Power train, fitting

| Power train, fitting |

| 1. |

Thoroughly clean off any remnants of sealing compound still adhering to the surfaces concerned. Wash the areas with benzine.

|

|

| 2. |

Apply a bead of flange sealant, part no. 93 21 795, approx. 1 mm thick on the centre of the sealing surfaces.

|

|

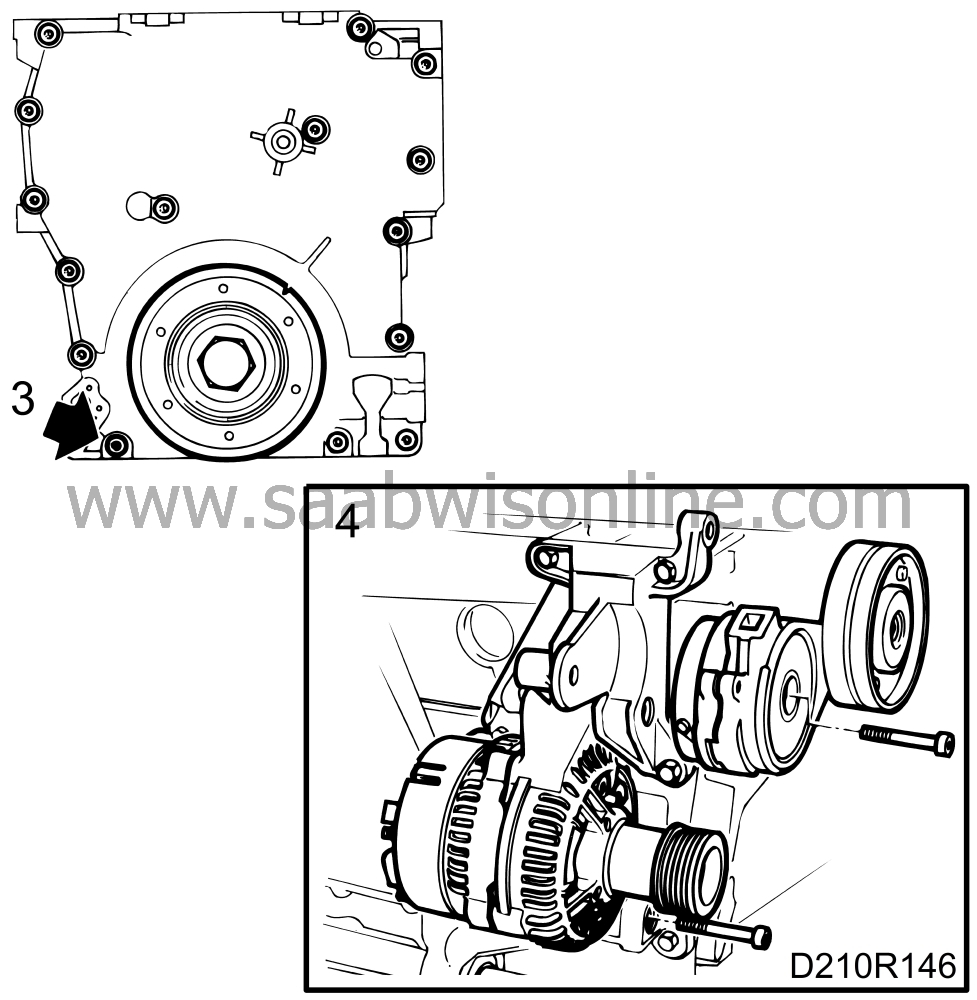

| 3. |

Fit the timing cover.

Tightening torque: 22 Nm (16 lbf ft). |

|

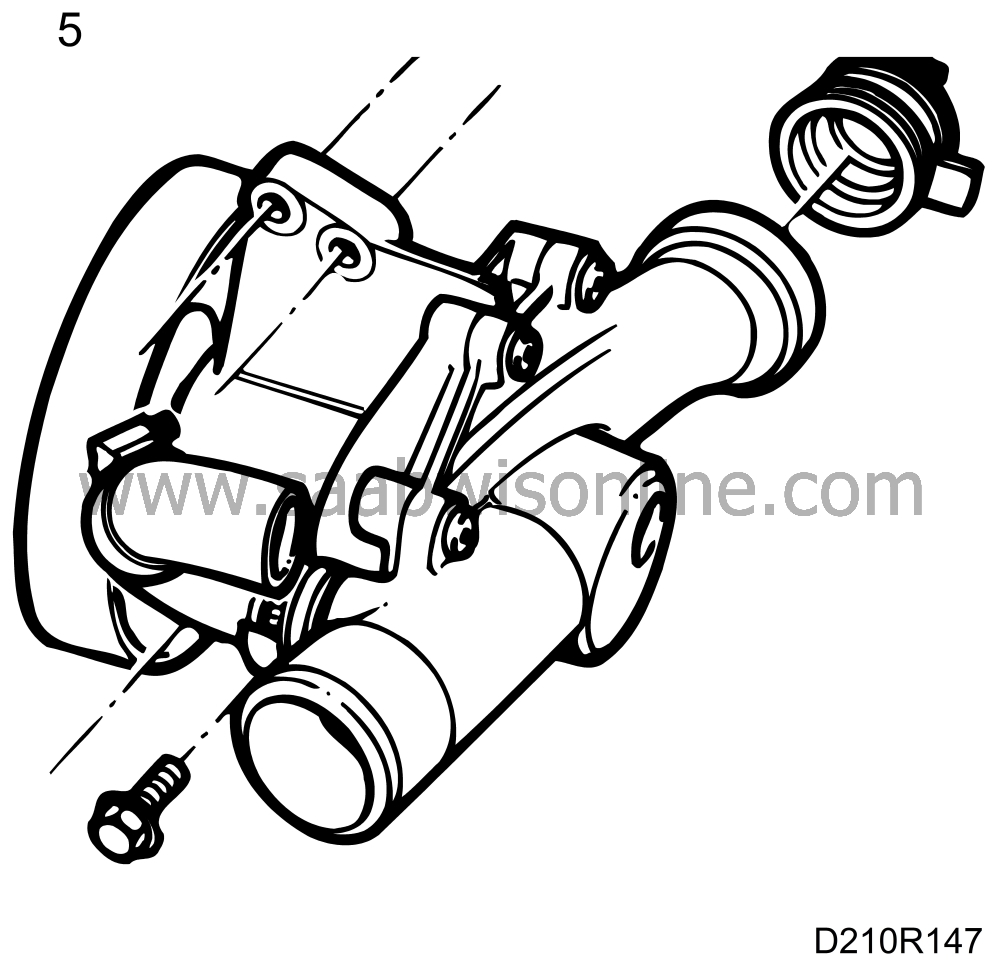

| 4. |

Fit the bolt for the support bearing bracket in the timing cover and refit the alternator and belt tensioner.

|

|

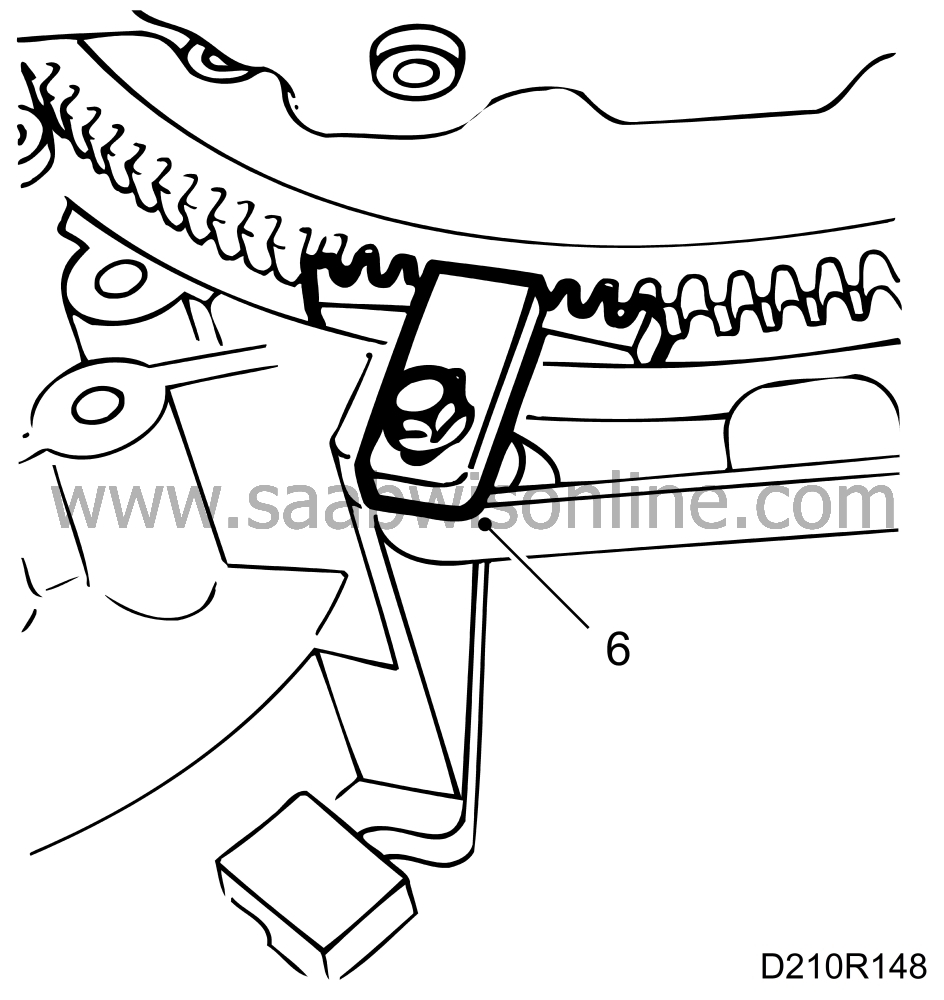

| 5. |

Inspect the water pump O-rings and change them as necessary. Lubricate the O-rings with petroleum jelly (Vaseline) and fit the water pump.

|

|

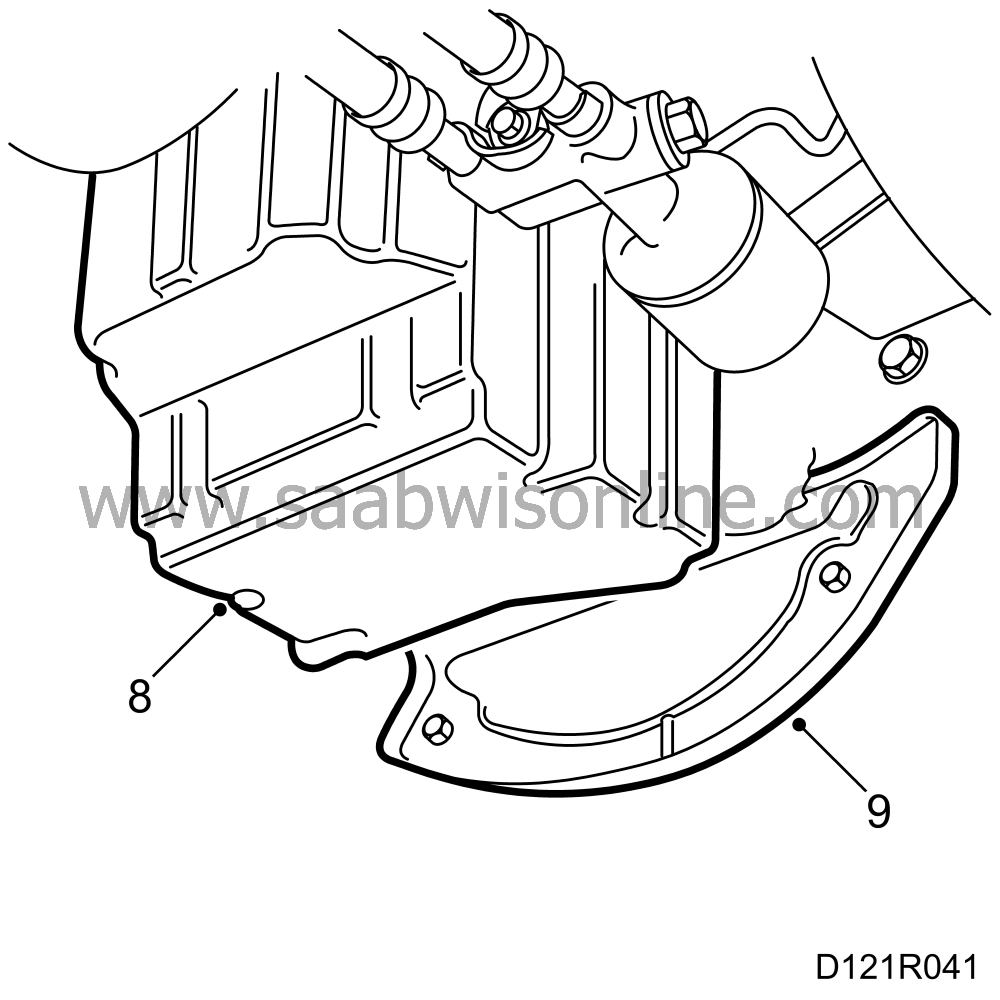

| 6. |

Fit the crankshaft pulley. Use flywheel locking segment 83 94 868.

Tightening torque 175 Nm (129.5 lbf ft). |

|

| 7. |

Make sure that there are no impurities or other foreign matter in the sump and clean its flange.

|

|

| 8. |

Apply an even bead of flange sealant, part no. 93 21 795, to the sealing surface of the oil sump and fit the oil sump.

Tightening torque: 22 Nm (16 lbf ft). |

|

| 9. |

Refit the cover plate.

|

|

| 10. |

Rotate the crankshaft through 45° and fit the cylinder head with a new gasket. Make sure that it is correctly seated on the locating sockets and that the chain is not trapped.

|

|

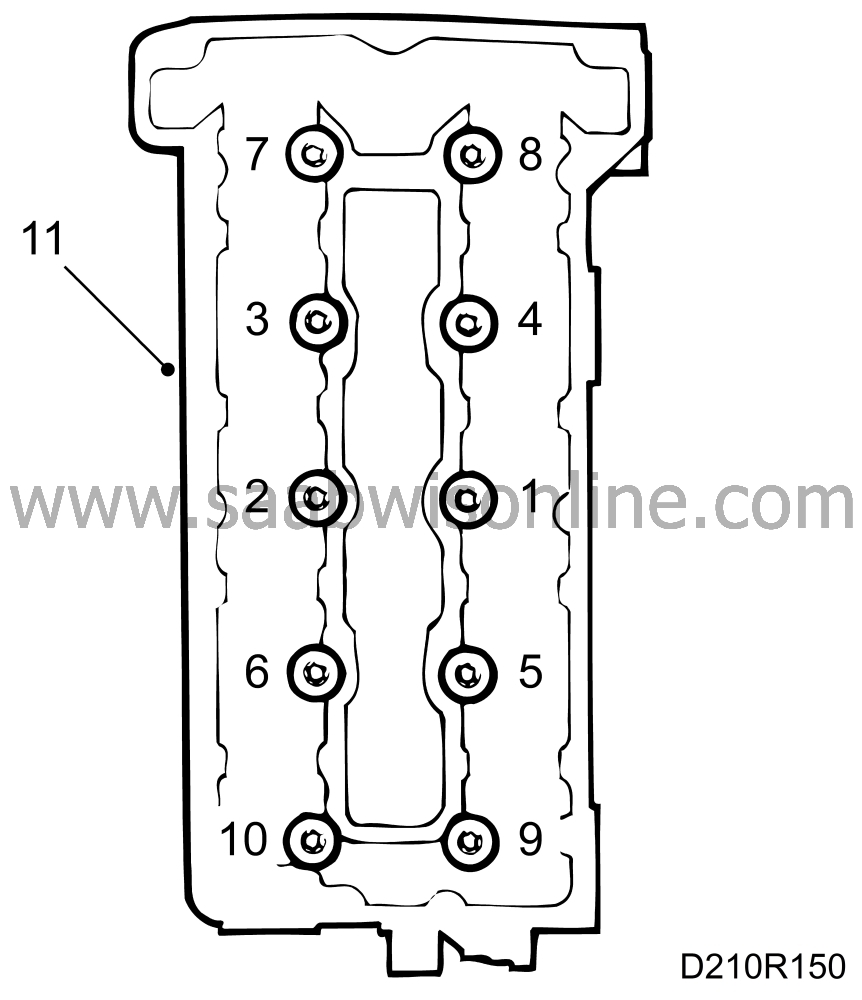

| 11. |

Fit the 10 torx bolts and

tighten them using a torque wrench in three stages: Stage I 40 Nm (30 lbf ft) Stage II 60 Nm (44 lbf ft) Stage III A further quarter-turn (90°

). Tighten the bolts in the order shown.

|

|

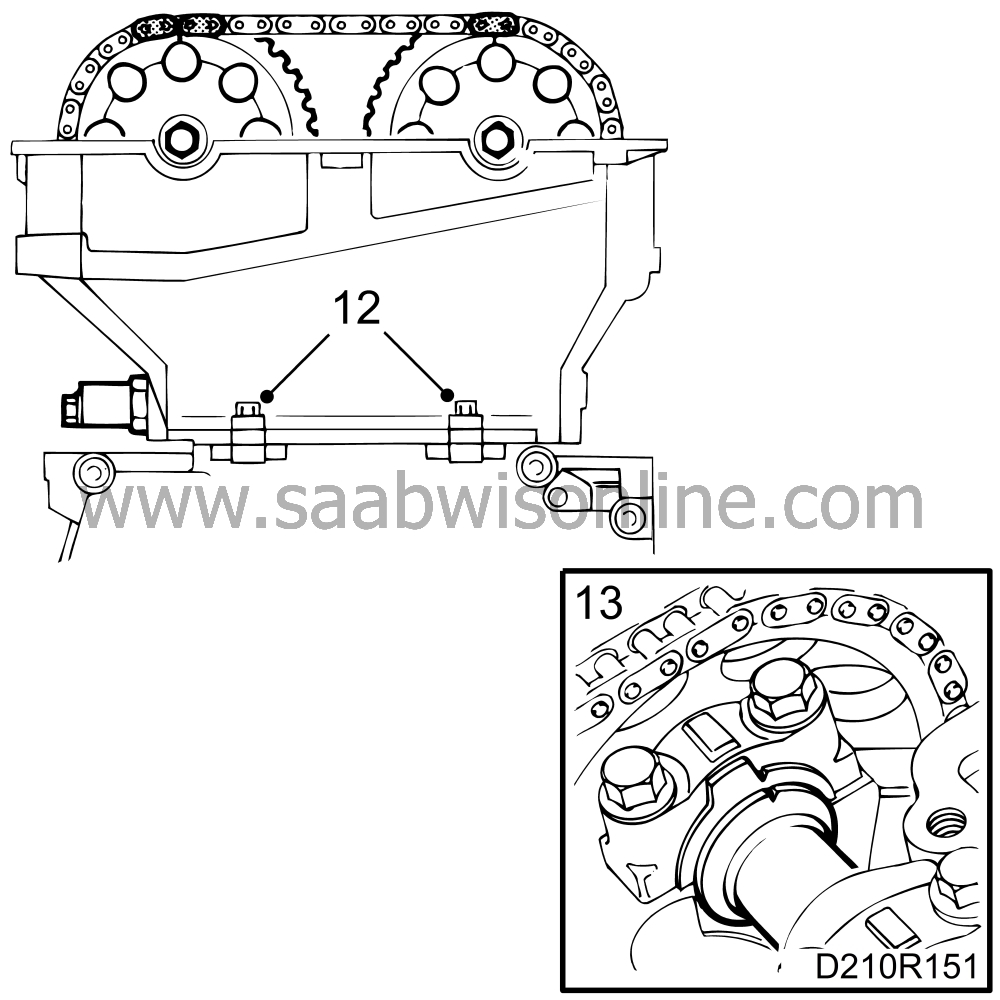

| 12. |

Fit the two bolts between the timing cover and the cylinder head.

Tightening torque: 22 Nm (16 lbf ft). |

|

| 13. |

Check that the camshafts are in line with their timing marks and that the 0° mark on the crankshaft is in line with the timing mark.

|

|

| 14. |

Fit the camshaft sprockets and chain. Start with the camshaft on the inlet side.

Do not tighten the bolts yet.

|

|

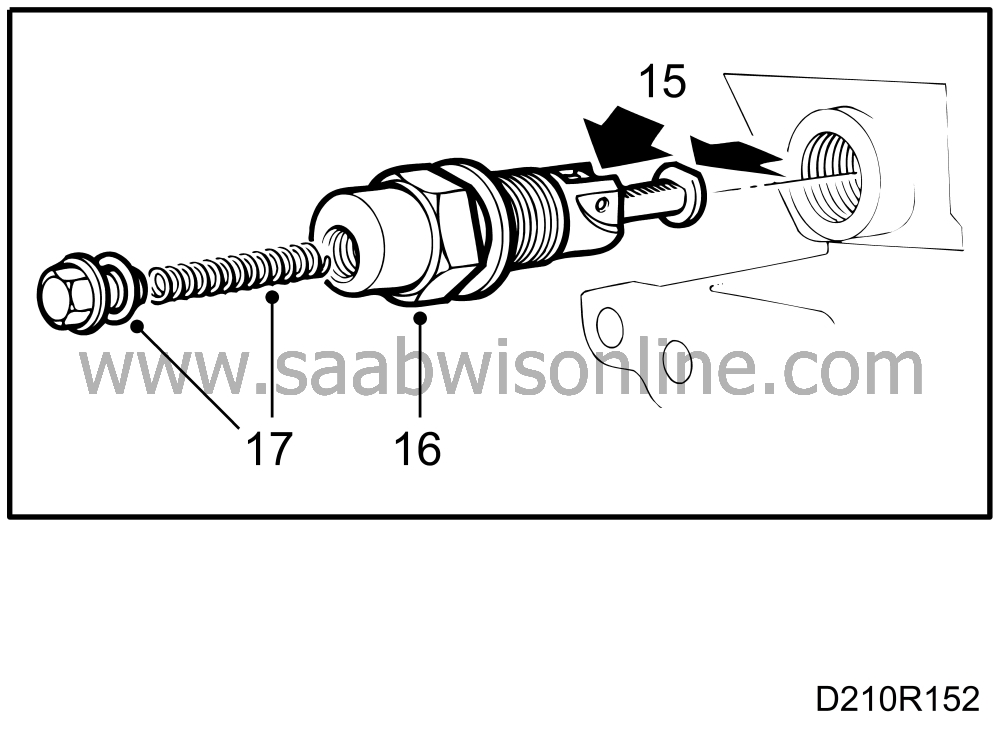

| 15. |

Prepare the chain tensioner for fitting by pressing down the catch and pushing in the chain tensioner.

|

|

| 16. |

Fit the chain tensioner, using a 27 mm socket.

Tightening torque: 63 Nm (47 lbf ft). |

|

| 17. |

Fit the plug for the chain tensioner with push rod and spring.

Tightening torque: 22 Nm (16 lbf ft). |

|

| 18. |

Check that the chain is correctly seated in the guides. Rotate the crankshaft two complete turns and check that the timing marks on the flywheel and camshafts are still in alignment.

|

|

| 19. |

Tighten the camshaft sprocket bolts.

Tightening torque: 63 Nm (47 lbf ft). |

|

| 20. |

Clean the flanges of the camshaft cover, using benzine.

|

|

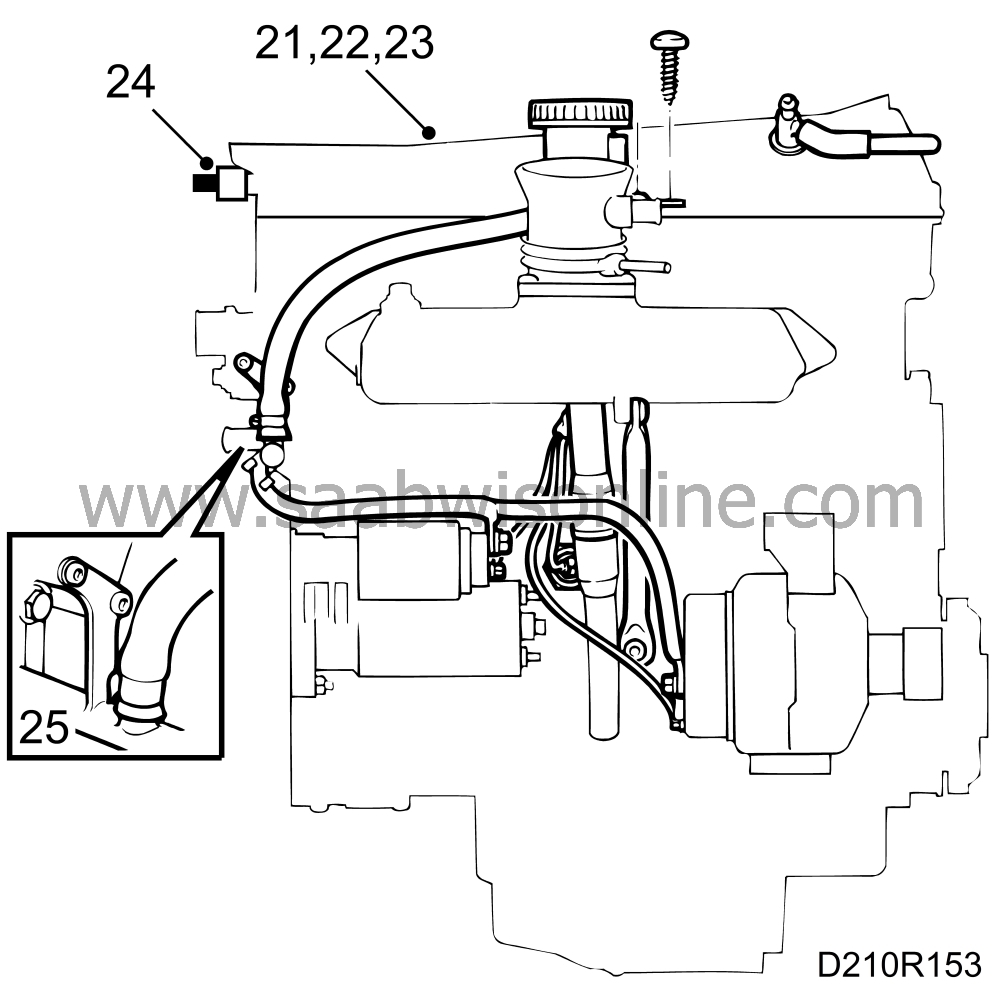

| 21. |

Apply soap to the open end of the camshaft cover and fit the cover, starting at the open end. Then tighten the bolt located furthest to the front at the timing end. Then continue all the way round, on both the inside and outside.

Tightening torque: 15 Nm (11 lbf ft). |

|

| 22. |

Fit the spark plugs.

Tightening torque: 28 Nm (20.7 lbf ft). |

|

| 23. |

Fit the ignition discharge module or ignition cables and the cover plate.

Tightening torque: 11 Nm (8 lbf ft). |

|

| 24. |

Plug in the ignition discharge module connector (turbo) and connect the crankcase breather and vacuum hoses to the camshaft cover.

|

|

| 25. |

Fit the bolts for the thermostat housing cover and reconnect the throttle body preheating hose.

|

|

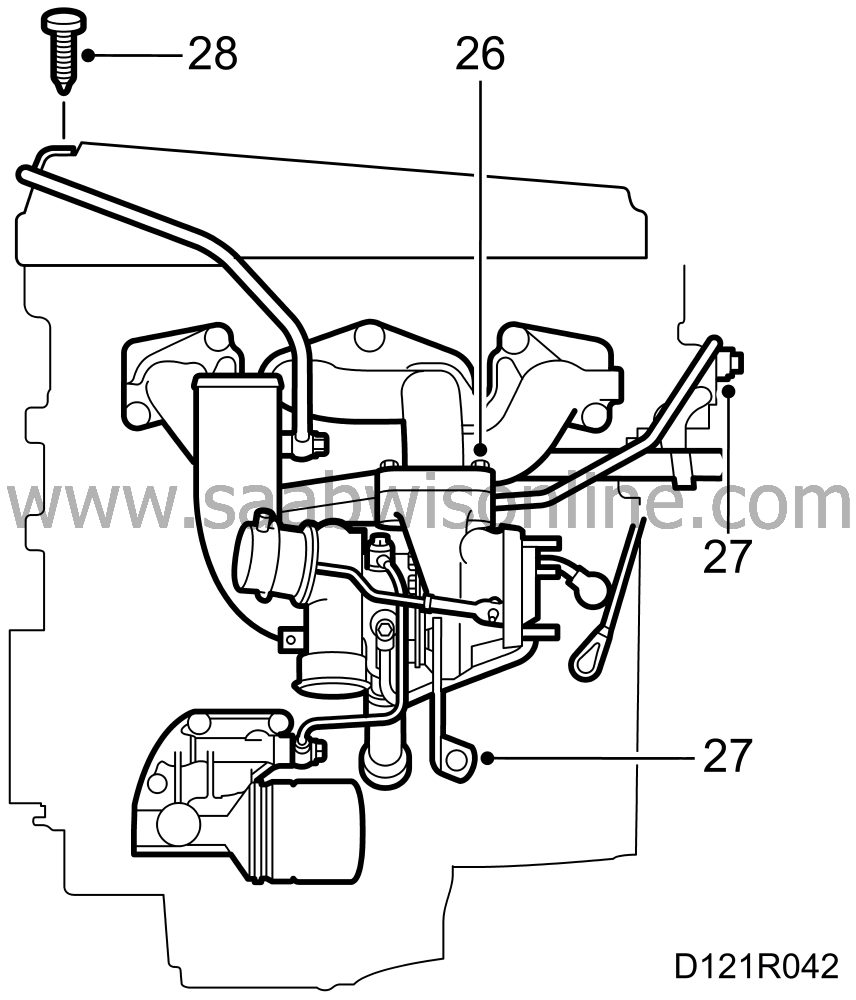

| 26. |

Fit the nuts for the turbocharger.

Tightening torque: 25 Nm (18.5 lbf ft). |

|

| 27. |

Tighten the bolts for the turbocharger steady bar, starting with the one in the block, and fit the water pipe to the thermostat housing (turbo).

|

|

| 28. |

Fit the crankcase breather pipe with inlet pipe (turbo).

|

|

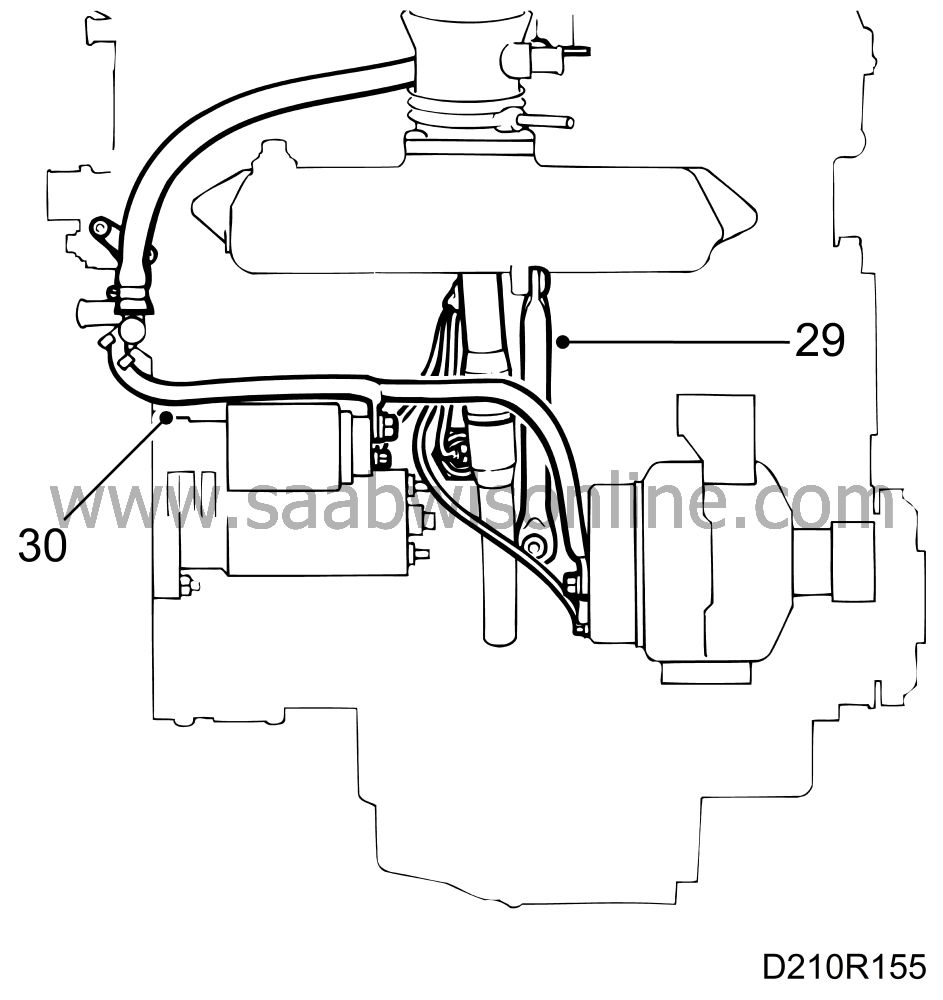

| 29. |

Tighten the bolts for the intake manifold steady bar, starting with the one in the block, and refit the oil filler pipe.

|

|

| 30. |

Check that the oil drain plug is tight and reconnect the leads to the oil pressure sensor, generator and starter motor.

|

|