Knock control

| Knock control |

| Knock sensors 1 and 2 |

The B258 engine has two knock sensors, one for each row of cylinders. Each knock sensor contains a piezoelectric element which is characterized by an ability to become electrically charged when subjected to pressure.

When knocking occurs in any of the cylinders it gives rise to heavy vibration and movement in the material which subjects the sensor to pressure. In the case of extremely severe knocking, the sensor can produce a current of up to about 500 mV.

The knock sensors are affixed to the cylinder rows by means of a through bolt. Tightening torque is extremely important for proper operation of the sensor and should therefore be strictly observed.

| Tightening torque: 22 Nm (16 lbf ft) |

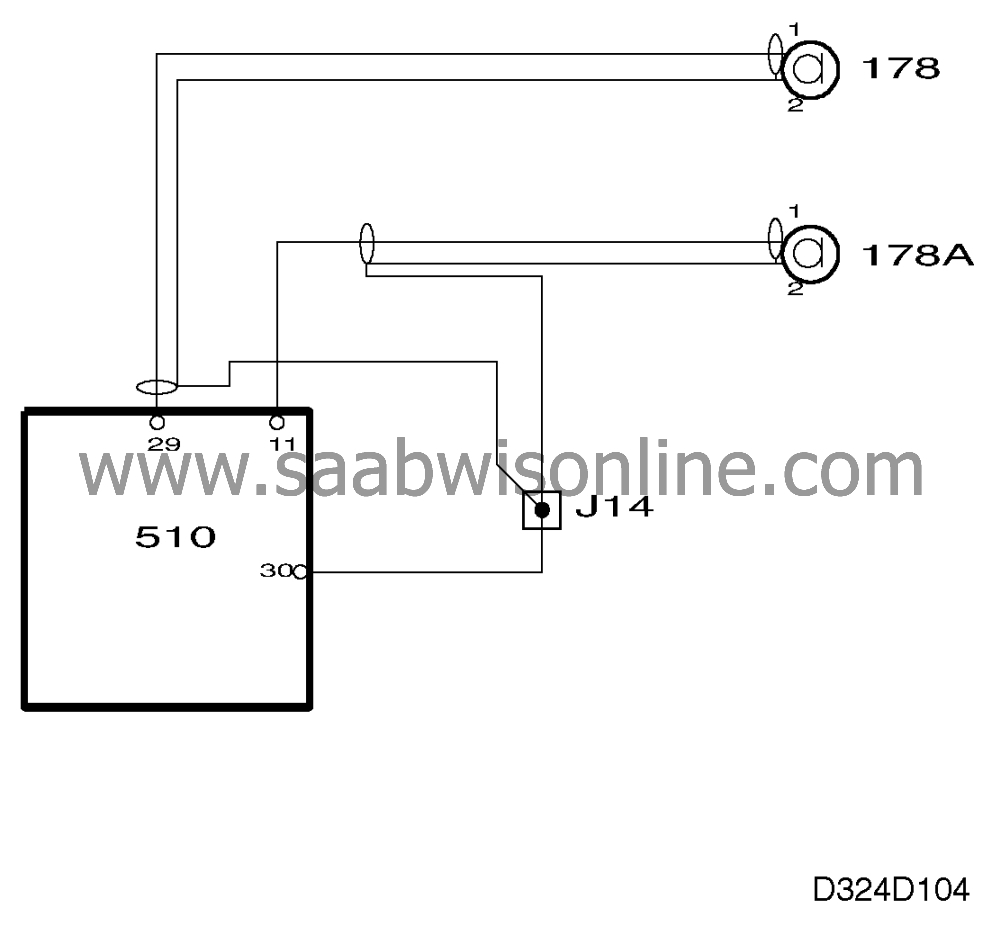

The control module receives information from the knock sensors on pin 11 (rear cylinder row) and pin 29 (front cylinder row) when knocking occurs. The knock sensors are grounded, together with other sensors, via pin 30 of the control module.

Since the signal voltage of the knock sensor is extremely low, the signal lead is screened. This reduces the risk of unwanted signal sources inducing a voltage in the lead and supplying the control module with spurious information. If the voltage in any signal lead exceeds a certain specified value, the control module will interpret this as serious knocking and retard the ignition in the cylinder concerned (see

for further details).

for further details).

In the event of a break in the sensor circuit, the control module switches to Limp-Home mode and retards the ignition by 12° in all cylinders (not at idling speed).