P0442,P0455

Symptom: The CHECK ENGINE lamp (MIL) is on. Possible fuel

odour.

Leakage in the purging system

Symptom of fault

The CHECK ENGINE lamp (MIL) is on. Possible fuel

odour.

Conditions

|

•

|

Diagnosis not yet performed this

trip

|

|

•

|

Front heated oxygen sensor OK

|

|

•

|

Vehicle speed = 0 for 7 sec.

|

|

•

|

Additional fuel from purging <10 of engine's fuel

requirement.

|

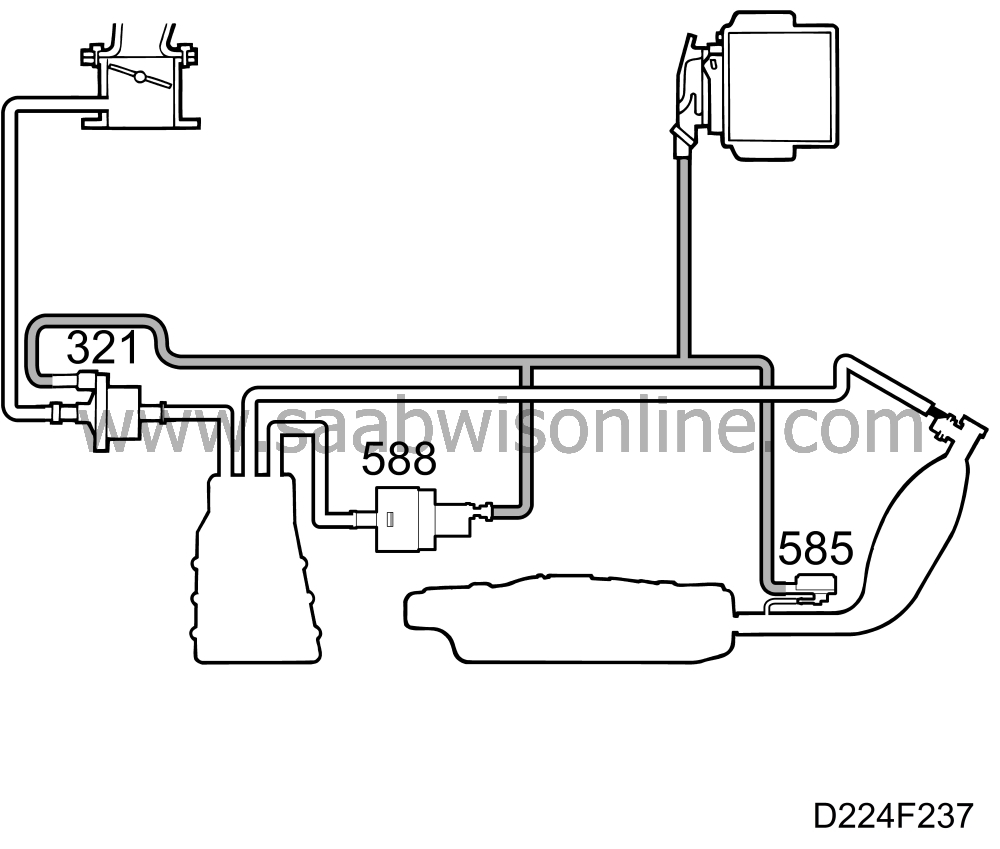

P0455: Serious leakage. When the supply air for the evaporative emission

canister is shut off and purging is active, no pressure drop occurs in the tank

P0442: Little leakage. When the supply air for the evaporative emission canister is shut

off and purging is active, pressure drops in the tank. When purging is subsequently stopped,

however, the pressure rises too fast.

Diagnostic help

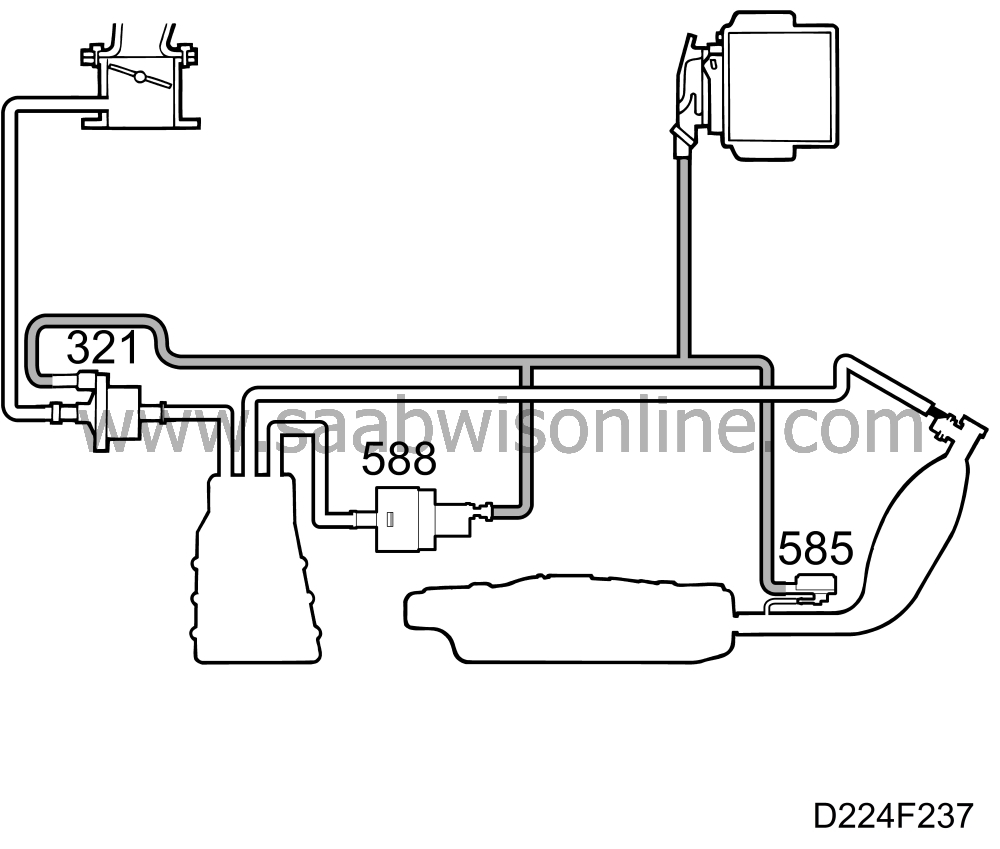

The diagnostic trouble code indicates a leak in one of the following

components:

|

•

|

Fuel filler cap not tightened

properly, damaged seal, etc.

|

|

•

|

Filler pipe or breather pipe

|

|

•

|

Tank, above surface of fuel

|

|

•

|

Line from rollover valve to evaporative emission canister

|

|

•

|

Evaporative emission canister

|

|

•

|

Evaporative emission canister shut-off valve

|

|

•

|

Line from evaporative emission canister to canister purge valve

|

|

•

|

EVAP canister purge valve

|

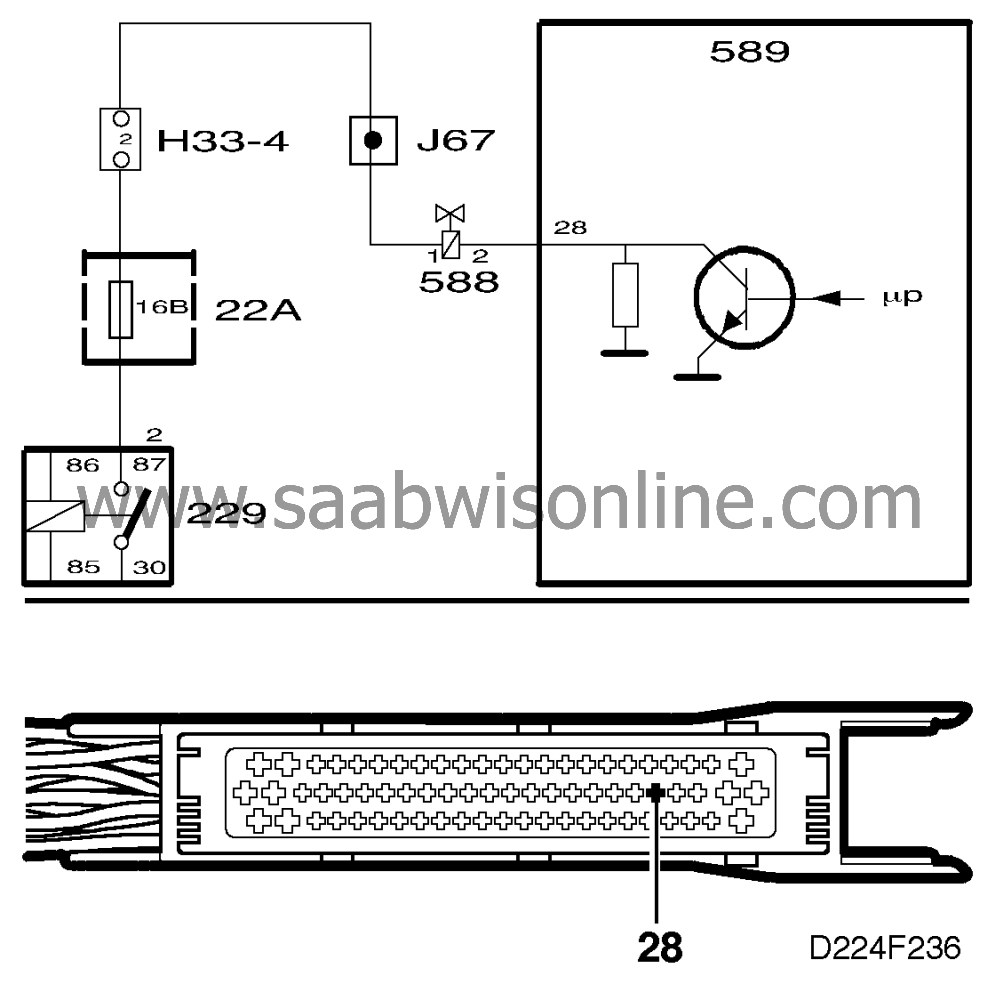

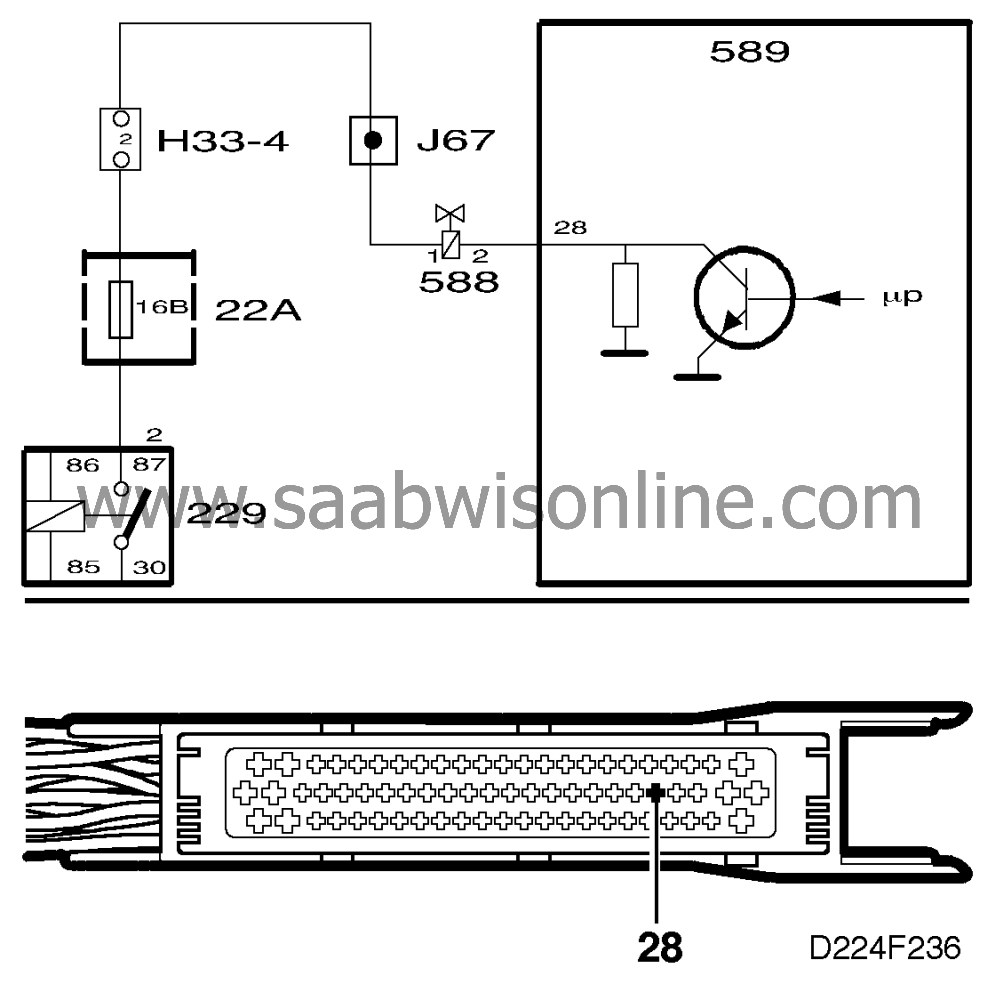

The evaporative emission canister's shut-off valve can be activated by the

ISAT scan tool.

|

-

|

Select "EVAP VALVE

SHUTOFF"

|

A tank pressure reading can be obtained with the ISAT scan tool.

|

-

|

Select

"READ FUNCTIONS".

|

A diagnostic trouble code will also be generated in the event of a break in the

circuit for the evaporative emission canister's shut-off valve and an incorrect constant

reading from the tank pressure sensor.

. Intermittent faults may occur as a result of

occasional short circuits and breaks in the wiring. Jiggle the leads and in-line connectors at

several places and in different directions to reveal faults in the wiring harness. Observe the

multimeter, ISAT scan tool or test lamp while carrying out this check.

Diagnostic procedure

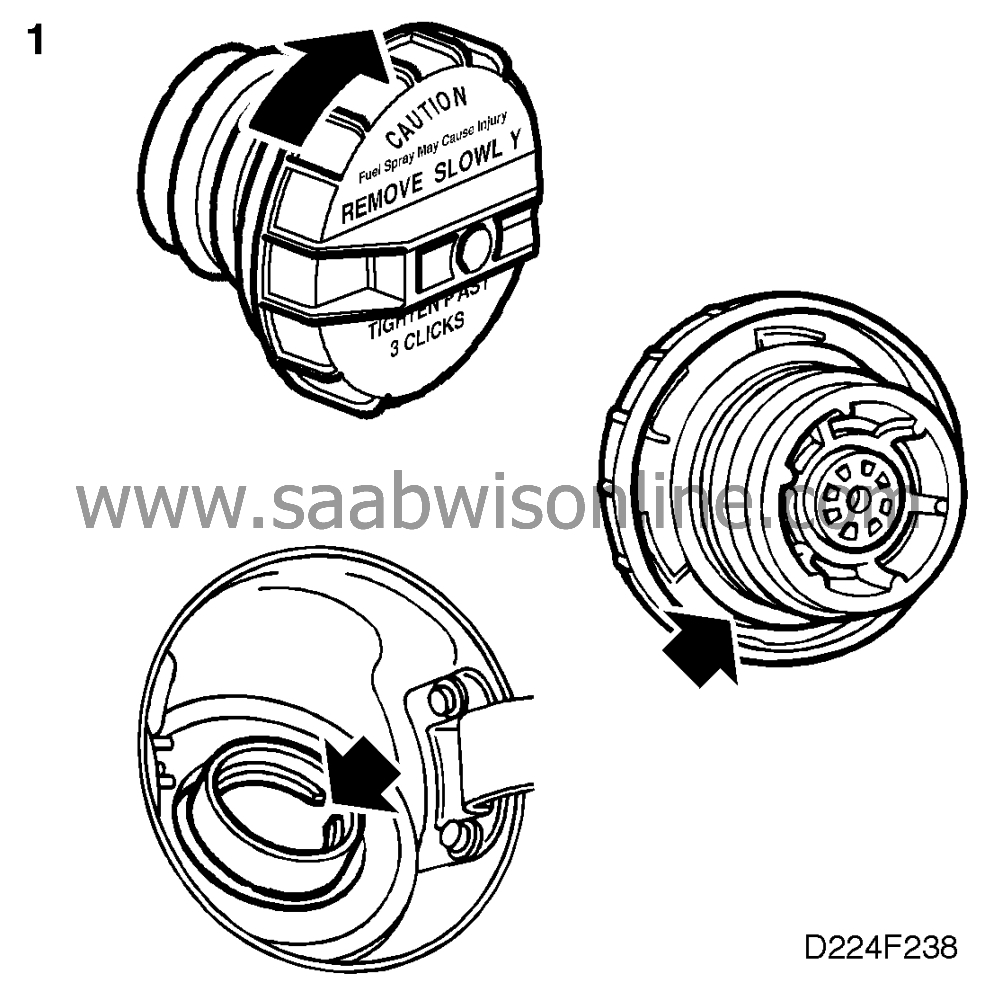

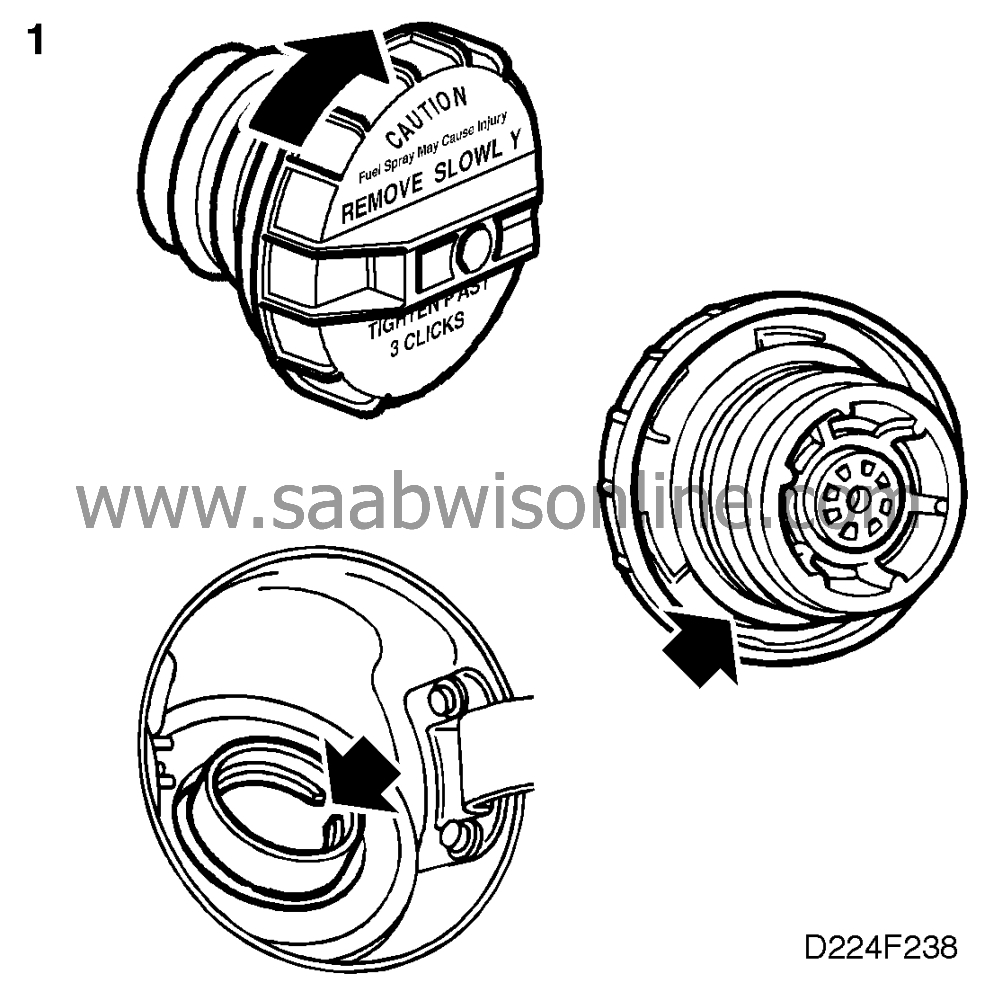

1. Check the fuel filler cap

|

-

|

If possible, check whether the filler

cap was properly tightened when the fault was discovered.

|

|

-

|

Check whether the filler cap is

properly tightened.

|

|

-

|

Check the filler cap's seal

and sealing surfaces

|

Is the fuel filler cap OK?

Continue with point 2.

Rectify the fault and proceed to point 5.

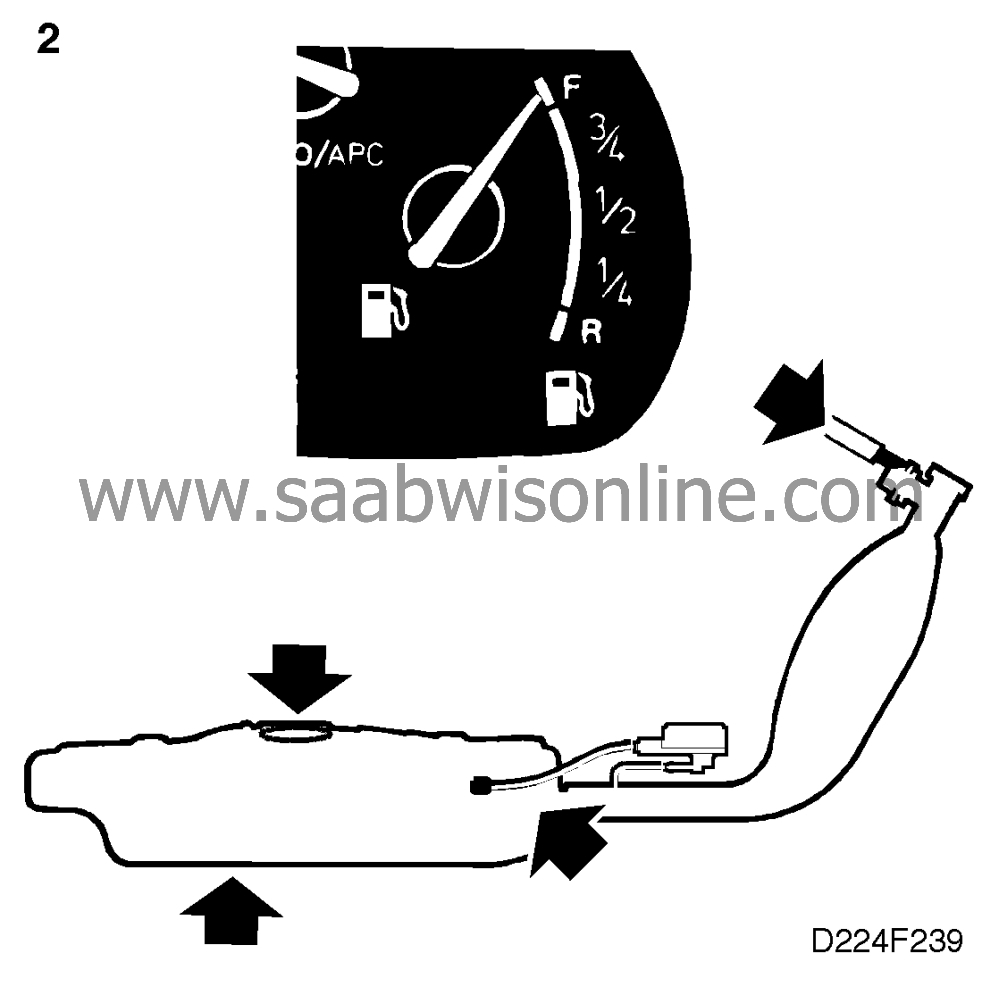

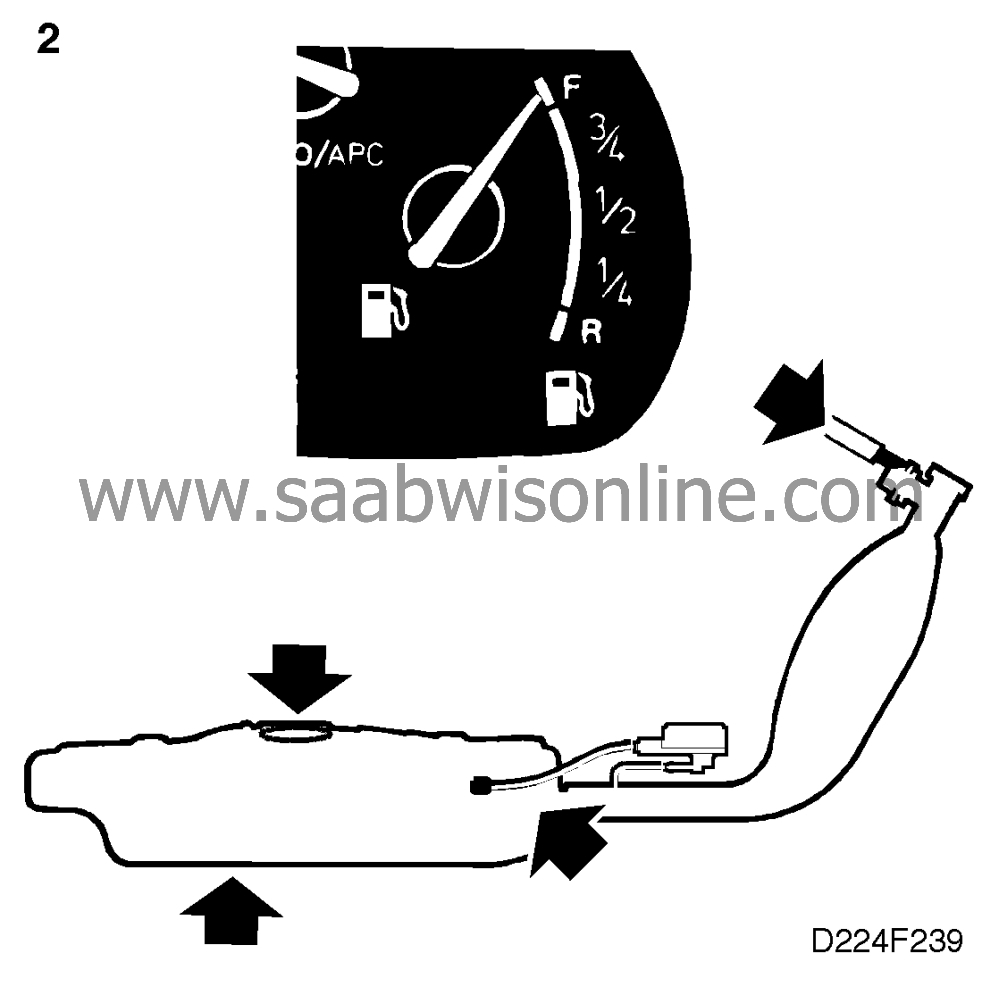

2. Check the fuel leakage

|

-

|

Fill the tank with fuel right up to the

top of the filler pipe.

|

|

-

|

Check visually whether any fuel

leaks out from the tank, filler pipe or breather pipe.

|

Any leakage?

Rectify the fault and proceed to point 5.

Continue with point 3.

3. Check the purge valve

|

-

|

Check that the purge valve is

closed when not supplied with current and opens when supplied with

current.

|

Is the thermostat OK?

Continue with point 4.

Change the valve and proceed to point 5.

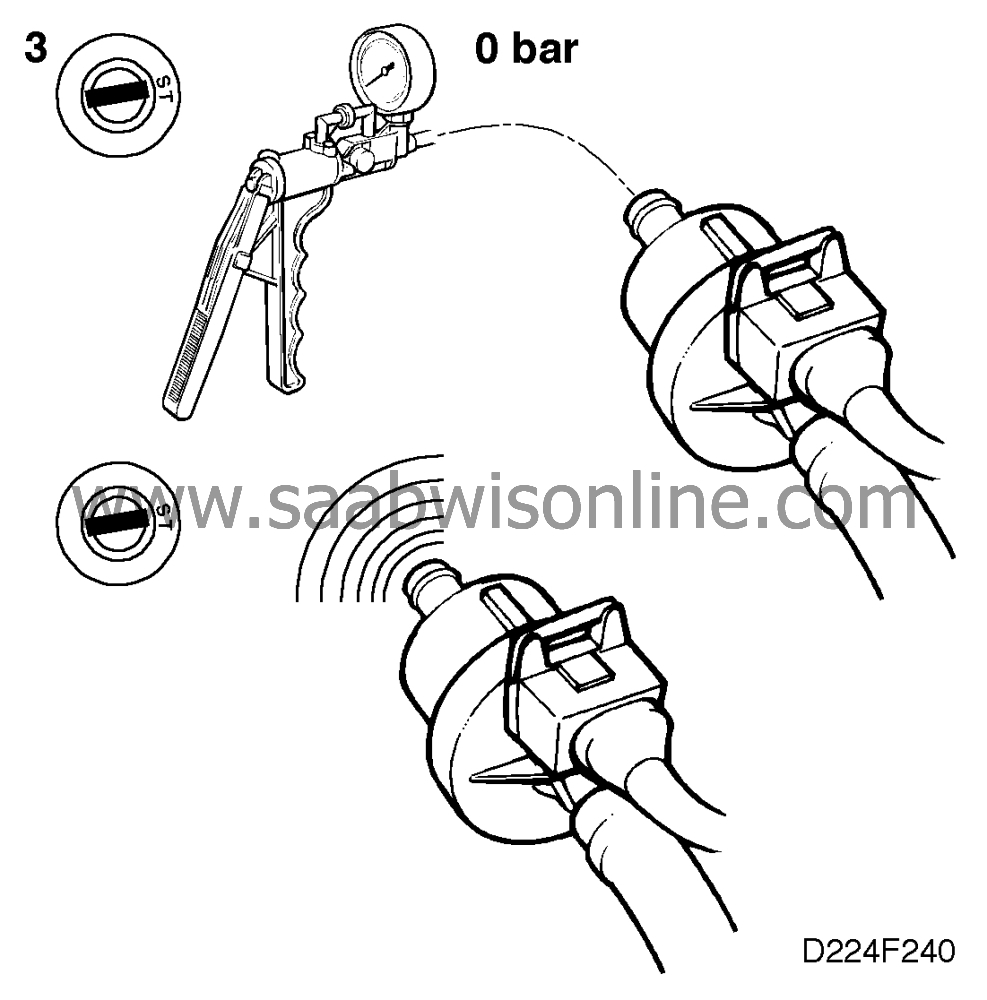

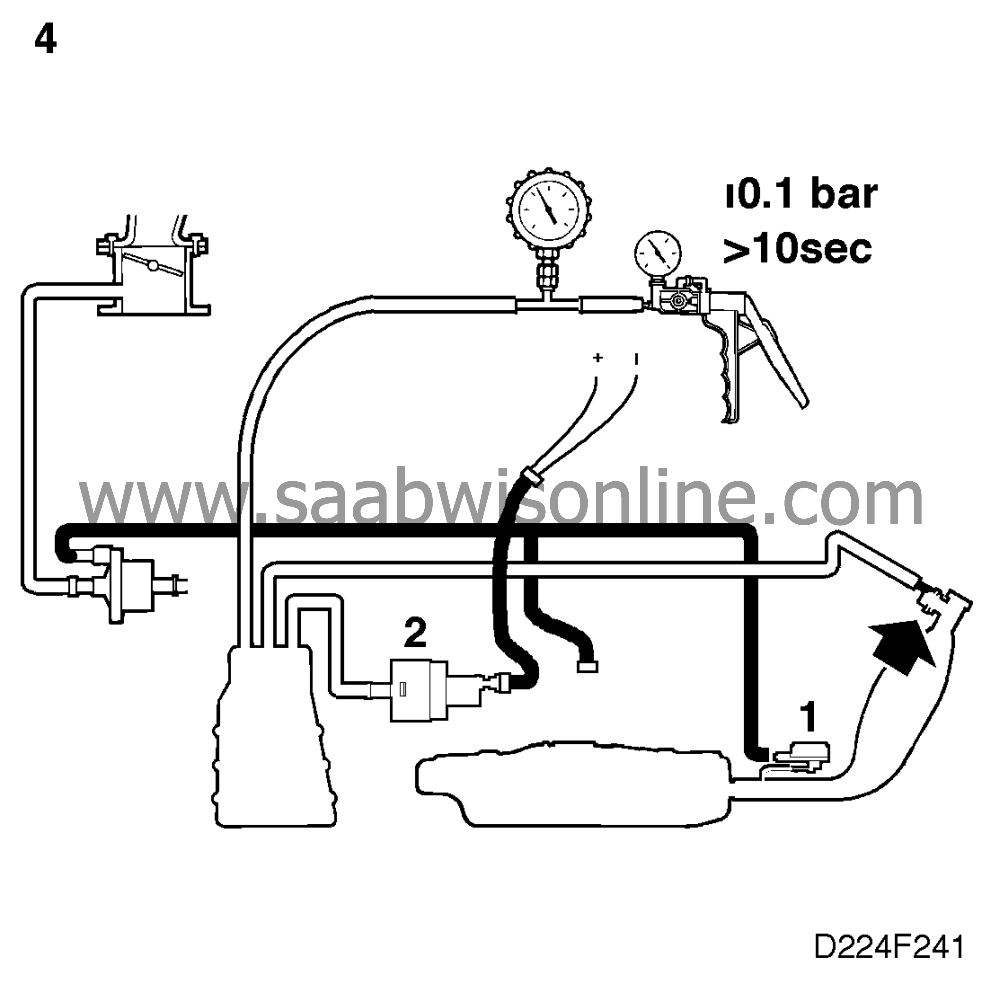

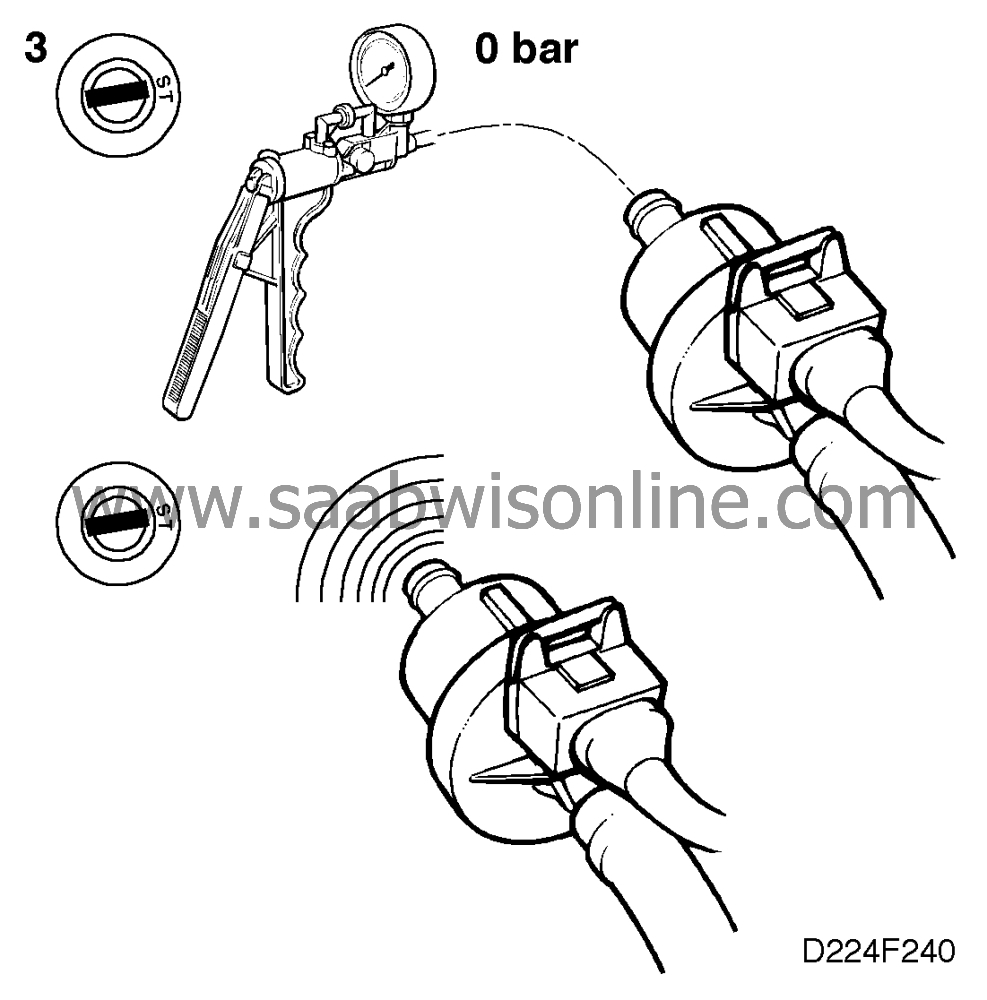

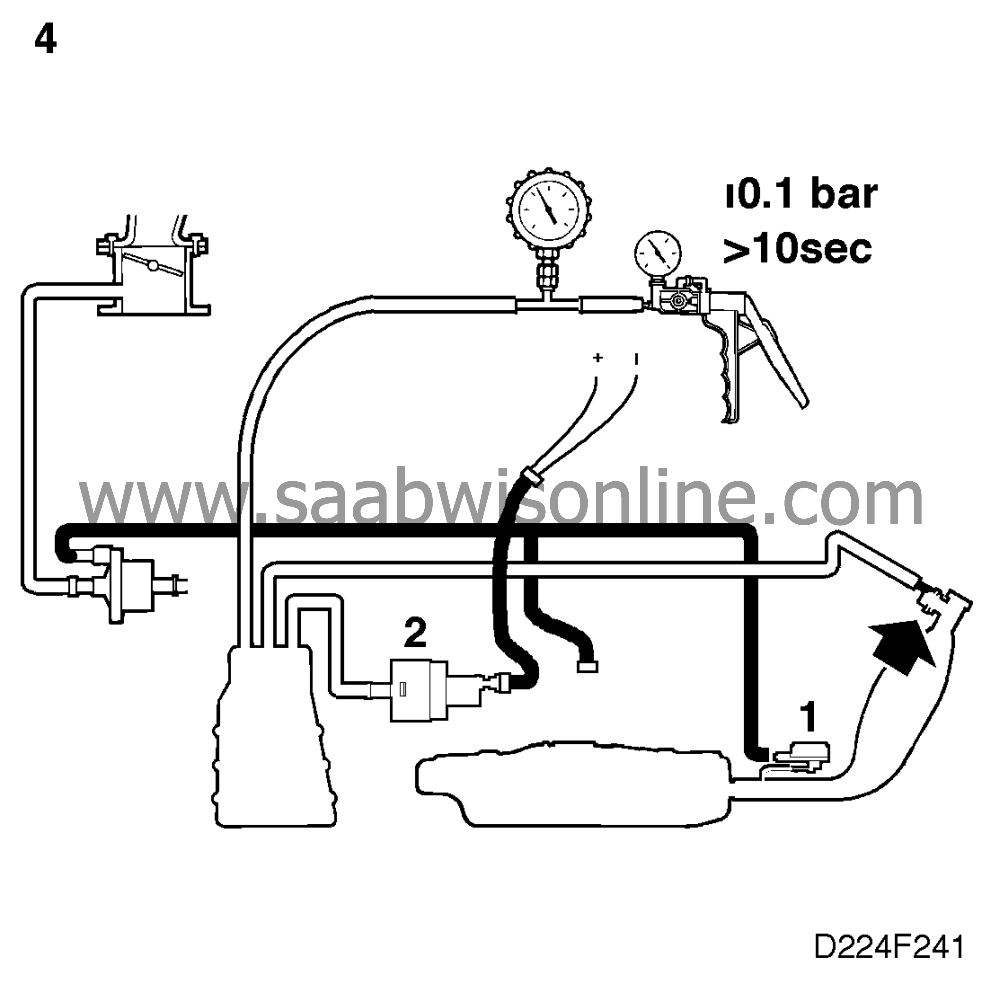

4. Check the purge valve

|

-

|

Ignition switch in the OFF

position.

|

|

-

|

Unplug the connector from the

evaporative emission canister's shut-off valve.

|

|

-

|

Connect the shut-off valve (male

connector) to the battery

|

|

-

|

Connect a pressure/vacuum pump

and pressure gauge to the evaporative emission canister's hose.

|

|

-

|

Remove the filler cap and close off

the rollover valve hole.

|

|

-

|

Using the pressure/vacuum pump,

lower the pressure to -0,1 bar.

|

The pressure should not visibly rise for 10 seconds.

Does the pressure rise?

The leakage has been traced to the evaporative emission canister, including

the lines connected to it, or the shut-off valve.

To check the electrical operation of the shut-off valve, use the ISAT scan tool and

activate the appropriate function. Rectify the fault and proceed to point 5.

Change the filler cap and continue with point 5.

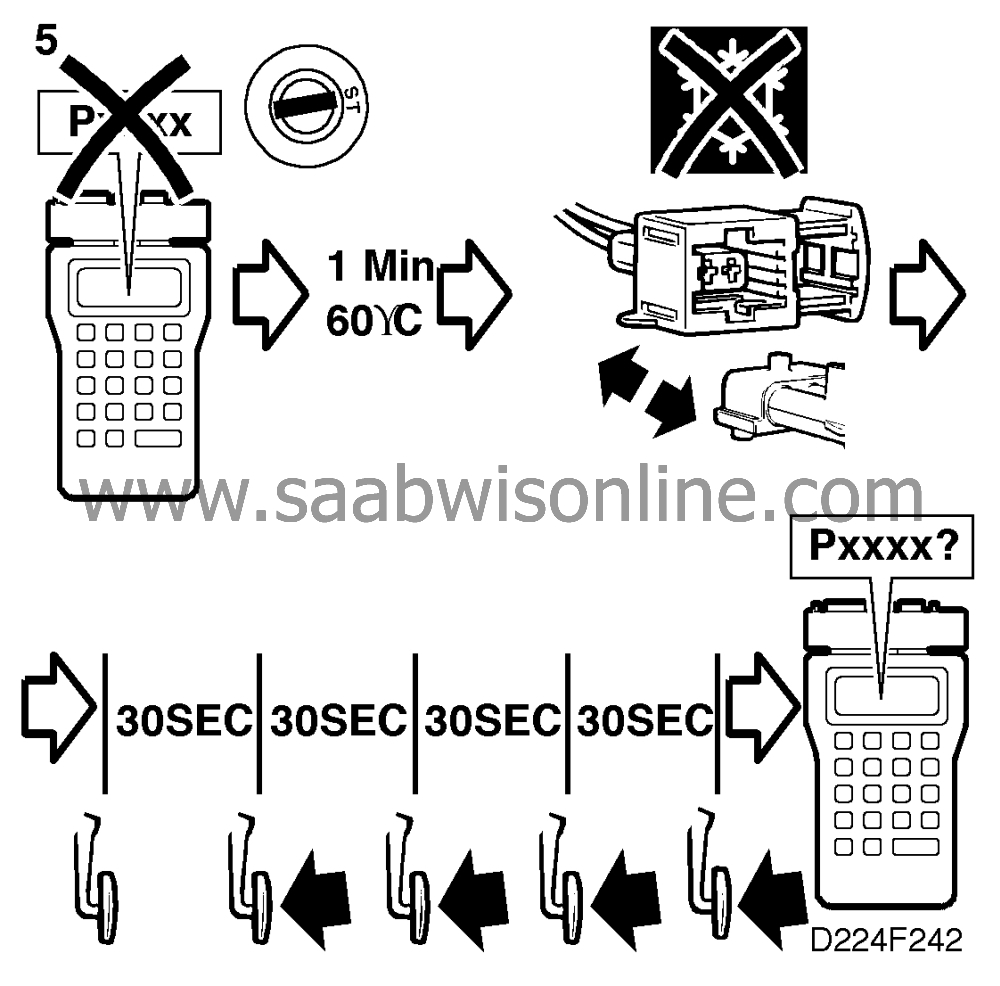

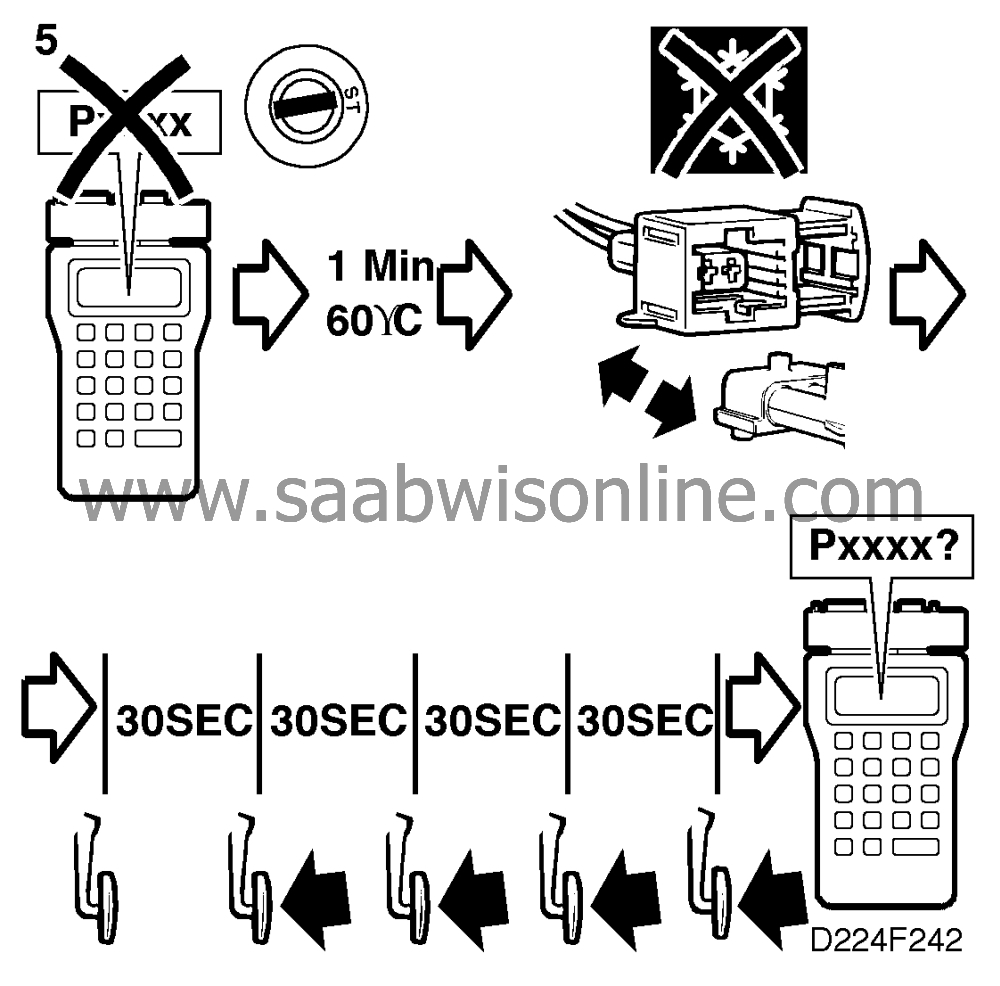

5. Final check:

|

-

|

Clear the diagnostic trouble

code.

|

|

-

|

Perform a driving

cycle:

|

|

|

•

|

Ignition switch in ON position, A/C

switched off and temperature sensor unplugged from the ICE so that the radiator fan runs

continuously

|

|

|

•

|

Start the engine and run it at idling speed until the temperature of the coolant

rises above 60°C (140°F), or for at least 1 minute.

|

|

|

•

|

Depress the accelerator a second or two and then run the engine at idling speed

for 30 seconds. Repeat three times.

|

|

-

|

Evaluation of the driving

cycle:

|

|

-

|

Connect an ISAT scan

tool.

|

|

-

|

Select

"DIAGNOSTIC STATUS".

|

Does the ISAT scan tool show "NOT READY"?

Repeat the driving cycle.

Check whether the diagnostic trouble code has recurred.

Has the diagnostic trouble code recurred?

Proceed to

.

.

The remedial measure taken was correct.

|

-

|

Connect the temperature

sensor to the ICE.

|

|

-

|

Clear the diagnostic trouble code

for the temperature sensor in the ICE.

|