Detecting leaks in the EVAP system

|

SERVICE INFORMATION

|

|

Bulletin Nbr:

|

234-1746 ed. 2

|

|

Date:

...........

|

November 1997

|

|

Market:

|

US only

|

|

|

Detecting leaks in the EVAP system

|

Saab 900 M96-97 with EVAP II.

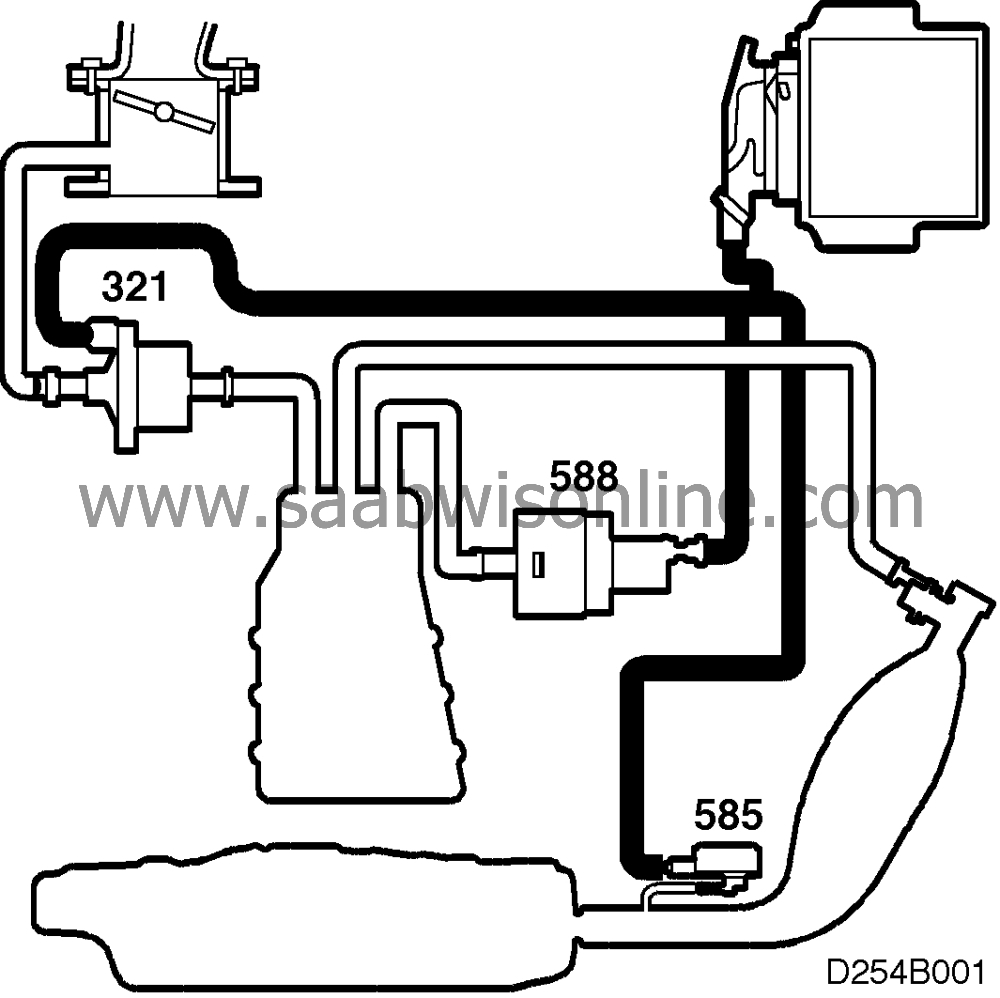

The leak detector is introduced to make it easier to locate small leaks in the EVAP system like cracks in hoses or cracked canister.

The leak detector should also be used to diagnose cars which have failed the I/M 240 test.

|

1.

|

Check that the pressure tester is in good condition and not leaking.

|

|

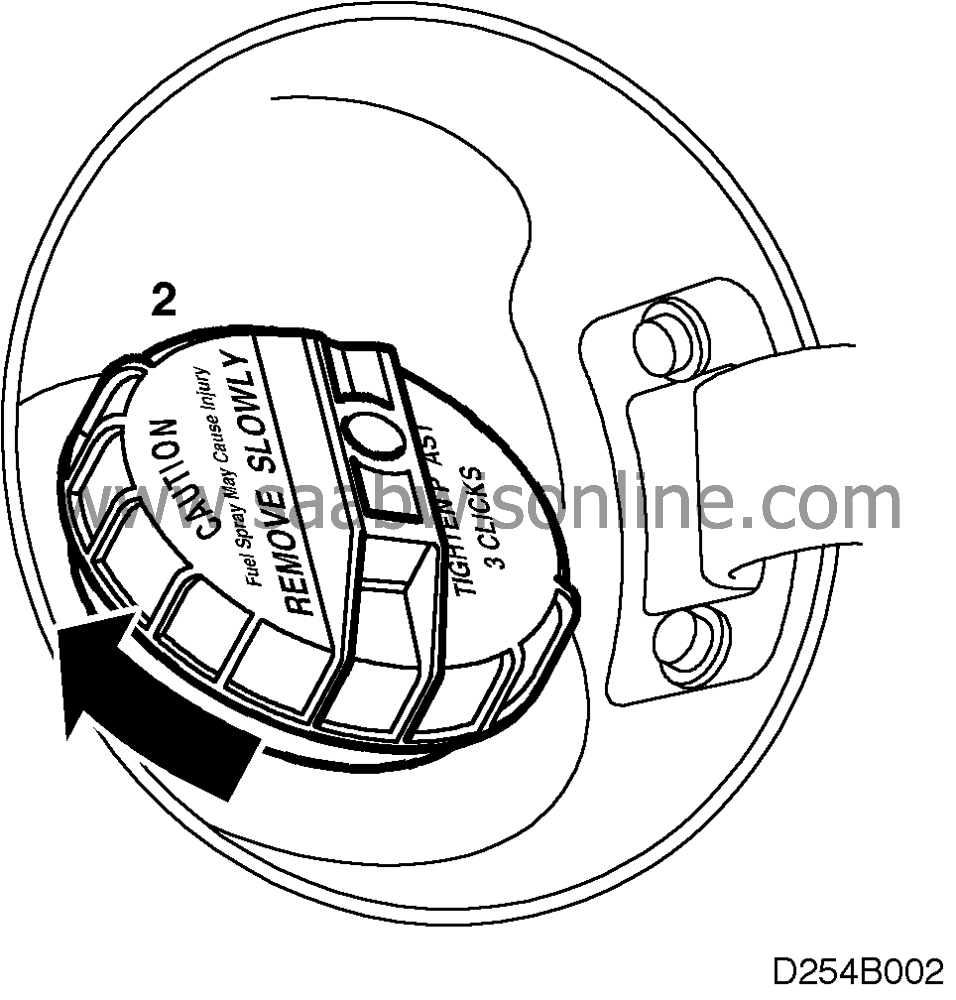

2.

|

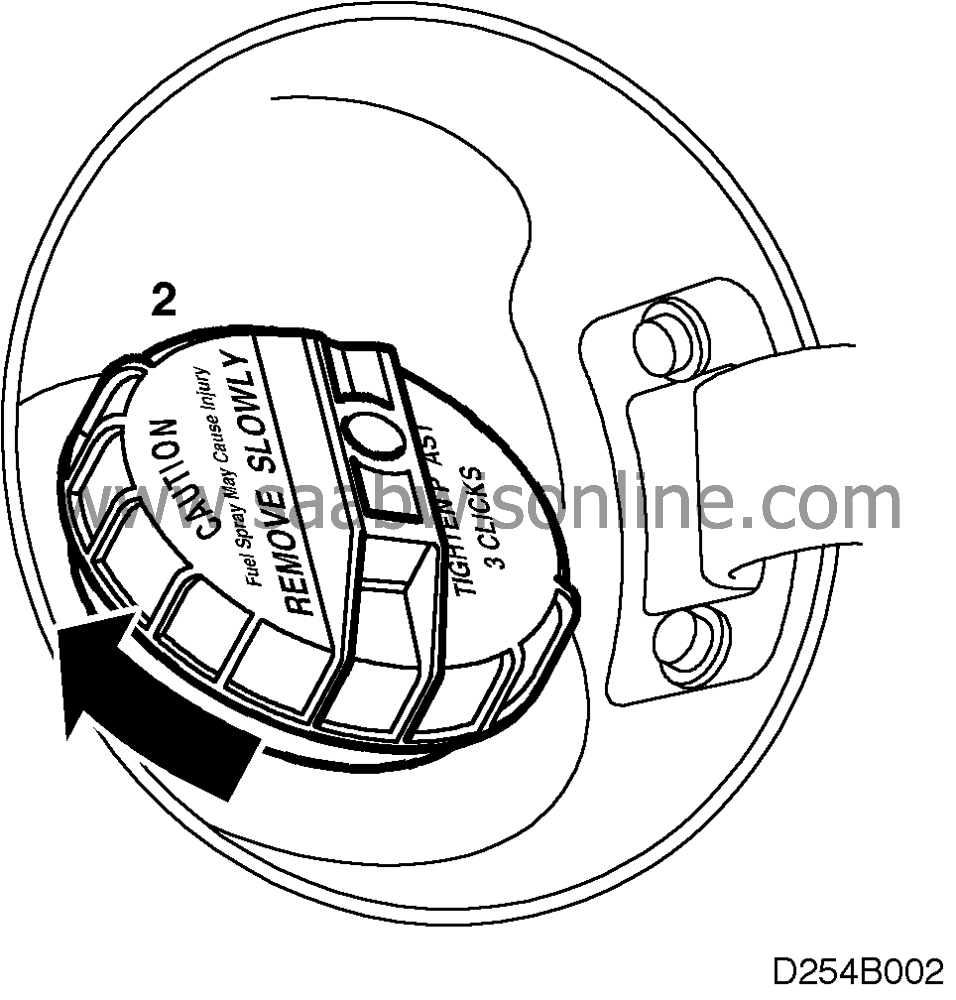

Check that the filler cap is on tight.

|

|

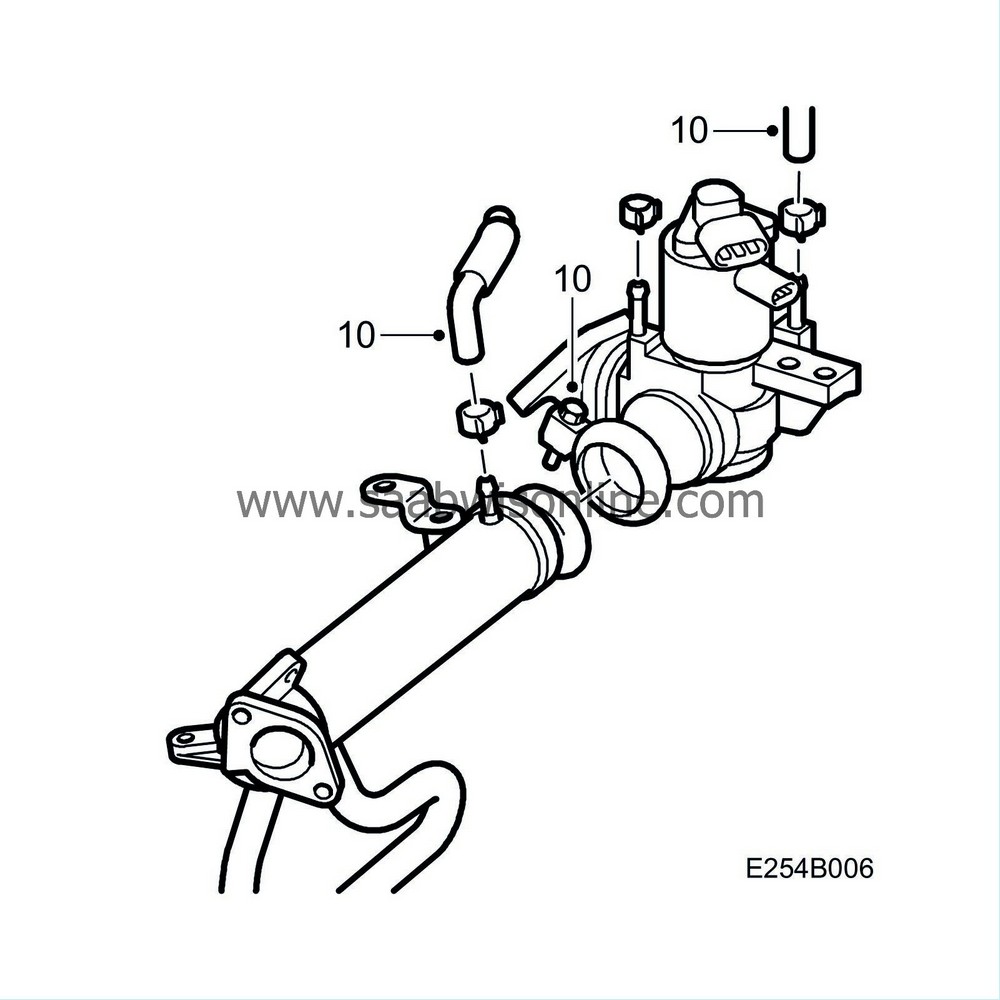

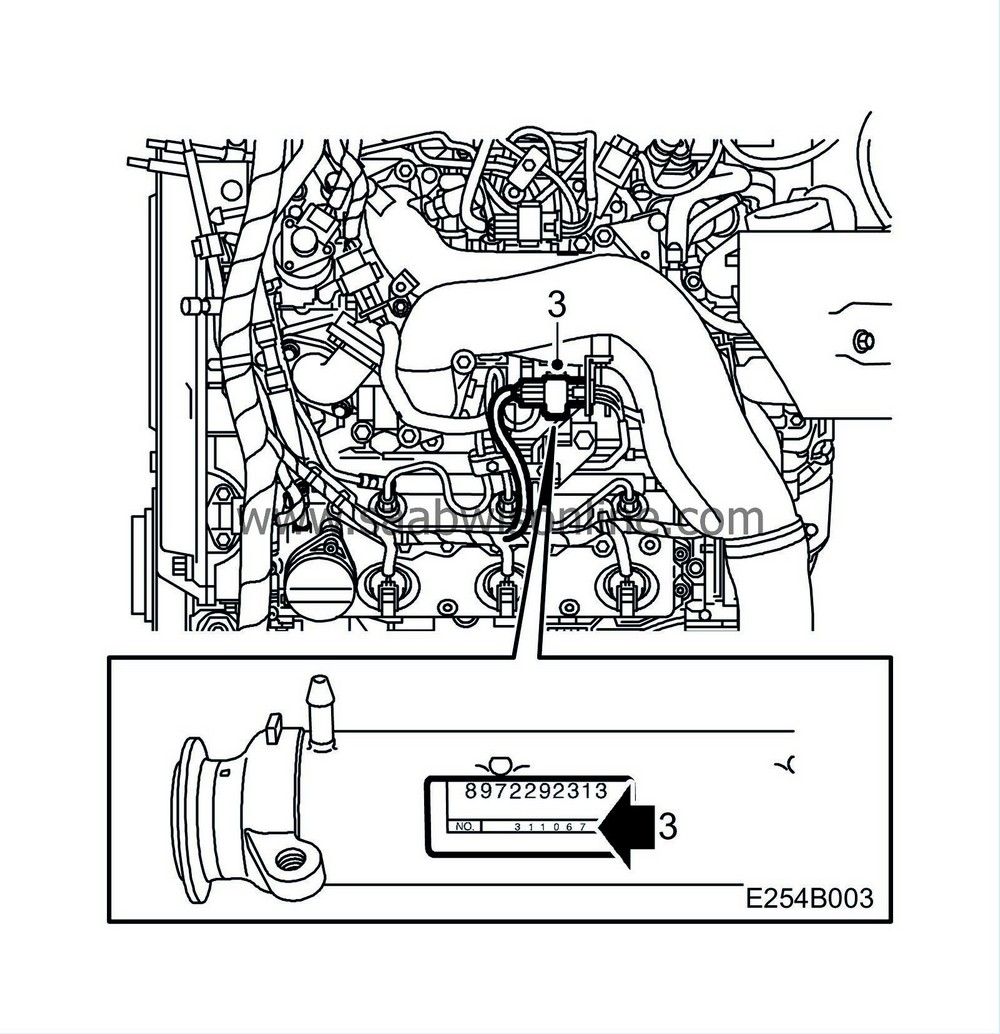

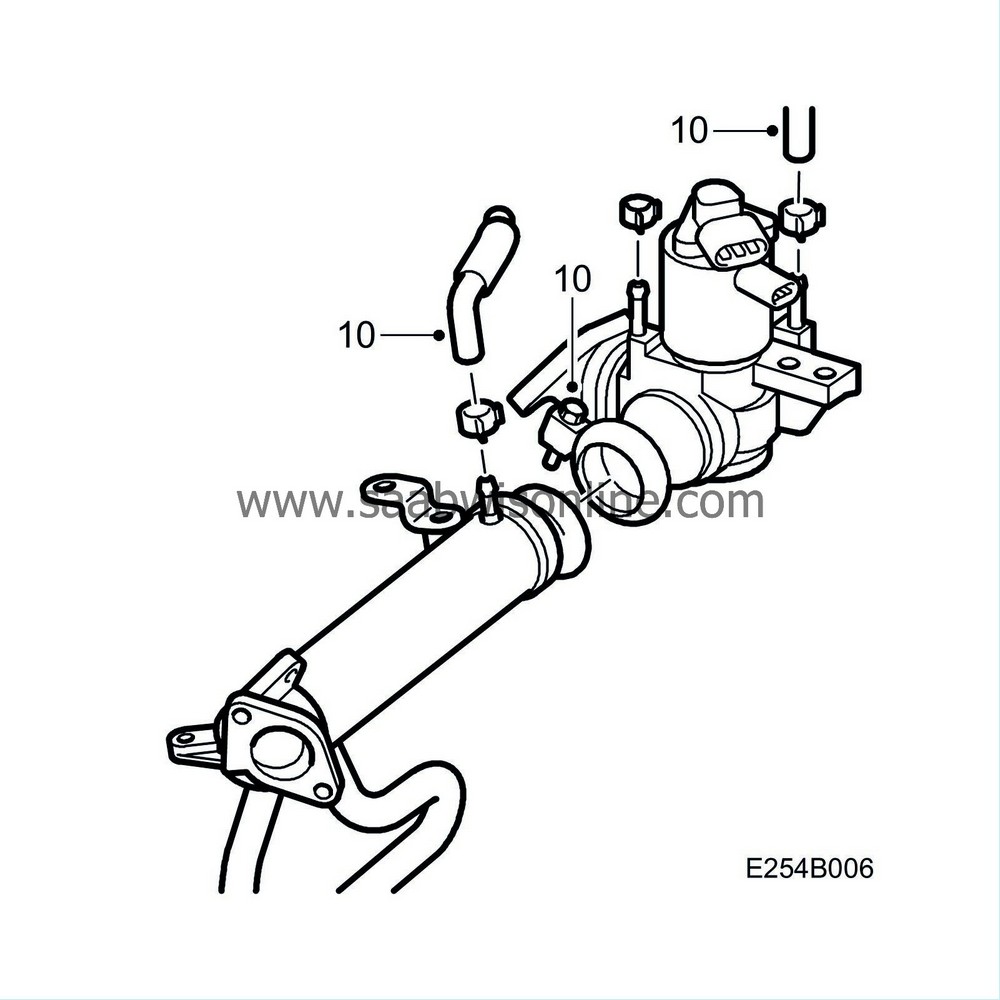

3.

|

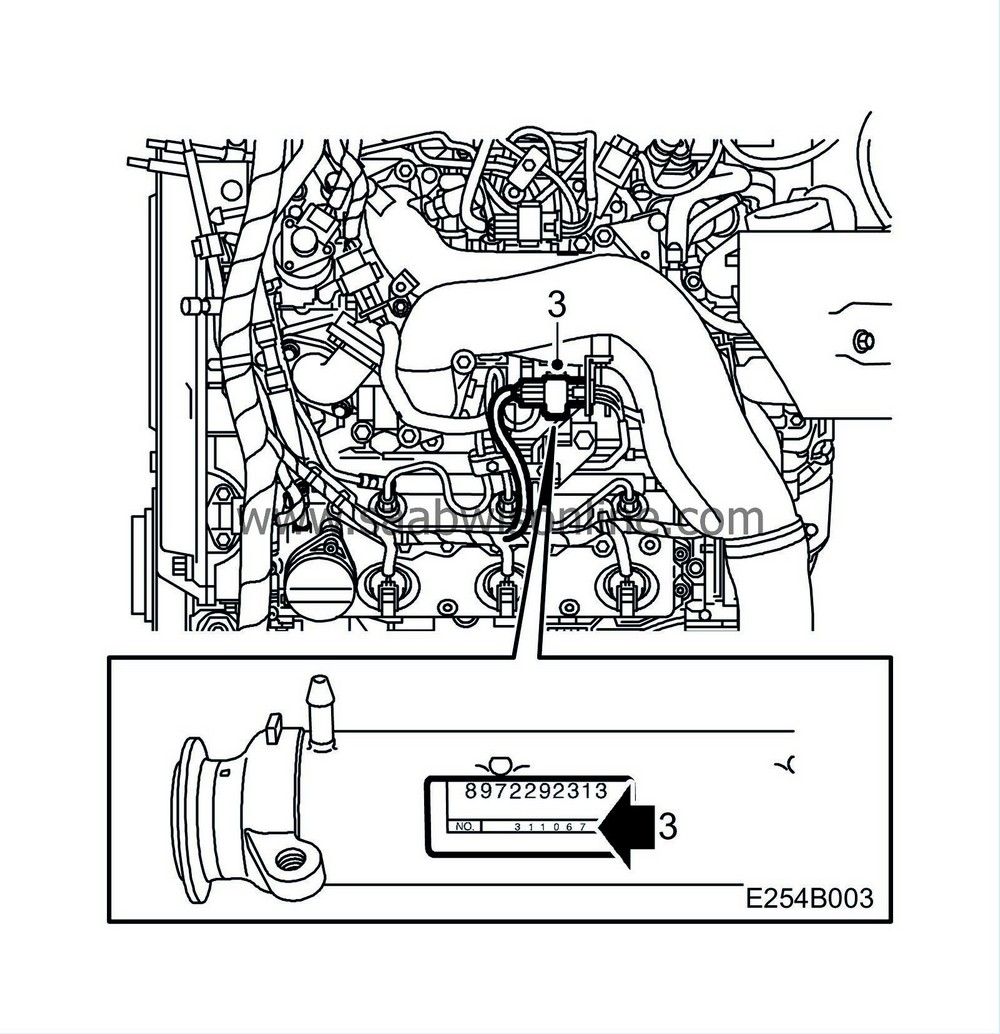

Using e.g. a ’T’ piece, connect pressure tester J41413 between the inlet on the EVAP canister purge valve and the hose.

|

Note

|

|

Do not fit the pressure tester adaptor to the filler cap connection, as this would prevent the filler cap from sealing in its normal position.

|

|

|

4.

|

Activate the EVAP canister shut-off valve by connecting battery voltage to the valve (male connector on M96).

|

|

5.

|

Pressurize the system and perform the pressure test, following the instructions in the Kent-Moore manual.

|

|

Action to be taken if leak detected

|

|

1.

|

Ensure that the shut-off valve is still energized.

|

|

2.

|

Disconnect the hose from the EVAP canister purge valve at the intake manifold.

|

Note

|

|

A leaking purge valve will

not

cause error code P0442 or P0445, but can make the system fail I/M 240.

|

|

|

3.

|

Raise the pressure again, following the instructions in the Kent-Moore manual.

|

|

4.

|

Use ultrasonic leak detector J41416 to trace the leak. Start with the hose that has been disconnected from the intake manifold and then follow the system lines and components. Make a visual check of the system at the same time.

|

Note

|

|

The ultrasonic leak detector is sensitive to ambient noise in the workshop, such as that made by exhaust-extraction equipment, compressors, air guns, air leaks from pneumatic equipment, etc.

|

|

Air flows from the ventilation equipment in the workshop can also create interference to the ultrasonic detector.

|

|

All such noise and interference can give rise to spurious readings indicating leaks in the EVAP system, even when there are none.

|

Always, therefore, adjust the sensitivity of the ultrasonic leak detector, so that the ambient noise, which often causes interference, is filtered out.

|

Note

|

|

Major leaks, such as those caused by a defective canister shut-off valve or a loose hose connection, are difficult to detect, as the noise generated by them is usually outside the sensitivity range of the ultrasonic detector.

|

|

For this reason, it is essential that you make a thorough visual inspection of the system components, to check for leaks not detected by the equipment.

|

If you suspect leakage from the EVAP canister (located on the inside of the RH front fender/wing) or its connections, this can be easily checked. Remove the side direction indicator and insert the microphone there.

|

|

5.

|

Rectify any leaks detected and test the system again.

|

|

6.

|

Restore the car to its normal condition.

|