45291/25291 , 45292 /25292 ,45293 /25293 , 45294 ,25294

Symptom: Motor cannot be operated manually.

|

|

45291

/

25291

,

45292

/

25292

,

45293

/

25293

,

45294

,

25294

|

Fault symptom 1:

|

•

|

Motor cannot be operated manually.

|

Diagnostic trouble codes

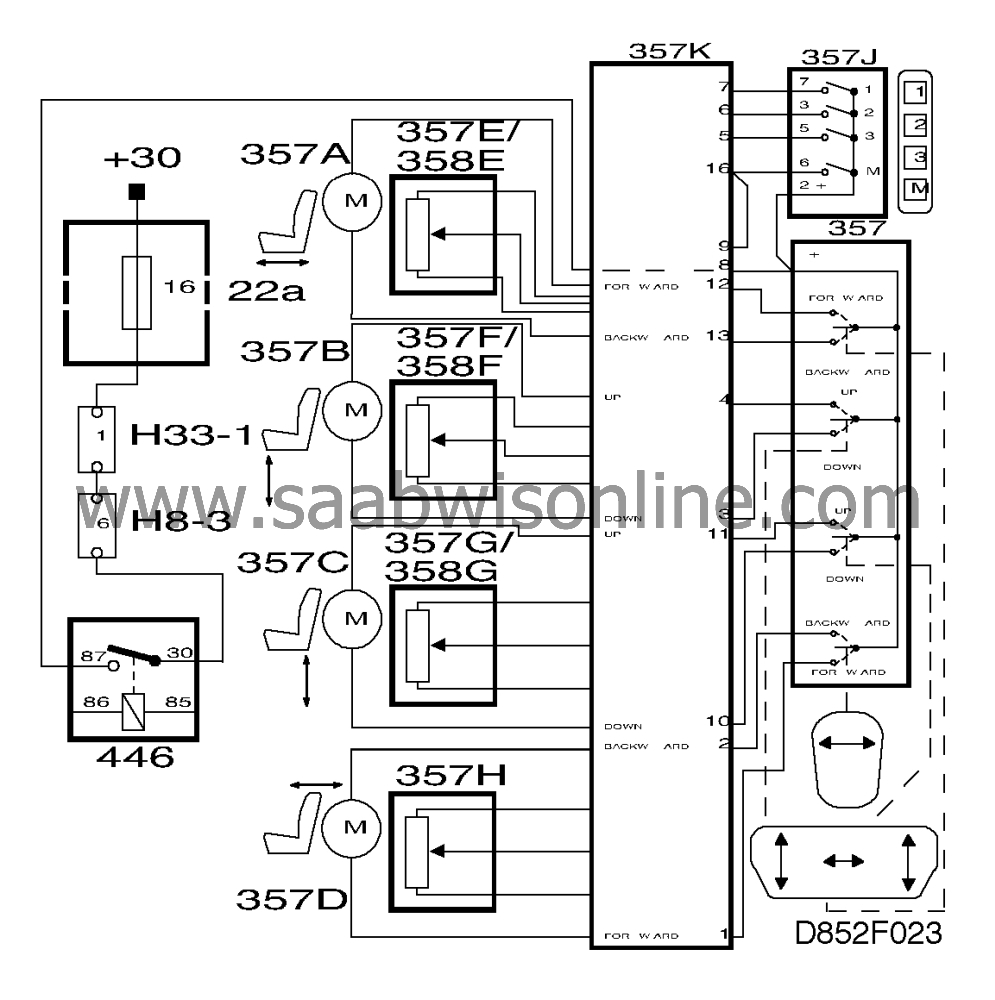

XX291 - Seat front pot changes to stored settings too slow XX292 - Legroom adjust pot changes to stored settings too slow XX293 - Seat rear pot changes to stored settings too slow XX294 - Backrest pot changes to stored settings too slow

Probable causes 1:

|

•

|

Break in connection between motor and electronic unit.

|

Diagnostic procedure 1:

|

1.

|

Clear the diagnostic trouble codes and end communication.

|

|

2.

|

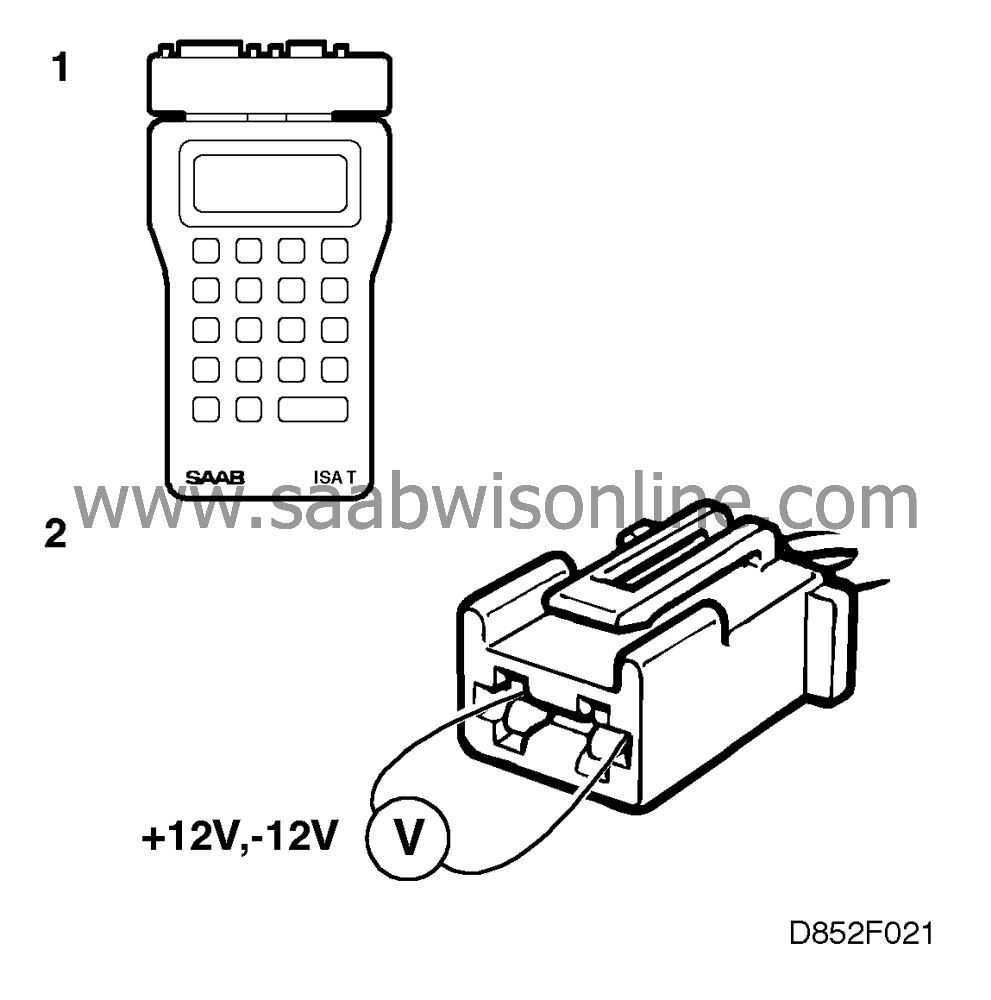

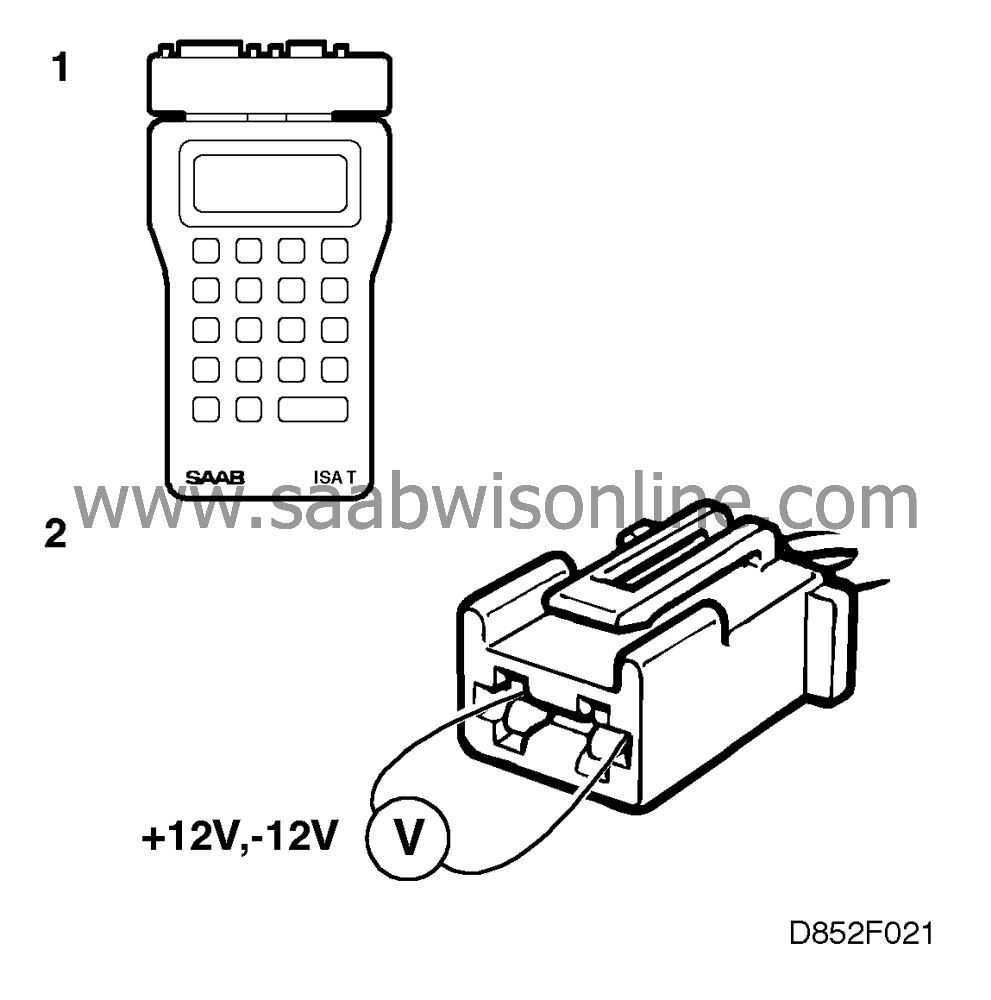

Unplug the connector from the motor and connect a voltmeter across pins 1 and 2 of the connector.

|

|

3.

|

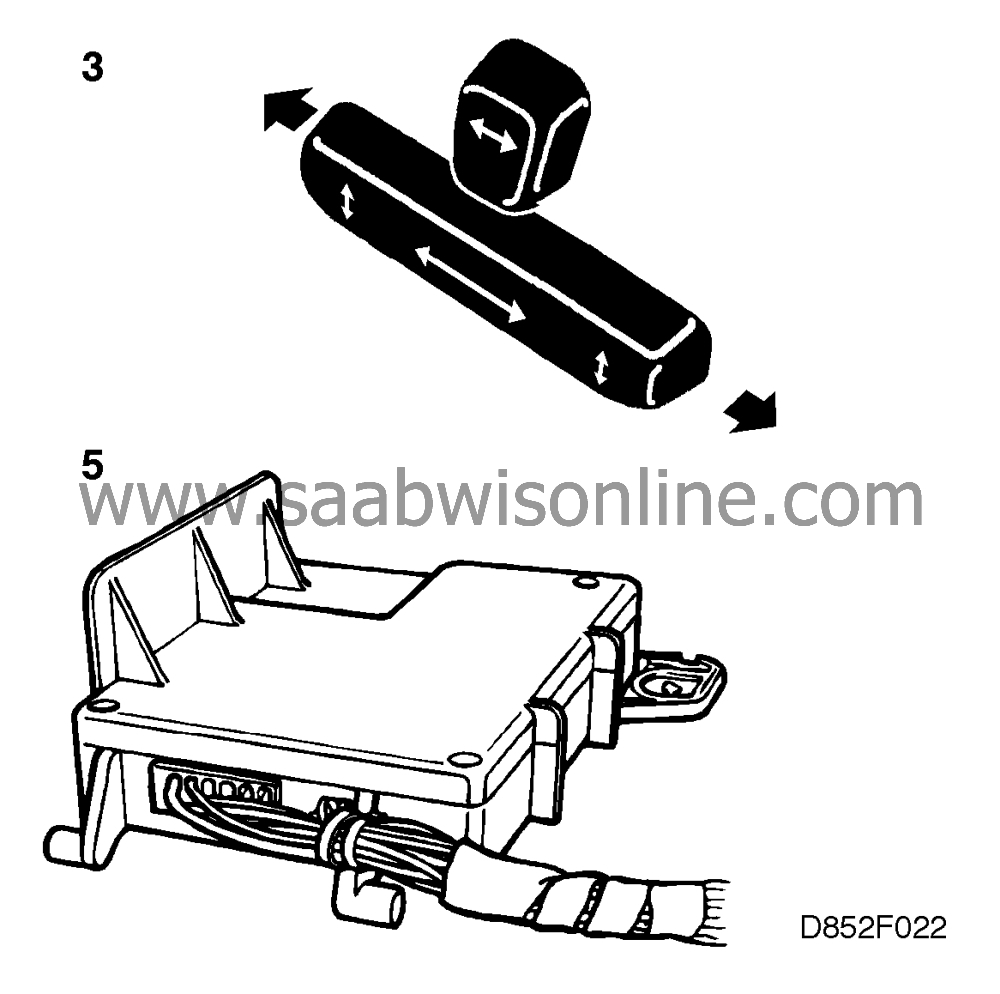

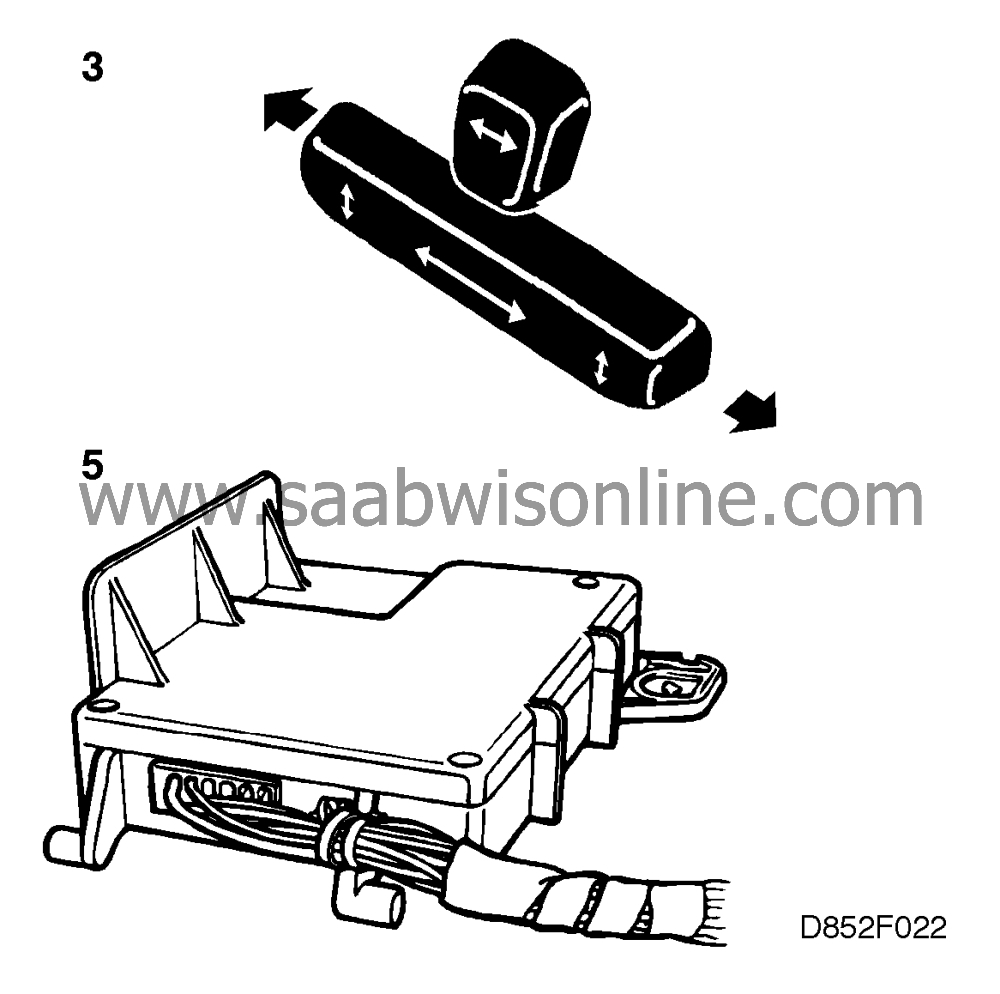

Use the manual control to run the motors in both directions. The voltage across pins 1 and 2 should then alternate between +12 V and -12 V (battery voltage), depending on the command given with the manual control.

|

|

4.

|

If the voltage is OK, try a new motor.

|

|

5.

|

If no voltage reading is obtained, check the wiring between the electronic unit and the motor for continuity.

|

Fault symptom 2:

|

•

|

The motor runs at normal speed when the manual controls are used but will not run at all when a seat setting stored in the memory is selected.

|

Probable cause of fault 2:

Potentiometer fault - the potentiometer does not change its setting because it slides on the motor shaft or because of some other mechanical fault.

Diagnostic procedure 2:

|

1.

|

Run the motor concerned using the manual controls until the seat reaches one of its end positions. If any motor cannot be operated by means of the manual controls, this method cannot be used to test its potentiometer.

|

|

2.

|

Connect the ISAT, select "Obtain readouts" and then the potentiometer in question. The ISAT will then show 123 or the like, which is the reading obtained from the potentiometer.

|

|

3.

|

End communication after this and then run the motor to the seat's opposite end position. Obtain a potentiometer reading again in the same manner as before.

|

|

4.

|

The difference between the readings obtained should be 100 - 200 units if the potentiometer readings were taken at the seat's end positions. If the potentiometer reading does not change by a sufficient amount between the seat's end positions, the reason is probably that the potentiometer slides on the motor shaft. In such case it must be changed.

|

Fault symptom 3:

|

•

|

The motor runs at an abnormally slow speed when the manual controls are used and not at all when a seat setting stored in the memory is selected.

|

Probable cause of fault 3:

Mechanical fault causing the seat to bind or jam.