Dips in idling speed and engine rpm

|

|

Dips in idling speed and engine rpm

|

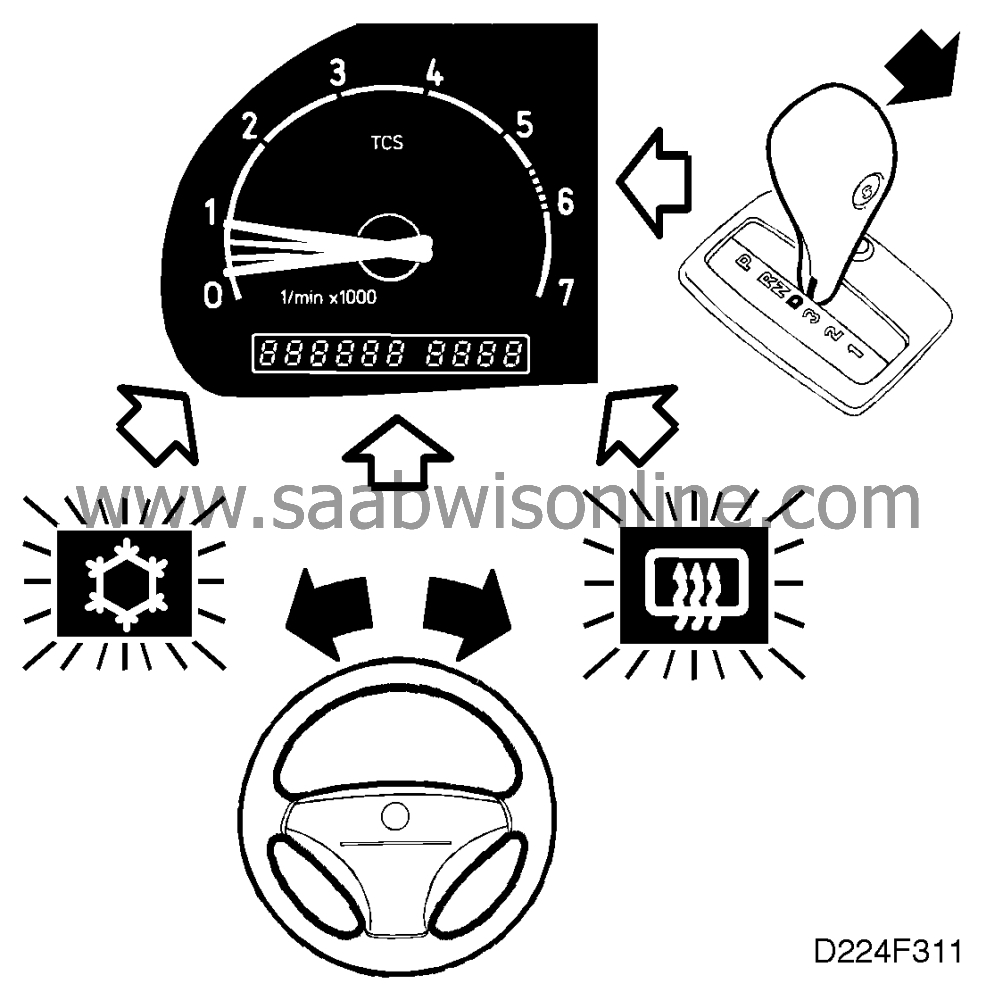

Symptom of fault

Idling speed drops drastically when the engine has to cope with a sudden load demand

in connection with the engagement of high-current electrical equipment such as the A/C, ACC,

power steering, electrically heated rear window or, on cars with automatic transmission,

selection of a gear position.

Conditions

No diagnostic trouble codes.

Diagnostic procedure

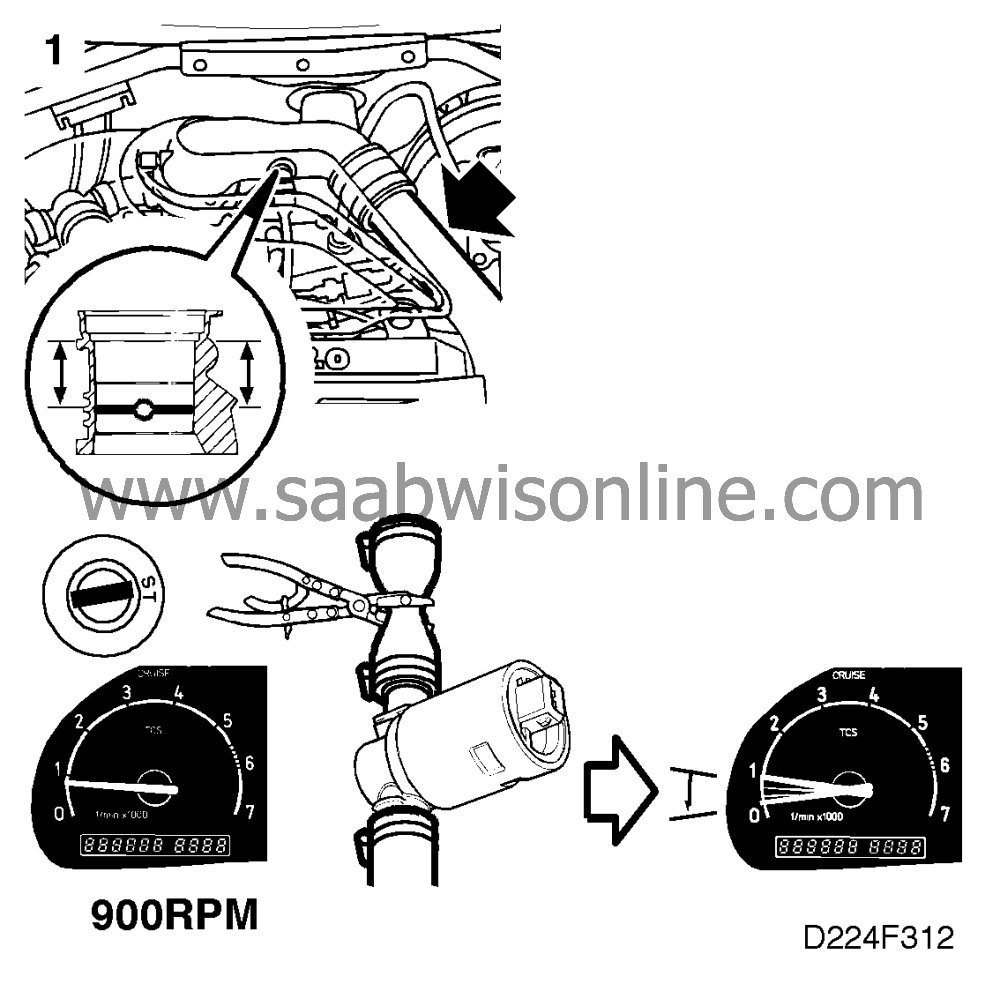

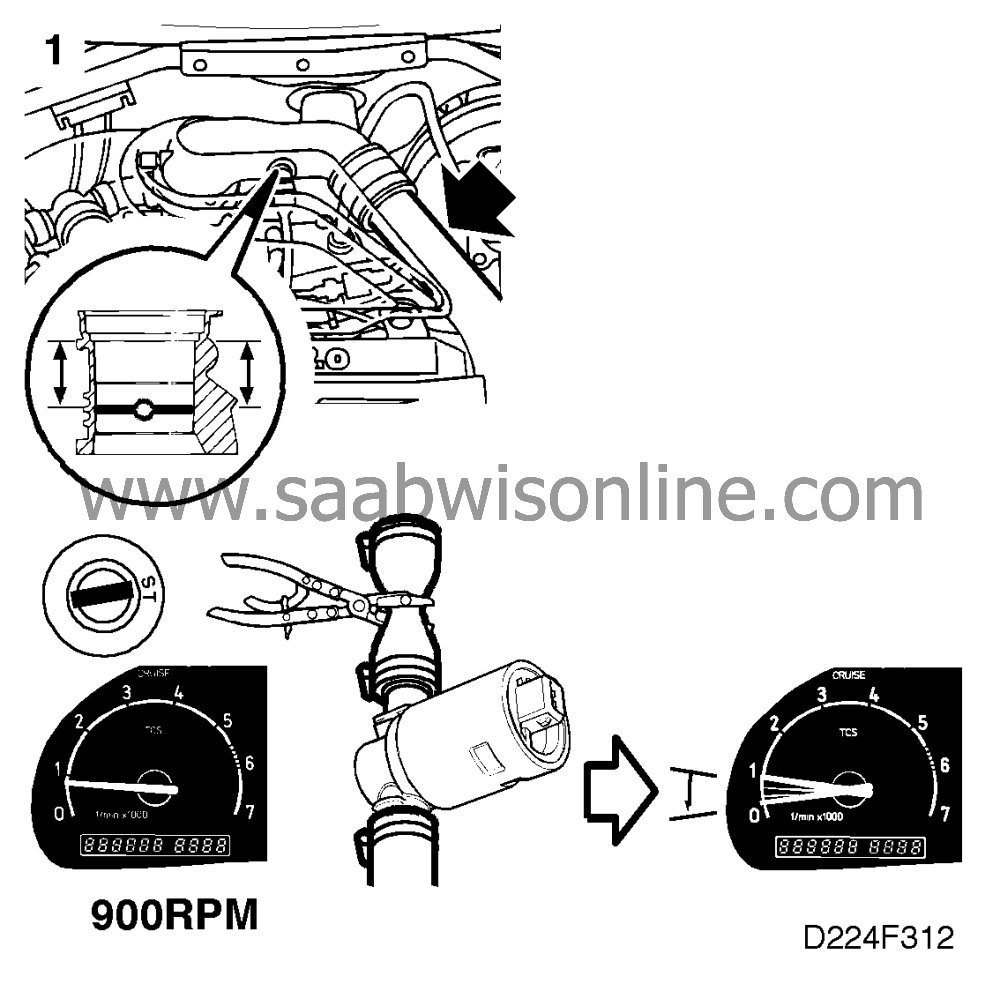

1. Check for air leakage

|

-

|

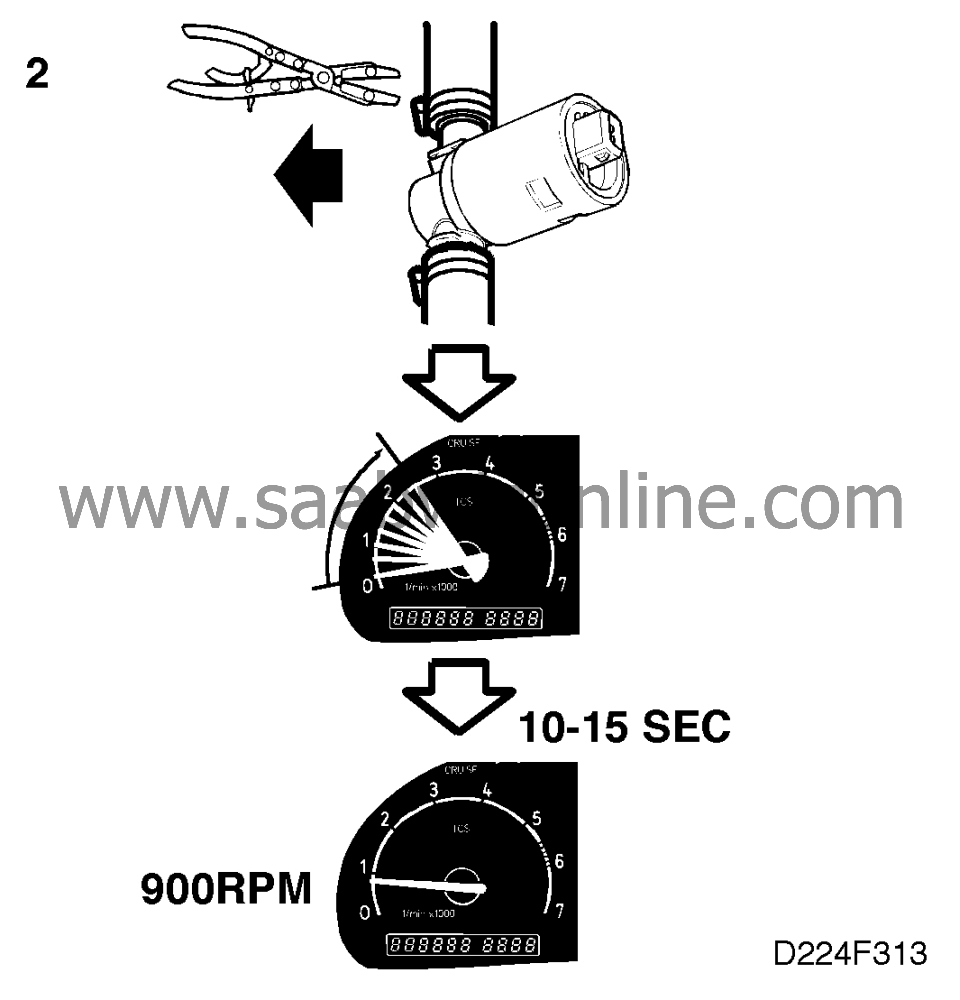

Start the engine, warm it up and

then run it at idling speed.

|

|

-

|

Constrict the flow of air through the

idle air control valve by pinching off the air hose using a pair of pliers. Do not restrict the flow

of air so much that the engine stalls.

|

Idling speed should drop drastically.

Has engine speed dropped?

Continue with point 2.

Continue fault diagnosis by checking:

• poorly adjusted throttle

• Air leakage (after throttle)

Rectify as necessary and continue with point 6.

2. Check idle speed control operation

|

-

|

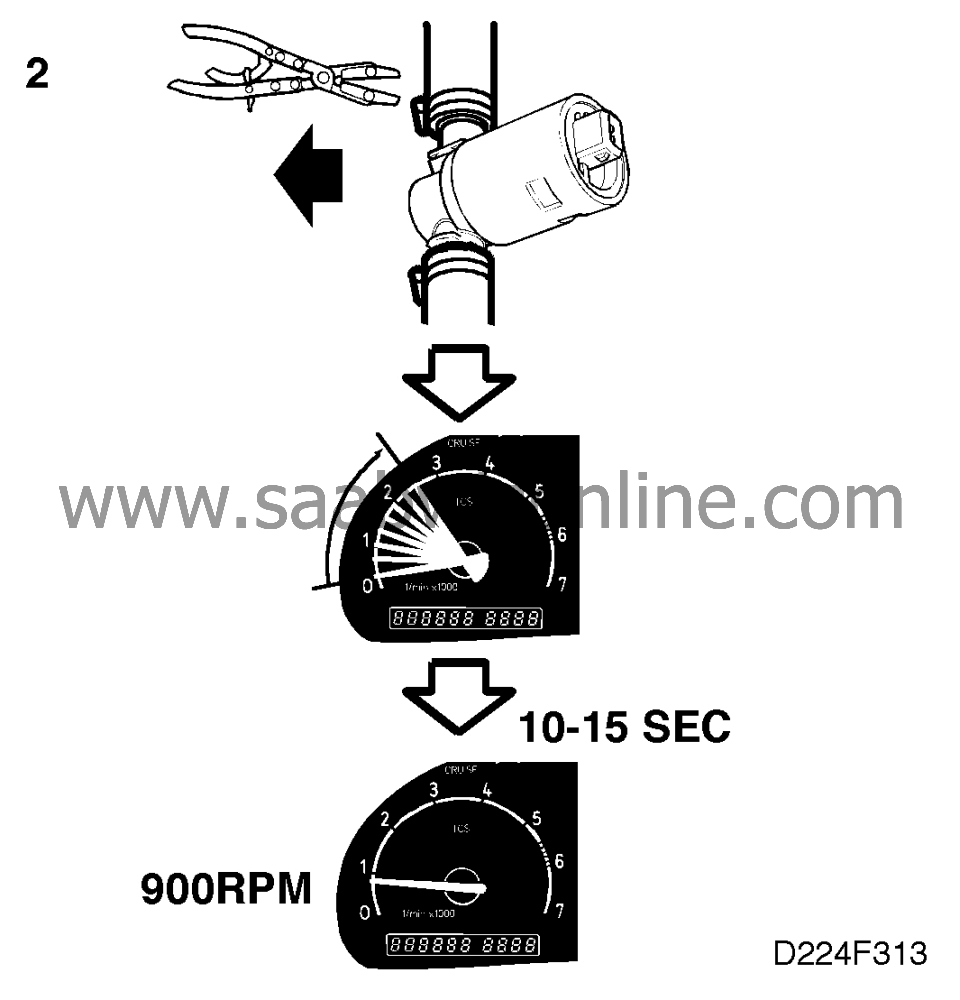

Remove the pliers constricting the

flow of air.

|

Idling speed should increase sharply and then stabilize in about 10-20 seconds

at the nominal speed of 900 rpm (warmed-up engine).

Functionality OK?

Continue with point 5.

Continue with point 3.

3. Check operation of the control valve

|

-

|

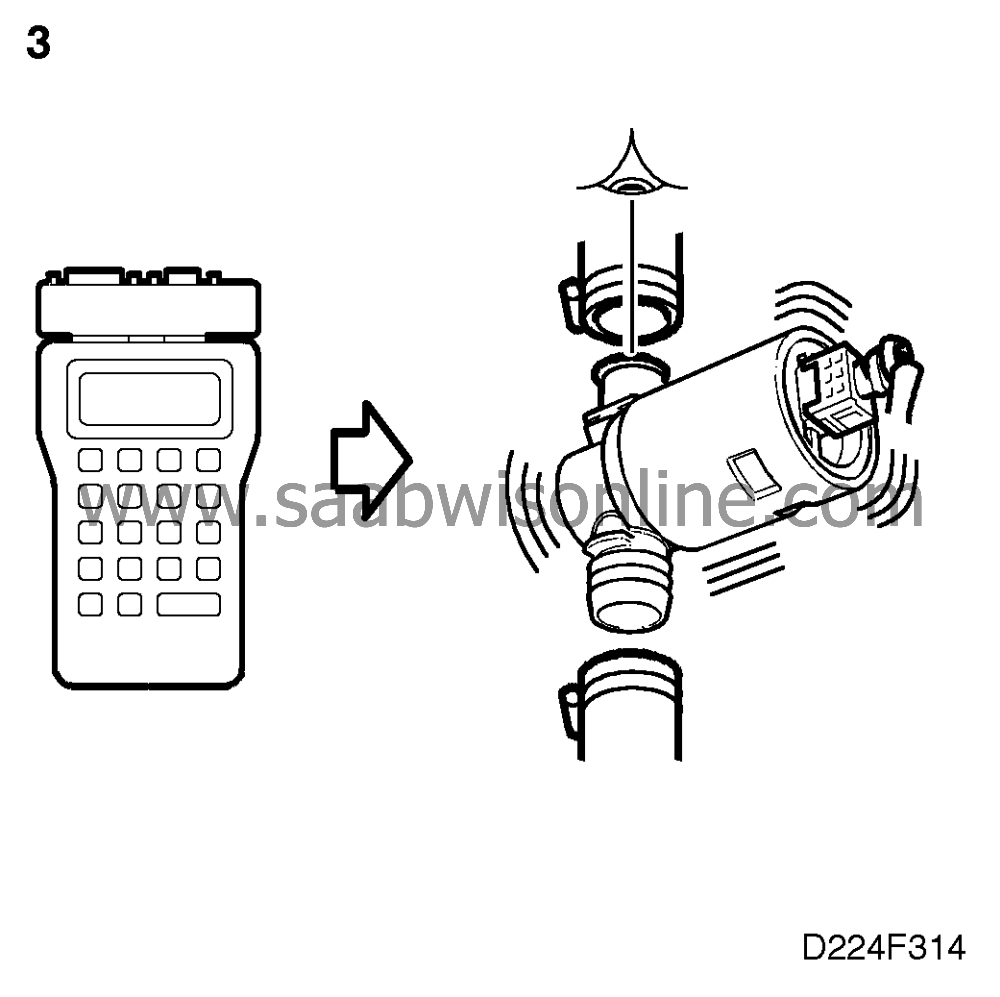

Disconnect the valve's air

hoses.

|

|

-

|

Remove the idle air control valve.

|

|

-

|

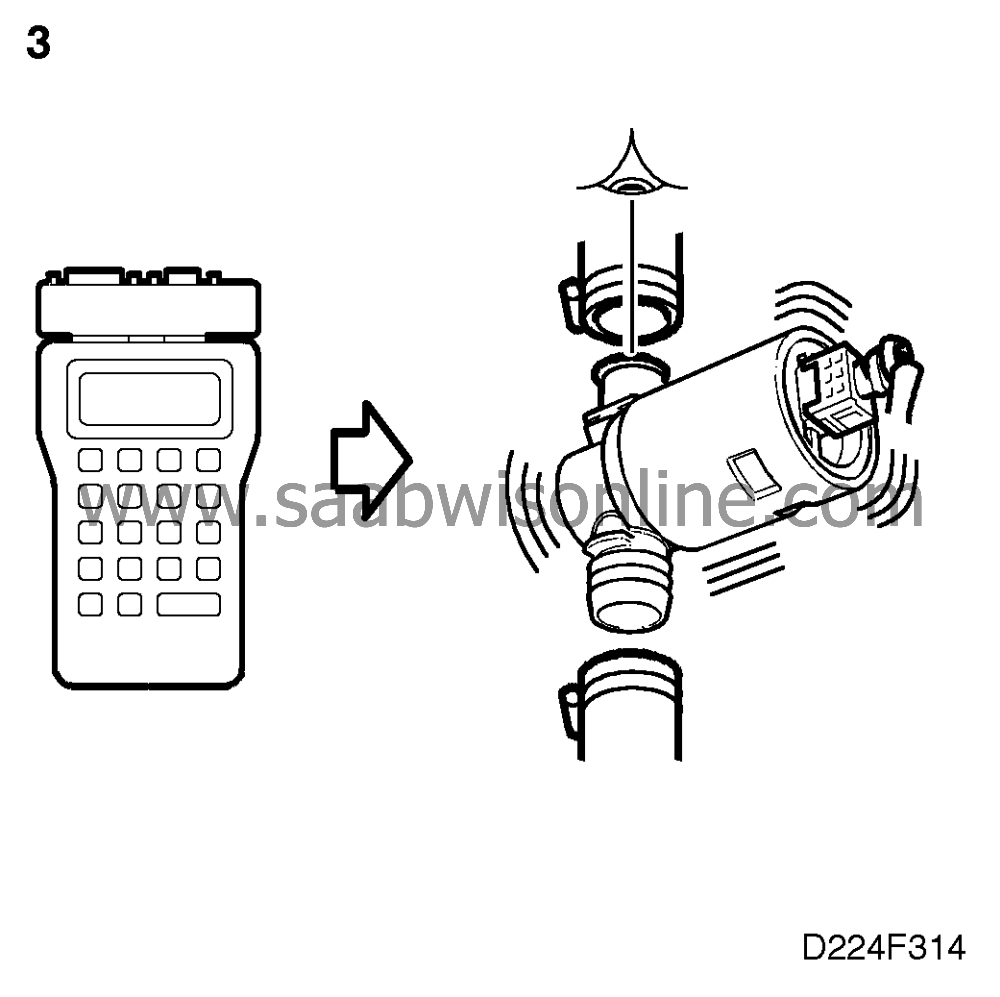

Plug in the idle air control

valve's electrical connector.

|

|

-

|

Connect an ISAT scan tool.

|

|

-

|

Ignition switch in ON position.

|

|

-

|

Check visually that the valve

rotates without tending to bind.

|

Is the control valve OK?

Continue with point 4.

Change the idle air control valve and then continue with point 6.

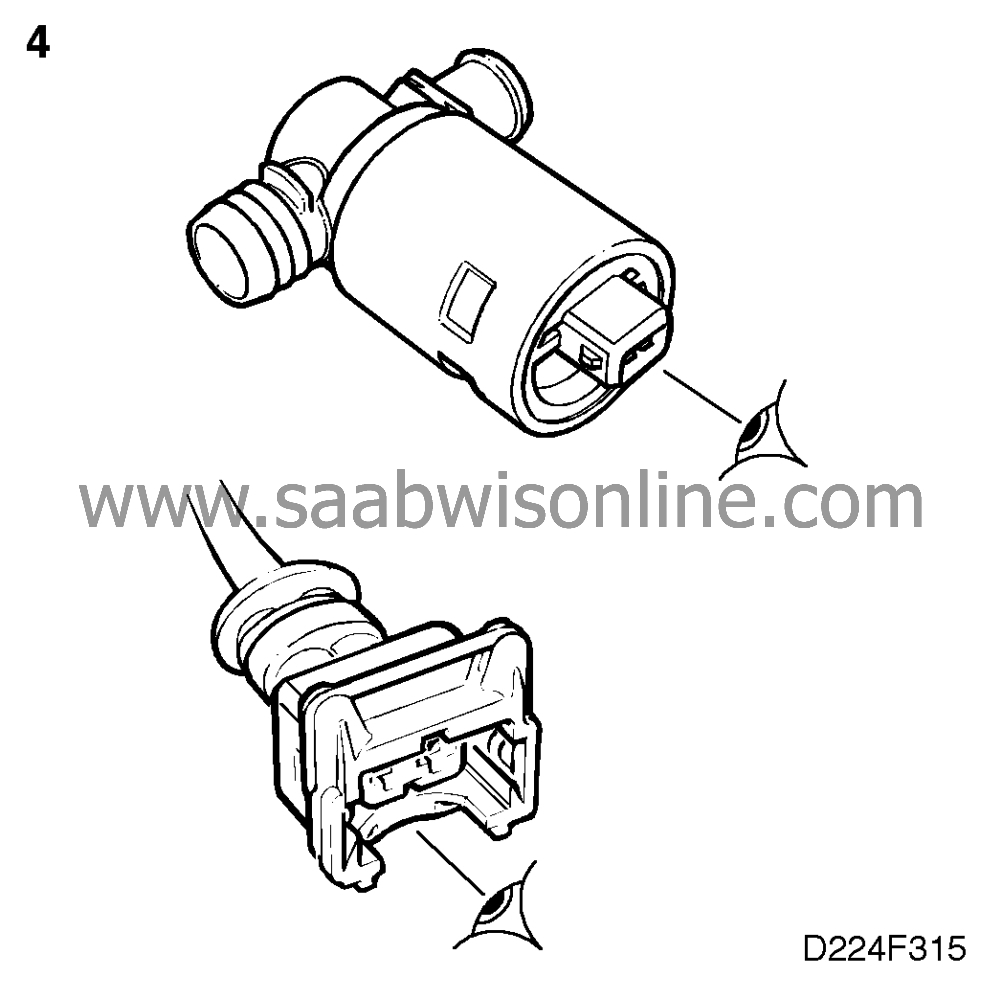

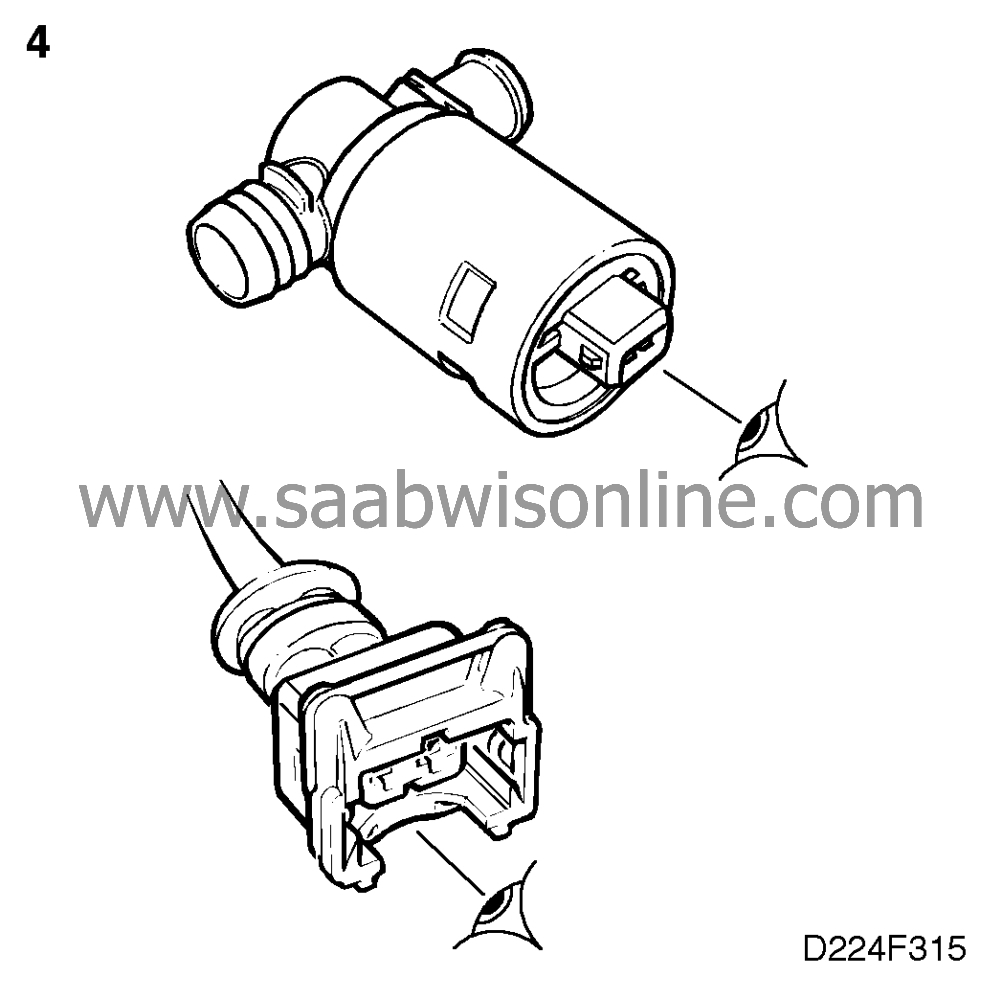

4. Check the idle air control valve switch and/or connector

|

-

|

Carry out a visual check of the

control valve's switch and connector. If necessary, clean and grease the switch and/or

connector.

|

|

-

|

Check whether engine revs

continue to dip.

|

Does the engine still dip?

Continue with point 5.

Continue with point 6.

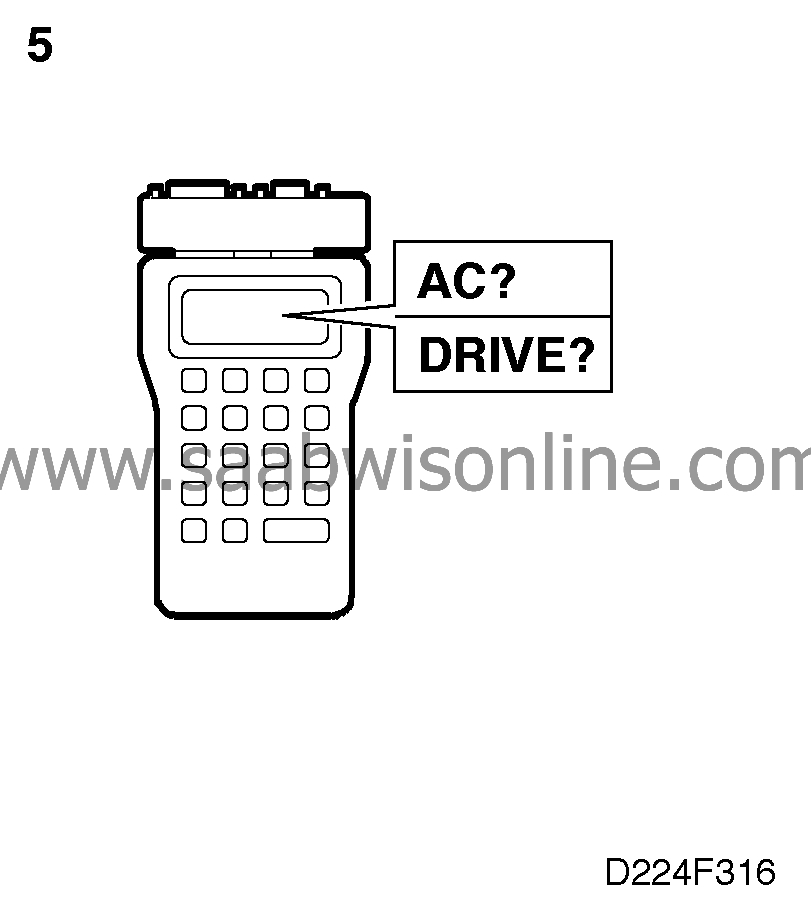

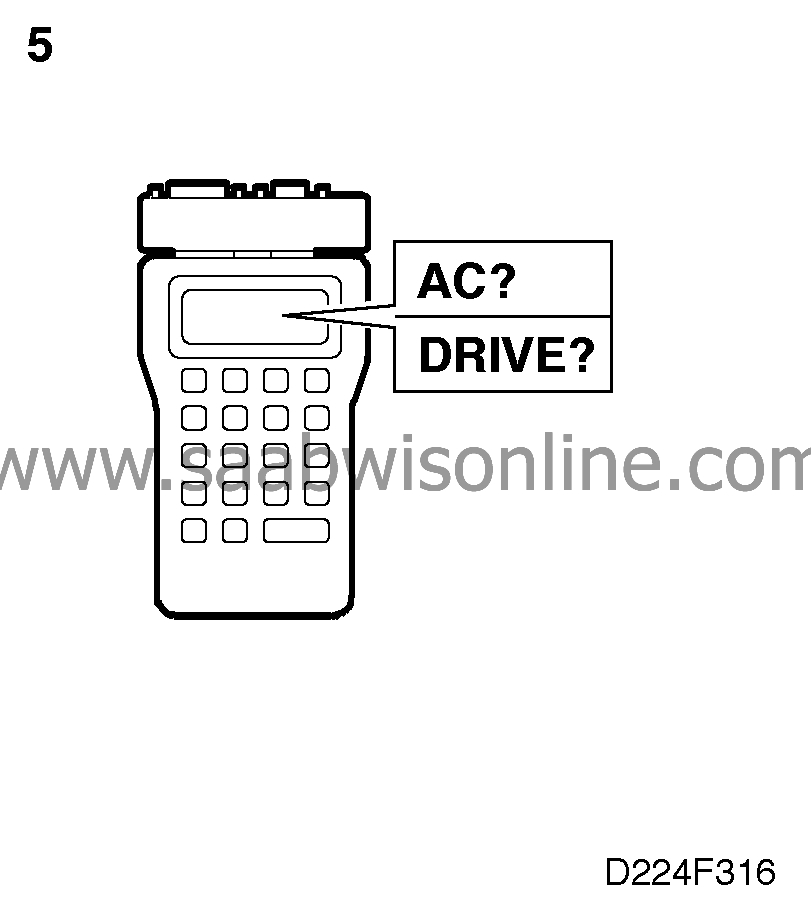

5. Check the engine load

|

-

|

Check that the Trionic control

module receives the correct input signals to compensate for any changes in engine load.

Depending on the trouble, continue fault diagnosis with:

|

|

|

•

|

Fault diagnosis, DRIVE, on

.

.

|

|

|

•

|

Fault diagnosis, other trouble. Continue as described

below.

|

|

-

|

Try changing the idle air control

valve.

|

|

-

|

Check whether the idle air control

valve works.

|

Does the engine still dip?

Continue with point 6.

Change the idle air control valve and then continue with point 6.

6. Final check

|

-

|

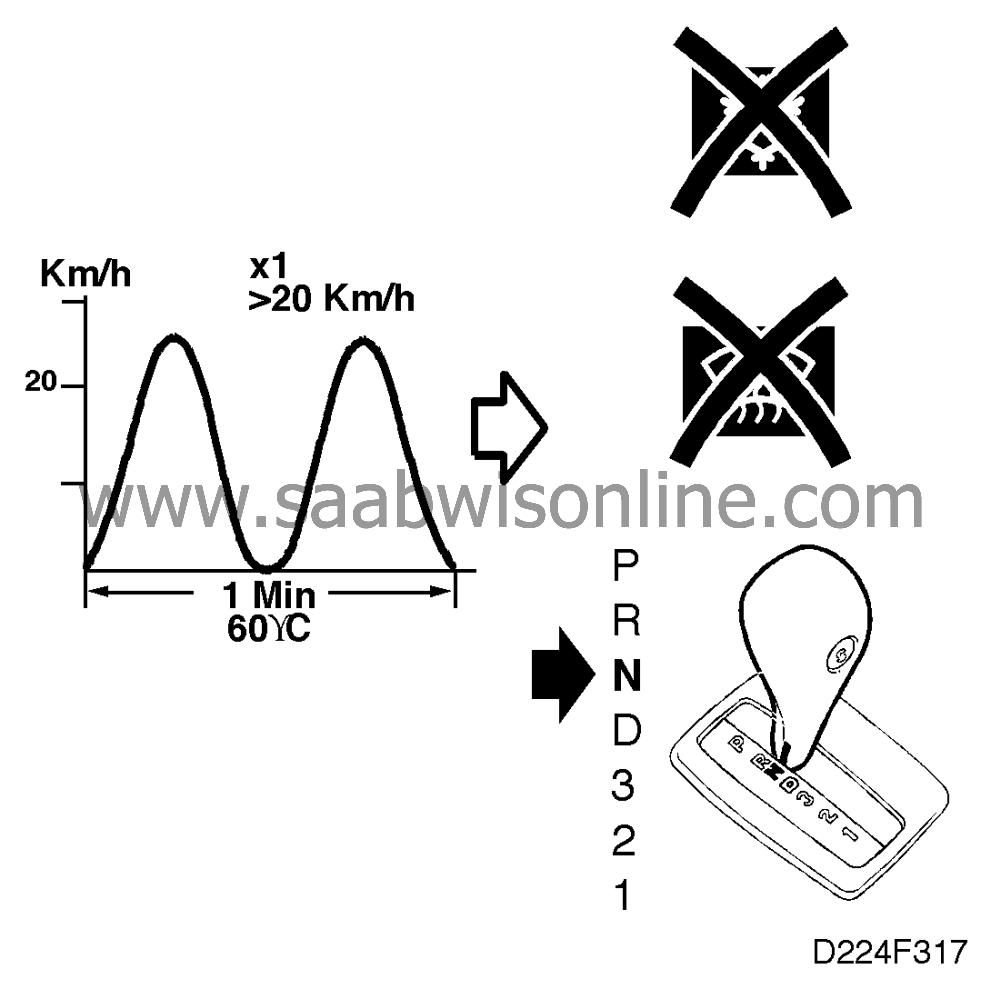

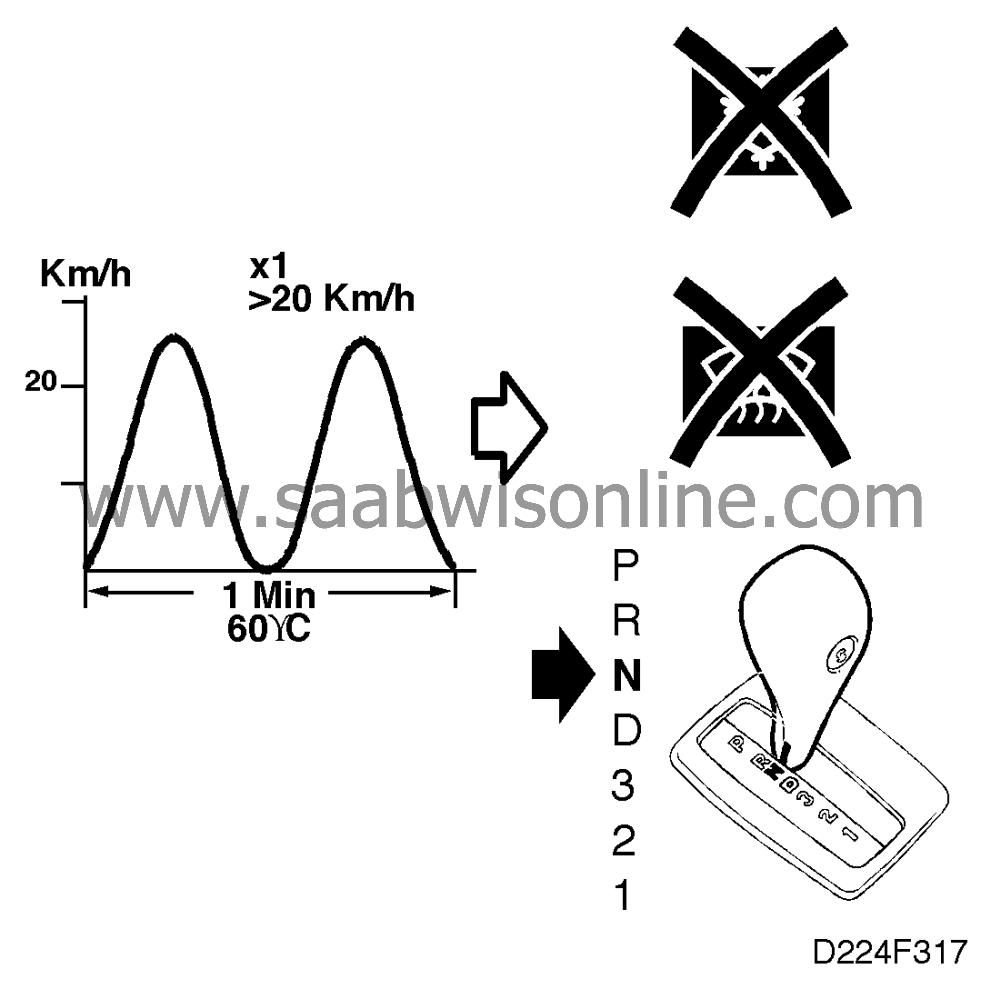

Perform a driving

cycle:

|

|

|

•

|

Drive the car at varying engine

loads and rpm for 5 minutes.

|

|

|

•

|

Car speed should exceed 20 km/h at some time during the driving

cycle

|

|

|

•

|

Stop the car, apply the handbrake and run the engine at idling

speed

|

|

|

•

|

Switch off the A/C and all electrical equipment. If the car has automatic

transmission, select position P. Allow the engine to stabilize its idling speed for 10

sec.

|

|

|

•

|

Switch on the A/C and all electrical equipment. If the car has automatic

transmission, select position D. Allow the engine to stabilize its idling speed for 10 sec.

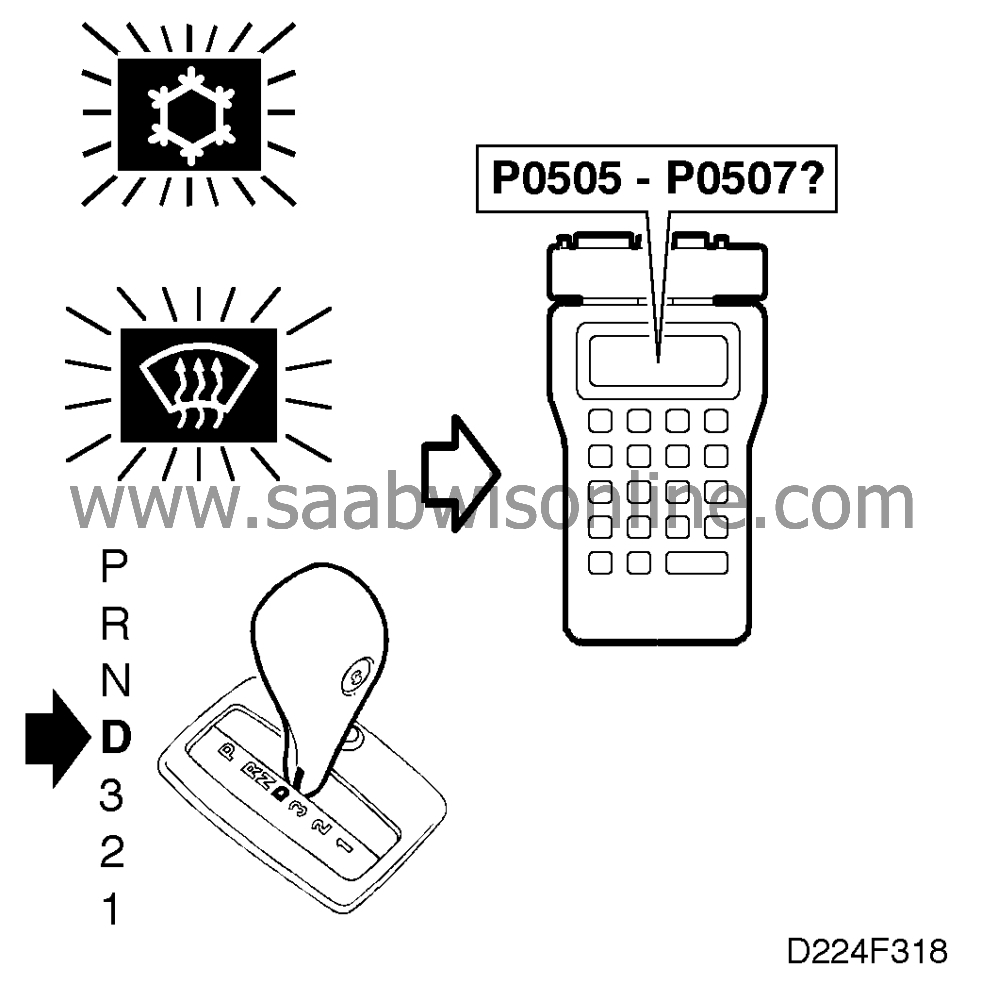

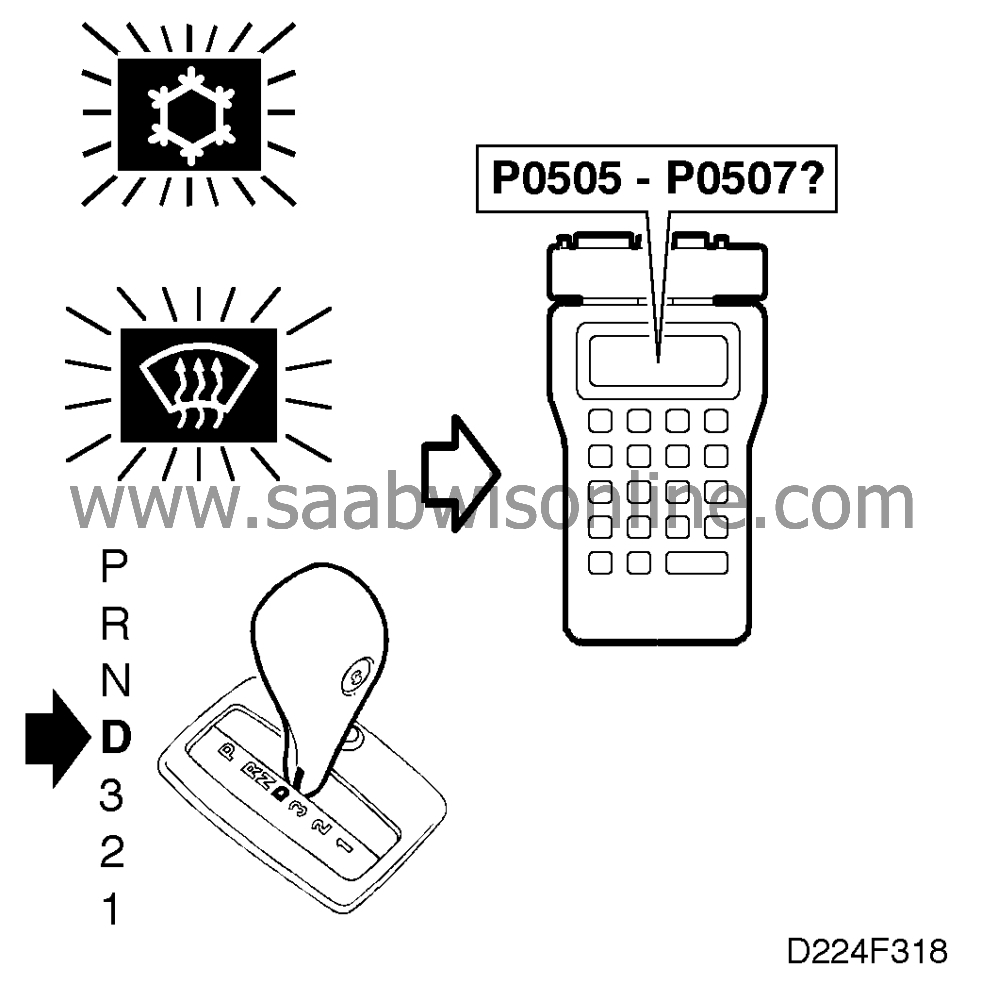

Evaluation of driving cycle: Check whether diagnostic trouble codes P0505-P0507 have been

generated.

|

Has any of the diagnostic trouble codes been generated?

Proceed to

.

.

The remedial measure taken was correct.

.

.