Principle of operation, mass air flowsensor

| Principle of operation, mass air flow sensor |

| Mass air flow sensor |

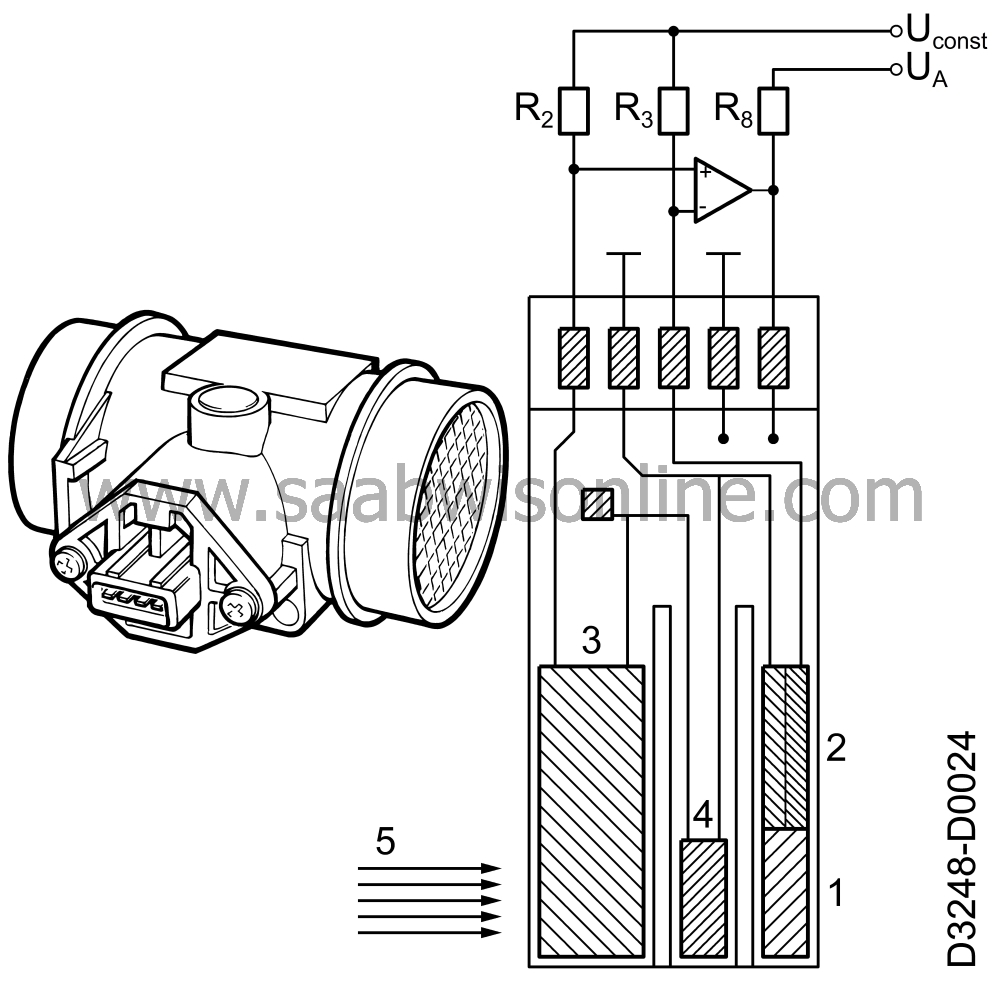

In the MOTRONIC system an electrically-heated sensor element is encapsulated in plastic. This records the air mass consumed by the engine.

The sensor element consists of a resistive sensor (1), a thermal resistor (2), a temperature sensor (3) and a calibration resistor (4) for the temperature sensor.

The resistive sensor is part of an equalization circuit which conducts current through the thermal resistor in such a way that it always maintains a constant temperature.

Since the thermal resistor is mounted together with the resistive sensor, it will also maintain a constant temperature.

When the engine load increases and the mass air flow (5) consequently also increases, its cooling effect on the thermal sensor increases. This forces the equalization circuit to increase the current (and the temperature) through the thermal resistor.

It will therefore be evident that current consumption through the thermal resistor is determined by the engine load and that the voltage drop which arises across the resistor is directly proportional to the inlet air mass.

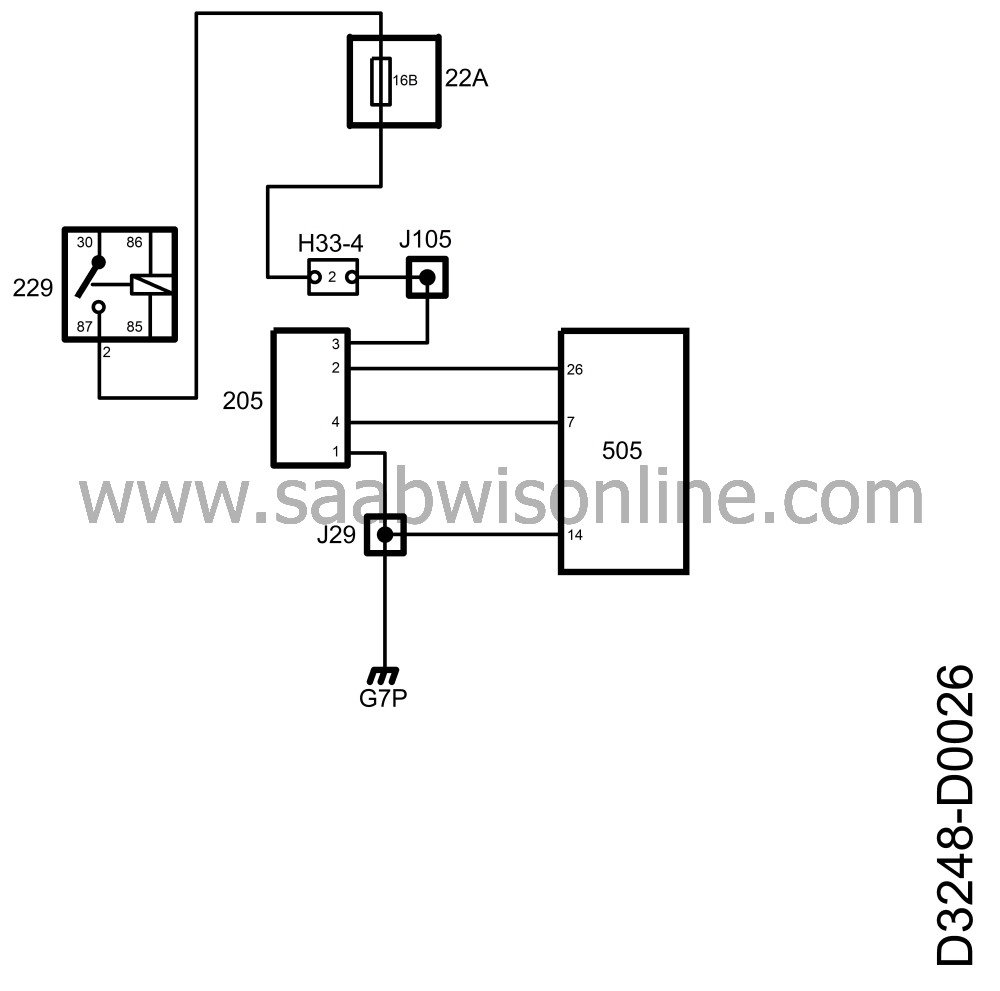

The voltage drop occurs across pins 1 and 4 of the mass air flow sensor and the control module thus receives information via pin 7.

The sensor needs no burn-off function to clean it as is the case with the air mass meter using a filament (hot wire).

Should operation of the mass air flow sensor malfunction for any reason, engine management will be taken over temporarily by the throttle position sensor which sends information on the position of the throttle to the control module. This results in efficient engagement of the Limp-Home mode.

The mass air flow sensor can be changed only as a complete unit.

The control module is supplied with continuous information on the engine load (inlet air mass) through variations in the voltage applied to pin 7.

The mass air flow sensor is supplied with voltage from pin 87 of the main relay and is grounded through power ground G7P.

Pin 26 of the control module supplies signal ground to pin 2 of the mass air flow sensor.

Through the temperature compensation which is designed to take place when increased air flow is counteracted by higher current intensity through the thermal resistor, the voltage drop across the resistor also increases and the voltage applied to pin 4 (and pin 7 of the control module) drops. Accordingly, the voltage applied to pin 7 of the control module may vary from about 5 V at full load to about 1 V at idling speed. (When measured with a BOB at full throttle and under no-load conditions, a reading of about 3 V will be obtained.)

In the event of a faulty or absent signal on pin 7 of the control module, the CHECK ENGINE lamp (MIL) lights up and the system goes into Limp-Home mode. In this mode the control module uses information from the throttle position sensor to regulate the amount of fuel supplied to the engine.