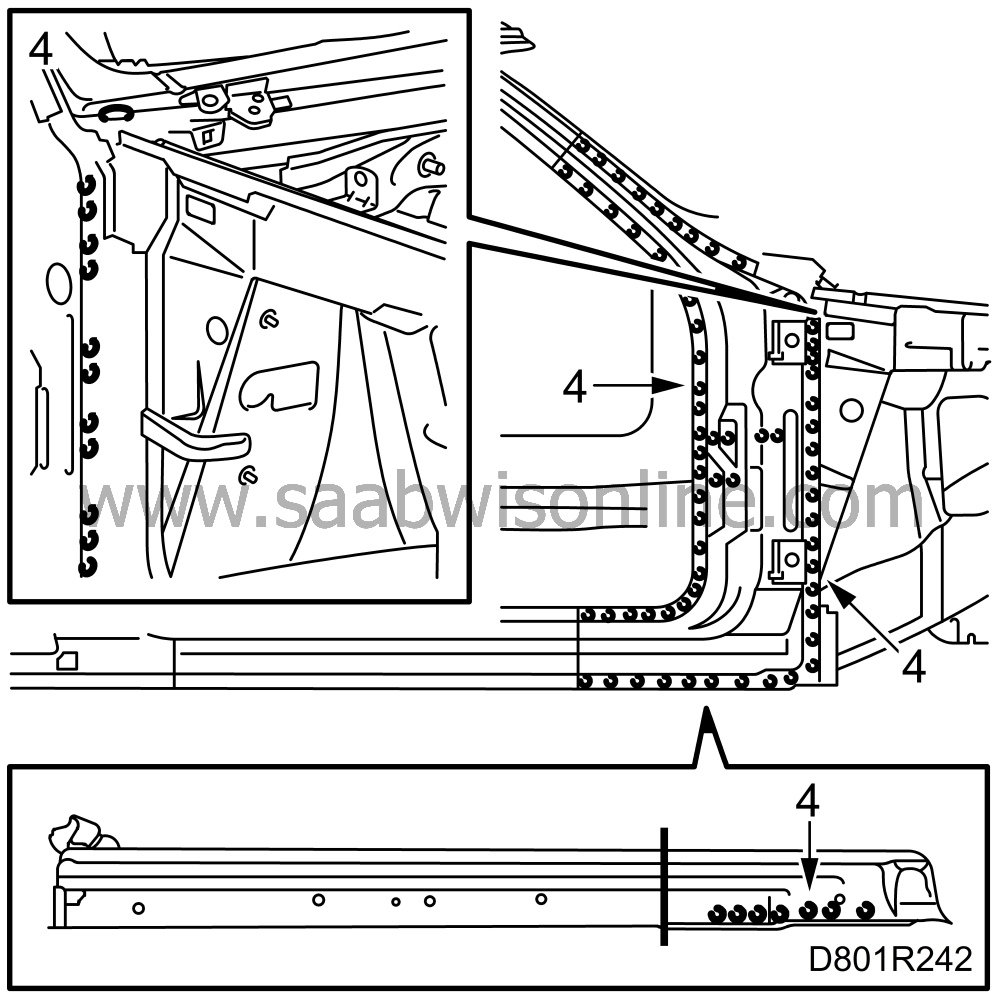

| 4. |

Drill out the spot welds.

|

|

| 5. |

Use a grinder on the damaged parts of the A pillar and sill and knock them loose.

|

|

| 6. |

Realign any deformed metalwork. If only the outer panel is to be replaced proceed to point 33.

|

|

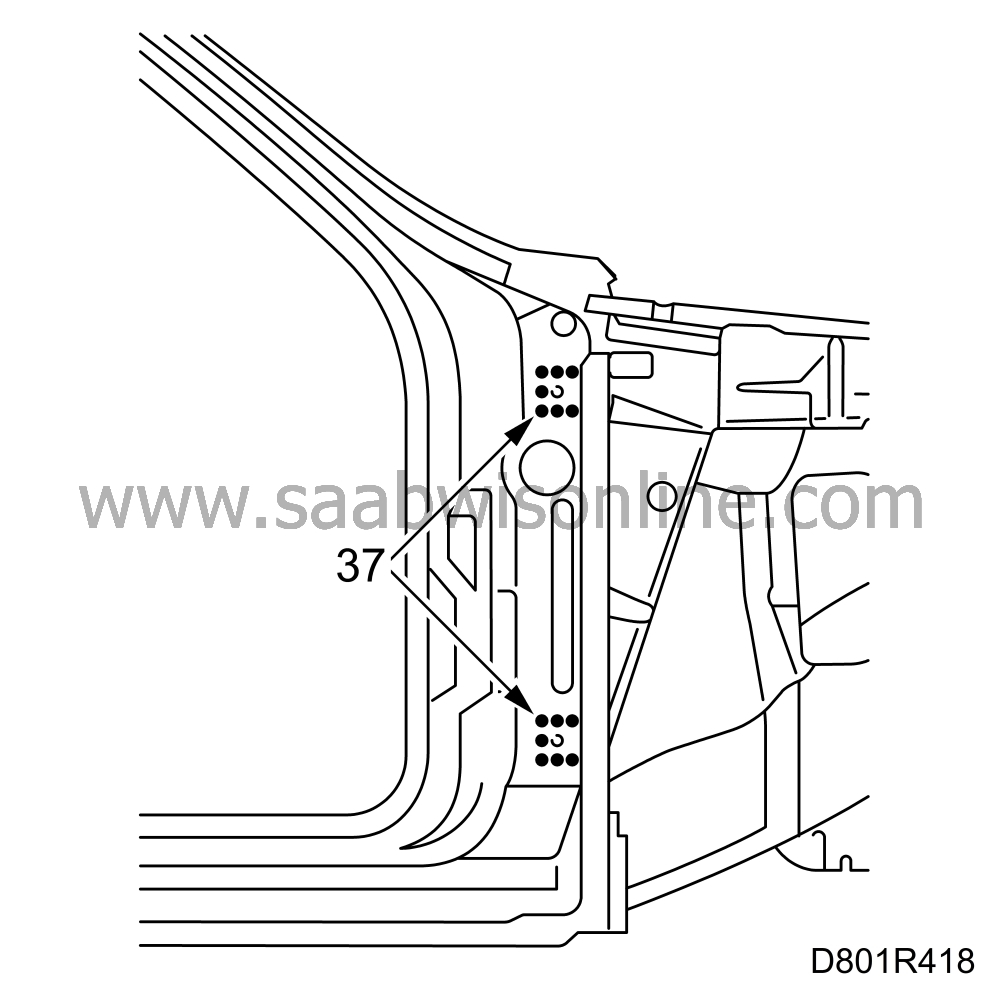

| 7. |

Cut the sill reinforcement at the front. The reinforcement must not be cut at a point further forward than that shown in the illustration.

|

|

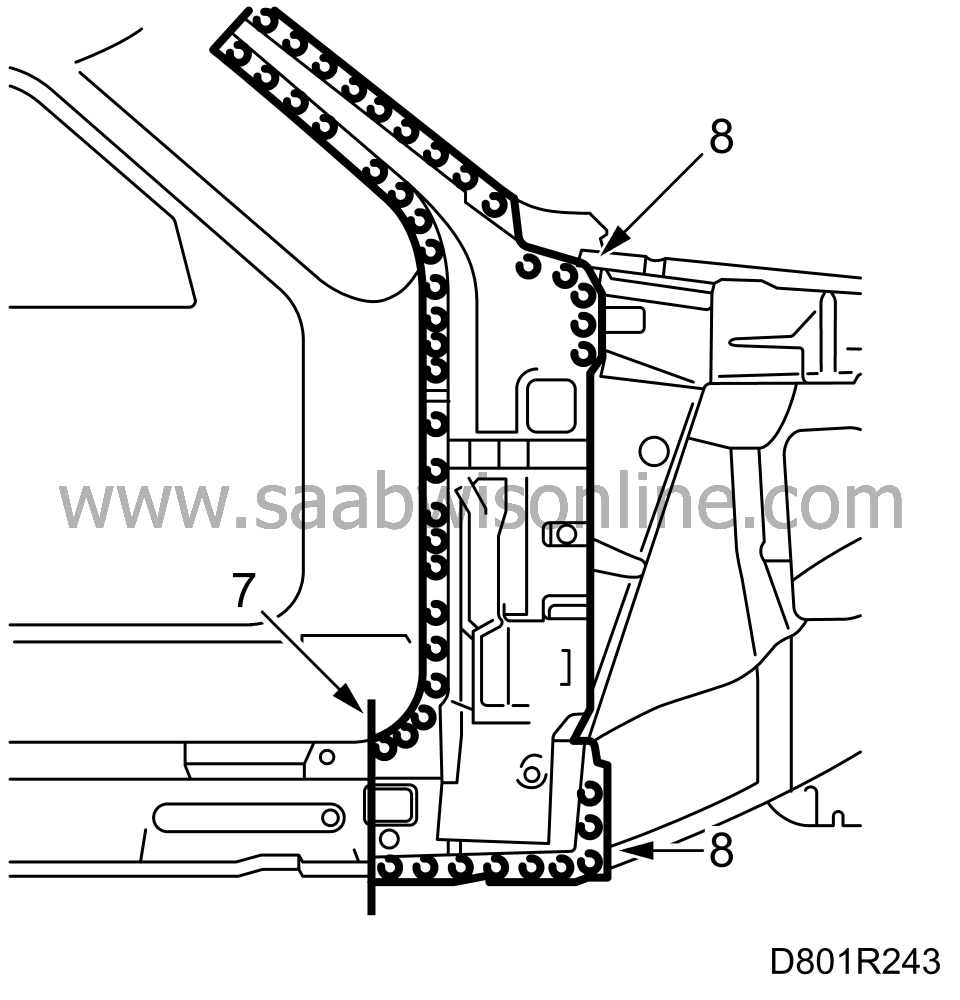

| 8. |

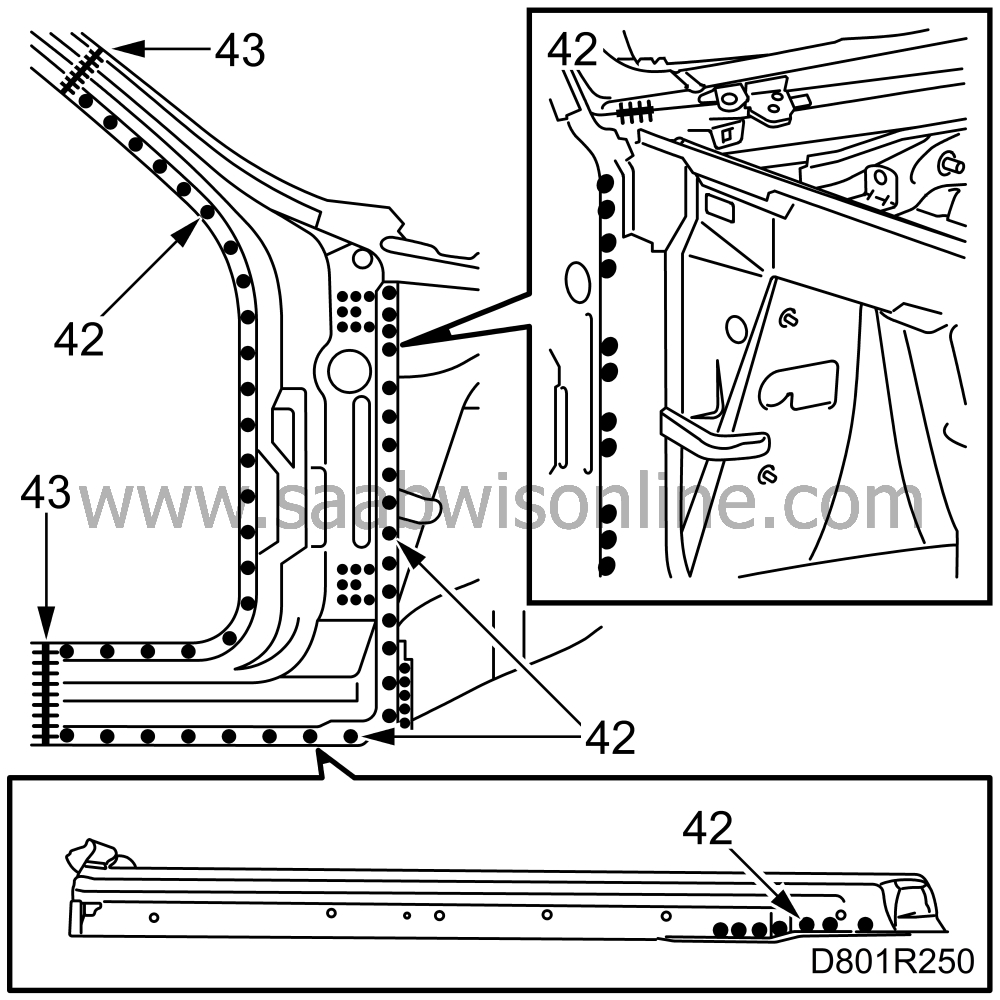

Drill out the spot welds in the upper and lower reinforcement and knock them away.

|

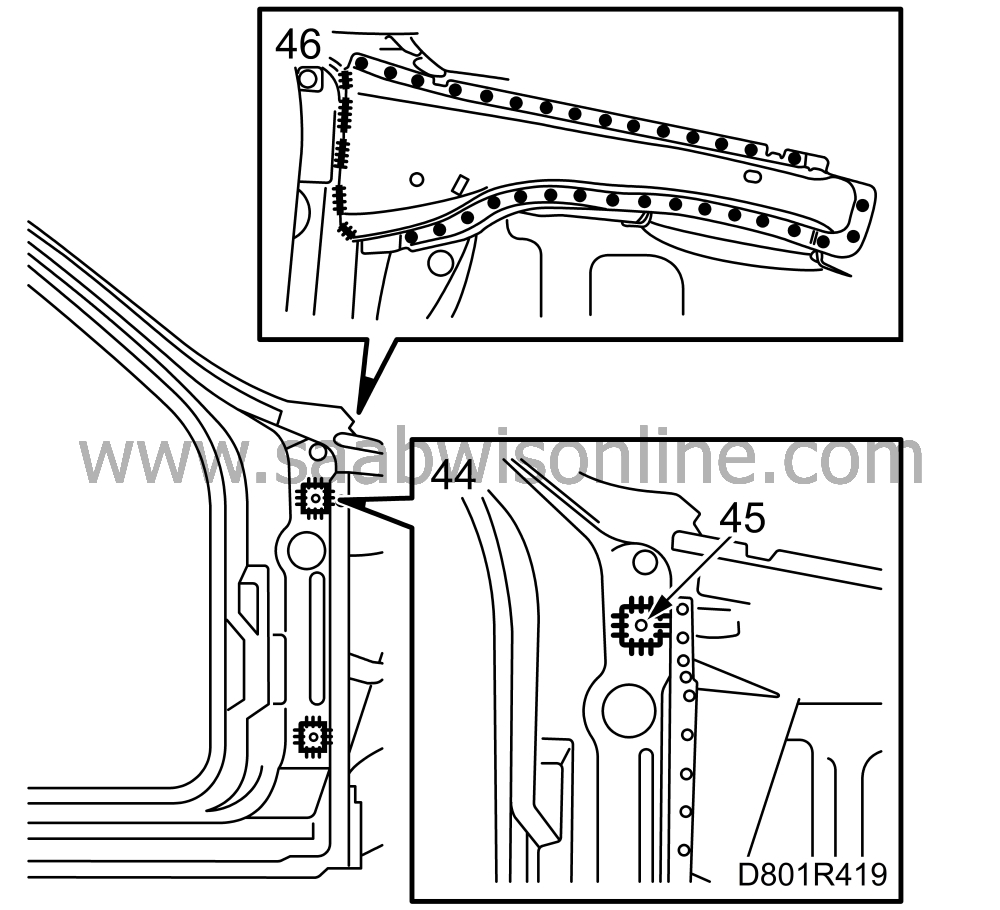

|

| 9. |

Realign any deformed metalwork.

|

|

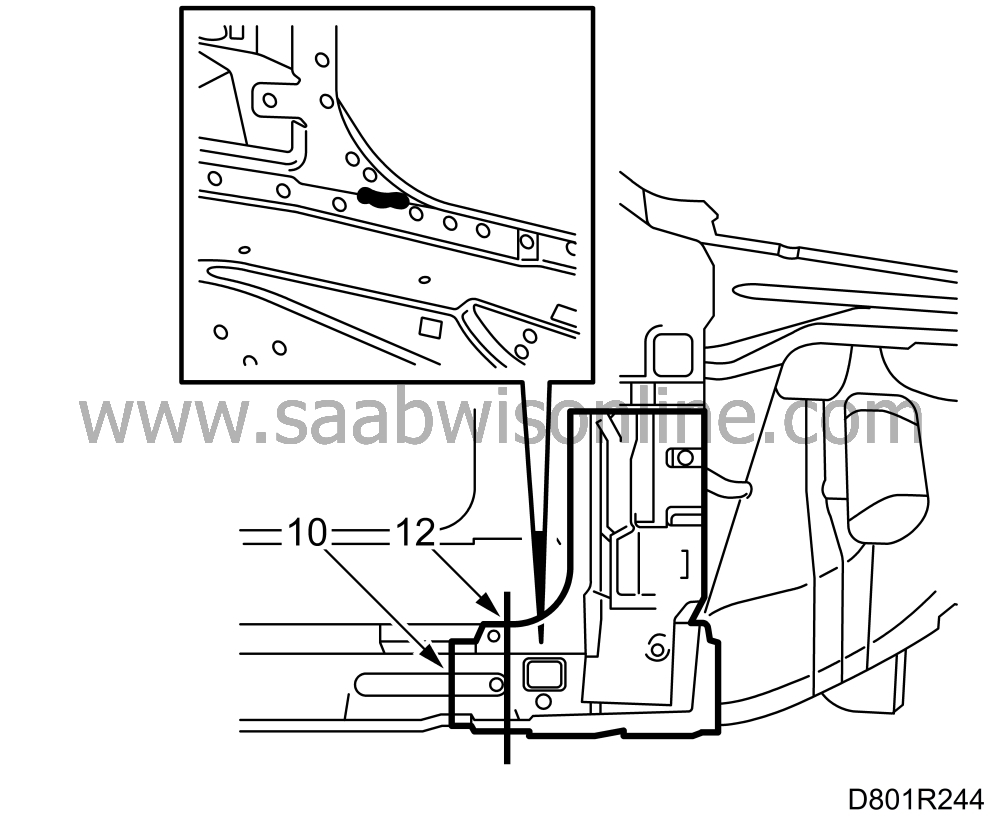

| 10. |

Cut the new sill reinforcement roughly to size so that it will overlap the joint by about three centimetres.

|

|

| 11. |

Fit the new sill reinforcement in position and fix it with a few welding clamps.

|

|

| 12. |

Cut through both the new and the old sill reinforcement simultaneously so that the joint can be welded edge-to-edge.

|

|

| 13. |

Remove the new sill reinforcement. Use a grinder to clean the areas on the reinforcement and body that are to be welded.

|

|

| 14. |

Apply welding primer to the surfaces which are to be spot welded. Use Teroson Zinkspray.

|

|

| 15. |

Position the reinforcement and fix it with a couple of welding clamps.

|

|

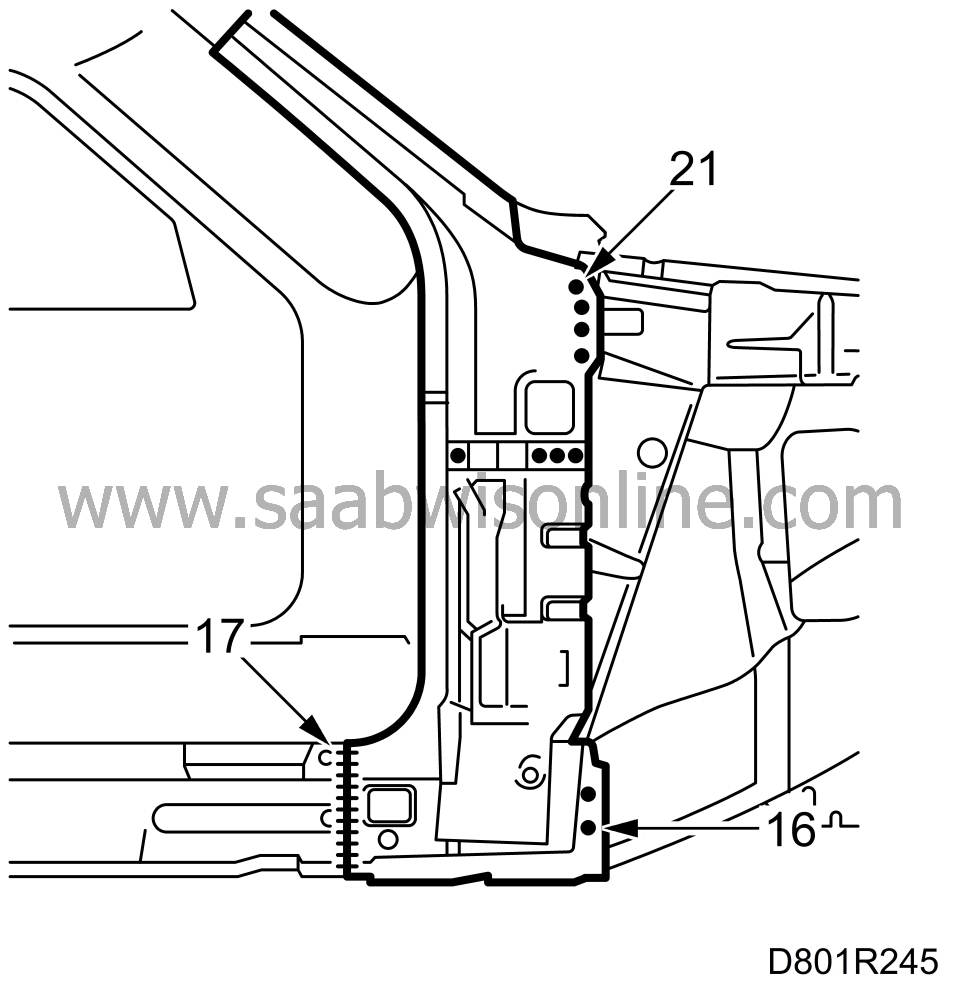

| 16. |

Spot weld the sill reinforcement.

|

|

| 17. |

Weld the joint.

|

|

| 18. |

Use a grinder to clean the areas that are to be welded on the body and the new lower A-pillar reinforcement.

|

|

| 19. |

Apply welding primer to the surfaces which are to be spot welded. Use Teroson Zinkspray.

|

|

| 20. |

Position the A-pillar reinforcement and fix it with a couple of welding clamps.

|

|

| 21. |

Spot weld the A-pillar reinforcement.

|

|

| 22. |

Grind the welds clean.

|

|

| 23. |

Wash off surplus welding primer. Welding primer makes for poorer adhesion of paint, filler and sealant.

|

|

| 24. |

Apply primer to all surfaces that have been ground clean. Use Standox 1K Füllprimer.

|

|

| 25. |

Cut the outer panel spare part roughly to size so that it will overlap the joint by about three cm.

|

|

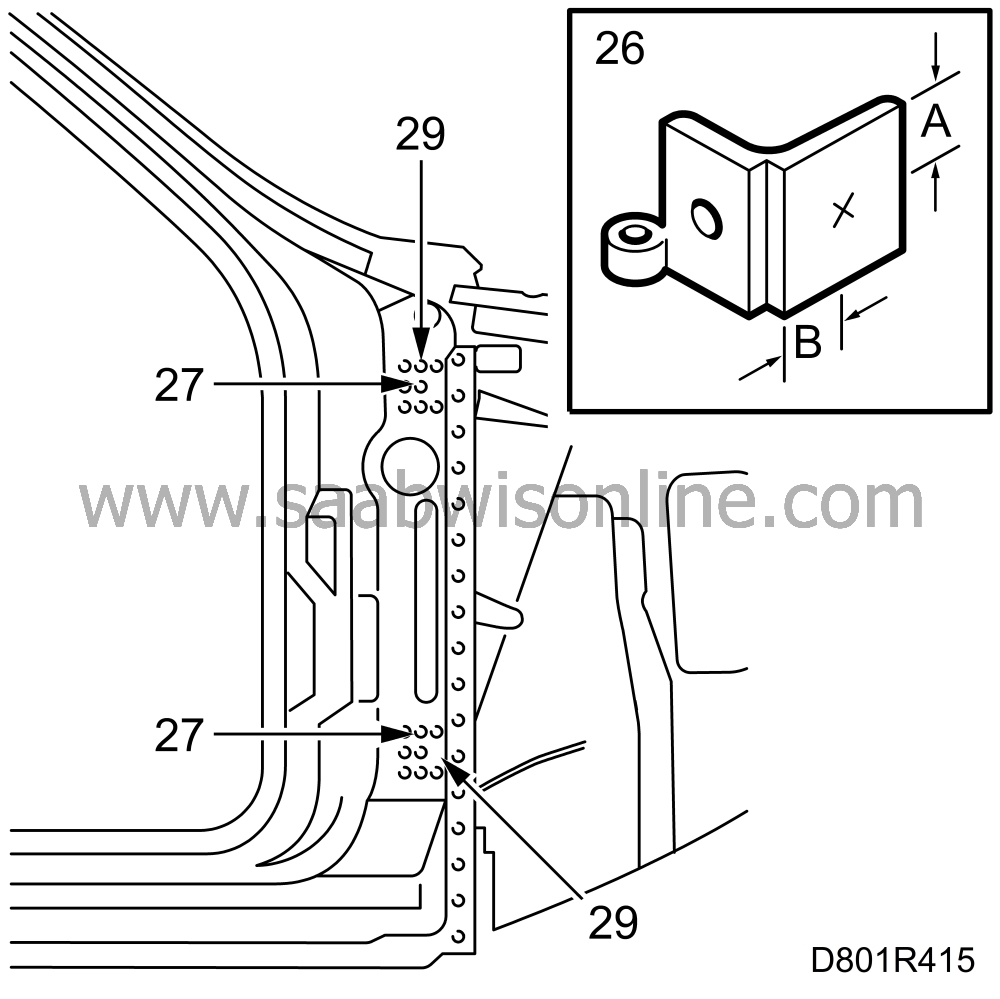

| 26. |

Drill holes in the hinges as shown. Use a 6 mm bit.

Upper hinge: A = 20.0 mm B = 26.6 mm Lower hinge: A = 25.1 mm B = 26.6 mm |

|

| 27. |

Drill holes for the hinge mountings in the outer panel according to the pre-stamped punch marks in the A pillar.

|

|

| 28. |

Attach the hinges on the outer panel with nuts and bolts. Score around the hinge to mark out its position.

|

|

| 29. |

Remove the hinges and drill holes for plug welding in the hinge markings. The outer panel is to be welded to the reinforcement so that the hinges can subsequently be welded to both the outer panel and the reinforcement.

|

|

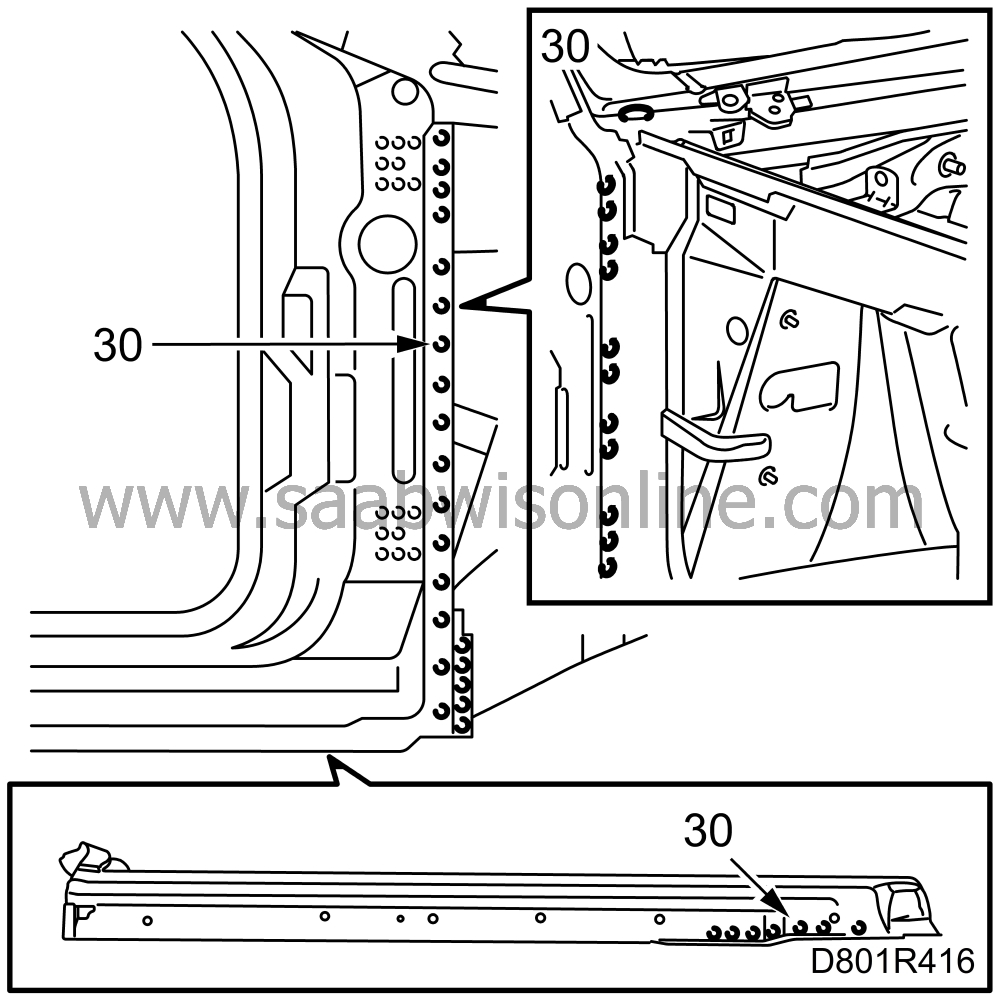

| 30. |

Drill holes for plug welding in the outer panel.

|

|

| 31. |

Use a grinder to clean the areas on the outer panel and body that are to be welded.

|

|

| 32. |

Apply welding primer to the surfaces which are to be spot welded or plug welded. Use Teroson Zinkspray.

|

|

| 33. |

Position the outer panel and fix it with a few welding clamps.

Cut out for the hinges if only the outer panel is to be replaced. If only the outer panel is replaced, proceed to point 42. |

|

| 34. |

Screw the hinges to the A pillar.

|

|

| 35. |

Fit the door, front wing and bonnet in position and adjust the door aperture. Mark the joint position.

|

|

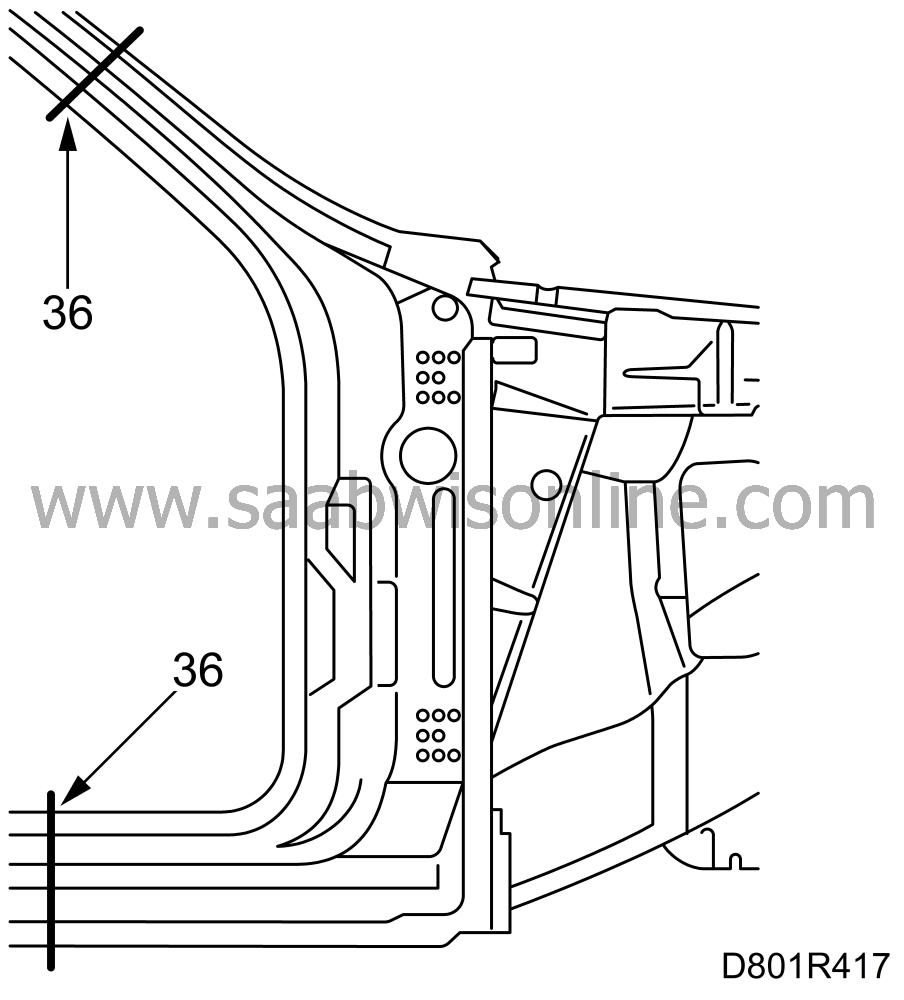

| 36. |

Remove the door, front wing, bonnet and hinges. Cut through the outer panel and body simultaneously at the welding points so that the joints can be welded edge-to-edge.

|

|

| 37. |

Plug weld the outer panel to the reinforcements at the hinge position markings.

|

|

| 38. |

Grind the welds clean.

|

|

| 39. |

Fit the hinges in position and screw them in place.

|

|

| 40. |

Fit the door, front wing and bonnet in place and adjust the hinges to their exact positions.

|

|

| 41. |

Secure the hinges with a couple of tack welds and remove the door.

|

|

| 42. |

Fit the outer panel in place, securing it with spot welds and plug welds.

|

|

| 43. |

Weld the joints on the A pillar and sill.

|

|

| 44. |

Weld the hinges in place.

|

|

| 45. |

Remove the nuts and bolts and weld up the holes in the hinges.

|

|

| 46. |

Weld the reinforcement to the outside of the wheel housing.

|

|

| 47. |

Grind the welds clean.

|

|

| 48. |

Wash off surplus welding primer. Welding primer makes for poorer adhesion of paint, filler and sealant.

|

|

| 49. |

Apply primer to all surfaces that have been ground clean. Use Standox 1K Füllprimer.

|

|

| 50. |

Seal joints and metal folds with putty. Use Terostat 1K-PUR.

|

|

| 51. |

Apply anti-corrosion agent to inside surfaces after painting. Use Terotex HV 400 or Mercasol 1.

|

|