Checking crankshaft clearances

| Checking crankshaft clearances |

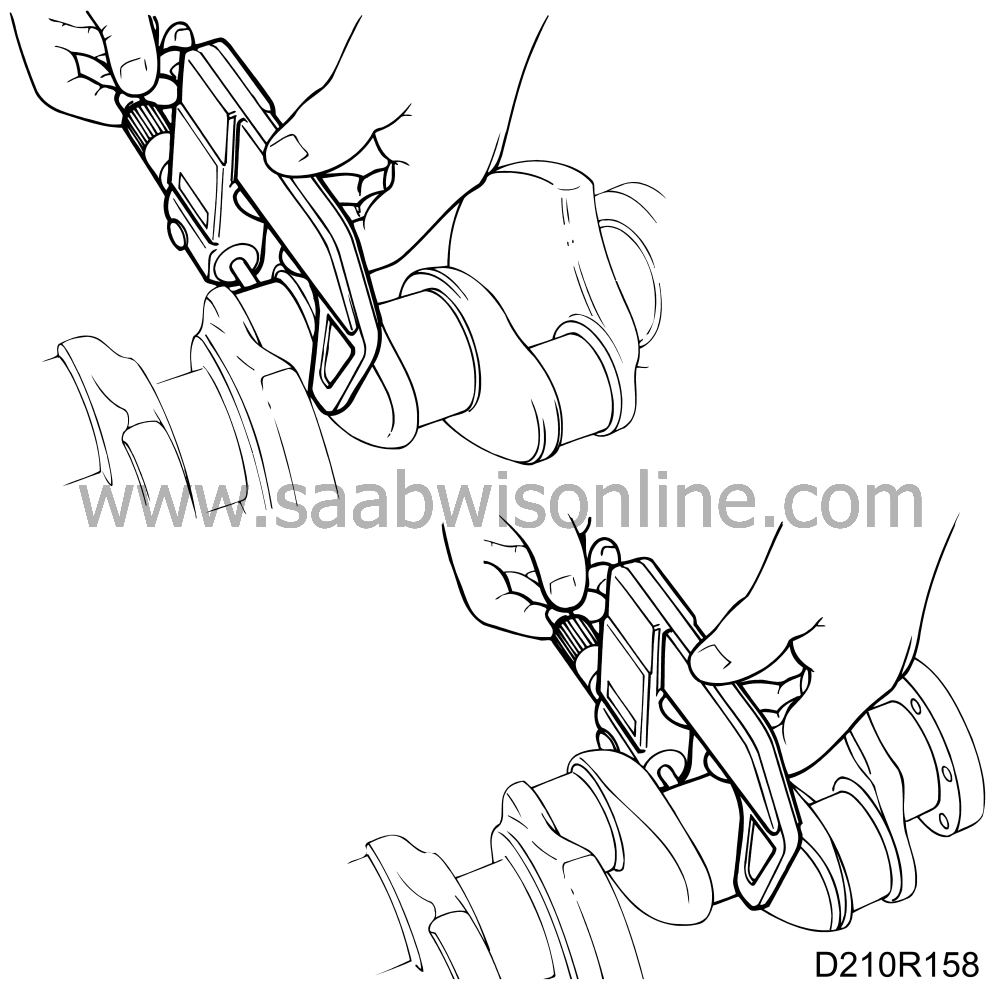

Crankpins can be ground down to the first undersize using a straight grinding wheel. If they are ground down beyond that, a grinding wheel capable of grinding radii must be used since undercutting only suffices to the first undersize. Check that the shaft is straight to within 0.10 mm, using a dial gauge. Place the shaft with crankpins No. 1 and No. 5 in V-blocks, position a dial gauge on the middle crankpin and rotate the shaft.