Points to remember when diagnosingfaults

|

|

Points to remember when diagnosing

faults

|

|

Important

|

|

Diagnostic trouble codes should only be used for diagnostic purposes. It is by no means

certain that they indicate a defective component.

|

|

|

It is impossible to give any general rules for the procedure to follow when

diagnosing faults in each individual case. Depending on the fault symptoms and other

information available, one method may be best in some situations and another method best in

others.

However, the following points may serve as guidance when diagnosing faults in the

main instrument display panel's control module.

|

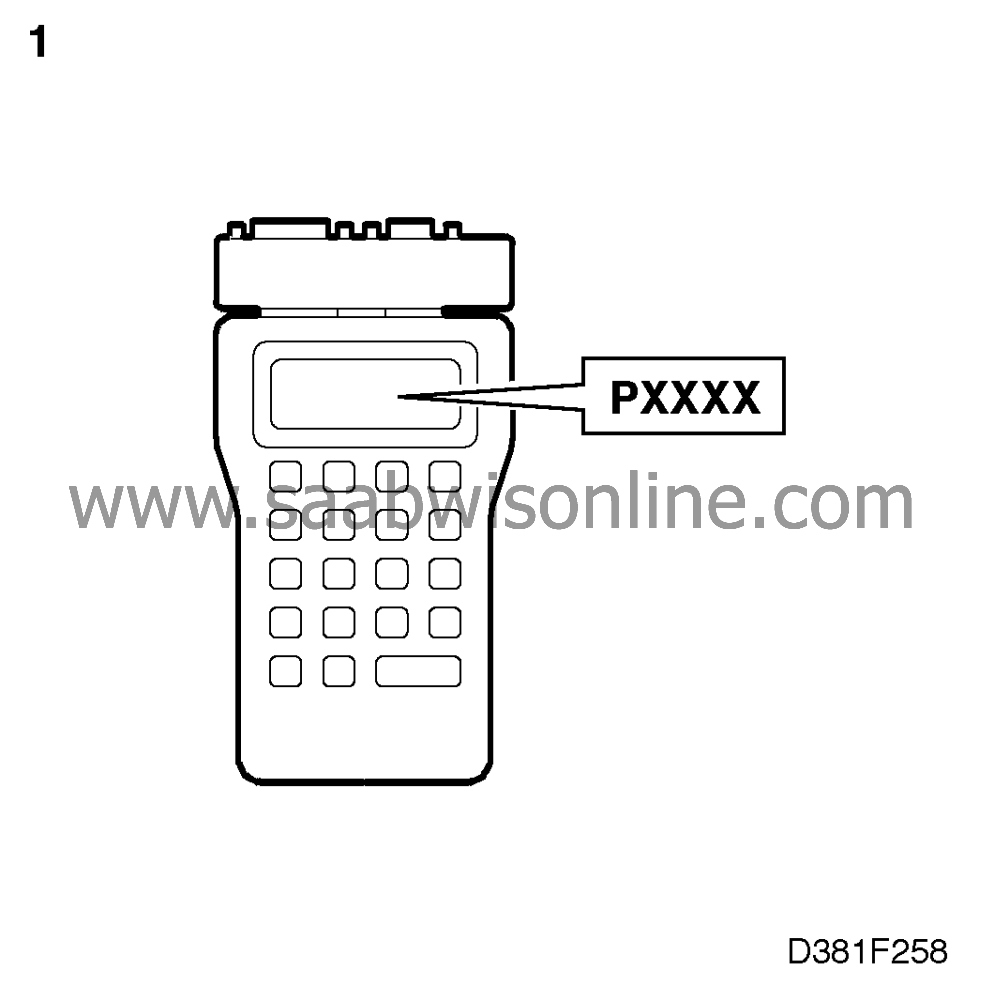

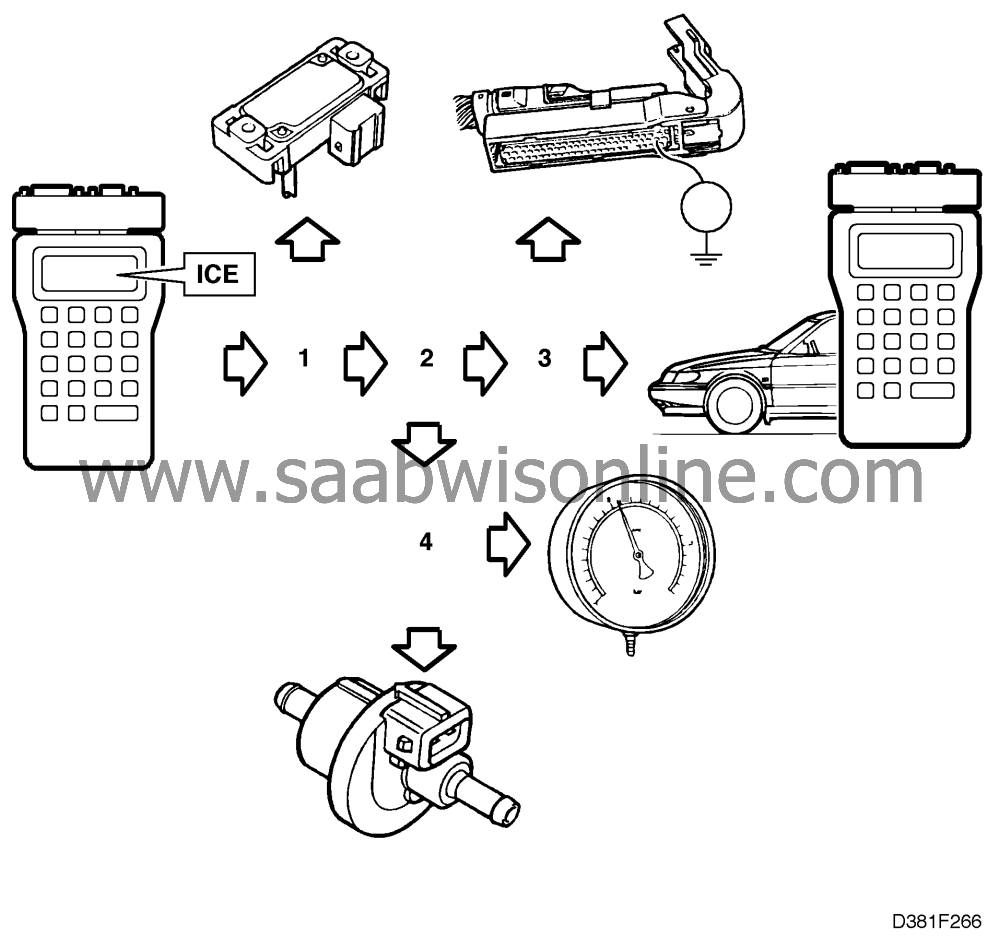

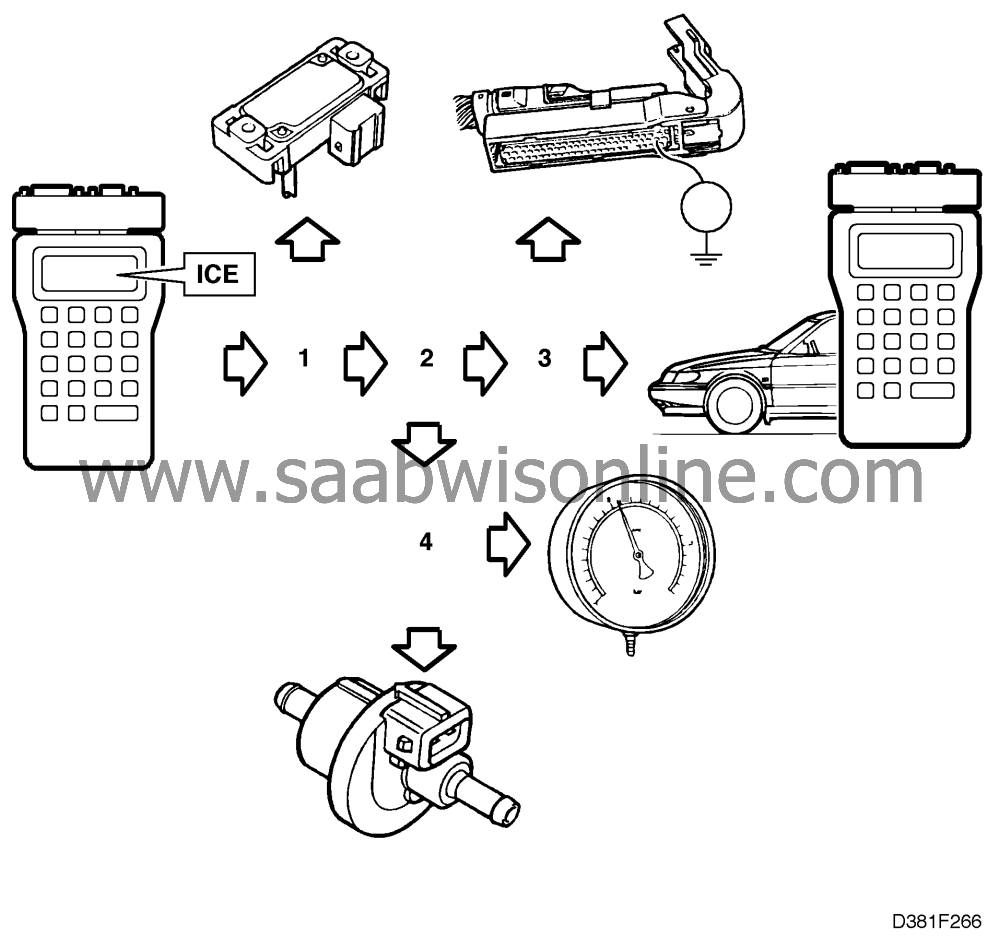

1.

|

Always begin by using an ISAT

Scan Tool to read the diagnostic trouble codes, if any. Use the "ALL SYSTEMS" command to

obtain readouts of all diagnostic trouble codes. Make a note of the trouble codes or save them

in the ISAT Scan Tool's internal memory by using the "SAVE FAULT CODES"

command.

Diagnostic trouble codes stored in the internal memory can be retrieved by using the

"RECALL FAULT CODES" command.

Diagnostic trouble codes present:

Continue with "Fault

diagnosis with diagnostic trouble codes".

No diagnostic trouble codes present:

Continue with

"Fault diagnosis, components".

|

|

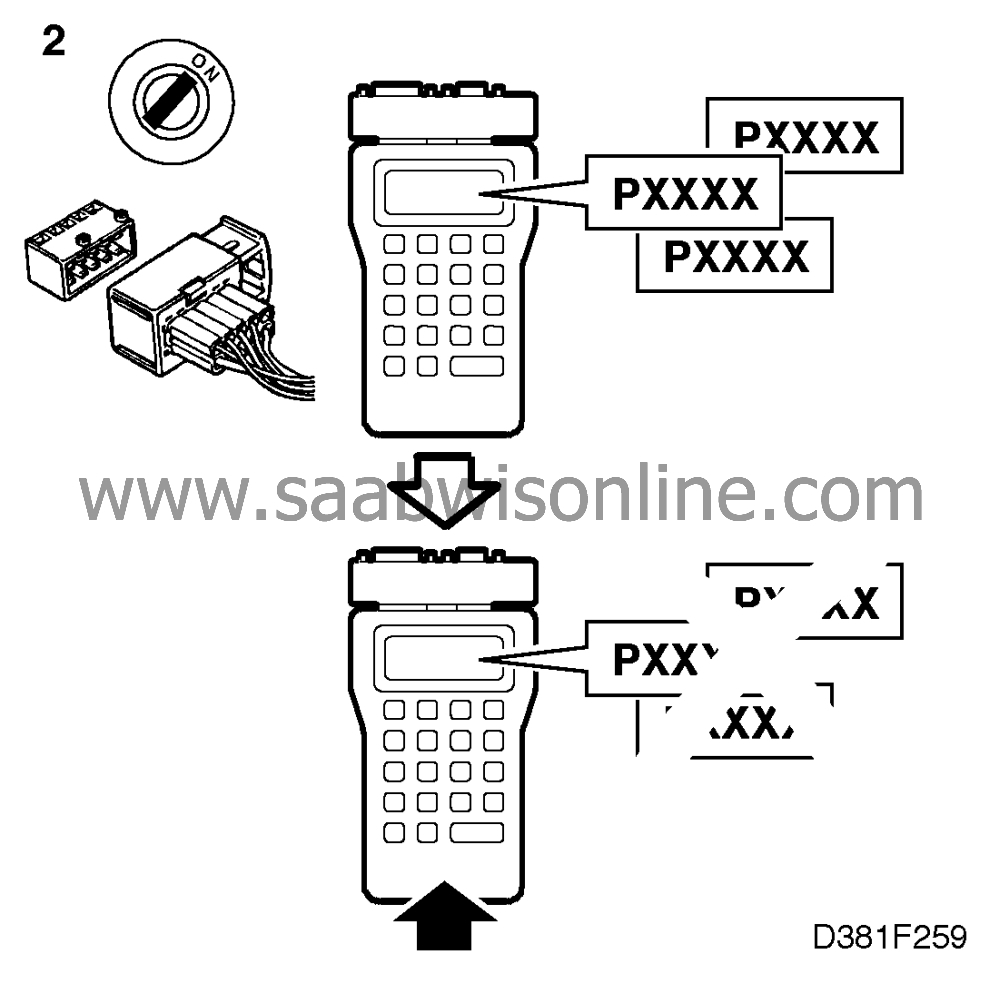

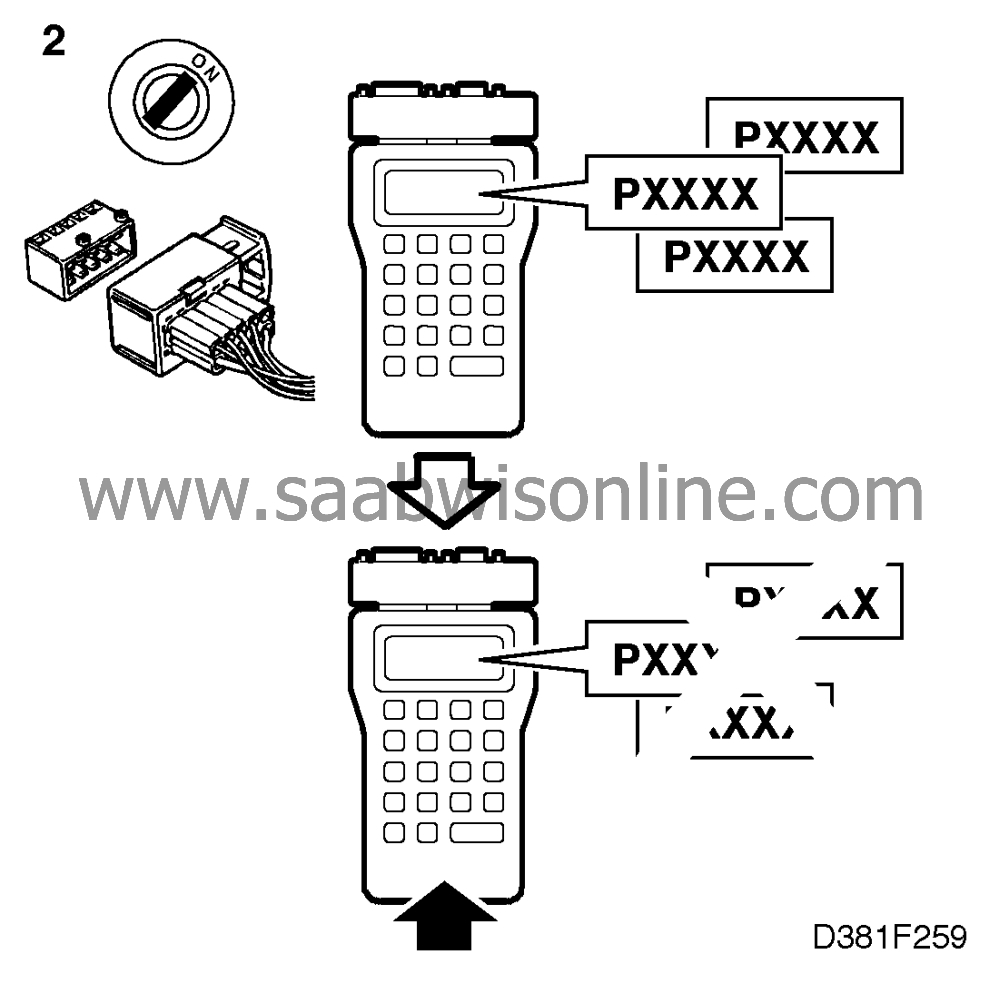

2.

|

In some fault diagnosis procedures, electric wiring is disconnected or connectors

unplugged while the ignition switch is in the ON position. This can give rise to the generation

of diagnostic trouble codes. Therefore, when the work is finished, always clear any diagnostic

trouble codes that may have been generated. Clear all trouble codes by using the "CLEAR"

command.

|

|

3.

|

Check fuses 13, 17, 18, 30 and 34.

|

|

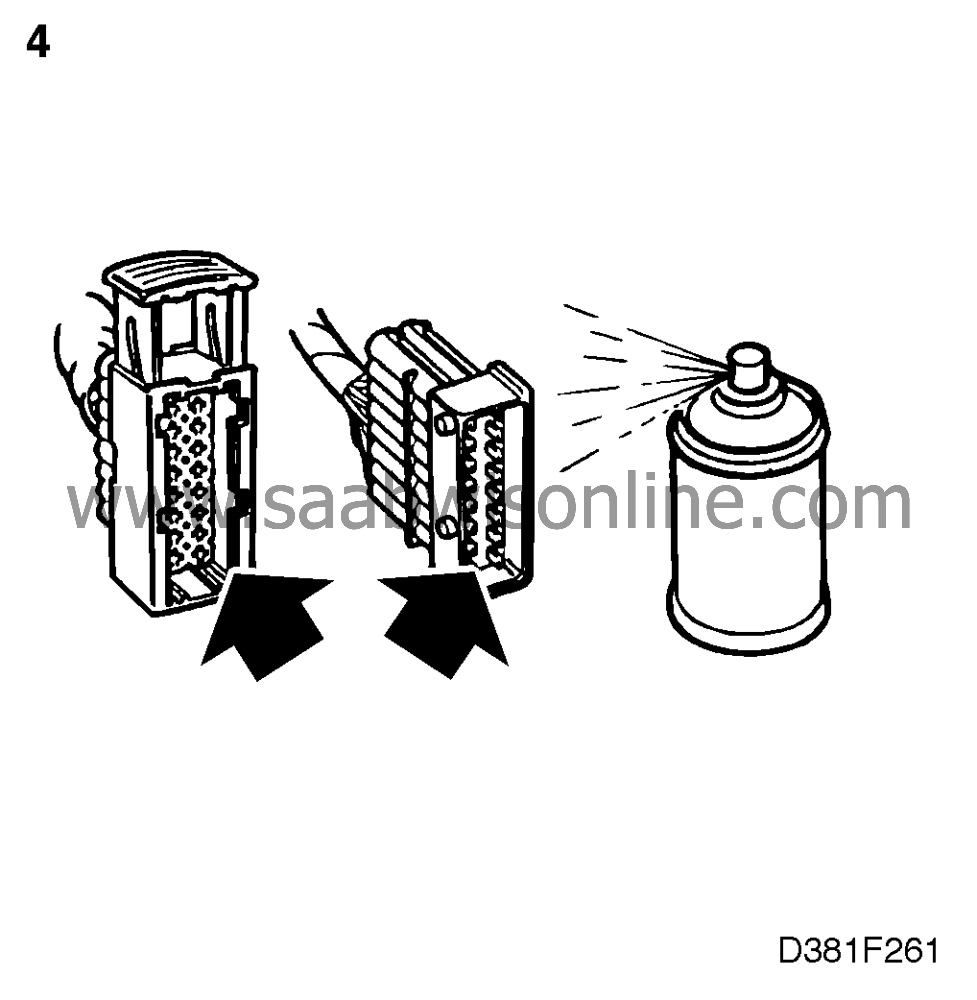

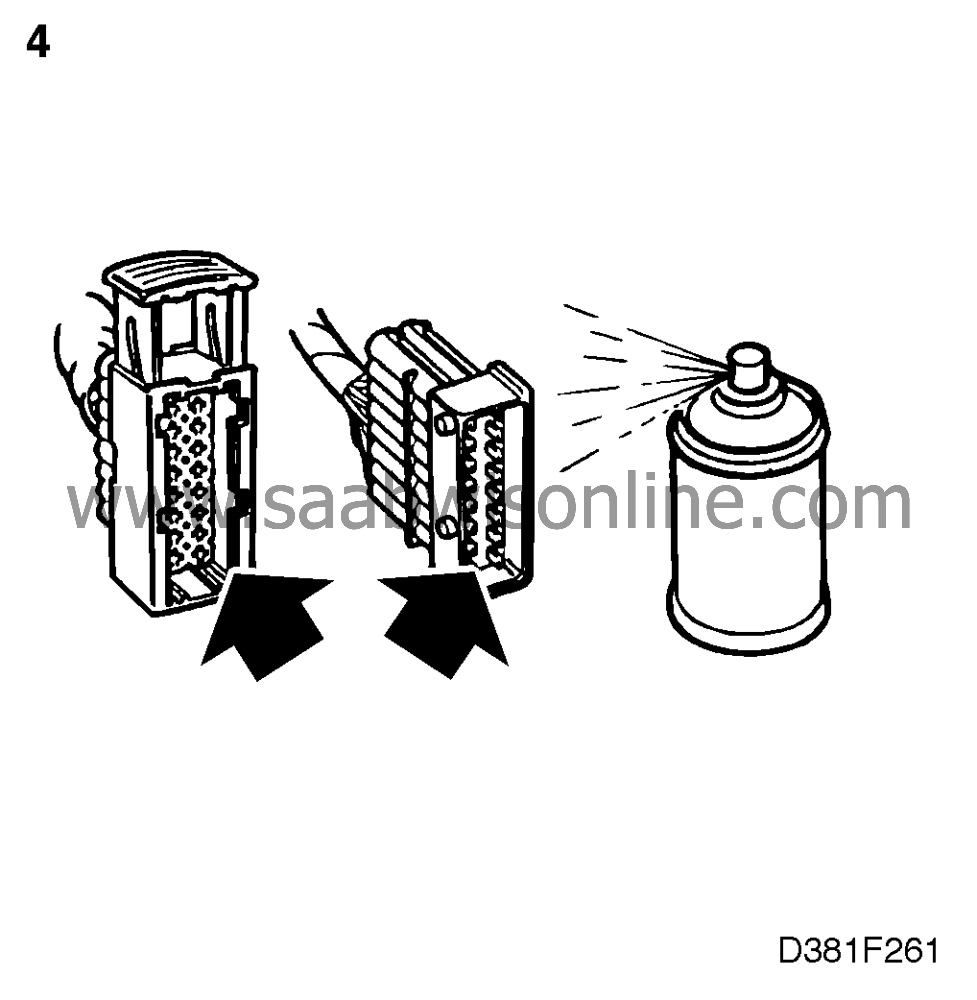

4.

|

Inspect connectors, particularly for corroded pins, excessive play, pin slide-out,

or anything else that may have an adverse effect on conductivity. If poor electrical contact is

suspected of causing the trouble, always spray KONTAKT 61 contact cleaner (part No. 45-30

04 520) on the female contacts (sockets) in connectors.

|

|

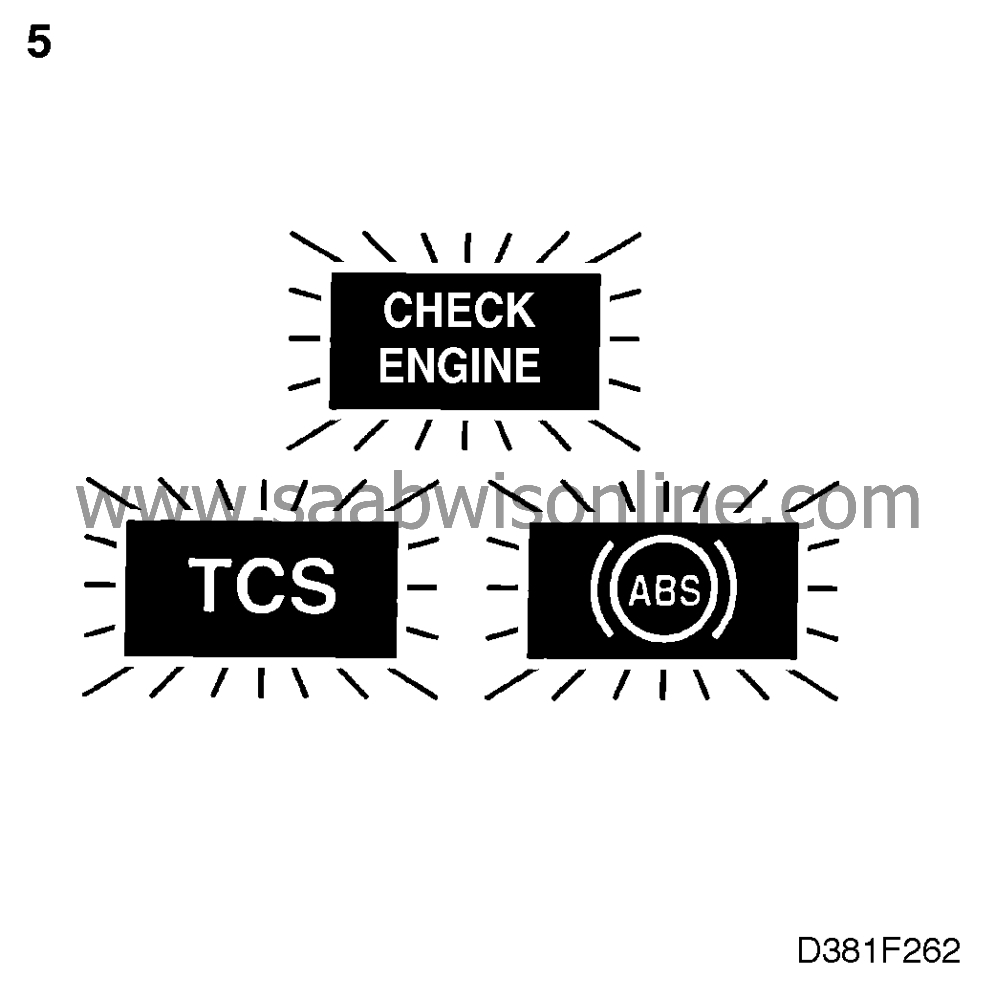

5.

|

Check whether the CHECK ENGINE lamp (MIL) or any other warning

lamp is on.

|

|

6.

|

Faults may be either constant or intermittent.

A constant fault displays continuous fault criteria, i.e. the fault exists only under certain

conditions. Examples of such conditions are:

|

|

|

•

|

Defective connectors (see point 4).

|

|

|

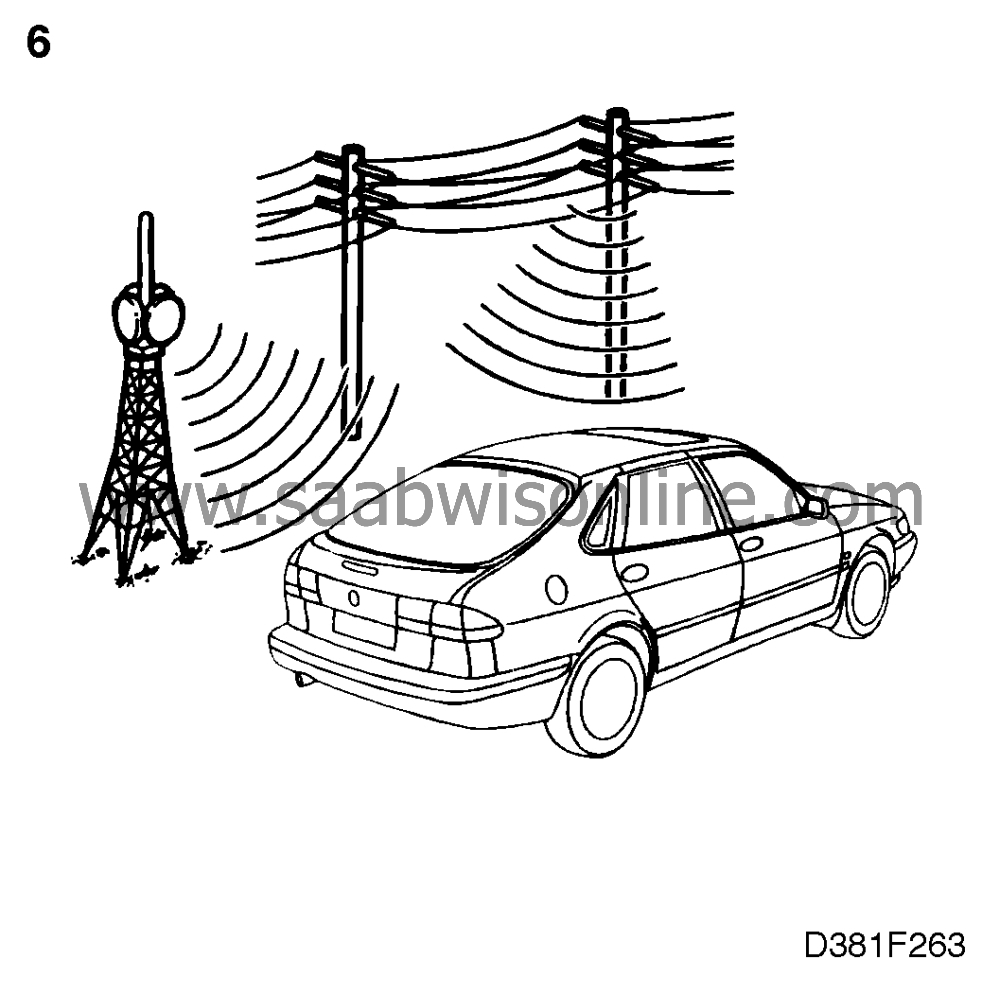

•

|

Electromagnetic interference. Such interference may be caused by the

car's own equipment or by some outside source when the car passes places where

powerful transmitters are located, such as airports, radio and TV masts, and high-tension

cables.

|

|

|

•

|

Defective components. Poor contact in relays, solenoids, etc. can give rise to

interference through sparking and arcing.

Intermittent faults call for careful analysis to avoid the replacement of

components that are in perfect working order,

|

|

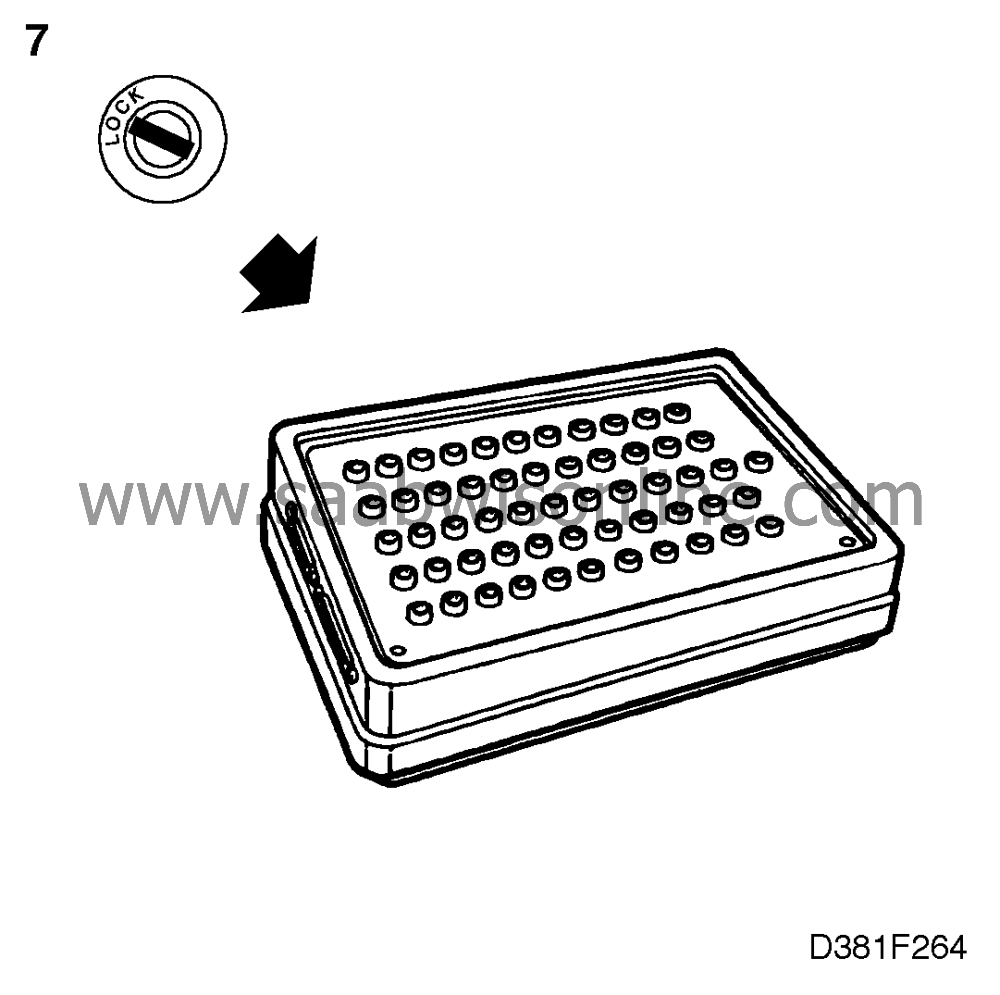

7.

|

In general, the following rules are applicable:

|

|

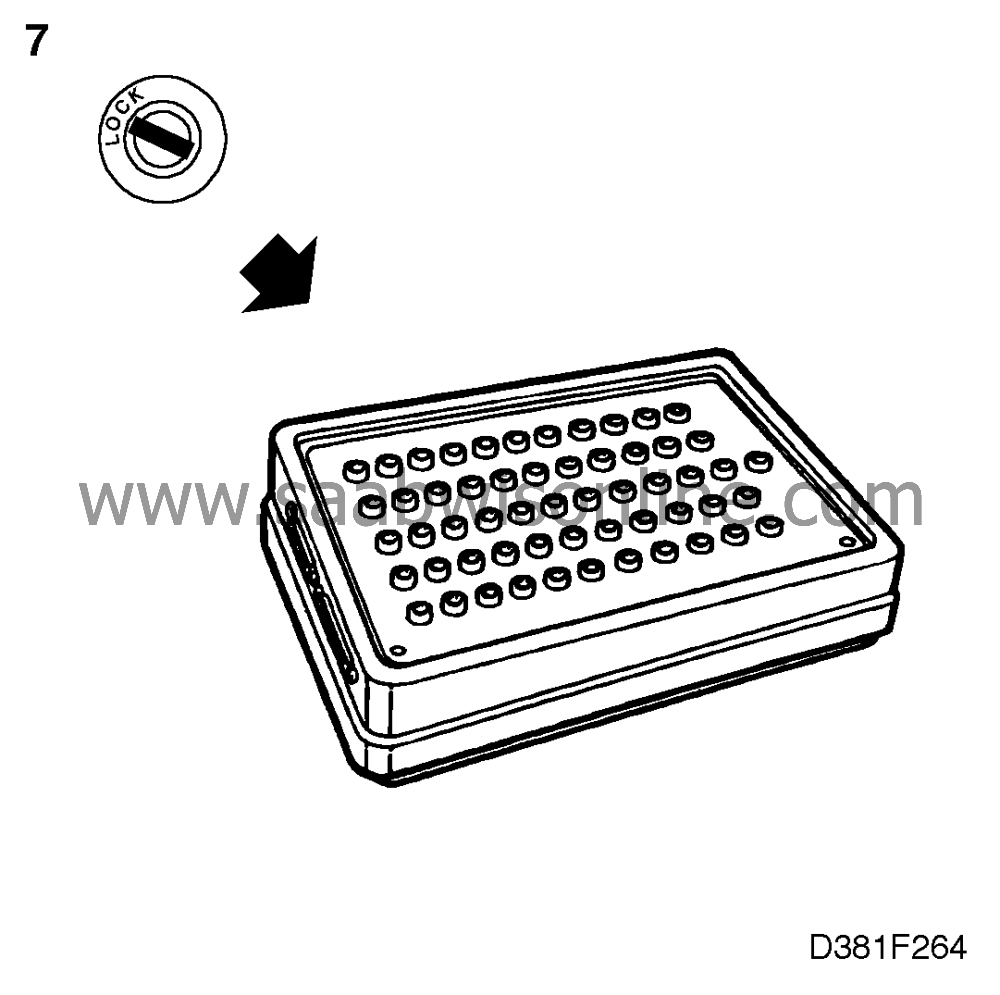

|

•

|

Before connecting a BOB, make sure that the ignition

switch is in the OFF position.

|

|

|

•

|

When unplugging connectors, make sure that the ignition switch is in the OFF

position.

|

|

|

•

|

When carrying out resistance measurements, make sure that the

ignition switch is in the OFF position.

|

|

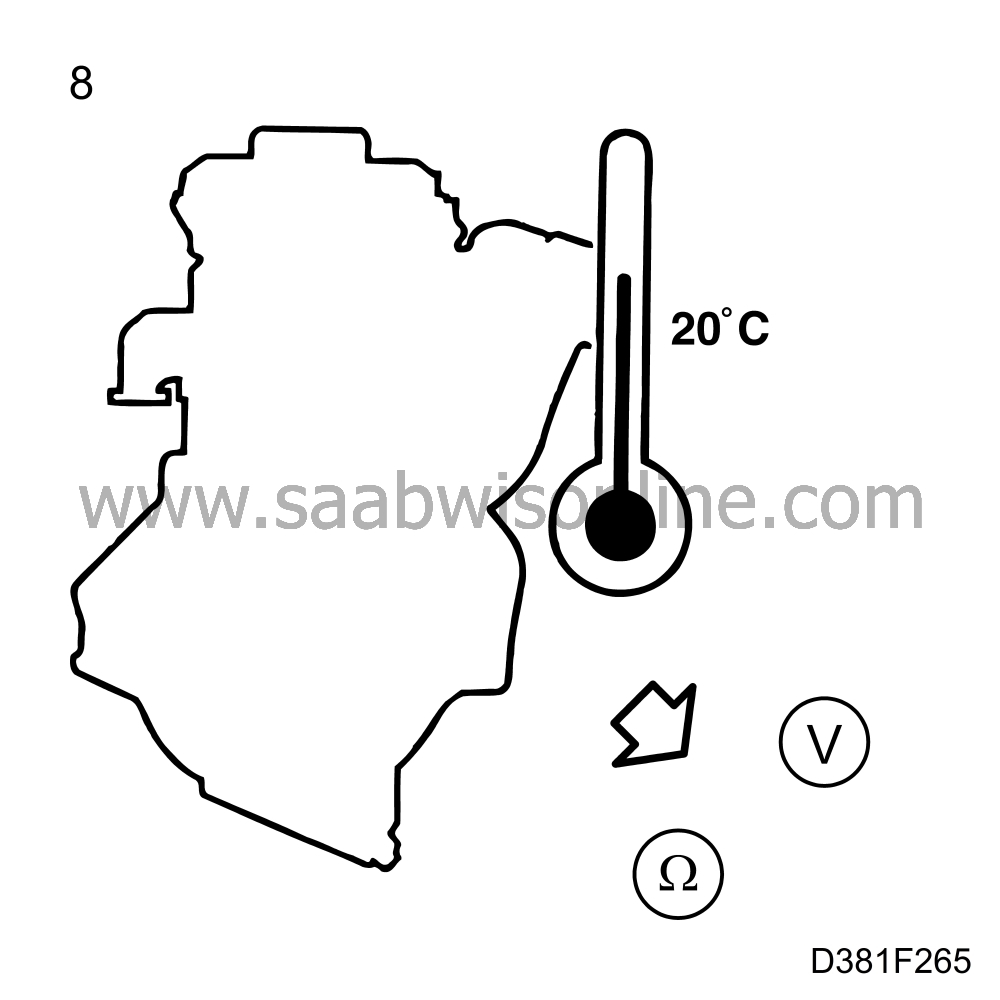

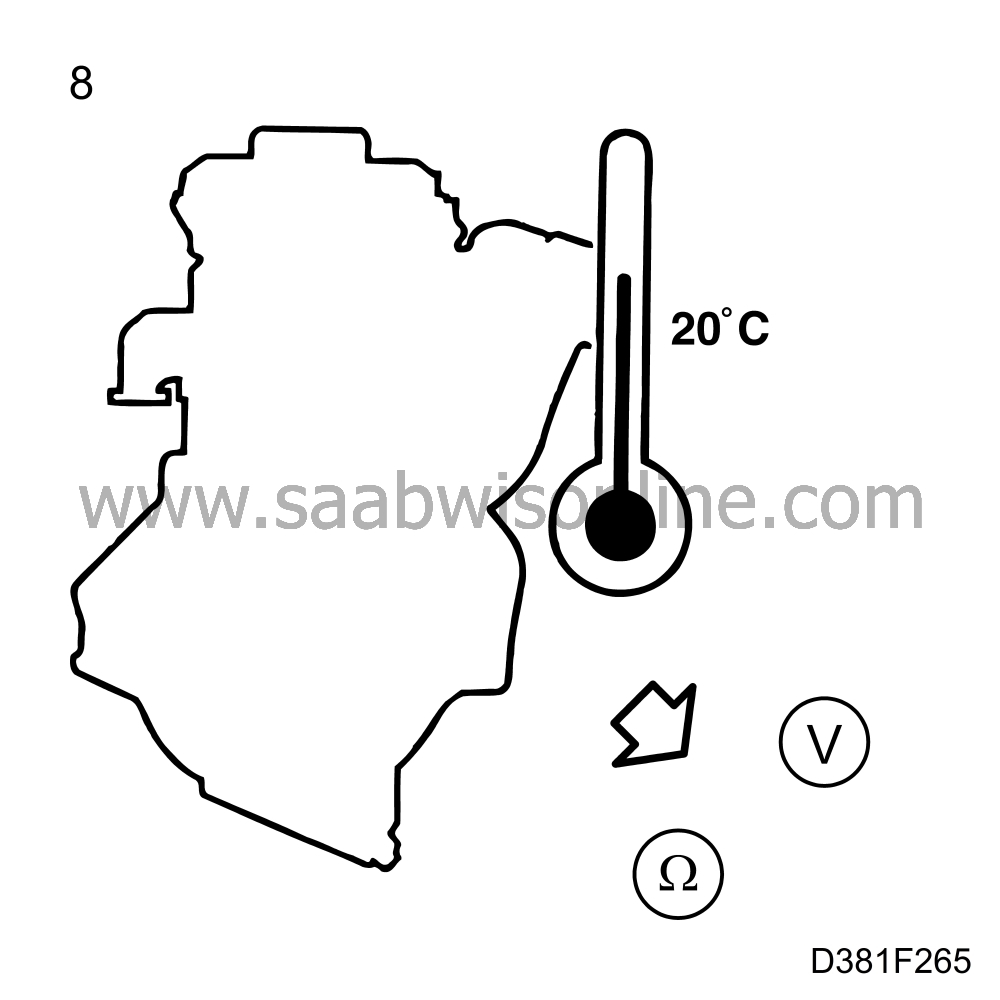

8.

|

Measuring the resistance of solenoids and relays. Nominal resistance is

specified at 20øC (68øF). The resistance of the windings is temperature-

dependent to a high degree and increases with rising temperature.

Exercise caution when judging the results of such resistance measurements.

|

|

9.

|

The strategy for fault diagnosis, with or without diagnostic trouble codes, is

based on the occurrence of only one fault, the primary fault. However, this fault may in its turn

generate other faults, consequential faults. Once the primary fault is rectified, the symptoms of

the consequential faults will disappear. The probability of two independent faults occurring at

the same time is judged to be slight and such a situation is not covered in this

manual.

|

|

10.

|

When you have finished fault diagnosis, with or without diagnostic trouble codes,

and taken the necessary remedial measures, always check that the diagnostic trouble codes

and/or fault symptoms no longer occur.

|