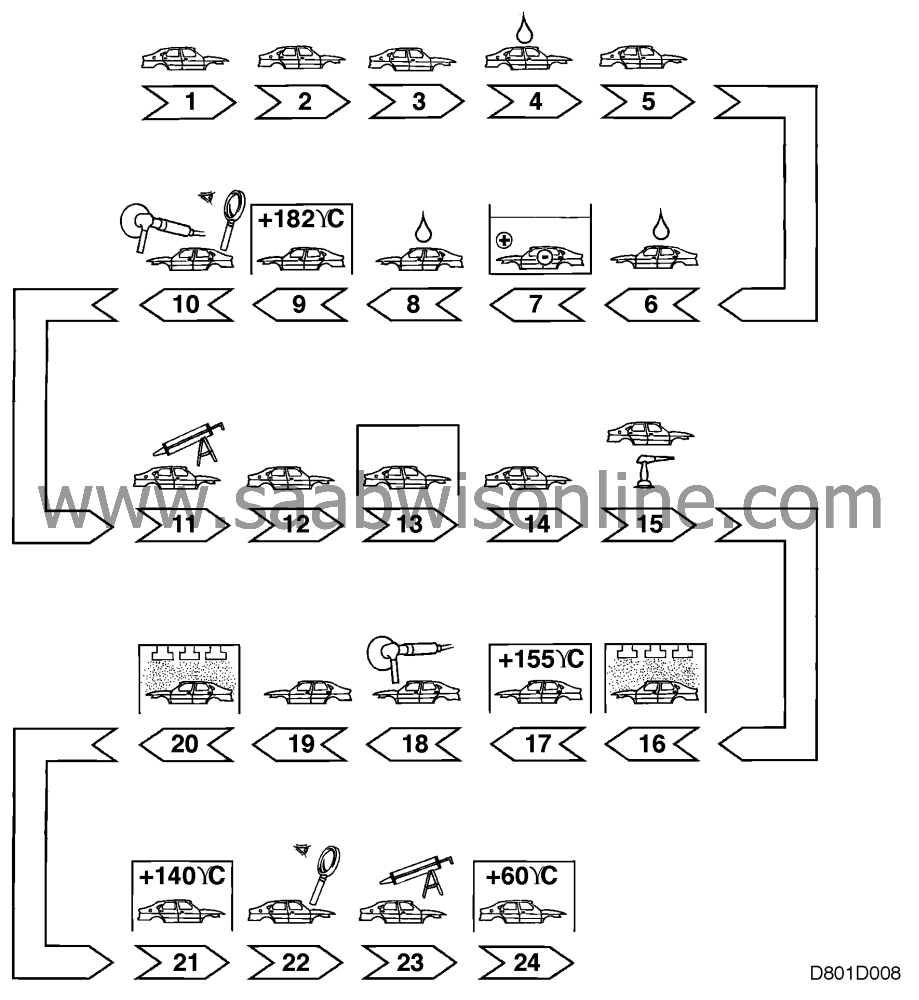

The surface treatment process

|

|

The surface treatment process

|

Corrosion protection measures are begun as early as in the

body shop. Galvanized sheet metal is used for those parts of the car

body that are most exposed to corrosive attacks. See also page

800Ä15.

|

1.

|

Cleaning

the body shell from the body shop.

When the

body shell arrives at the paint shop it goes through an initial coarse

cleaning process. Here all the filings, etc. left over from the

mechanical machining processes are removed as well as most of the oil

and grease that the body has picked up in the body assembly shop.

|

|

2.

|

Degreasing

To obtain as good a foundation as

possible for the subsequent surface treatment, the remaining oil and

grease is removed from the body by means of an alkali degreasant.

|

|

3.

|

Phosphatizing

Phosphatizing gives basic

corrosion

protection as well as a good foundation for the primer.

|

|

4.

|

Rinsing

The body is rinsed to flush away the

remnants

of the phosphatizing process.

|

|

5.

|

Passivation

A chromiferous solution is sprayed

over the

body. This densifies the phosphate layer and so further increases

corrosion protection efficiency.

|

|

6.

|

Rinsing

The body is rinsed with desalinized

water.

|

|

7.

|

Cathodic electrodip (ED)

The body is submersed

in a

bath of anti-corrosion paint and a negative electric charge is applied to the body. The

positively charged paint particles are then attracted to the body in the same way as iron filings

are attracted to a magnet. A layer of

anti-corrosion paint is thus deposited on the entire body surface,

including almost inaccessible places in cavities, joints and the like.

|

|

8.

|

Rinsing

After the ED bath, the body is dipped

and

rinsed clean of surplus paint particles.

|

|

9.

|

Oven drying

The paint from the ED bath dries in

17

minutes at a temperature of +182°C.

|

|

10.

|

Inspection and grinding

Any specks of dust and

paint runs are removed.

|

|

11.

|

Sealing

Seams, folds, joints, etc. are sealed with

PVC

sealing compound throughout the body. The purpose of this is chiefly to

prevent moisture from getting in but the sealant also has a sound- absorbing effect.

|

|

12.

|

Sound absorbing material

Sound absorbing

material is

affixed at strategic points in the body to reduce resonant noise.

|

|

13.

|

Oven drying

The body passes through an IR

oven to

harden the sealant. The sound absorbing material also softens and

shapes itself to the contours of the bodywork.

|

|

14.

|

Cleaning

Dust is removed from the body.

|

|

15.

|

Undersealing

Stone damage protection

compound and

underseal are applied to all bottom pan and wheel arch surfaces.

|

|

16.

|

Undercoat

The undercoat constitutes a good

foundation

for the finish paint as regards both adhesion and appearance. In

addition, it provides additional corrosion protection in that it

affords good protection against stone damage. The paint is applied by means of industrial

robots equipped with rotary spray nozzles. When they rotate, a fine mist of paint is formed

which migrates to the body and settles on it as an extremely even layer of paint. Inside

surfaces which are hard to reach are painted manually.

|

|

17.

|

Oven drying

The undercoat is oven-dried for 32

minutes

at a temperature of +155°C.

|

|

18.

|

Grinding

Any specks of dust and paint runs

rubbed down.

|

|

19.

|

Cleaning

Grinding dust and other foreign

particles are

removed from the body so that it is absolutely clean before the finish

paint is applied.

|

|

20.

|

Finish paint

Just like the undercoat, the finish

paint

is applied by means of industrial robots equipped with rotary spray

nozzles. Metallic paint is applied in two layers. First a thin layer with a high pigment content

and then a thick layer of clear transparent enamel

which protects the pigment and lends a high gloss to the finish

paint.

|

|

21.

|

Oven drying

The finish paint is oven-dried at a

temperature of +140°C.

|

|

22.

|

Final inspection

After painting the body is

carefully

inspected. If any paint runs, scratches, specks of dust or other

imperfections are found, the body is sent to be touched up before

proceeding to the next station.

|

|

23.

|

Anti-corrosion treatment

Penetrating cavity wax

is

sprayed into the cavities in sills, reinforcement members, etc.

|

|

24.

|

Oven

The body is heated up to +60°C for 15

minutes so

that the cavity wax will spread out as much as possible in the cavities.

|