Knock control

| Knock control |

Knock sensor

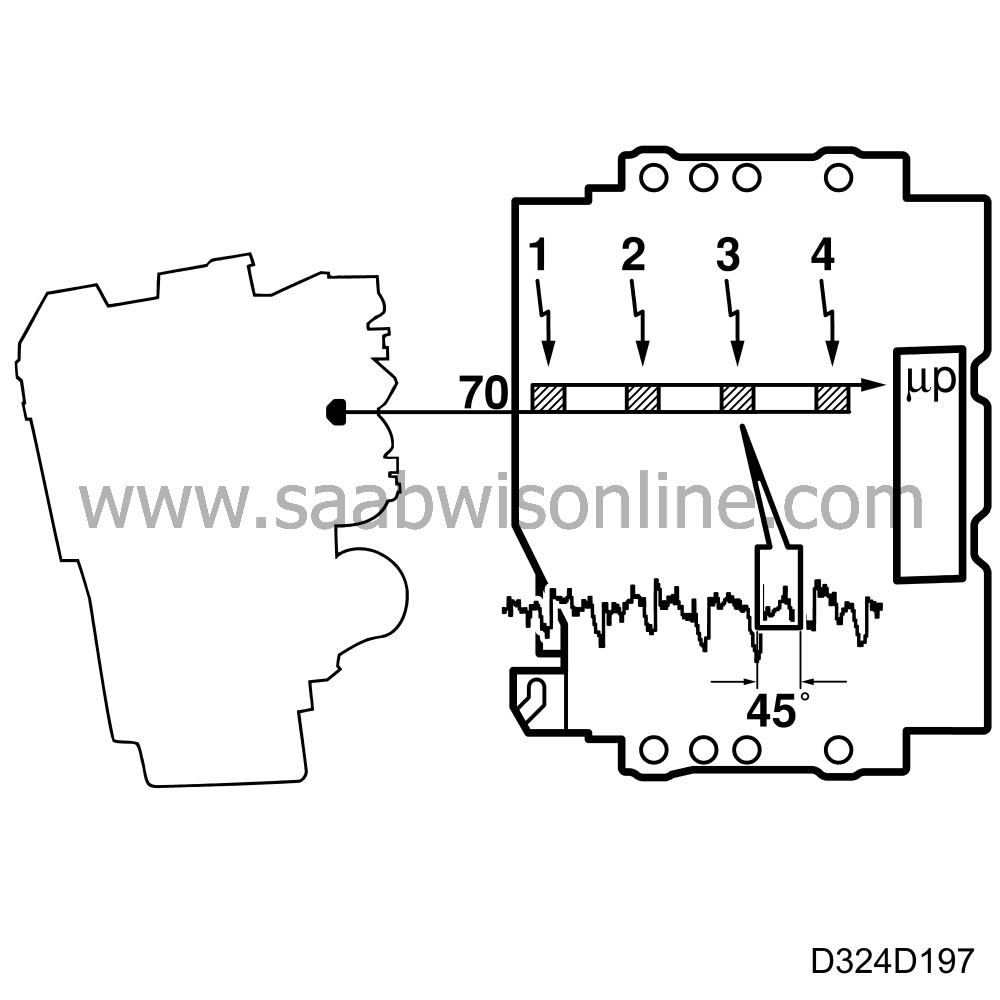

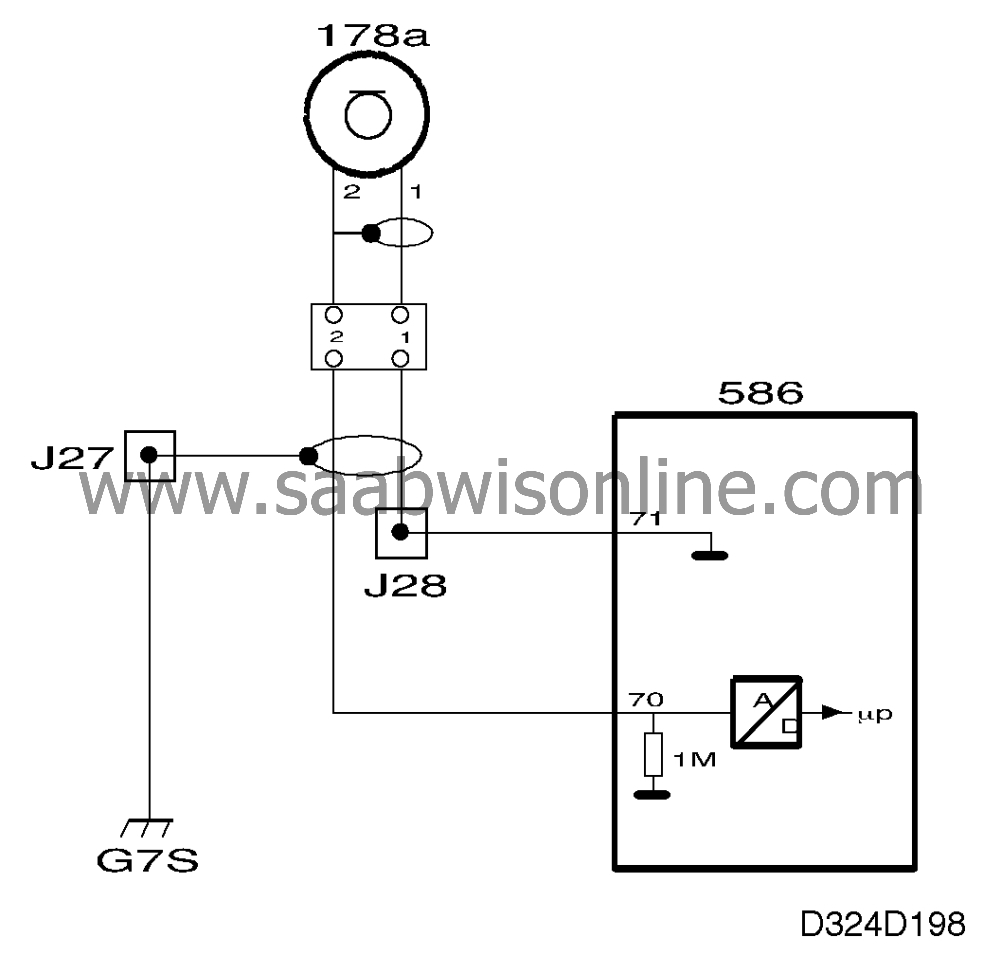

The B234 engine's knock sensor contains a piezoelectric element which produces an electric current when subjected to pressure.When knocking occurs in any of the cylinders it gives rise to severe vibration in the engine block, causing the sensor to generate alternating current. In the case of extremely severe knocking, the current generated in this way could amount to about 500 mV a.c.

The knock sensor is mounted on the cylinder bank by means of a through bolt. Tightening torque is extremely important for proper operation of the sensor and it should therefore be strictly observed.

Tightening torque 22 Nm (16 lbf ft)

The knock sensor is connected to pin 70 of the control module. The sensor is connected to ground via control module pin 71 and screened via pin 28.

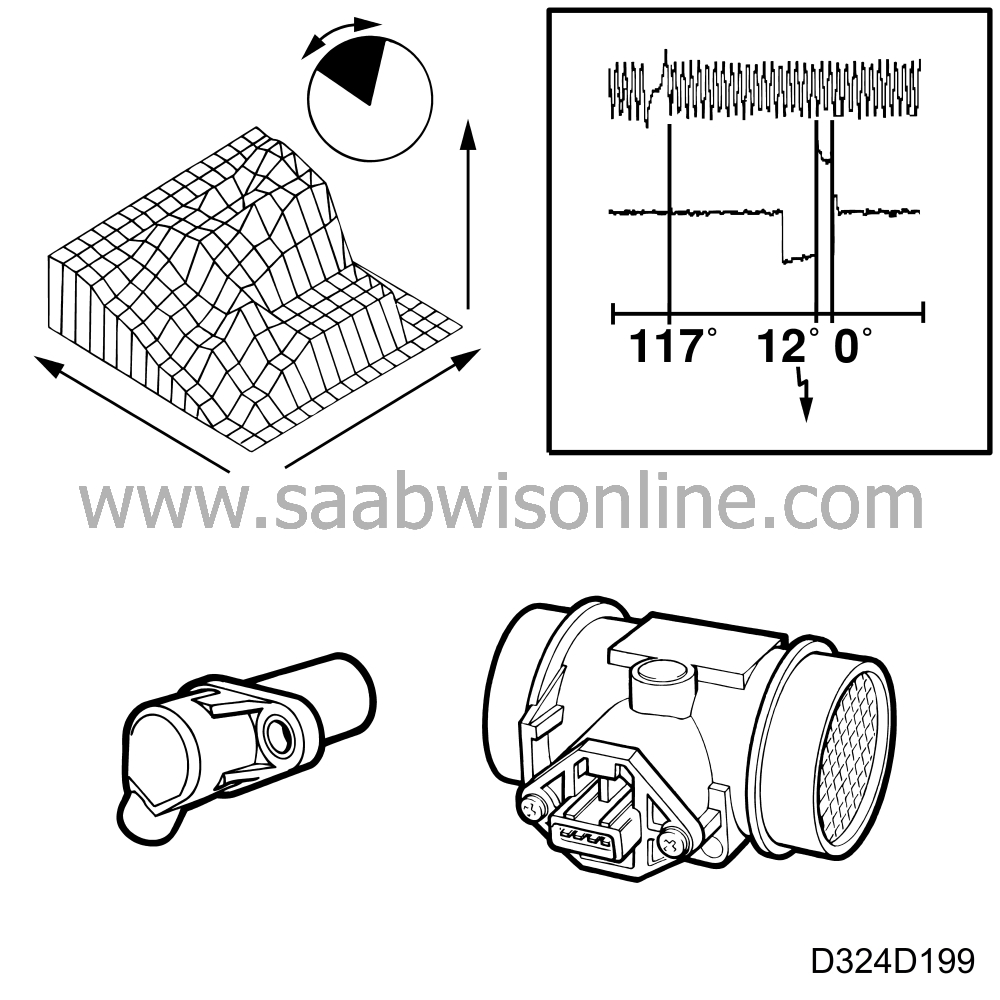

Knock control

If knocking occurs in any of the cylinders, the ignition will be retarded by 3° for that particular cylinder. If the knocking then stops, the ignition will be restored to what it was before in steps of 0.75°.On the other hand, should knocking continue in the same cylinder in spite of the ignition being retarded,the control module will retard the ignition an additional step of 3°, and so on up to a maximum of 13.5°.

When the throttle position exceeds a certain angle, the control module interprets this as full engine load or wide open throttle and obtains the ignition timing angle from another matrix with lower ignition timing values.

Should the sensor fail to work or in the event of a break in the circuit (no continuity), the ignition will be retarded by 12° in the event of a load on the engine which would entail a risk of knocking.