Upper A pillar outer panel (conv.)

|

|

Upper A pillar outer panel (conv.)

|

|

1.

|

Mount the car in an alignment bench with measuring fixture and cross-measure as necessary.

|

|

2.

|

Roughly cut the top of the outer panel on the A pillar, 150 mm from the edge of the windscreen frame.

|

|

3.

|

Grind down the continuous weld securing the outer panel of the A pillar to the windscreen member.

|

|

4.

|

Cut the outer panel around the upper hinge.

|

|

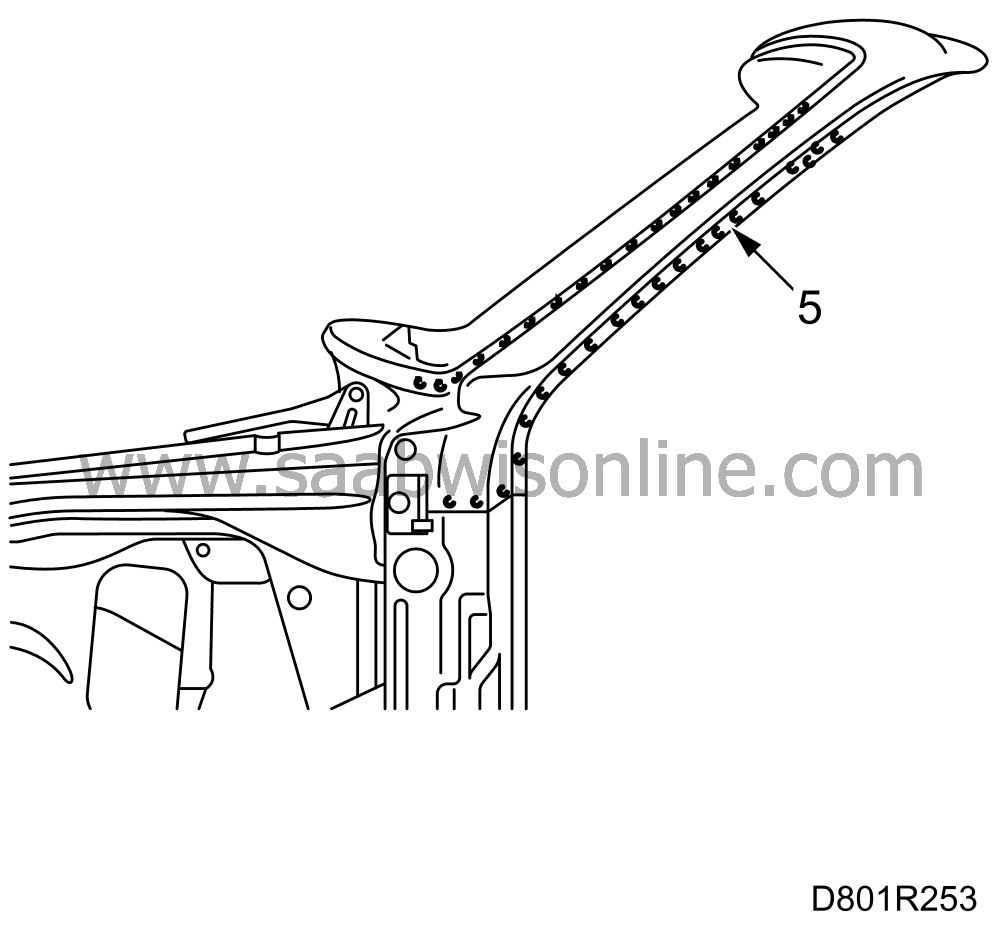

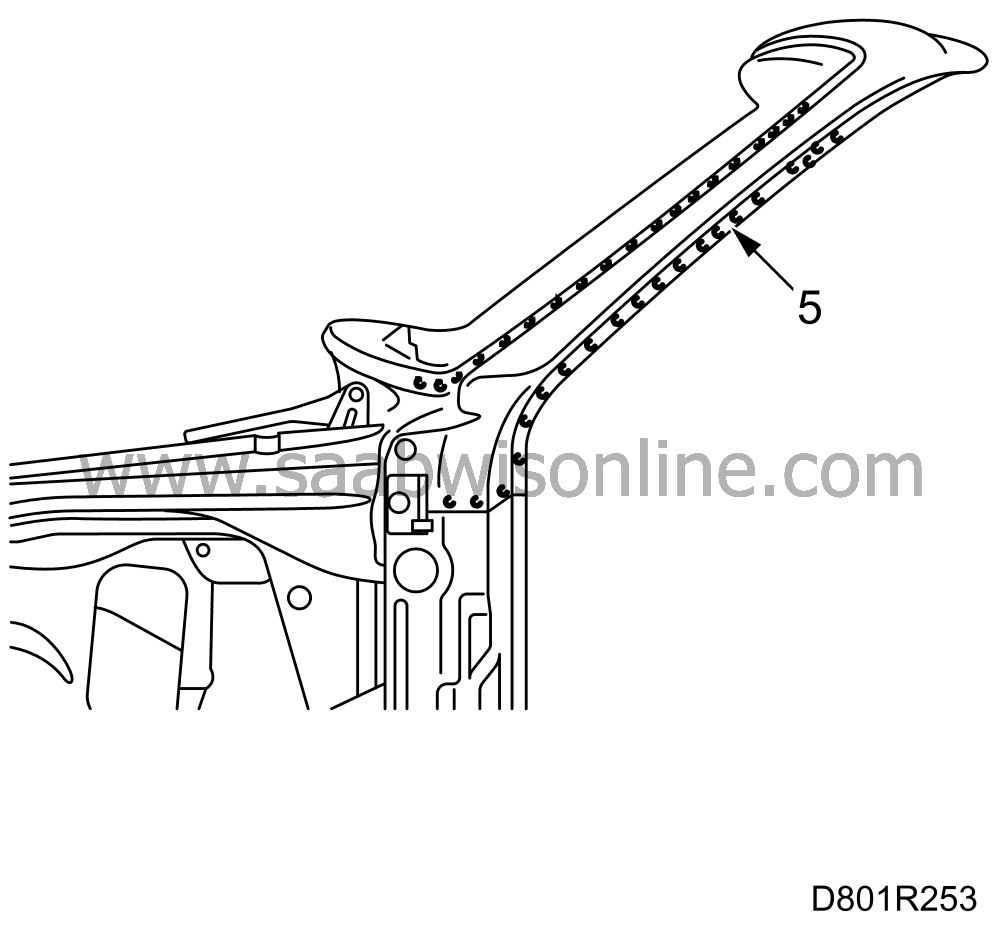

5.

|

Drill out the spot welds securing the outer panel of the A pillar.

|

|

6.

|

Knock away the outer panel of the A pillar and align any deformed metal.

|

|

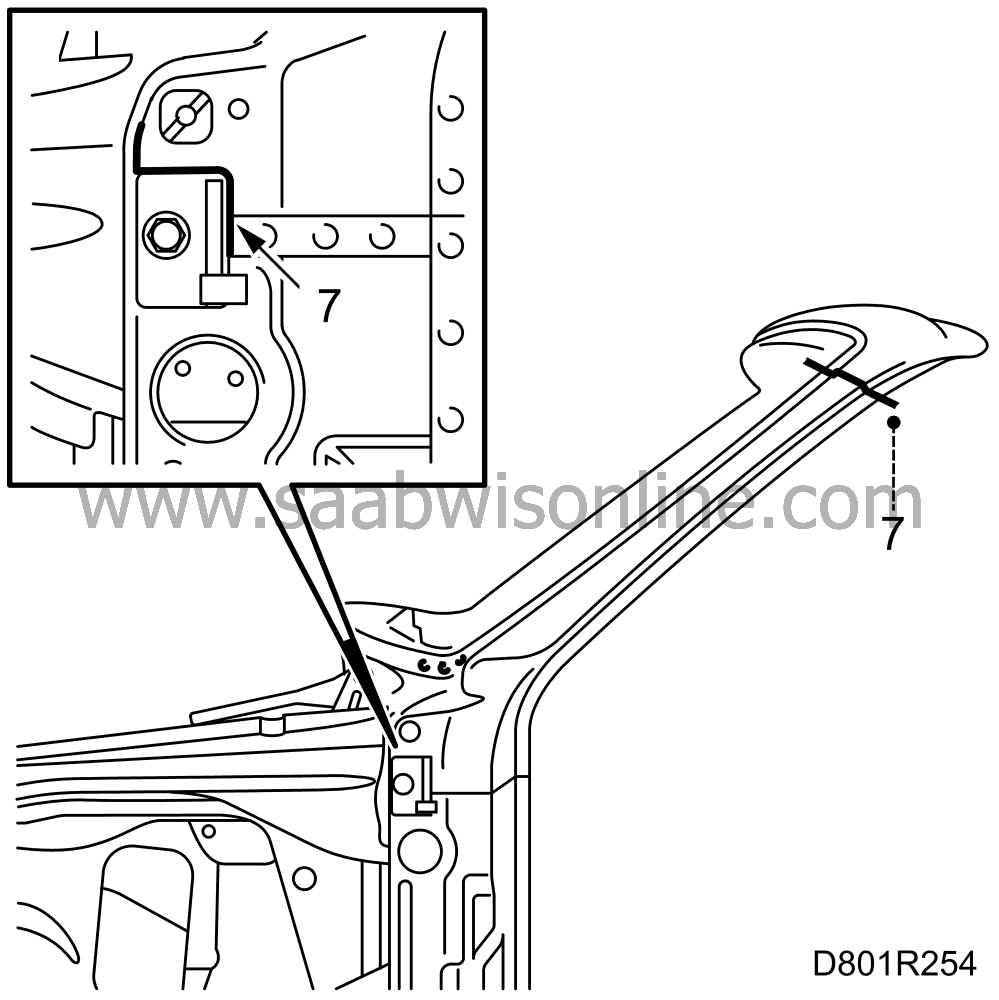

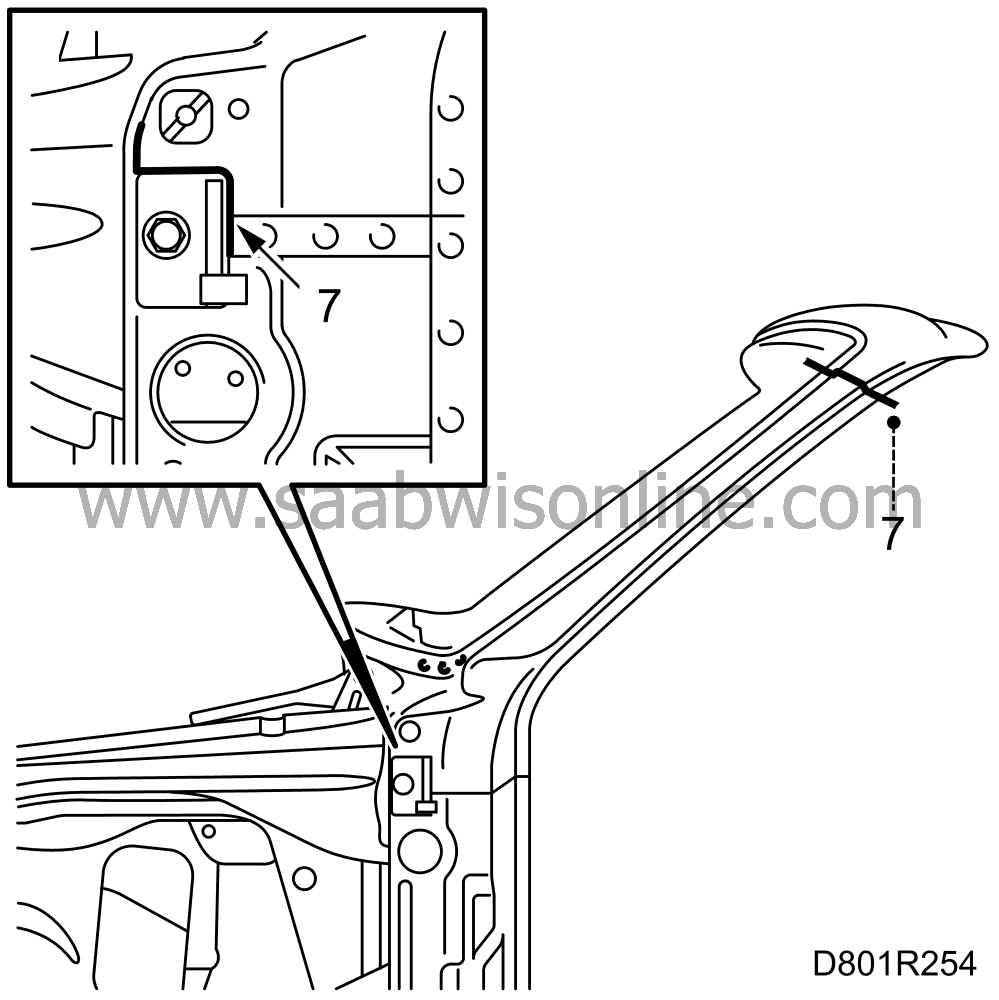

7.

|

Cut and position the new outer panel on the A pillar.

|

|

8.

|

Rub down the areas on the outer panel and body that are to be welded so they are clean.

|

|

9.

|

Apply welding primer to the surfaces to be plug and spot welded. Use Teroson Zinkspray.

|

|

10.

|

Put the outer panel in position on the body and fasten it with a few welding clamps.

|

|

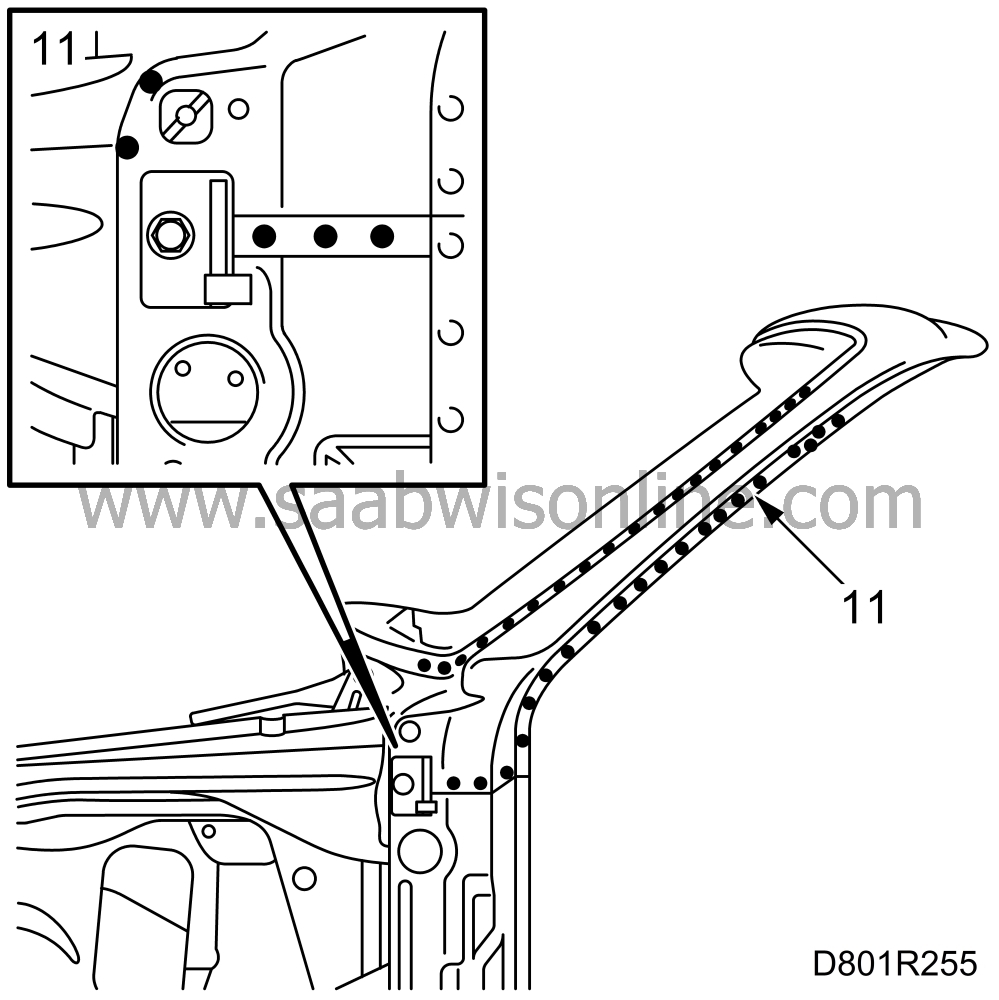

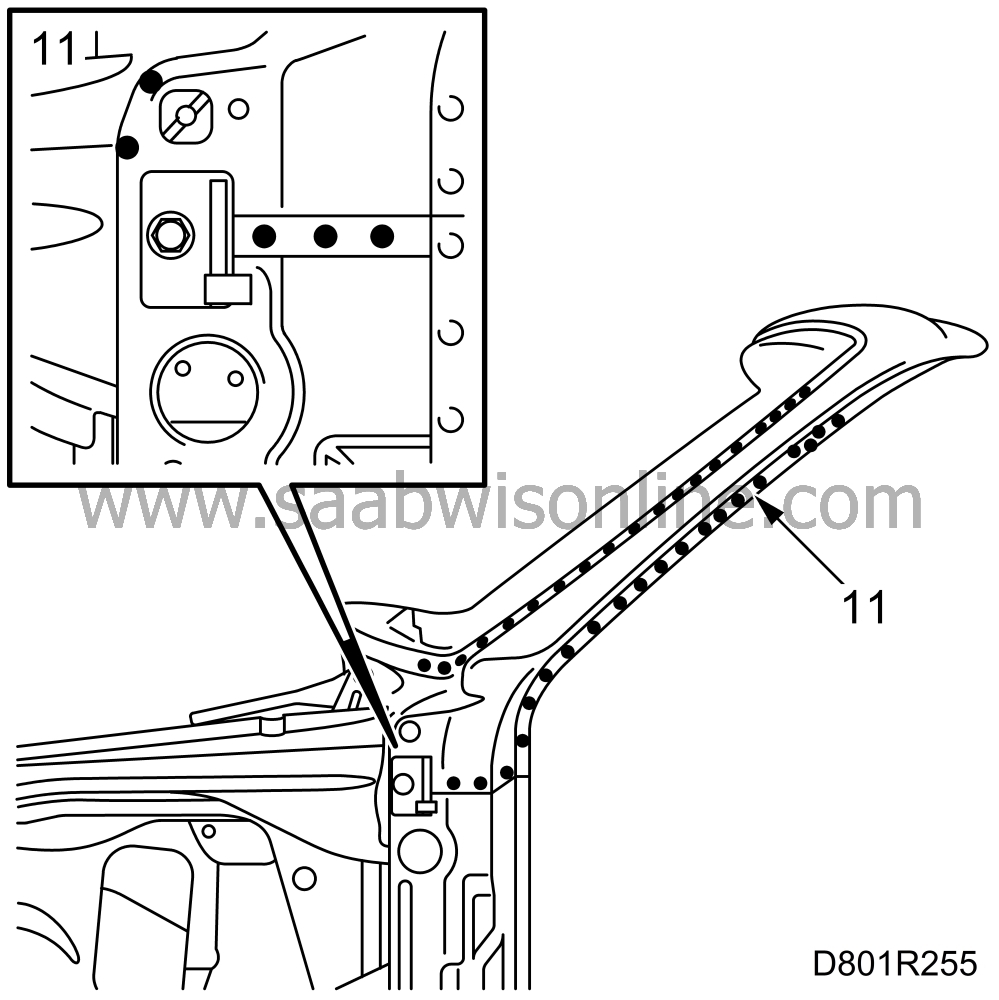

11.

|

Fasten the A pillar outer panel to the reinforcement, securing it with plug welds and spot welds.

|

|

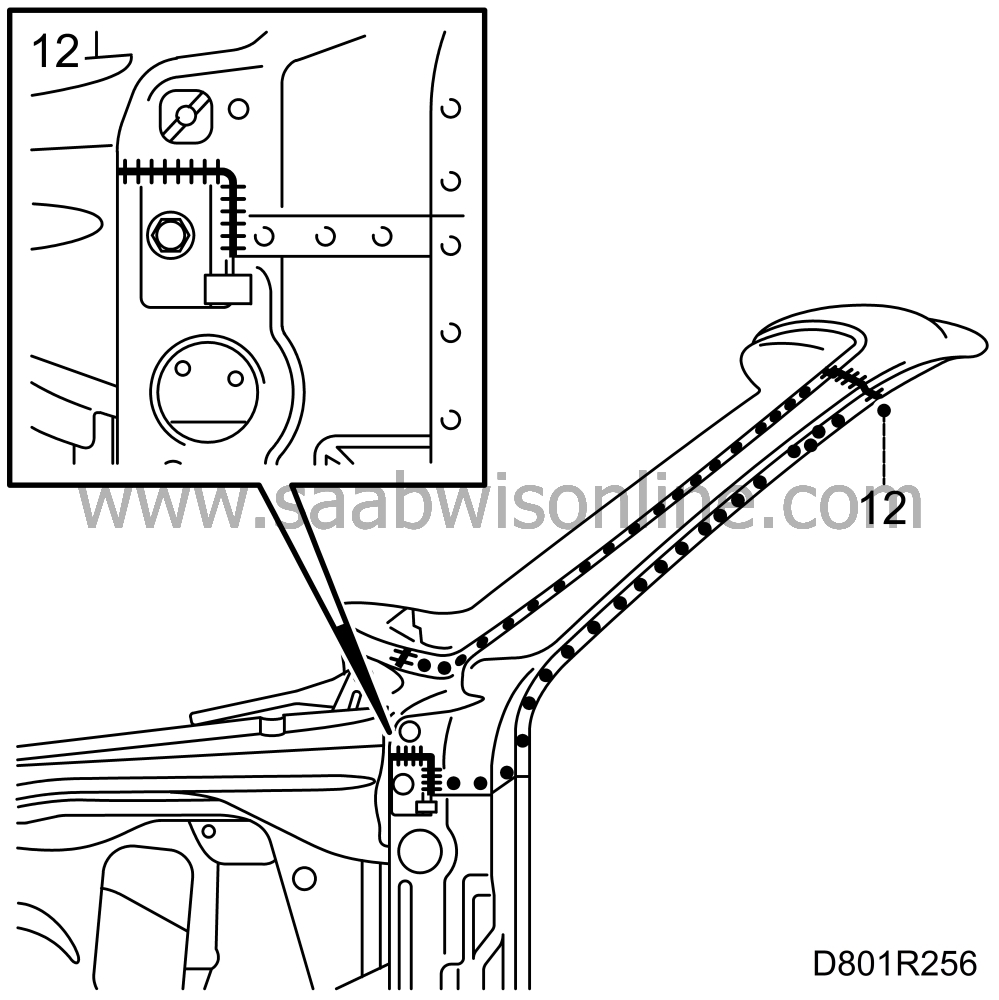

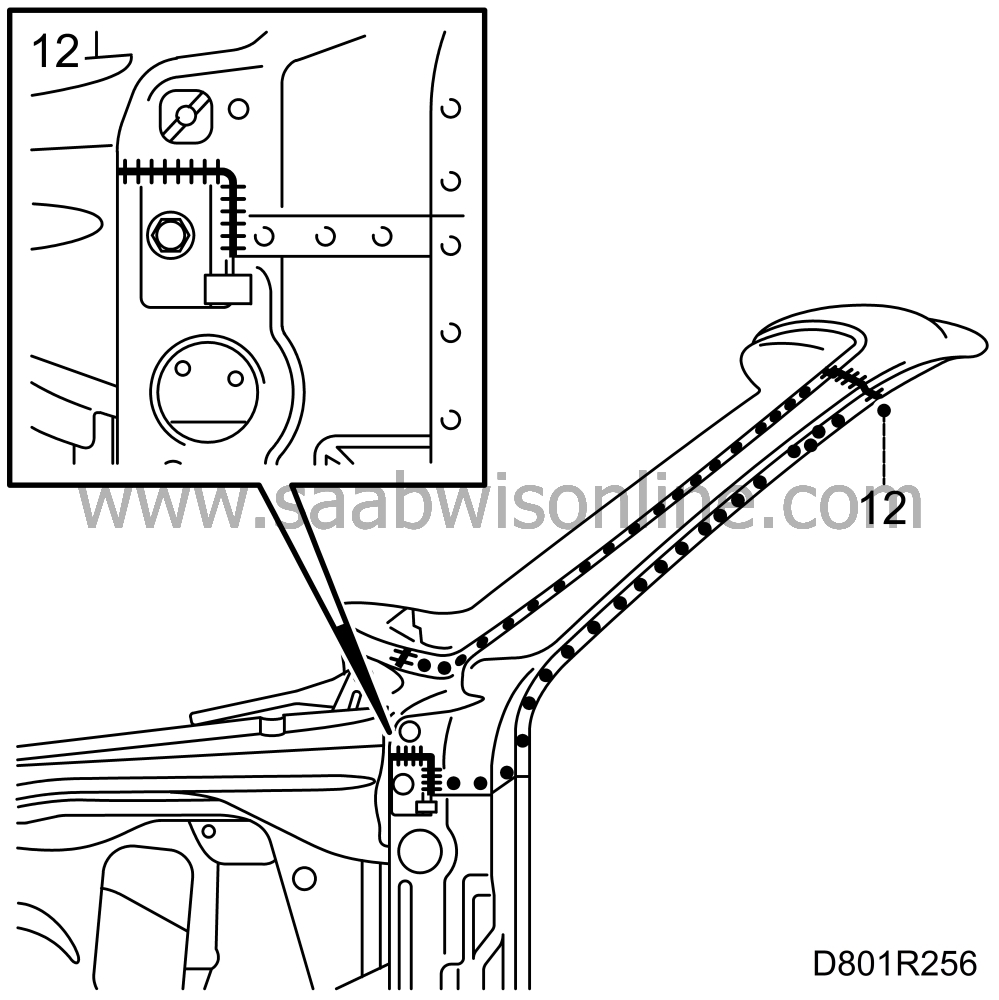

12.

|

All-weld the joint at the upper end of the A pillar and around the upper hinge.

|

|

13.

|

Grind the welds clean.

|

|

14.

|

Wash off surplus welding primer. Welding primer makes for poorer adhesion of paint, filler and sealant.

|

|

15.

|

Apply primer to all surfaces that have been ground clean. Use Standox 1K Füllprimer.

|

|

16.

|

Seal joints and metal folds with putty. Use Terostat 1K-PUR.

|

|

17.

|

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400.

|