Fault diagnosis, turbo pressure gauge(turbo/APC), (MIU 2)

|

|

Fault diagnosis, turbo pressure gauge

(turbo/APC), (MIU 2)

|

Fault symptoms

The turbo pressure gauge needle stands still at zero or maximum.

Diagnostic procedure

|

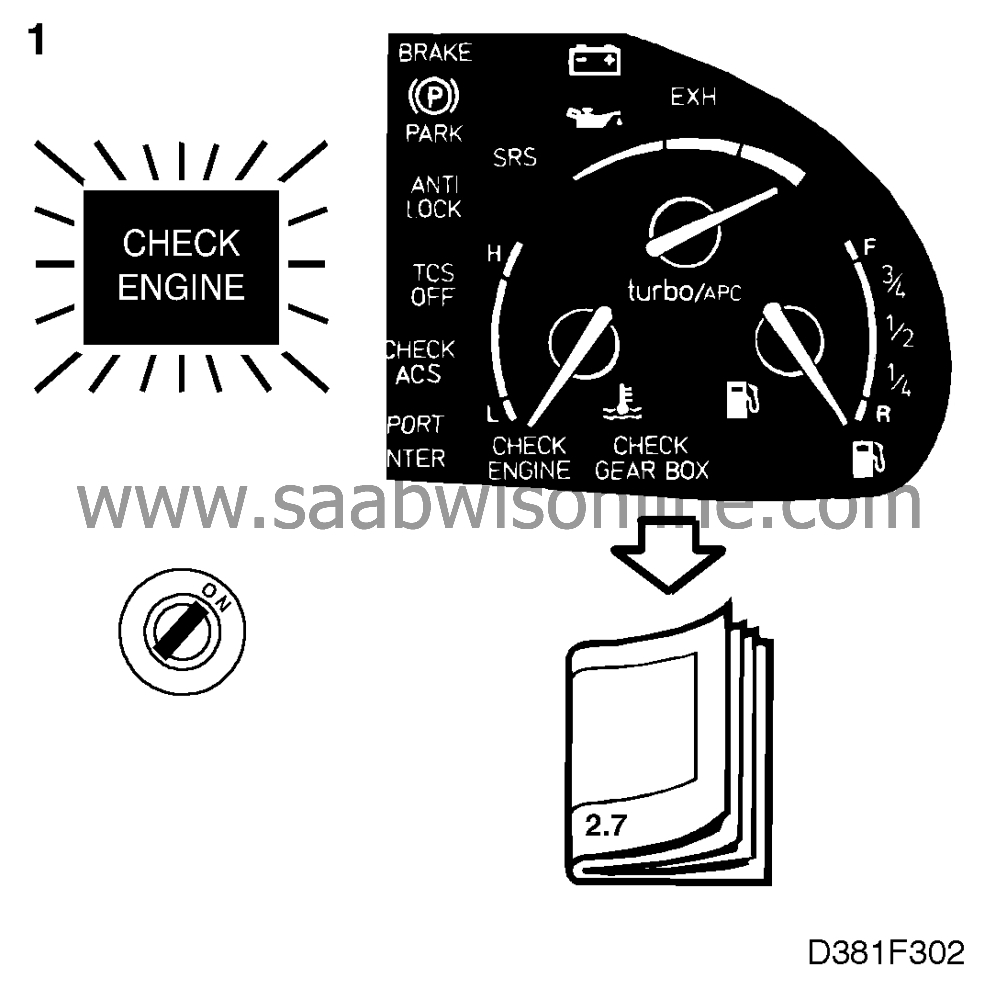

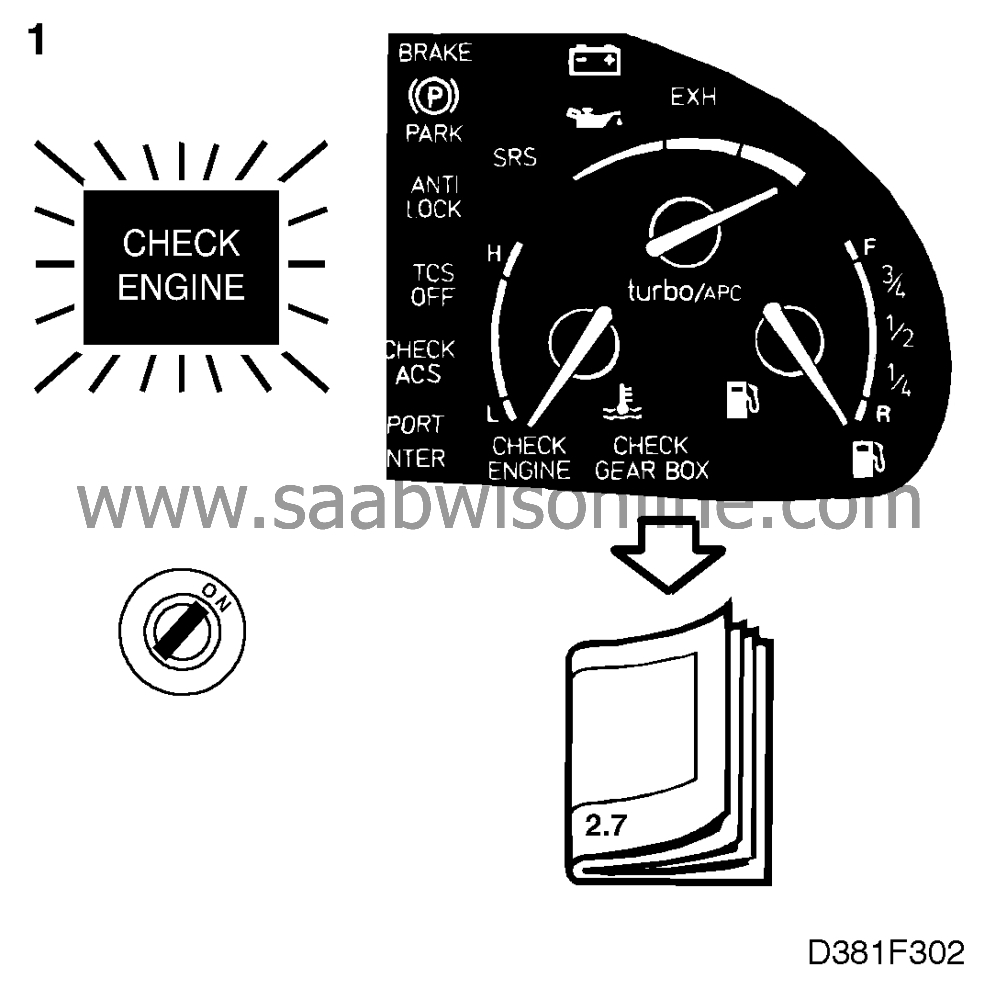

1.

|

If the CHECK ENGINE lamp (MIL) lights up or

the turbo/APC gauge needle indicates maximum pressure, continue fault diagnosis as

described in Service Manual 2:7 "TRIONIC Engine Management System".

If this is not the case, continue with point 2.

|

|

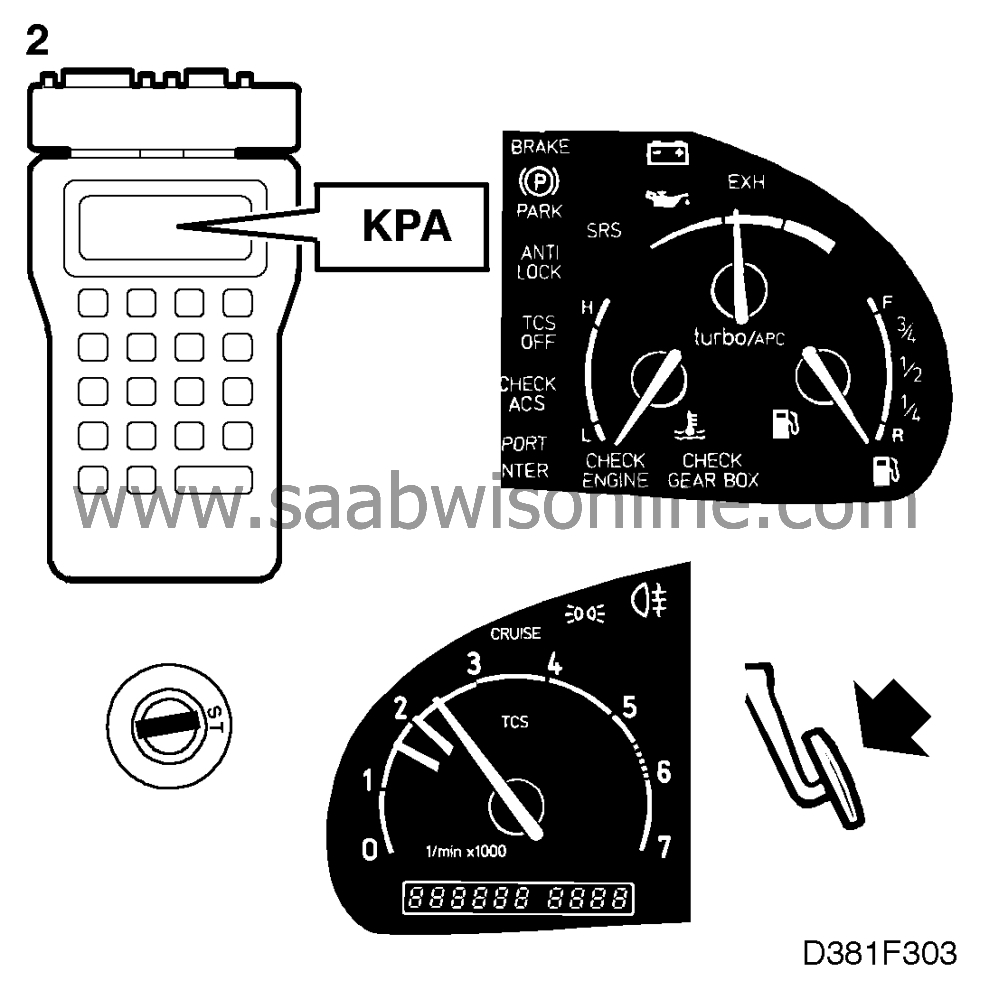

2.

|

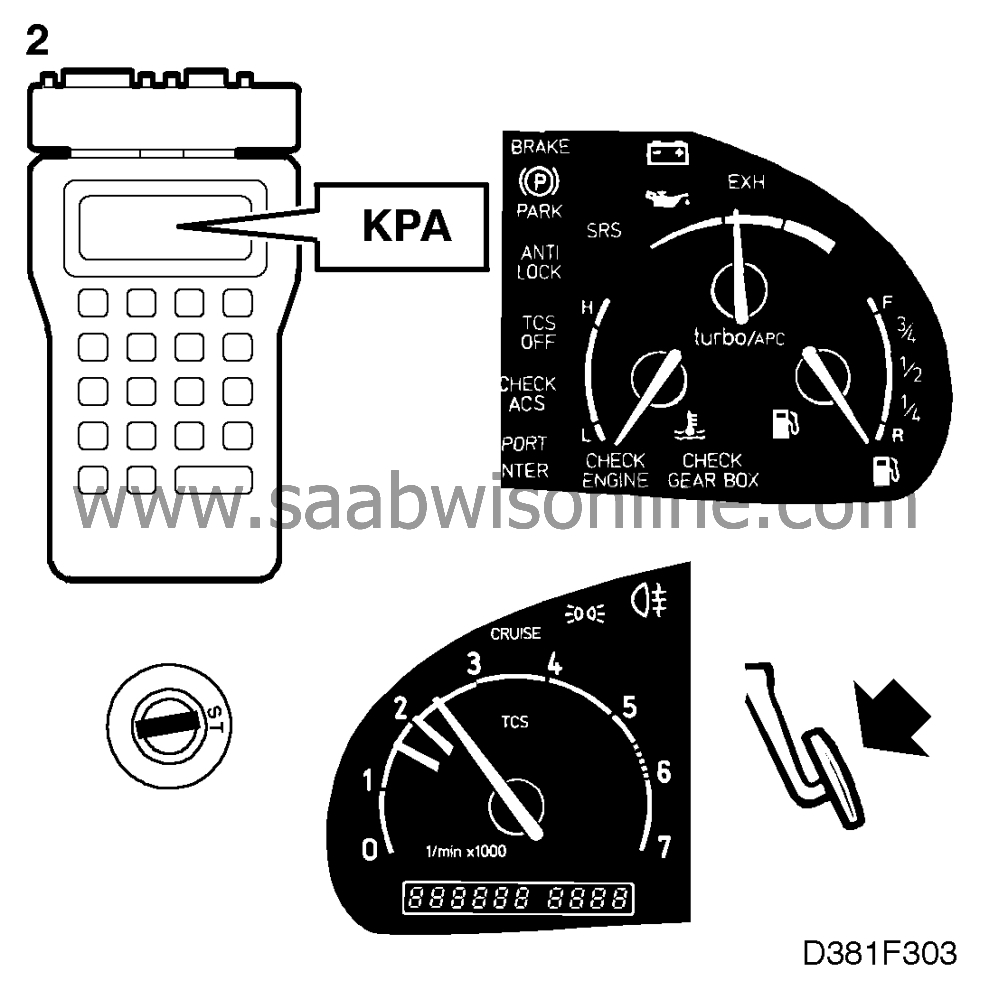

Connect the ISAT Scan Tool and select "READ VALUES" followed by "TURBO

PRESSURE".

Start the engine.

|

|

3.

|

If the system is in proper working order, the turbo pressure on the Scan Tool

display should vary with different engine rpm and loads.

|

|

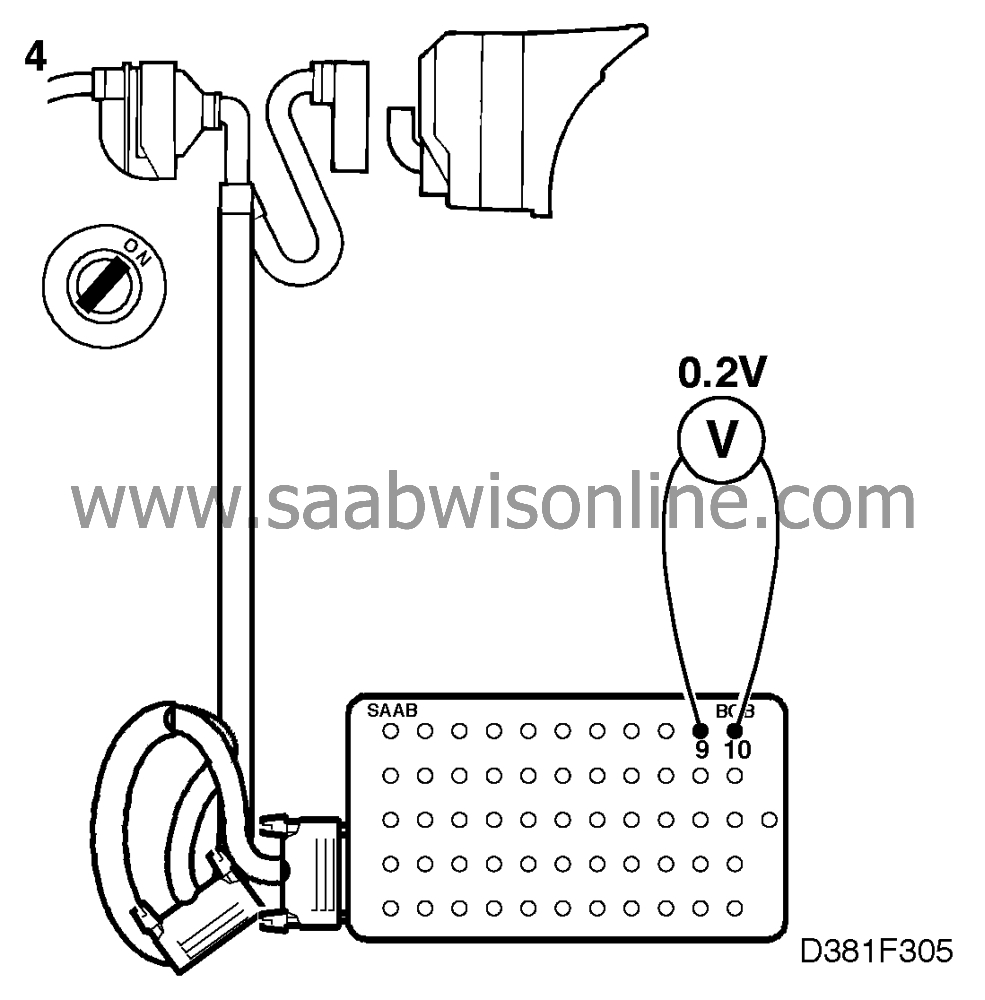

4.

|

If a signal is present, continue with point 8.

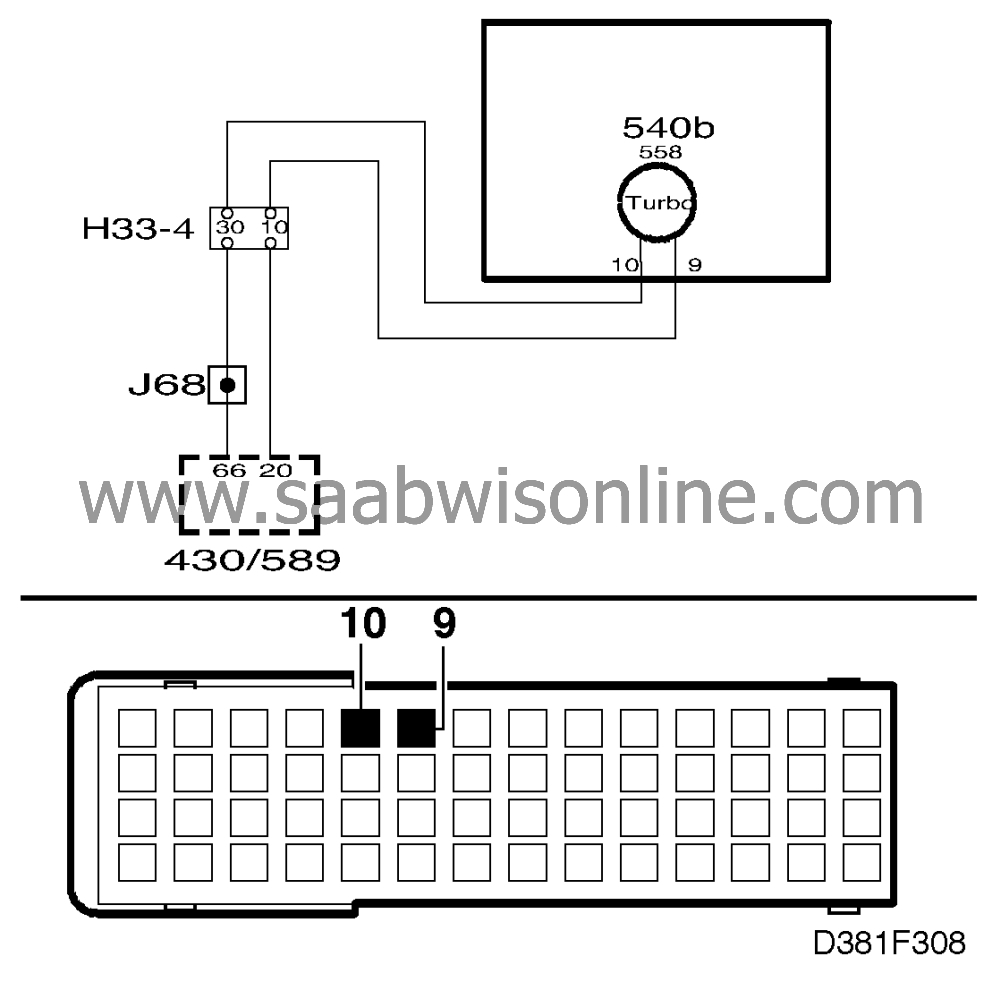

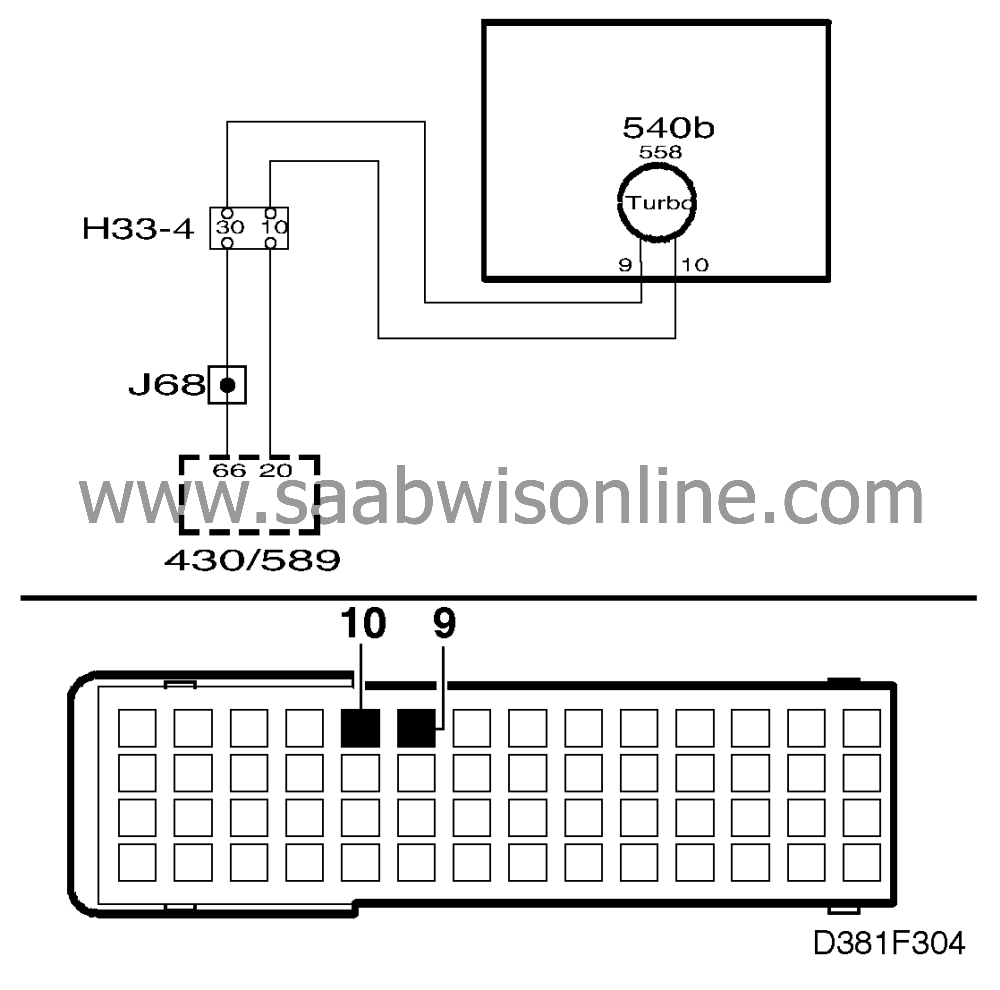

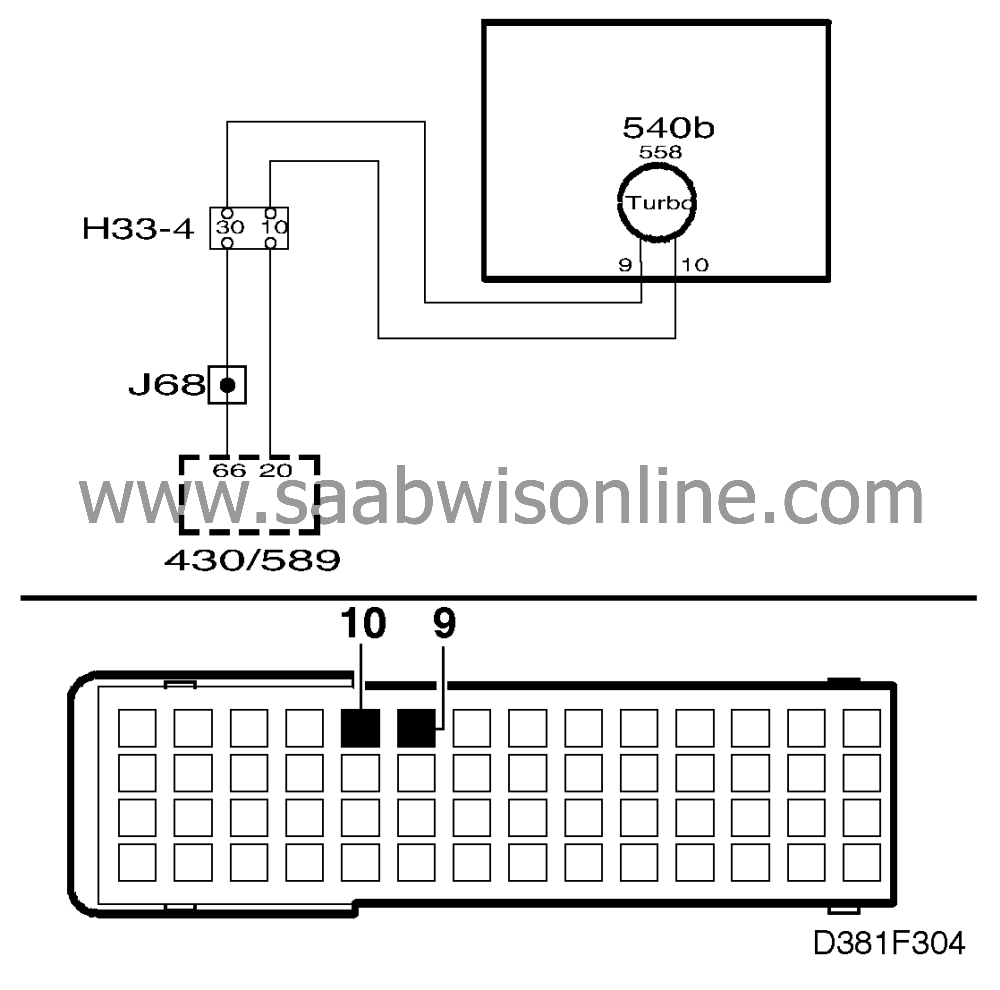

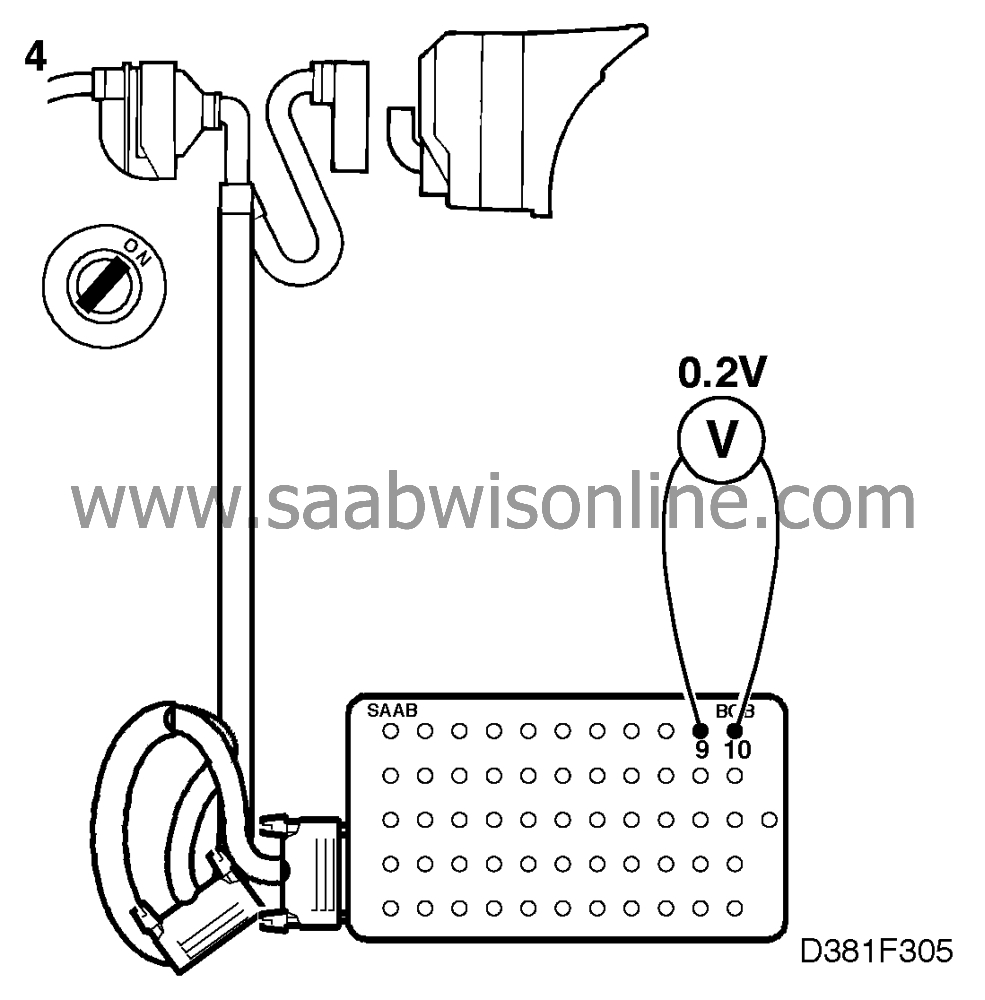

If no signal is present, check the input signal to the main instrument display panel by

connecting a BOB to the 56-pin connector behind the main instrument display panel (which

should not be connected).

Connect a voltmeter to pins 9 and 10. Start the engine and check whether a reading is

obtained. If correct, the reading should be between 0 and 2 V.

|

|

5.

|

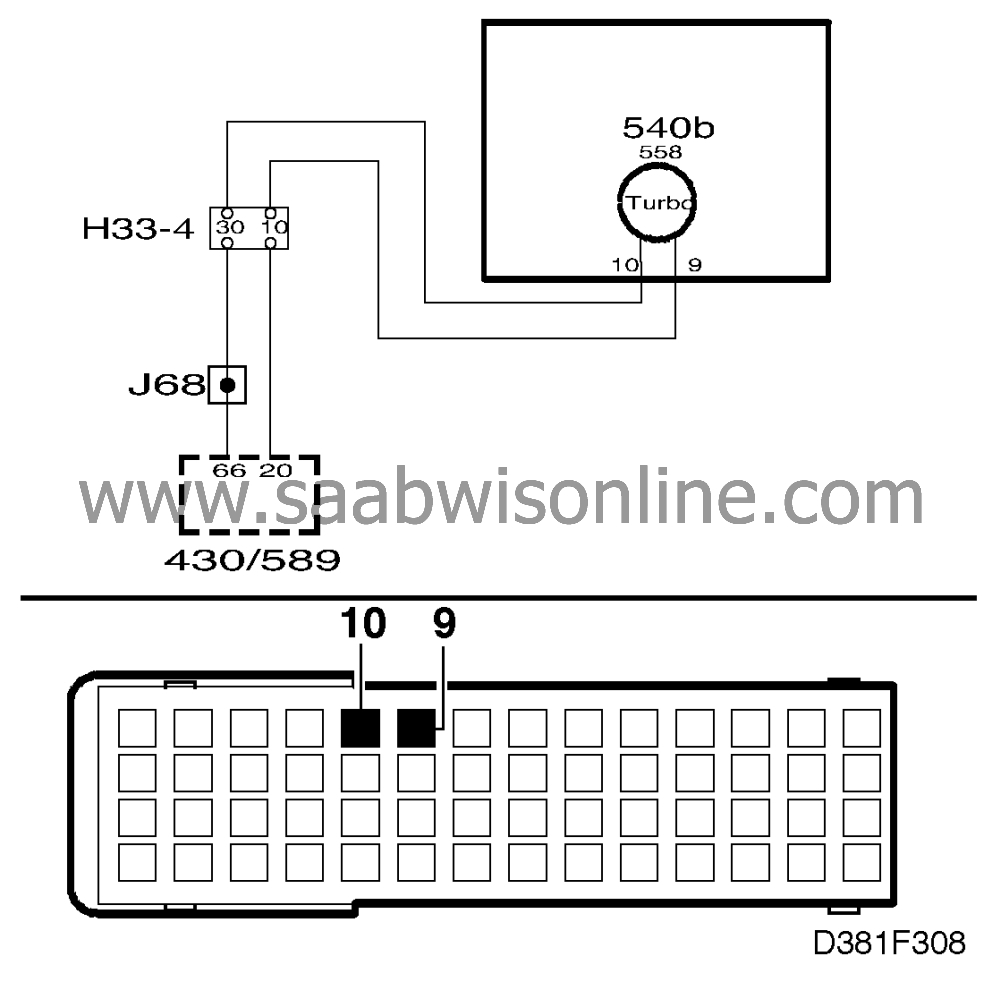

If no reading is obtained, check the wiring by connecting another BOB to the

TRIONIC control module's connector.

The main instrument display panel and the TRIONIC control module should not be

connected.

|

|

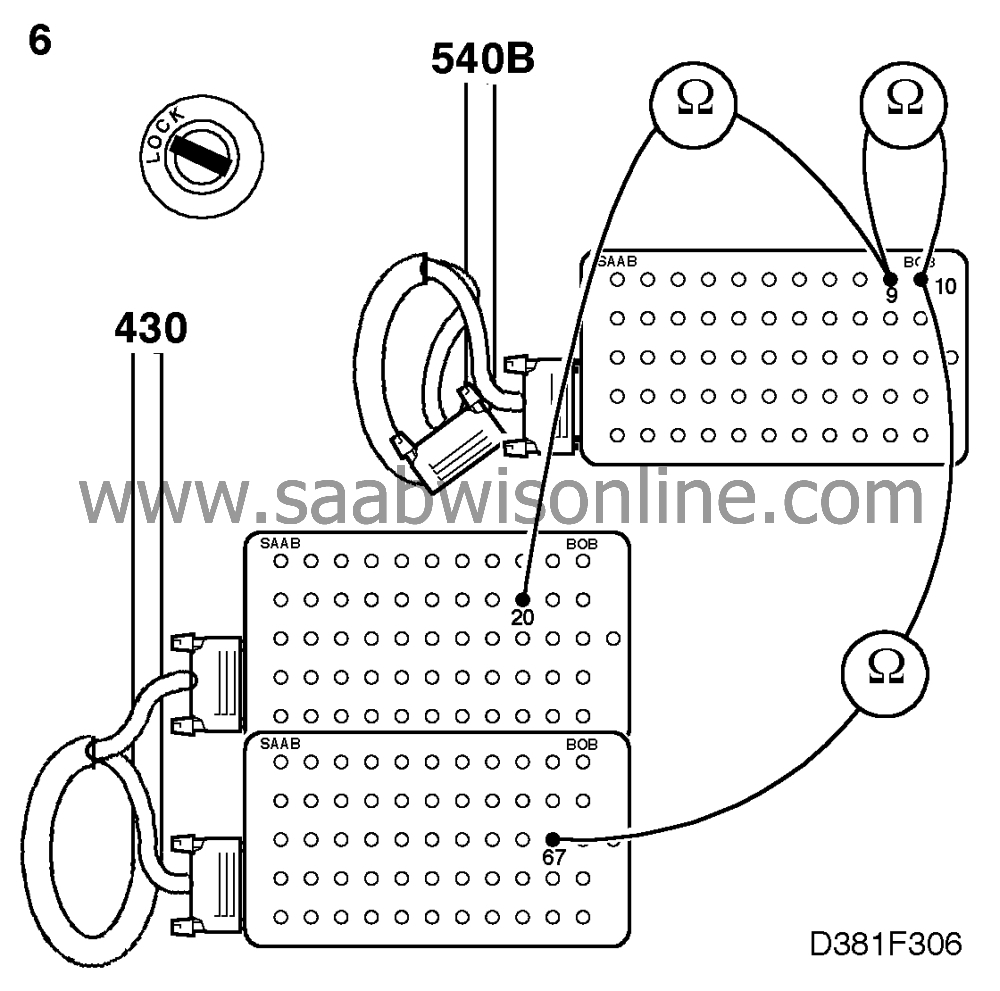

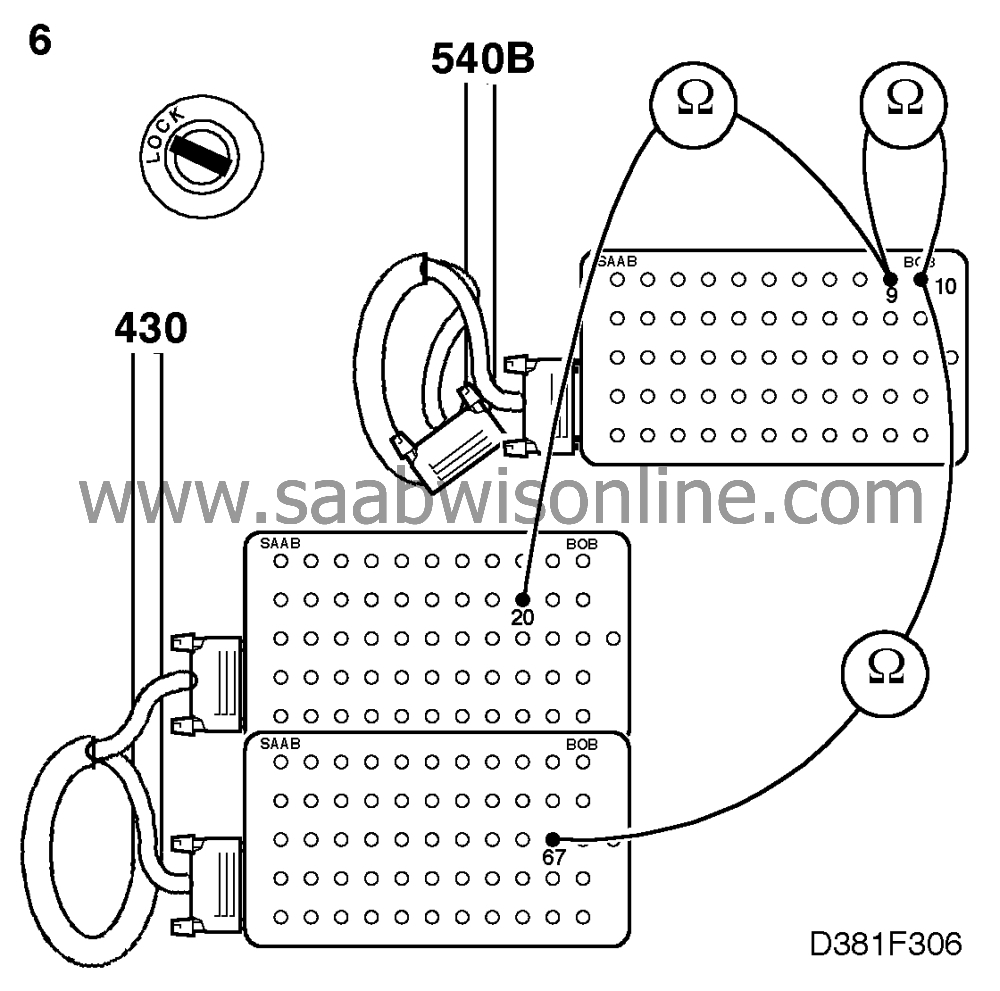

6.

|

Check the wiring for an open circuit (< 1 Ohm) or short circuit (OL) by taking a

reading across pins 9 and 10 on the BOB connected to the main instrument display panel and

pins 20 and 67 on the other BOB.

Take appropriate action in regard to any faults in the wiring.

|

|

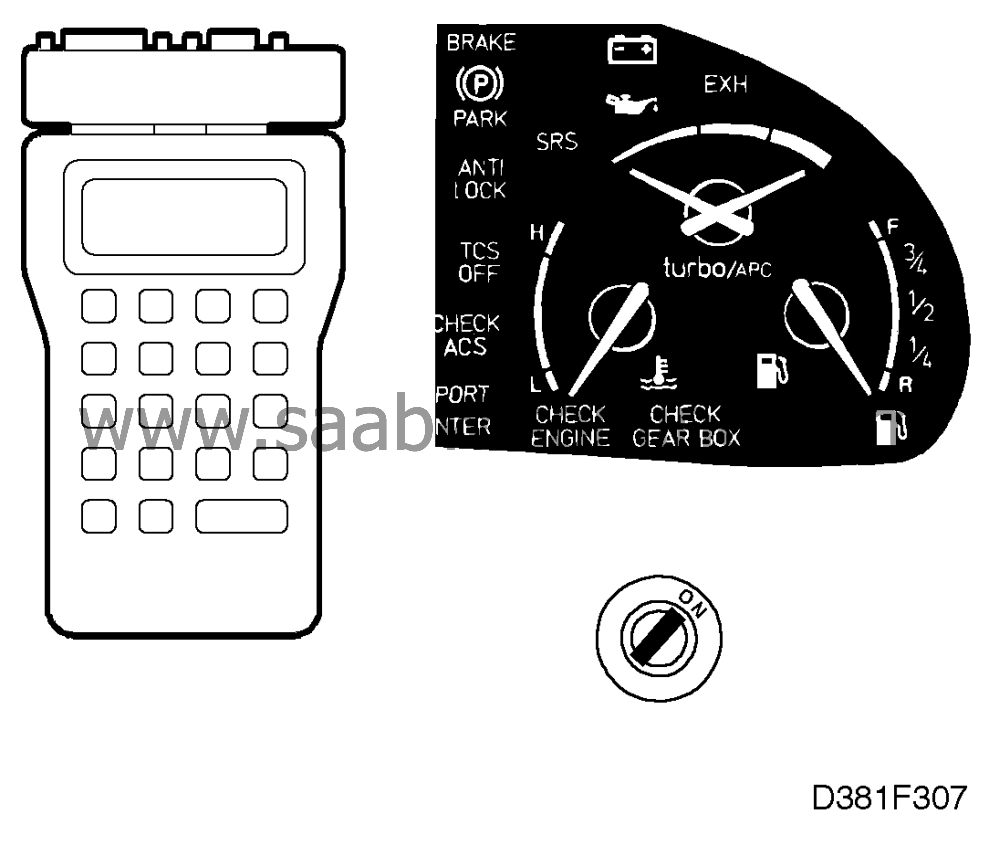

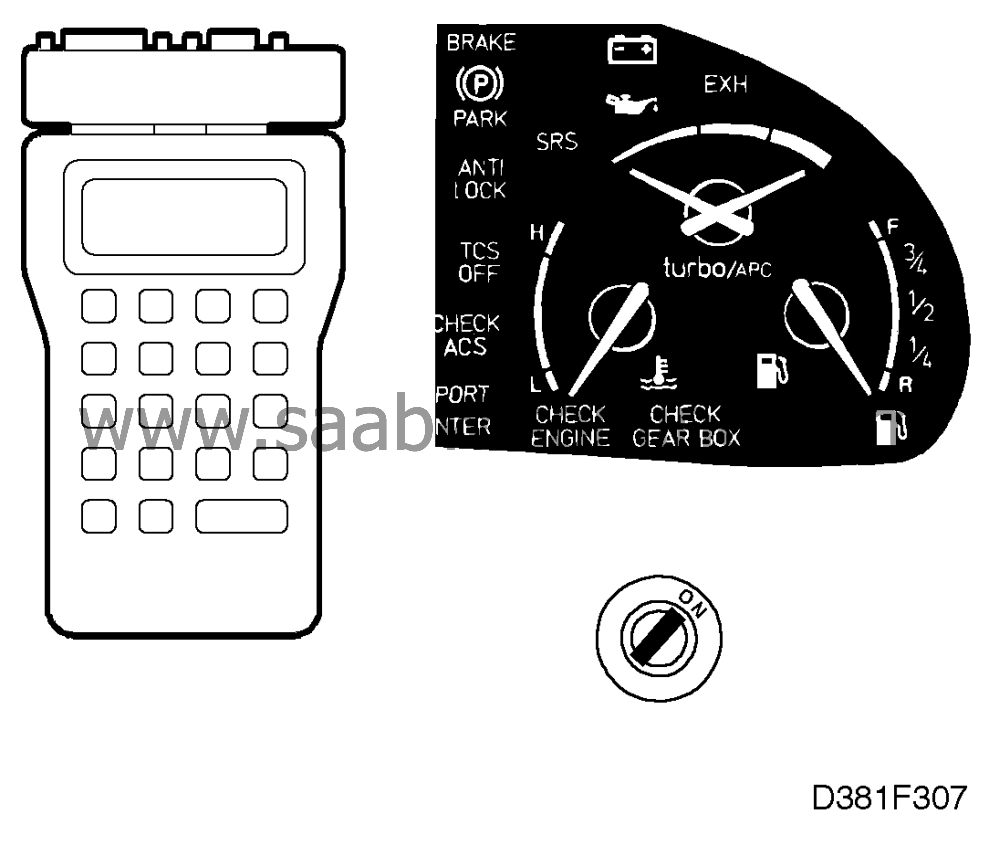

7.

|

Connect the ISAT Scan Tool and select "TEST FUNCTIONS" followed by

"TURBO GAUGE TEST".

If in proper working order the needle of the turbo/APC gauge should move from left to

right across the scale and back again.

If the turbo/APC gauge does not work, it could be due to an open circuit in the

connection between the processor card and the intermediate part of the main instrument

display panel.

Remove the main instrument display panel's rear section complete with

processor card and check that all leads connected to the connector marked CN3 are securely

located.

If any lead has worked loose or is broken, continue on

.

.

If the leads connected to the connector are all OK, the fault is probably in the

intermediate part with the indicating instruments. Continue on

.

.

|

|

8.

|

Connect the ISAT Scan Tool and select "TEST FUNCTIONS" followed by

"TURBO GAUGE TEST".

If in proper working order the needle of the turbo/APC gauge should move from left to

right across the scale and back again.

If the turbo/APC gauge works, there is probably an open circuit between the connector

and the processor on the processor card in the main instrument display panel.

Continue on

.

.

|