P0105,P0106, P0107, P0108

Symptom: The CHECK ENGINE lamp (MIL) is on. Impaired driveability. Basic boost

pressure only. Possible existence of other DTCs (misfiring, closed loop, boost pressure

control). The A/C compressor does not work. The turbo/APC gauge gives implausible

readings.

|

|

P0105

,

P0106

,

P0107

,

P0108

|

Manifold absolute pressure sensor

Symptom of fault

The CHECK ENGINE lamp (MIL) is on. Impaired driveability. Basic boost

pressure only. Possible existence of other DTCs (misfiring, closed loop, boost pressure

control). The A/C compressor does not work. The turbo/APC gauge gives implausible

readings.

Conditions

P0105: All-embracing DTC

P0106: <50 kPa or >140 kPa when the ignition switch is turned to the ON position

or when the engine is running and the pressure is constant for 60 seconds despite throttle

position changes.

P0107: Ignition switch in the ON position: <10 kPa for 2 seconds at wide throttle

opening.

P0108: Ignition switch in the ON position: >245 kPa for 2 seconds at slight throttle

opening

Diagnostic help

|

•

|

The turbo/APC gauge is electric

and shows the pressure sensor value

|

|

•

|

The pressure sensor reading can be obtained on an ISAT scan tool. Turn the

ignition switch to the ON position and then back to the OFF position.

|

|

-

|

Connect an ISAT scan

tool.

|

|

-

|

Select

"READ FUNCTIONS".

|

|

-

|

Select

"INTAKE PRESSURE".

The ISAT scan tool should show a reading of about 102 kPa (NOTE: the reading

is dependent on air pressure).

|

|

-

|

Engine running at idling speed.

|

If the pressure sensor is in perfect working order the reading obtained on the

ISAT scan tool should be 40-60 kPa.

Checking the wiring. Intermittent faults may occur as a result of occasional short circuits

and breaks in the wiring. Jiggle the leads and in-line connectors at several places and in

different directions to reveal faults in the wiring harness. Observe the multimeter, ISAT scan

tool or test lamp while carrying out this check.

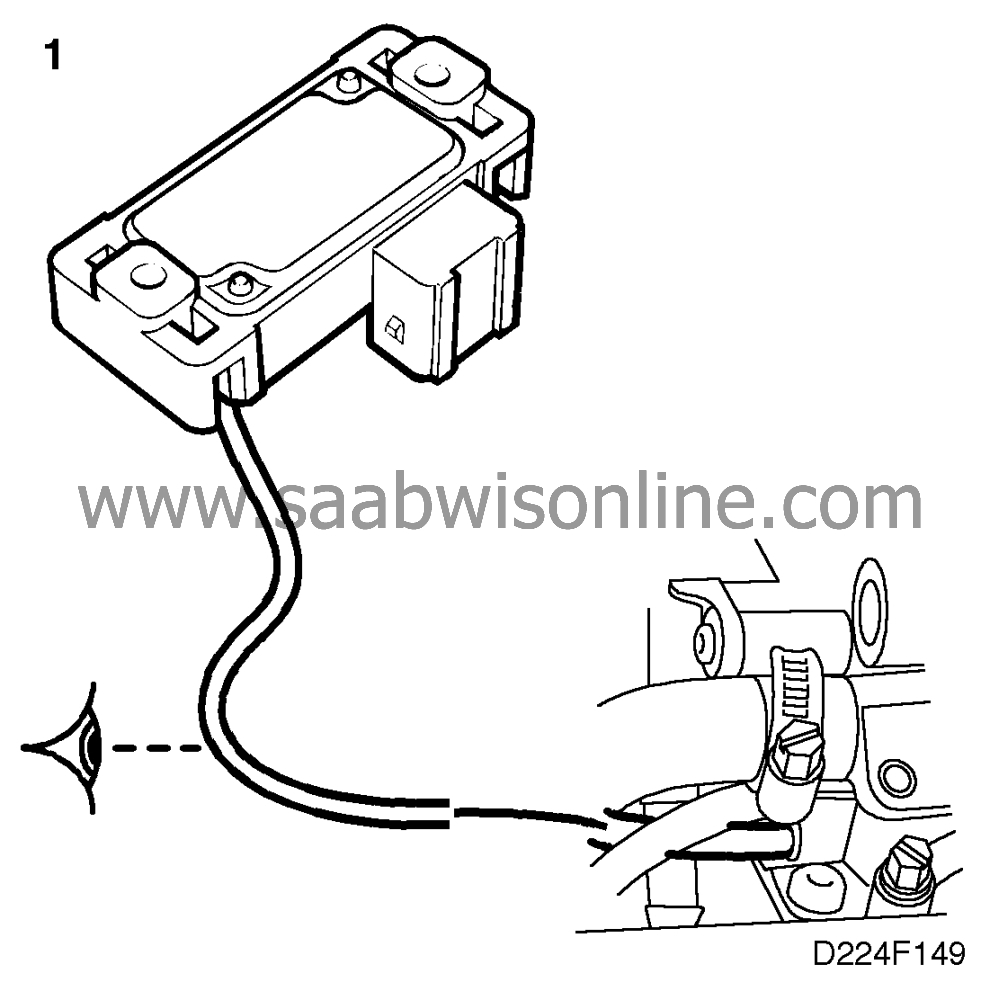

Diagnostic procedure

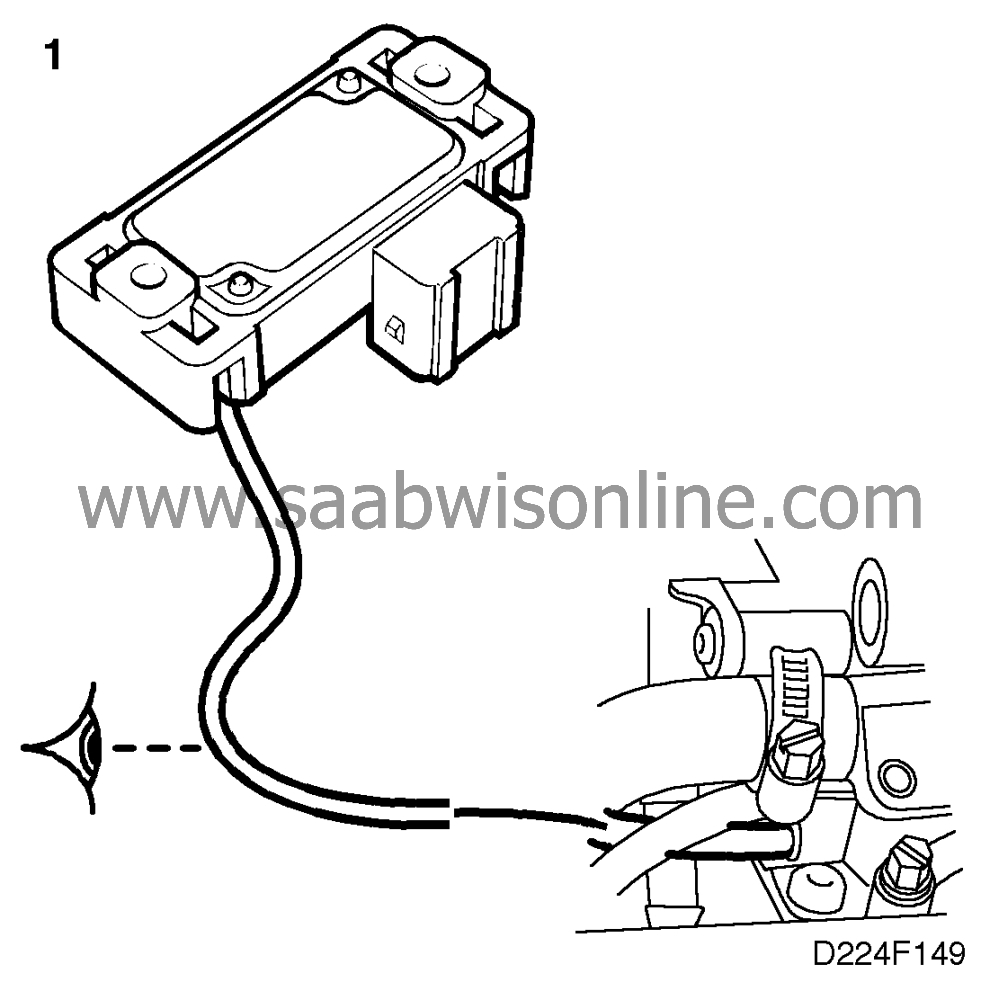

1. Check the vacuum hose

Inspect the vacuum hose between the pressure sensor and intake manifold for

breaks, leakage, pinching or clogging.

Inspect the vacuum hose between the pressure sensor and intake manifold for

breaks, leakage, pinching or clogging.

Is the vacuum hose OK?

Continue with point 2.

Rectify the fault and proceed to point 4.

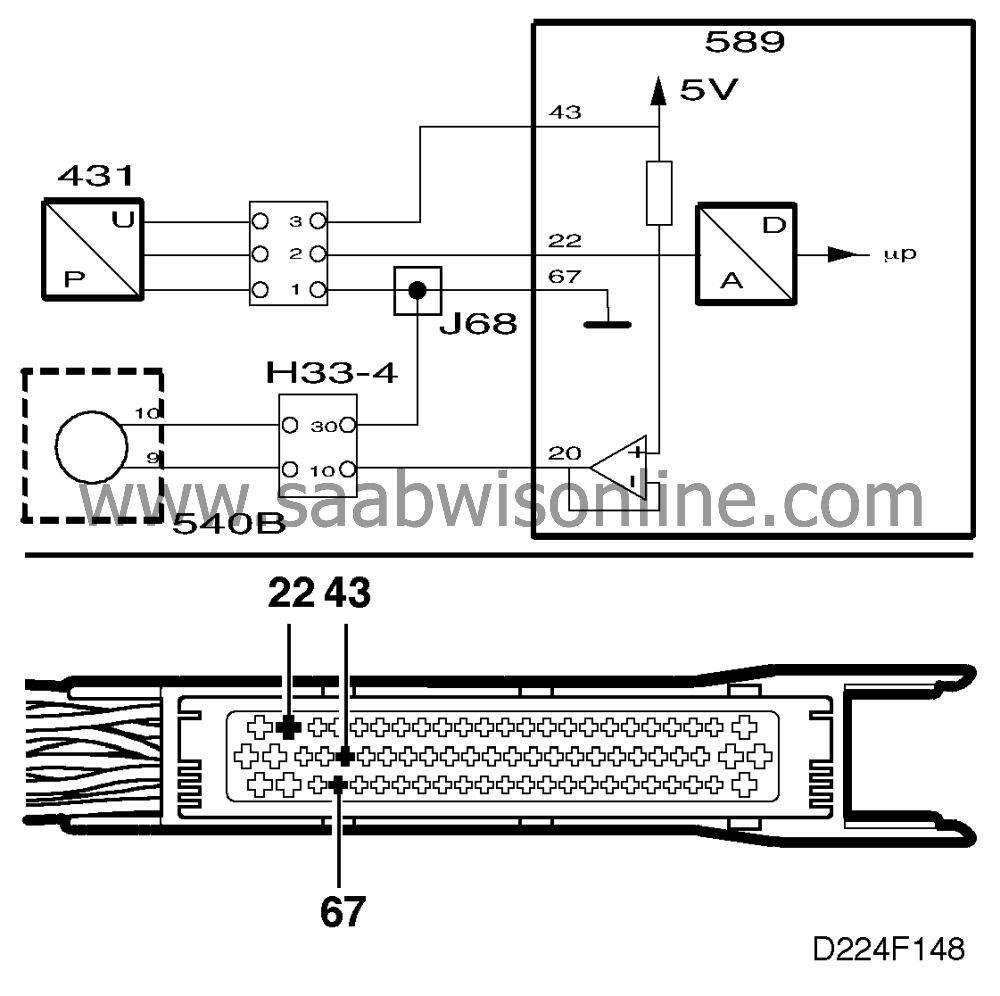

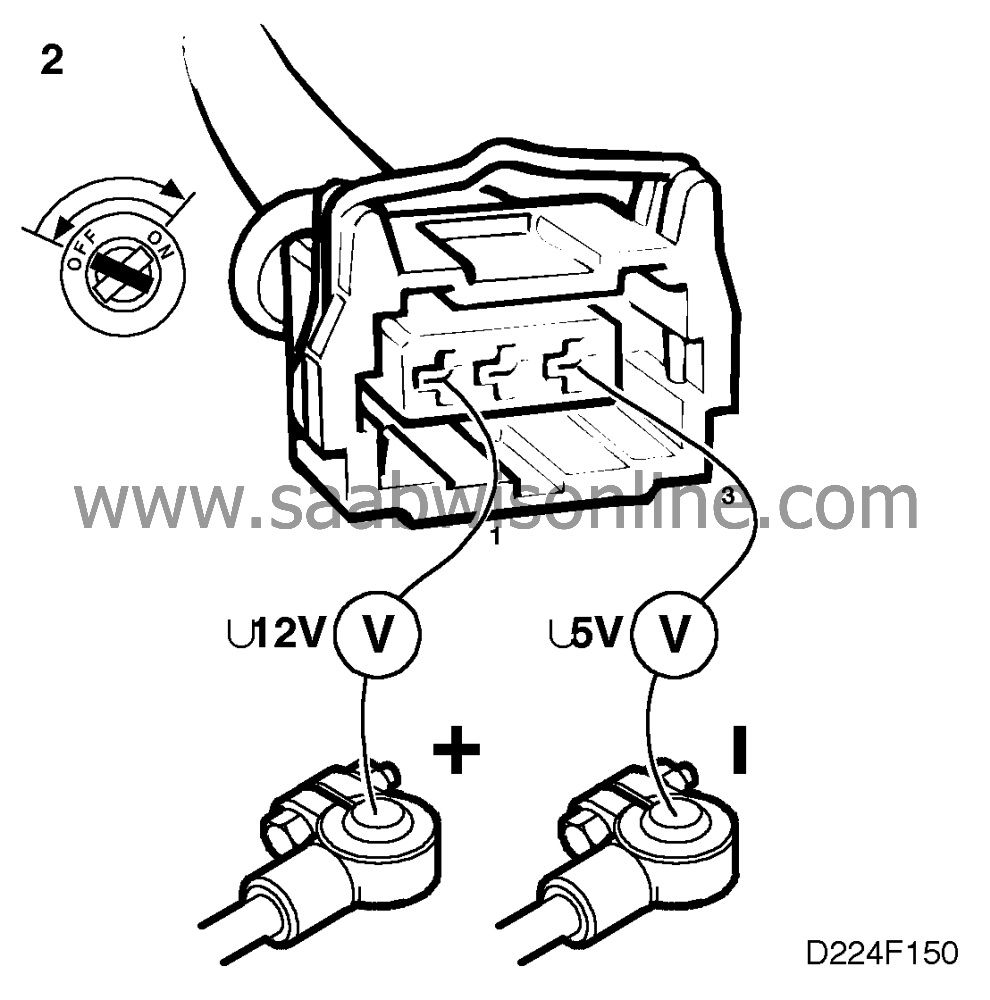

2. Check the pressure sensor's ground connection and power

supply

|

-

|

Turn the ignition switch to the ON

position and then back to the OFF position.

|

|

-

|

Unplug the pressure

sensor's 3-pin connector.

|

|

-

|

Take voltage readings in the

connector across:

• pin 3 and B-

__________ar;_____ (about 5 V)

• B+ and pin 1______ about 12

V

|

Are all readings OK?

Continue with point 3.

Rectify the lead in question and proceed to point 4.

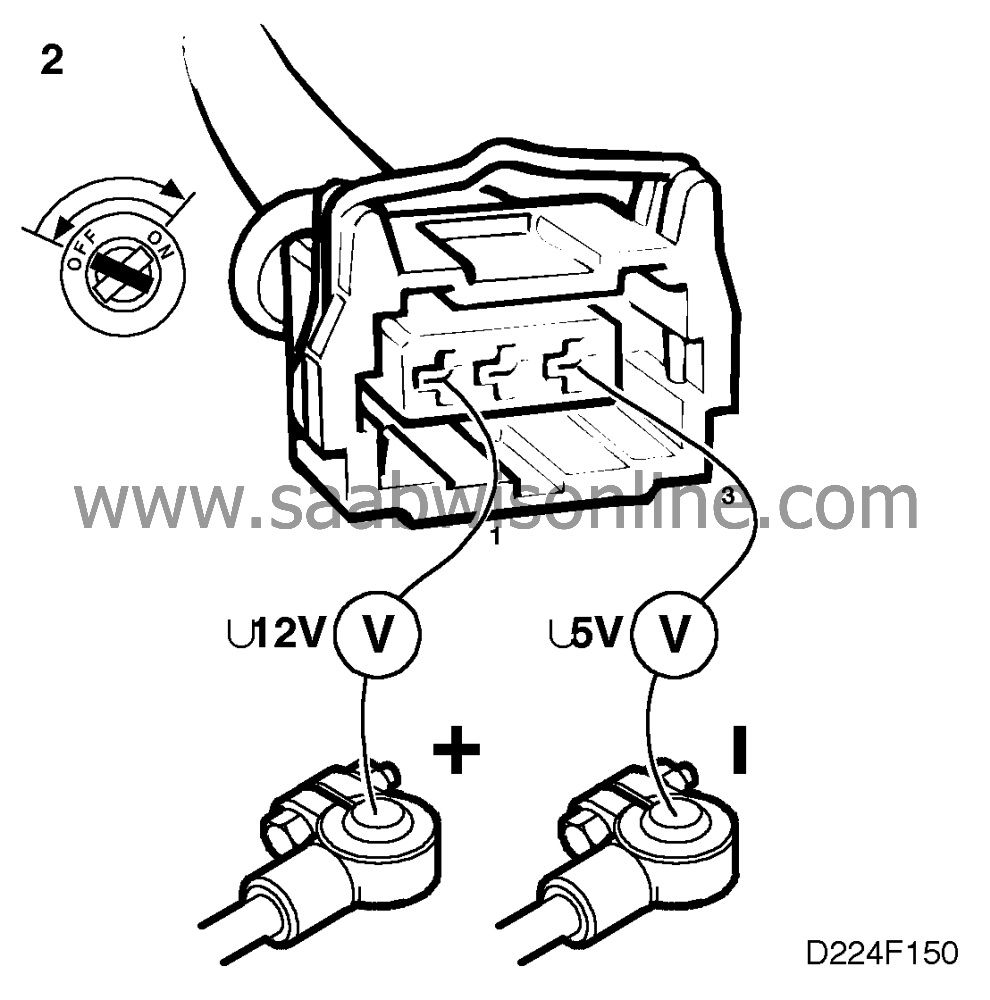

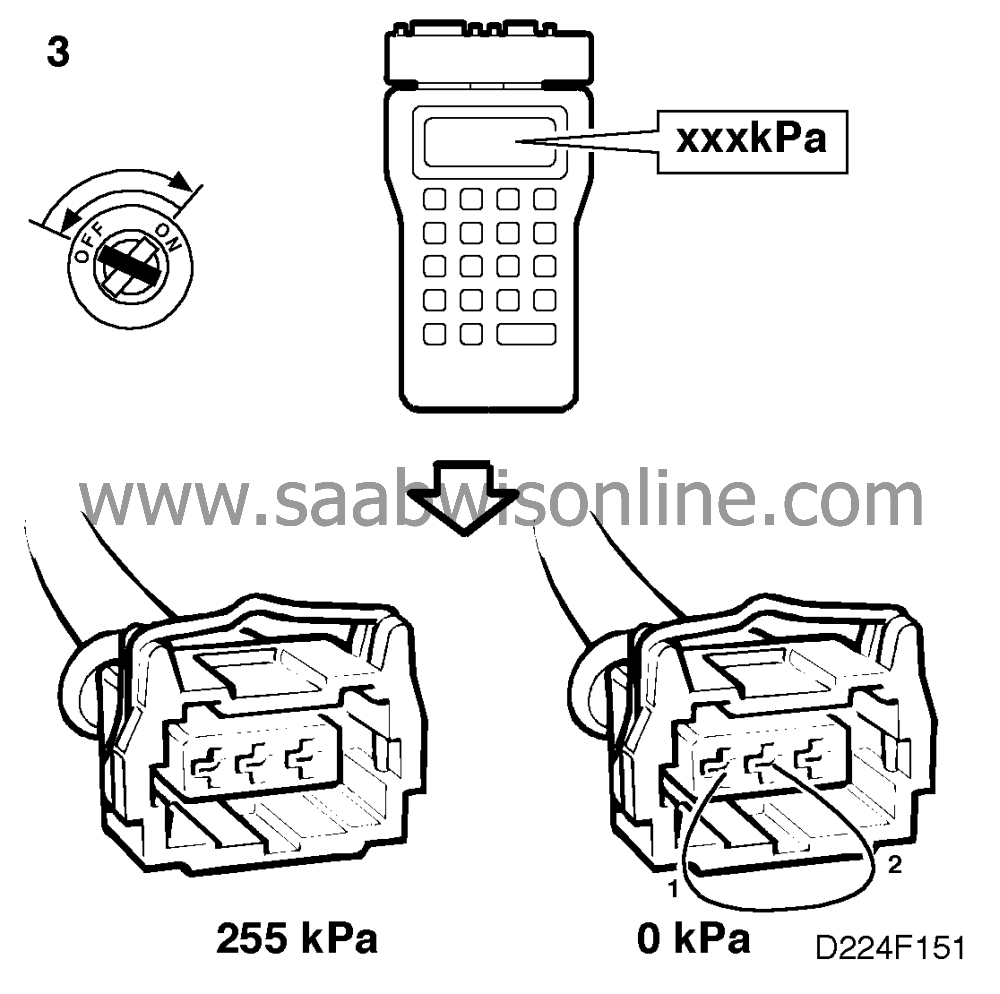

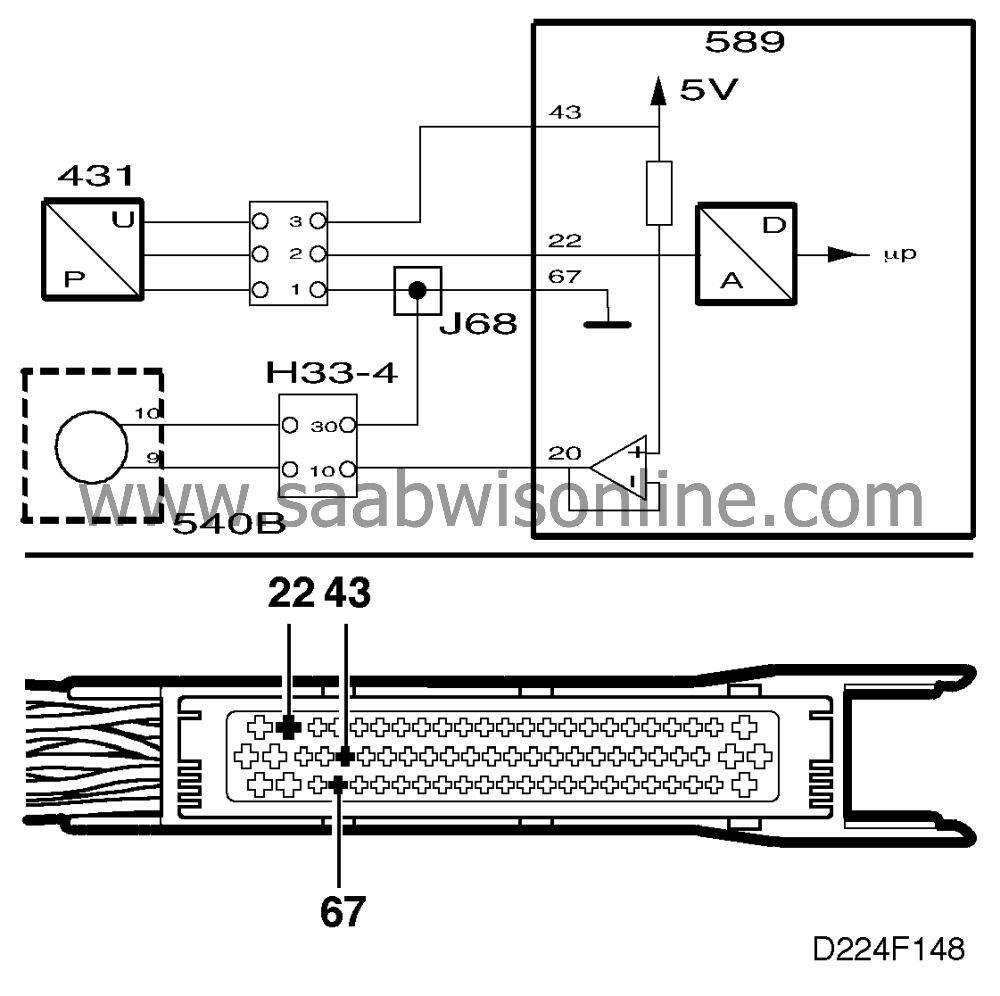

3. Check the electronic control module's

pressure sensor input

|

-

|

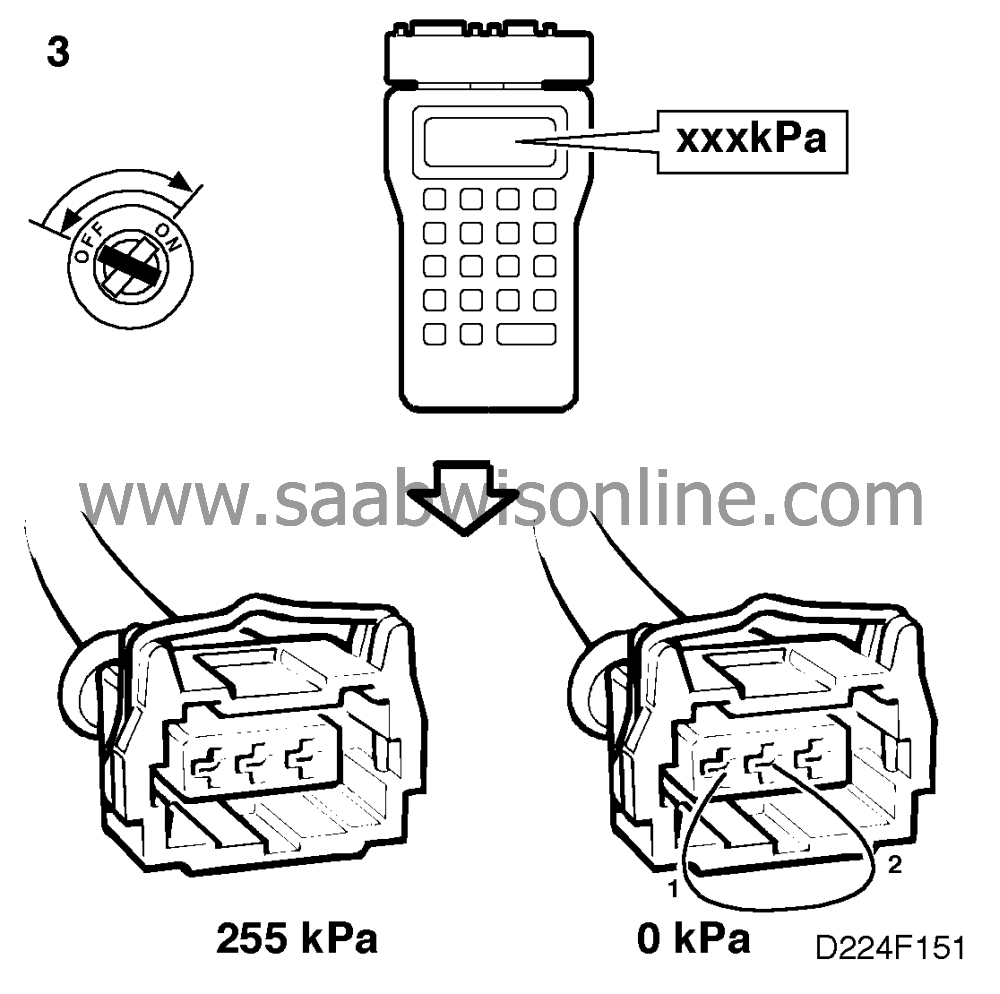

Turn the ignition switch to the ON

position and then back to the OFF position

|

|

-

|

Unplug the pressure

sensor's 3-pin connector.

|

|

-

|

Connect an ISAT scan tool. Select

"READ FUNCTIONS". Select

"INTAKE PRESSURE".

|

The ISAT scan tool reading should be 255 kPa.

|

-

|

Connect a jumper lead between

pins 2 and 1 of the pressure sensor connector.

|

The ISAT scan tool reading should be 0 kPa.

Are all readings OK?

Change the pressure sensor and continue with point 4.

Rectify the lead in question and proceed to point

4.

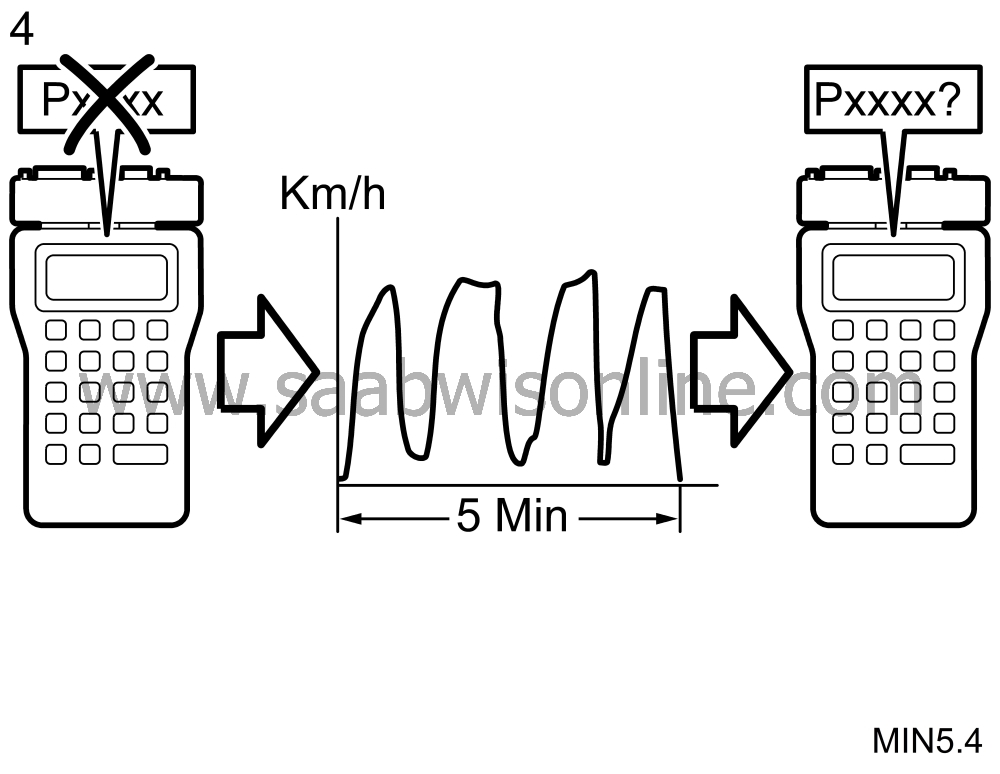

4. Final check

|

-

|

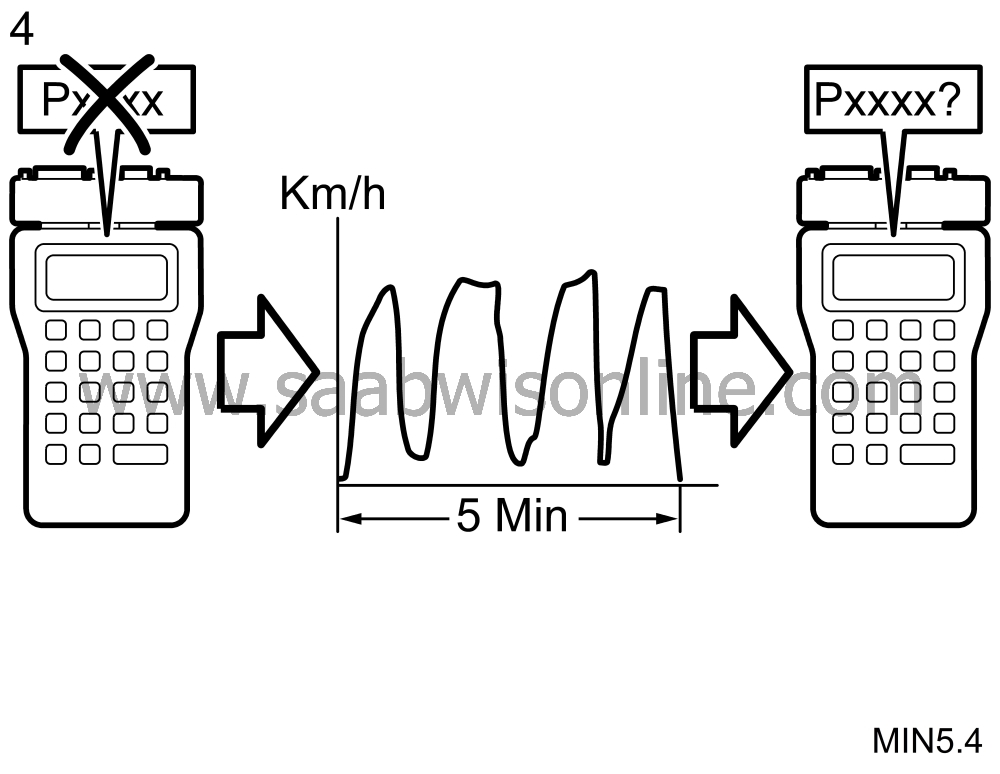

Clear the diagnostic trouble code.

|

|

-

|

Implementation of driving cycle:

Drive the car at varying engine rpm and loads for 5 minutes.

|

|

-

|

Evaluation of driving cycle: Check

whether the diagnostic trouble code has recurred.

|

Has the diagnostic trouble code recurred?

Proceed to

.

.

The remedial measure taken was correct.