Adjustment of basic boostpressure

|

|

Adjustment of basic boost

pressure

|

|

Important

|

|

Basic boost pressure is the point of departure for the Trionic system's pressure

regulating function and must therefore be adjusted to the correct level.

|

|

|

|

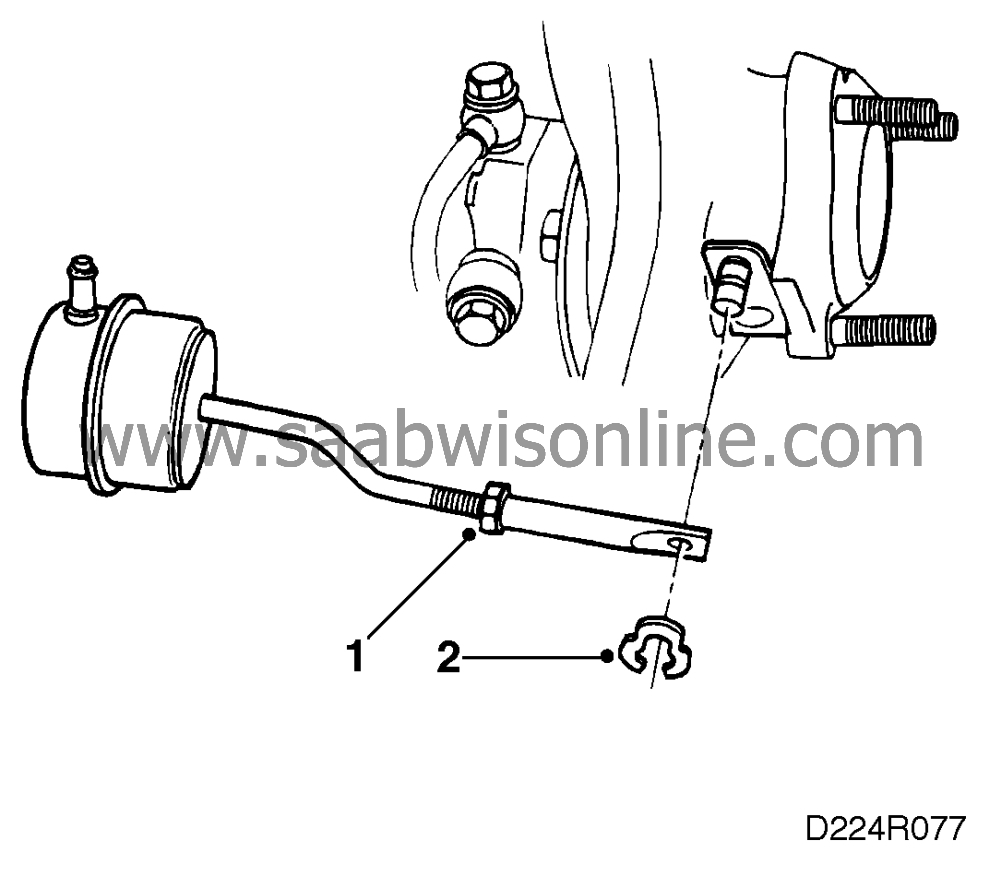

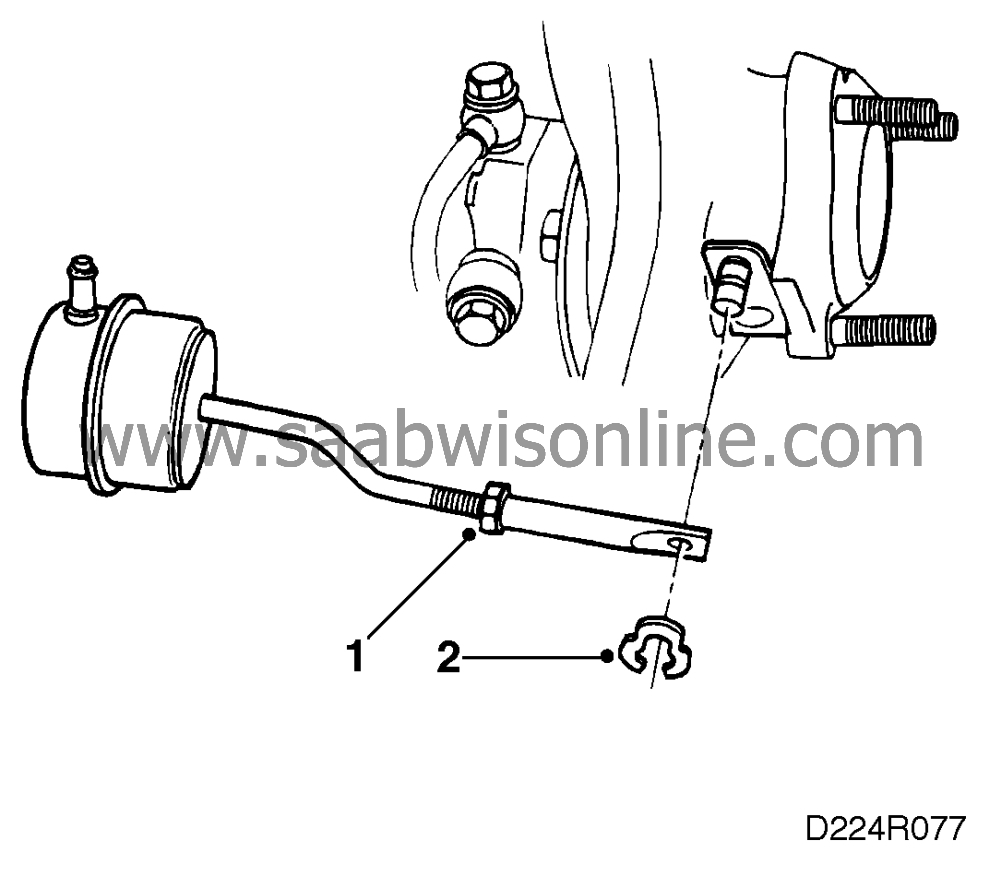

1.

|

Undo the end piece's

locknut and break the seal.

|

|

2.

|

Remove the circlip and unhook the push rod from the boost pressure

regulator's operating arm (the easiest way of performing the operation described in

point 2 is from underneath). Use special tool 83 94 538.

|

|

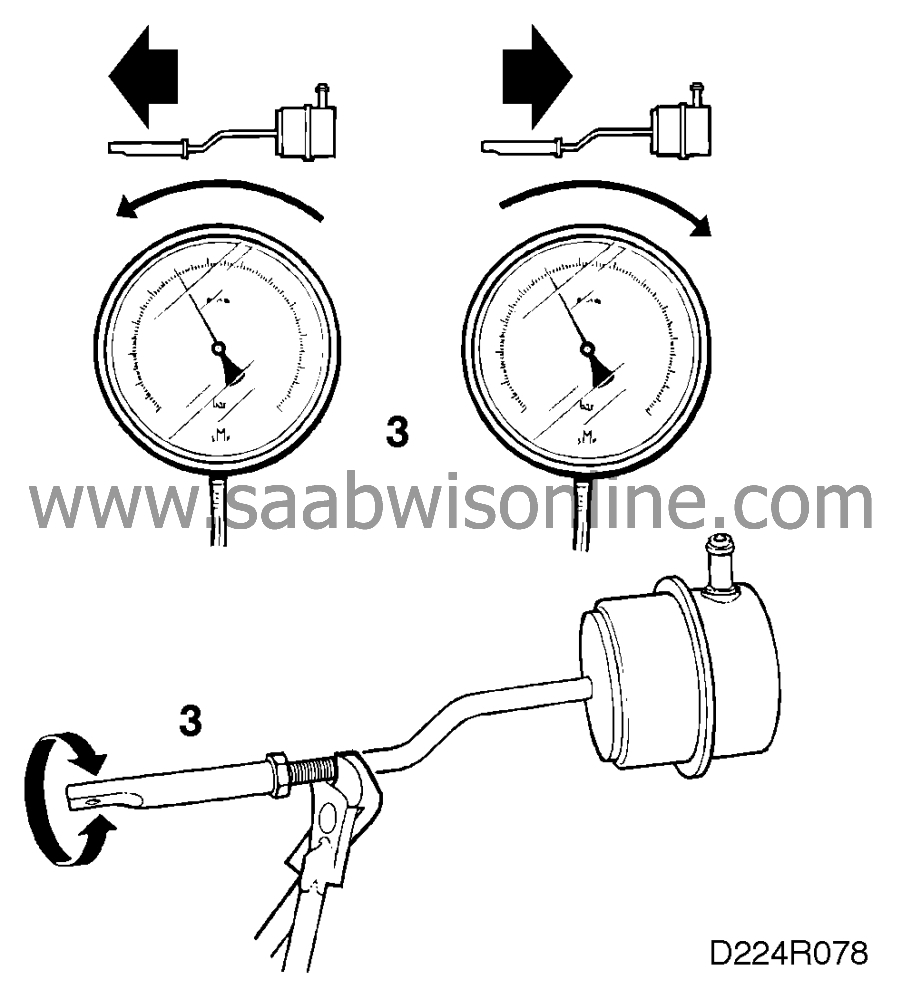

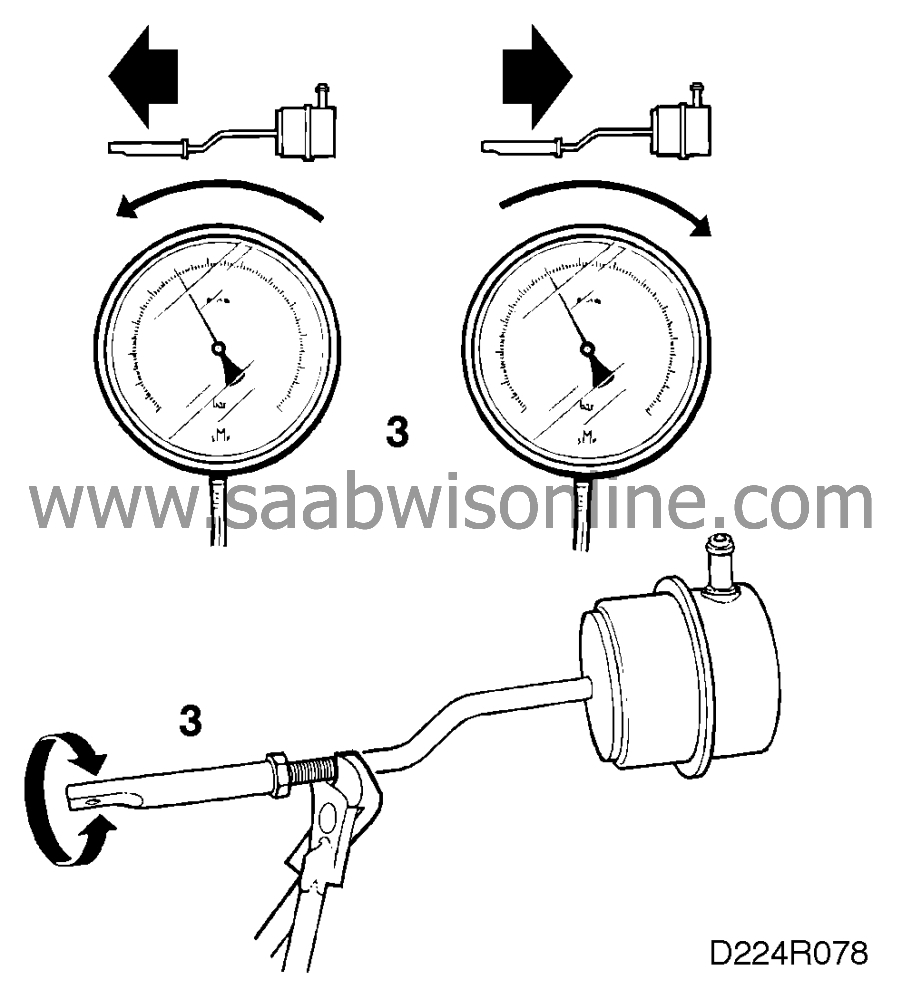

3.

|

Adjust basic boost pressure by screwing the end piece in if basic boost pressure

is too low or screwing the end piece out if basic boost pressure is too high. Turning the end

piece 1 complete revolution will change basic boost pressure by about 0.02

bar.

|

Important

|

|

The boost pressure regulator must never be "prestressed" (tightened) by less than 2

mm (2 turns) even if basic boost pressure cannot be adjusted so that it lies within the

tolerance limits of 0.40±0.03 bar.

|

|

|

|

|

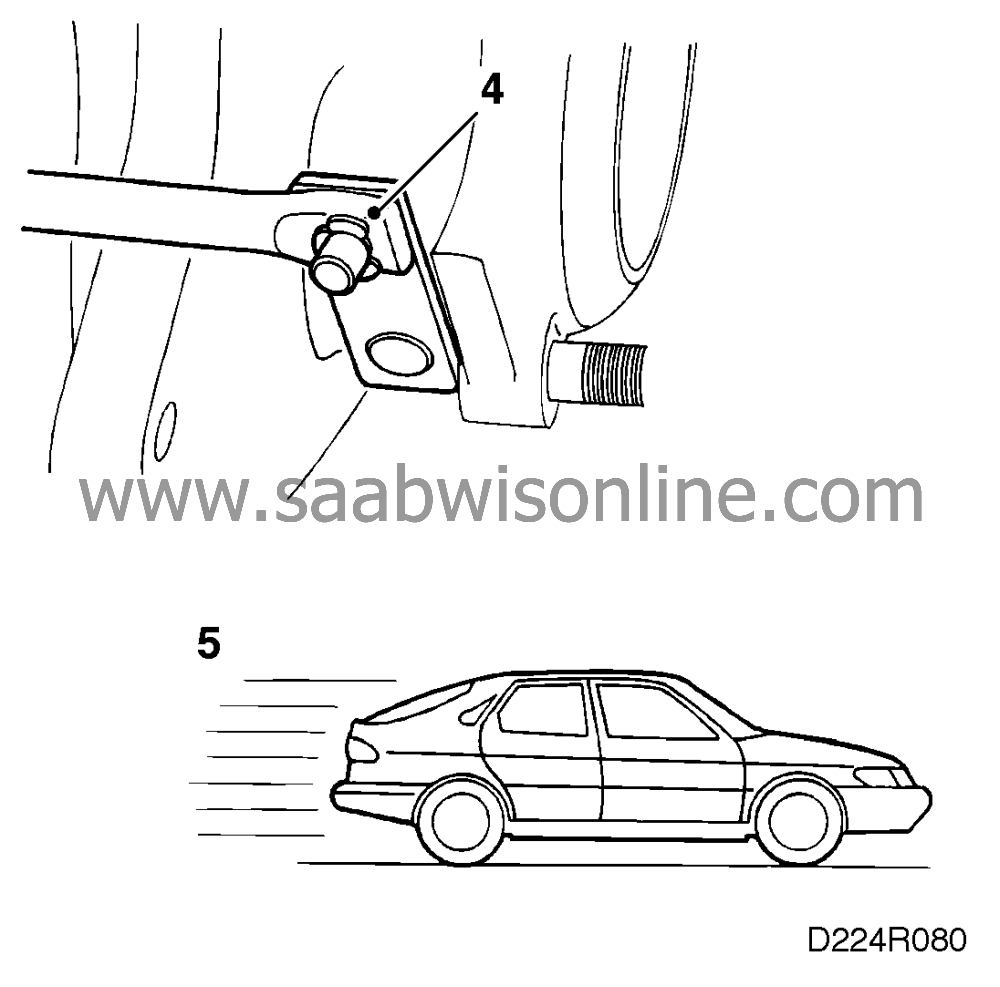

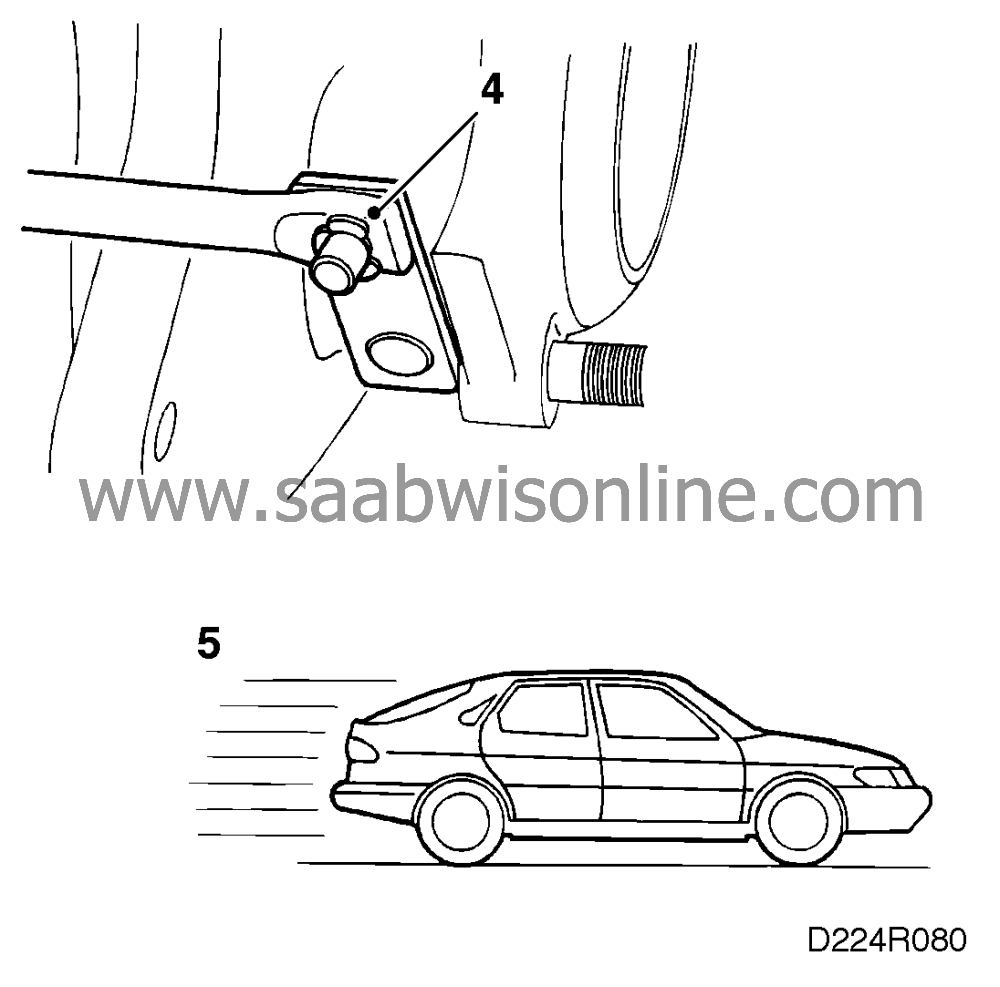

4.

|

Connect the pushrod to the actuator arm and fit the locking ring.

|

|

5.

|

Check the basic boost pressure on the road, see "Checking basic boost

pressure (on road)" in Service Manual 2:4 "Exhaust system, cooling system, turbo system". If

basic boost pressure cannot be adjusted, see "Control valve, turbo pressure" and "Diaphragm

unit" in Service Manual 2:4 "Exhaust system, cooling system, turbo system".

|