Detecting leaks in the EVAP system

|

SERVICE INFORMATION

|

|

Bulletin Nbr:

|

234-1746

|

|

Date:

...........

|

MARCH 1997

|

|

Market:

|

US ONLY

|

|

|

Detecting leaks in the EVAP system

|

Saab 900 M96-97 with EVAP II.

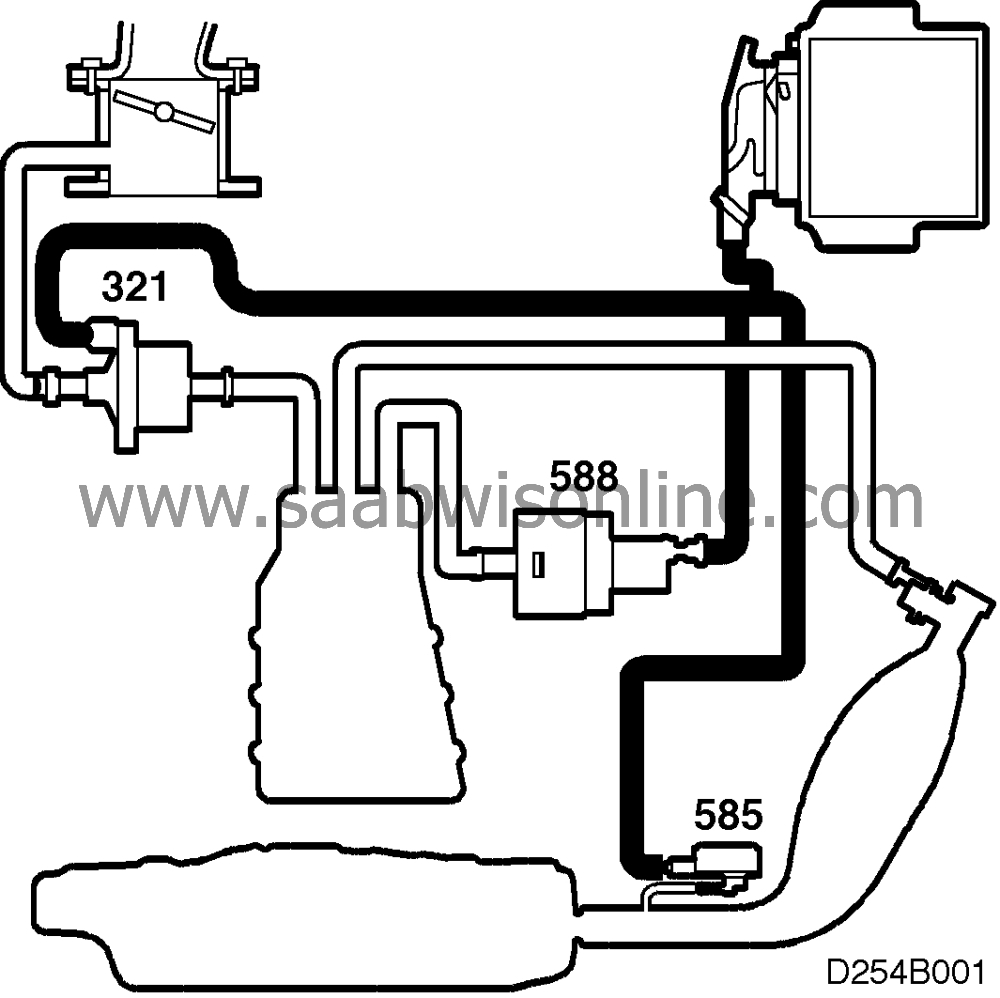

It is possible for spurious diagnostic trouble codes relating to leaks in the EVAP

system to occur. A method has therefore been developed for checking whether a code is

spurious or whether there really is a leak in the EVAP system.

|

1.

|

Check that the pressure tester is in good

condition and not leaking.

|

|

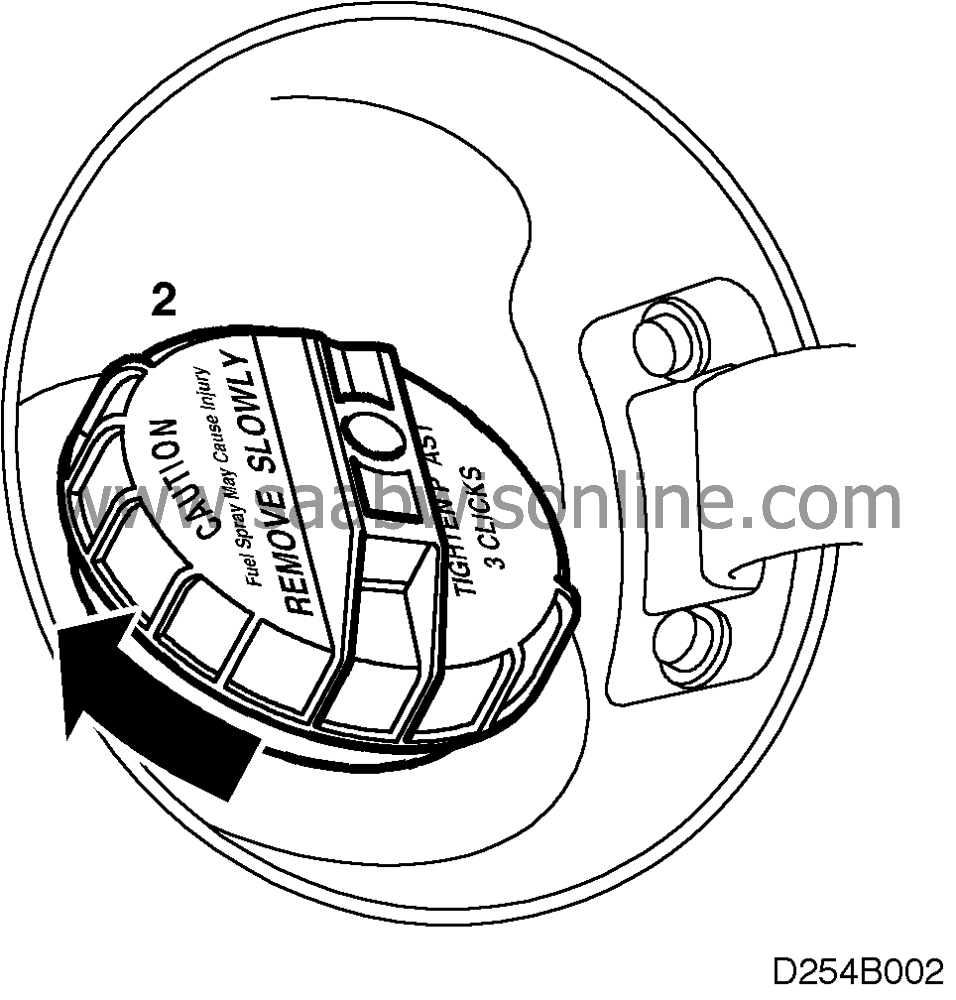

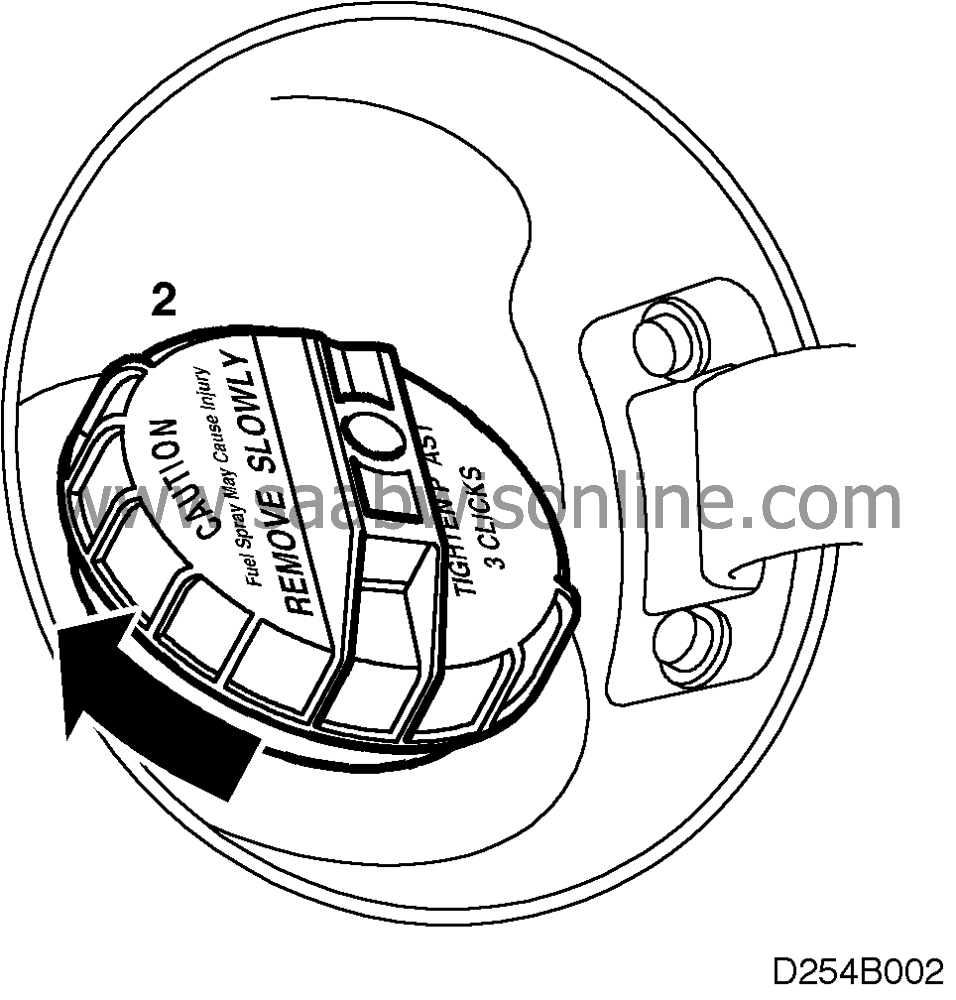

2.

|

Check that the filler cap is on tight.

|

|

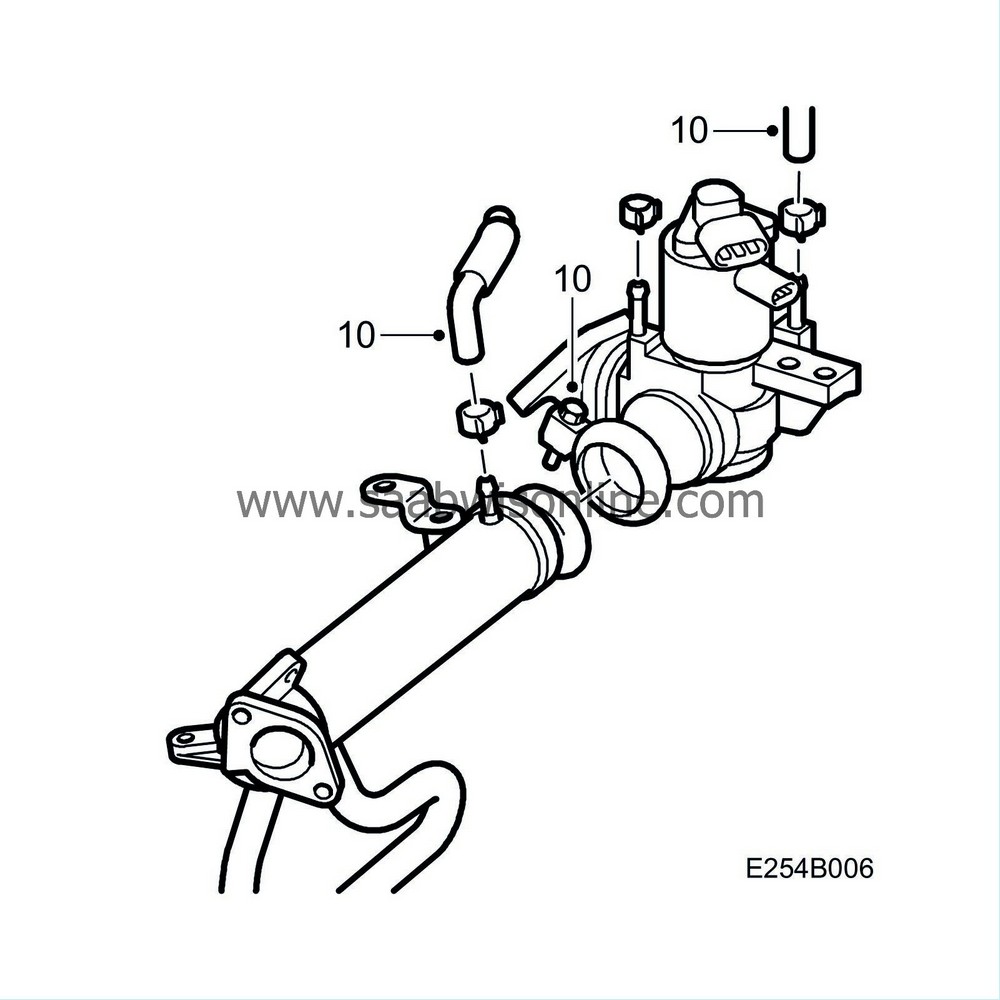

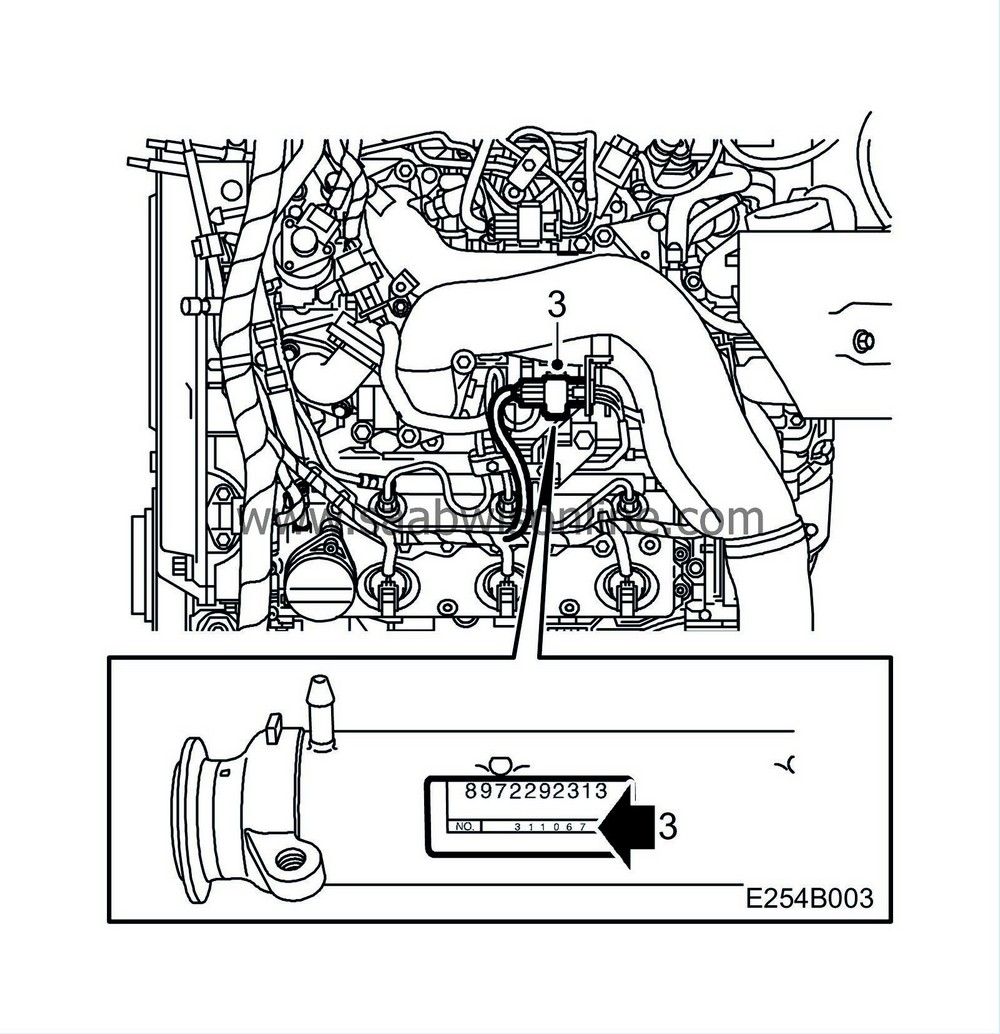

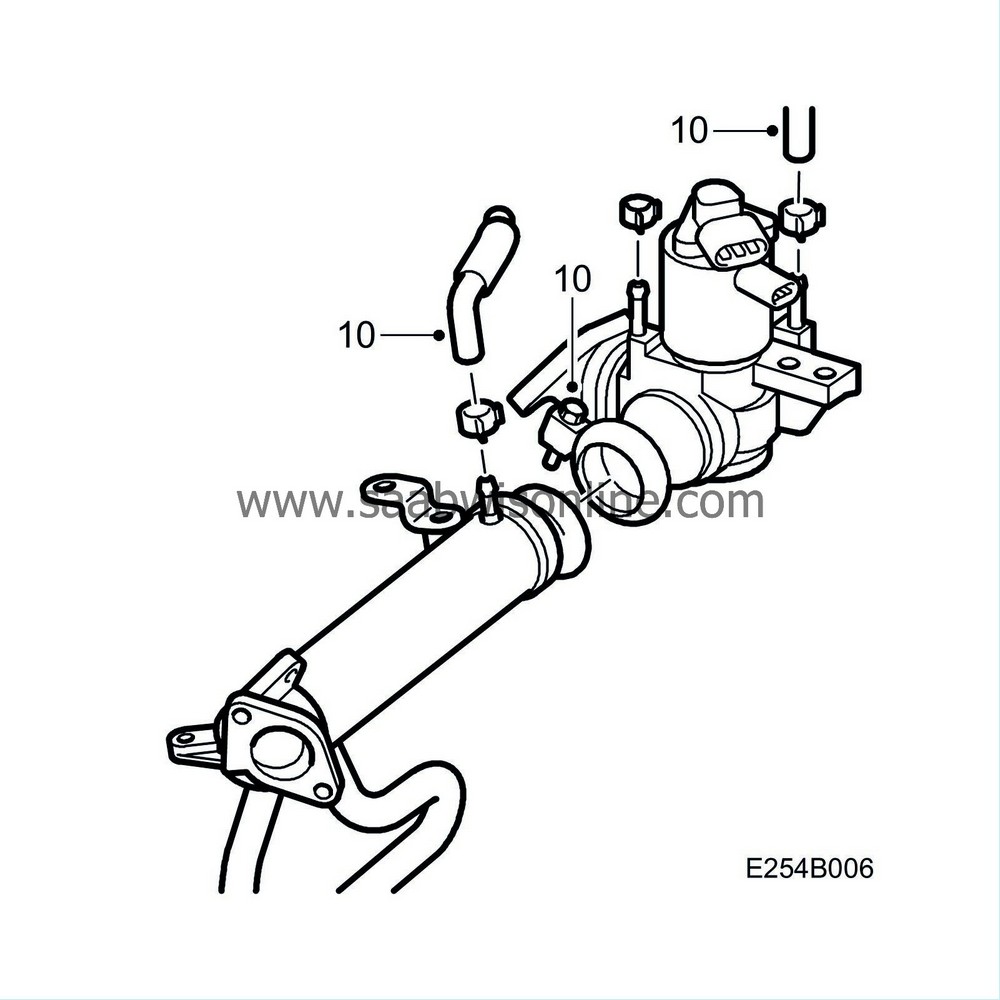

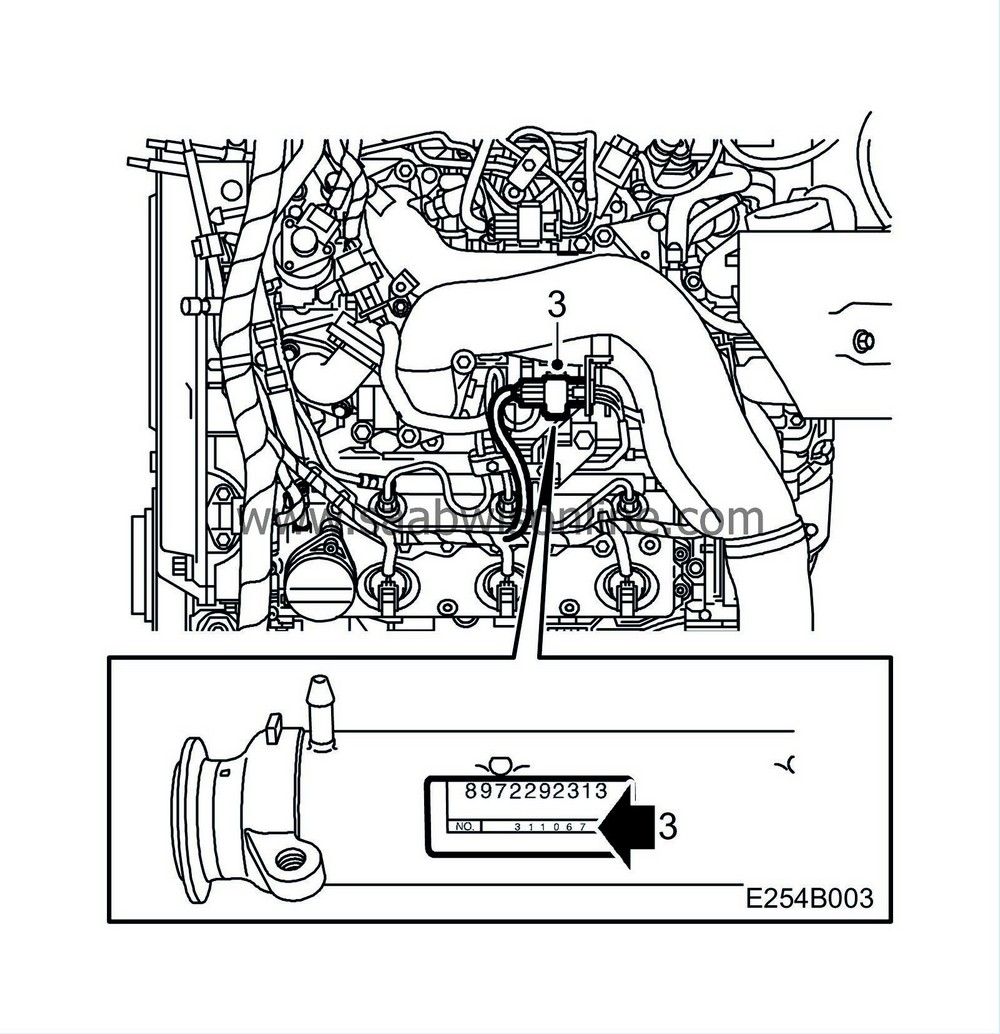

3.

|

Using e.g. a ’T’ piece, connect pressure tester J41413

between the inlet on the EVAP canister purge valve and the hose.

|

Note

|

|

Do not fit the pressure tester adaptor to the filler cap connection, as this would prevent

the filler cap from sealing in its normal position.

|

|

|

4.

|

Activate the EVAP canister shut-off valve by connecting battery voltage to the

valve (male connector on M96).

|

|

5.

|

Pressurize the system and perform the pressure test, following the instructions in

the Kent-Moore manual.

|

|

Action to be taken if leak detected

|

|

1.

|

Ensure that the shut-off valve is still

energized.

|

|

2.

|

Disconnect the hose from the EVAP canister purge valve at the intake

manifold.

|

|

3.

|

Raise the pressure again, following the instructions in the Kent-Moore

manual.

|

|

4.

|

Use ultrasonic leak detector J41416 to trace the leak. Start with the hose that

has been disconnected from the intake manifold and then follow the system lines and

components. Make a visual check of the system at the same time.

|

Note

|

|

The ultrasonic leak detector is sensitive to ambient noise in the workshop, such as that

made by exhaust-extraction equipment, compressors, air guns, air leaks from pneumatic

equipment, etc.

|

|

Air flows from the ventilation equipment in the workshop can also create interference to

the ultrasonic detector.

|

|

All such noise and interference can give rise to spurious readings indicating leaks in the

EVAP system, even when there are none.

|

Always, therefore, adjust the sensitivity of the ultrasonic leak detector, so that

the ambient noise, which often causes interference, is filtered out.

|

Note

|

|

Major leaks, such as those caused by a defective canister shut-off valve or a loose

hose connection, are difficult to detect, as the noise generated by them is usually outside the

sensitivity range of the ultrasonic detector.

|

|

For this reason, it is essential that you make a thorough visual inspection of the system

components, to check for leaks not detected by the equipment.

|

If you suspect leakage from the EVAP canister (located on the inside of the RH front

fender/wing) or its connections, this can be easily checked. Remove the side direction

indicator and insert the microphone there.

|

|

5.

|

Rectify any leaks detected and test the system again.

|

|

6.

|

Restore the car to its normal condition.

|