P0335

Symptom: The engine fails to start or misfires. Other diagnostic trouble codes

(misfiring, camshaft position).

Crankshaft position sensor

Symptom of fault

The engine fails to start or misfires. Other diagnostic trouble codes

(misfiring, camshaft position).

|

Note

|

|

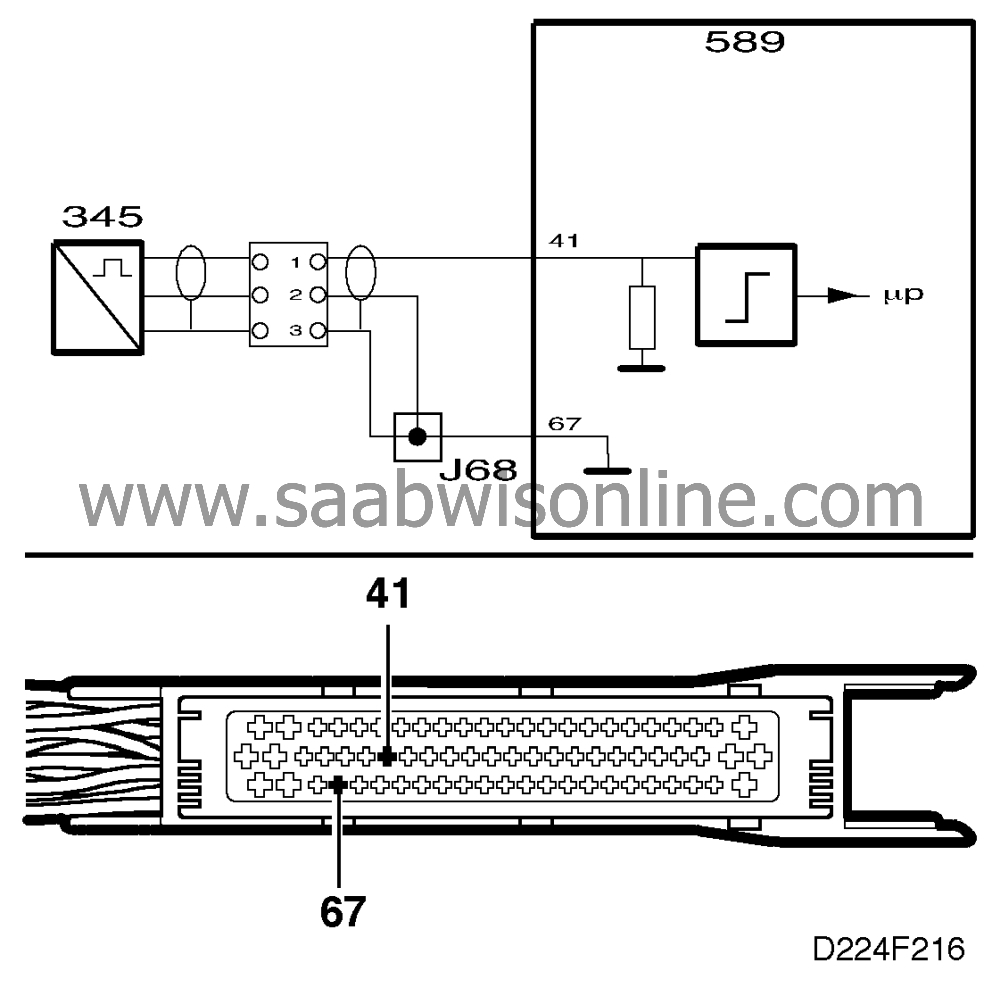

More diagnostic trouble codes will be generated if pin 67 of the control module is not

connected to ground.

|

Conditions

Vehicle speed >30 km/h. Engine speed >1500 rpm. Brakes not applied. The

sensor reads an incorrect number of ribs (teeth) per crankshaft revolution.

Diagnostic help

The diagnostic trouble code often indicates an intermittent fault. In the event of a

complete functional breakdown, the engine will not start and the diagnostic trouble code

cannot be generated. If the perforated ring, which is mounted on the crankshaft, has been

damaged in connection with work carried out on the basic engine, for instance, the diagnostic

trouble code may be generated.

Checking the wiring. Intermittent faults may occur as a result of occasional short circuits

and breaks in the wiring. Jiggle the leads and in-line connectors at several places and in

different directions to reveal faults in the wiring harness. Observe the multimeter, ISAT scan

tool or test lamp while carrying out this check.

Diagnostic procedure

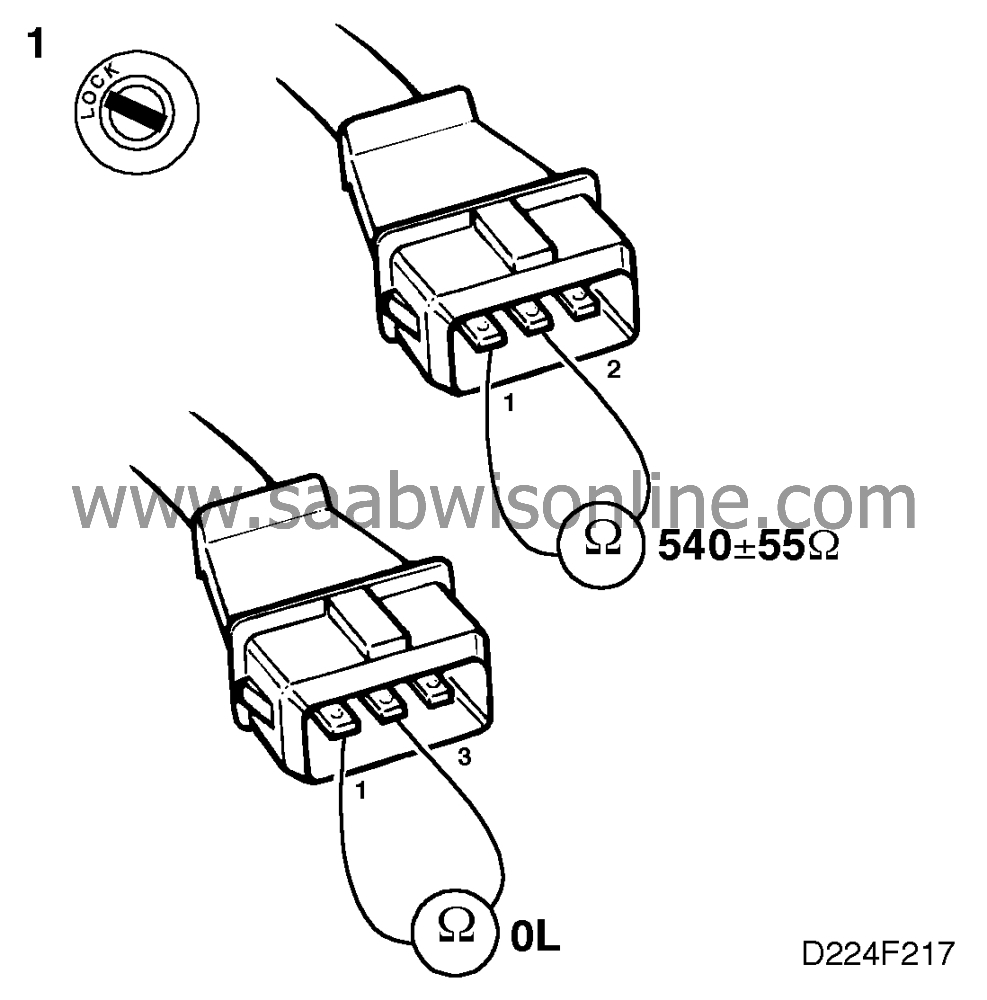

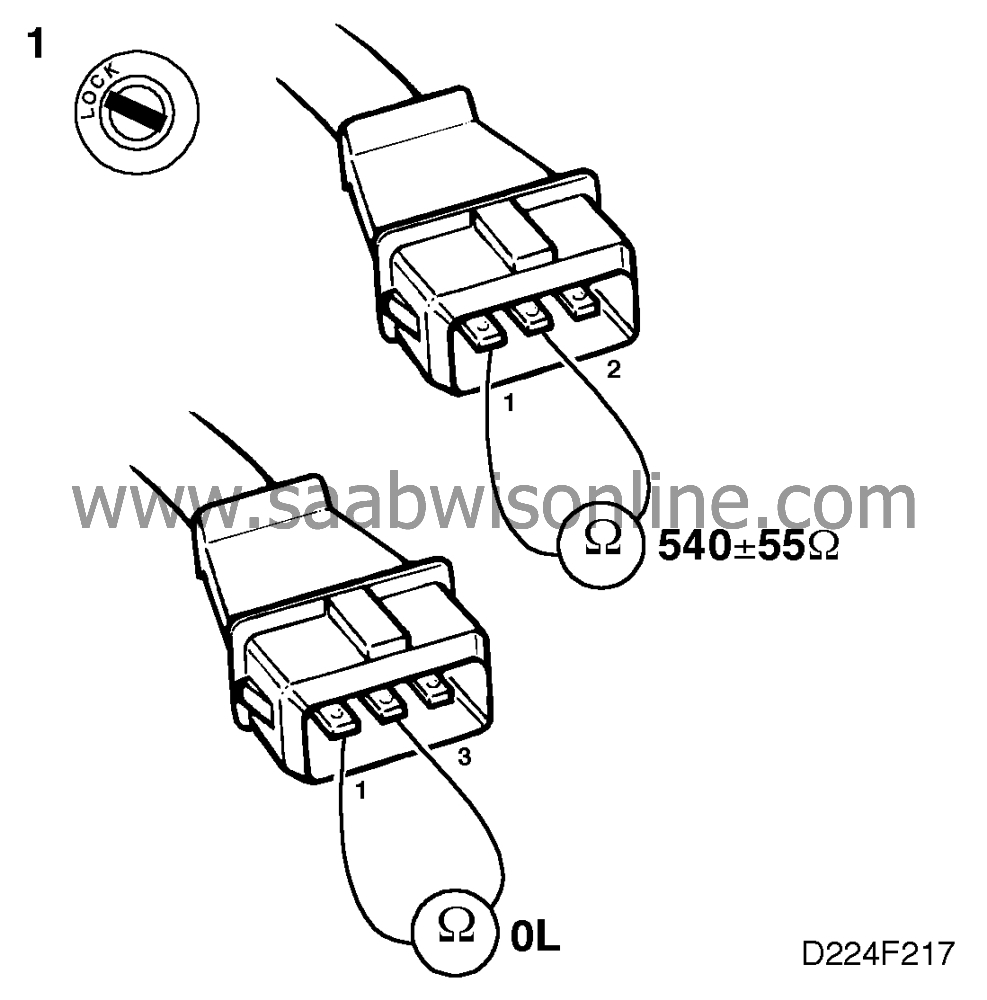

1. Check the resistance of the crankshaft position sensor

|

-

|

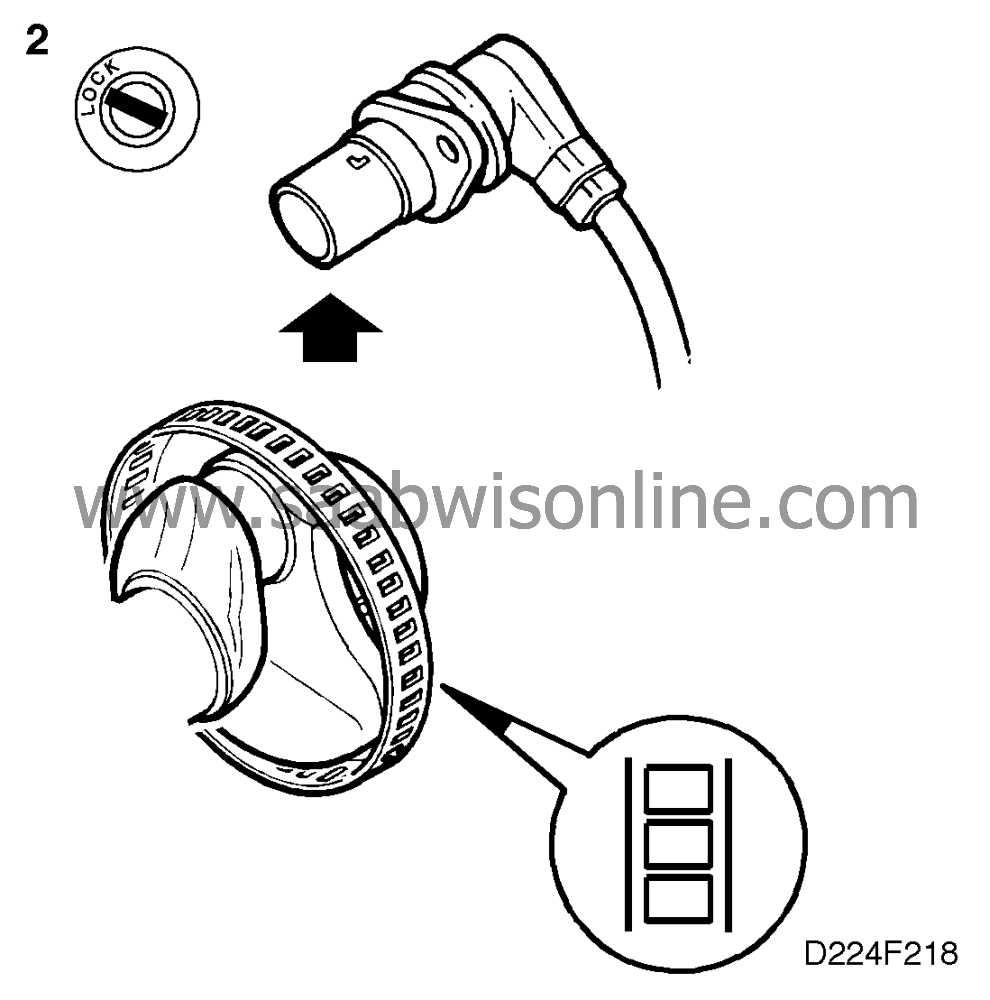

Unplug the crankshaft position

sensor's 3-pin connector.

|

|

-

|

Take a resistance reading on the

pins of the sensor's connector: Check the resistance of the sensor across pins 1 and 2.

|

Nominal resistance is 540±55 ohms.

|

-

|

Check for possible stray currents

between the signal lead and screened lead across pins 1 and 3.

|

Nominal resistance is infinite (OL - OverLoad).

Are the resistance readings OK?

Continue with point 2.

Change the crankshaft position sensor and continue with point 5.

2. Check the mounting of the crankshaft position

sensor

|

-

|

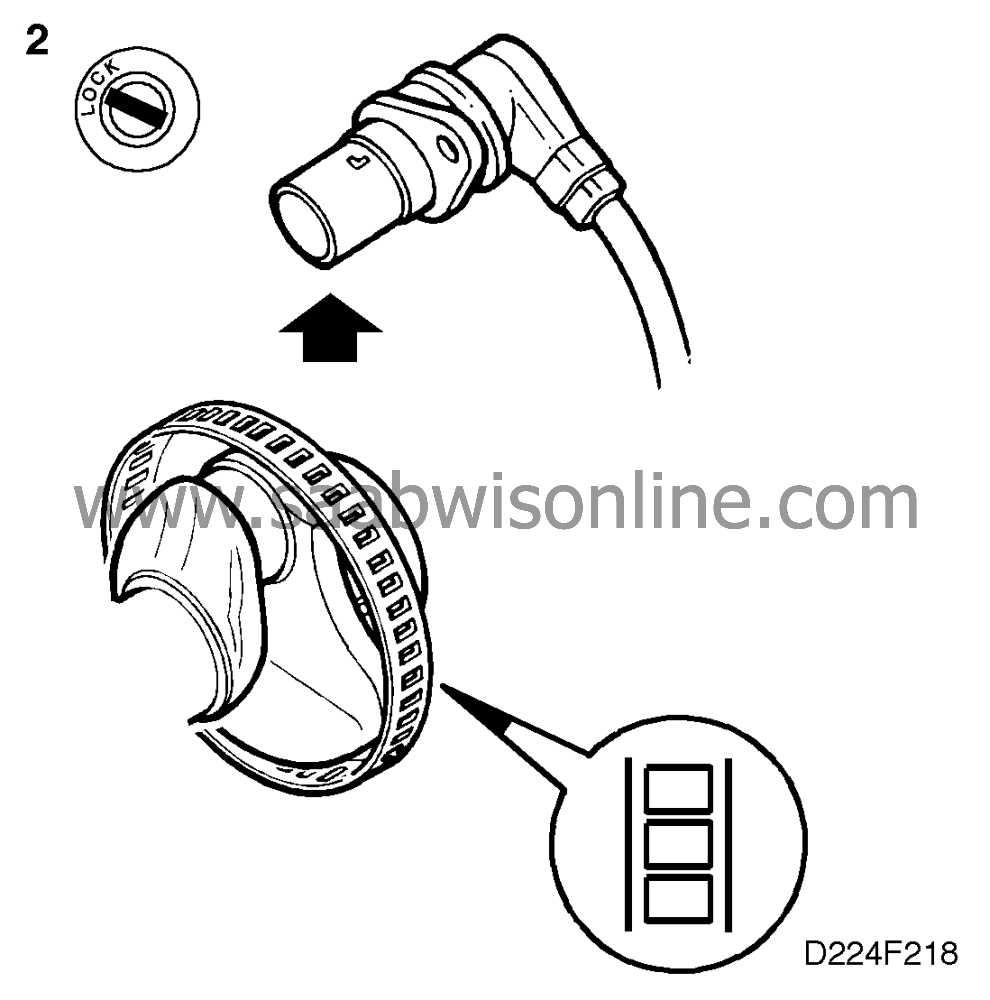

Remove the crankshaft position

sensor and check:

|

|

|

•

|

that the sensor tip is not soiled with

metal filings, swarf, etc.

|

|

|

•

|

that the perforated ring is firmly secured to the crankshaft (by prising it gently

with a screwdriver).

|

|

|

•

|

while the crankshaft is rotated, that the perforated ring is not skew, buckled or

otherwise damaged.

|

|

-

|

Brush off any metal shavings or

swarf on the sensor.

|

Is the perforated ring damaged or insecurely mounted?

See Service Manual 2:1 "Basic engine".

Continue with point 3.

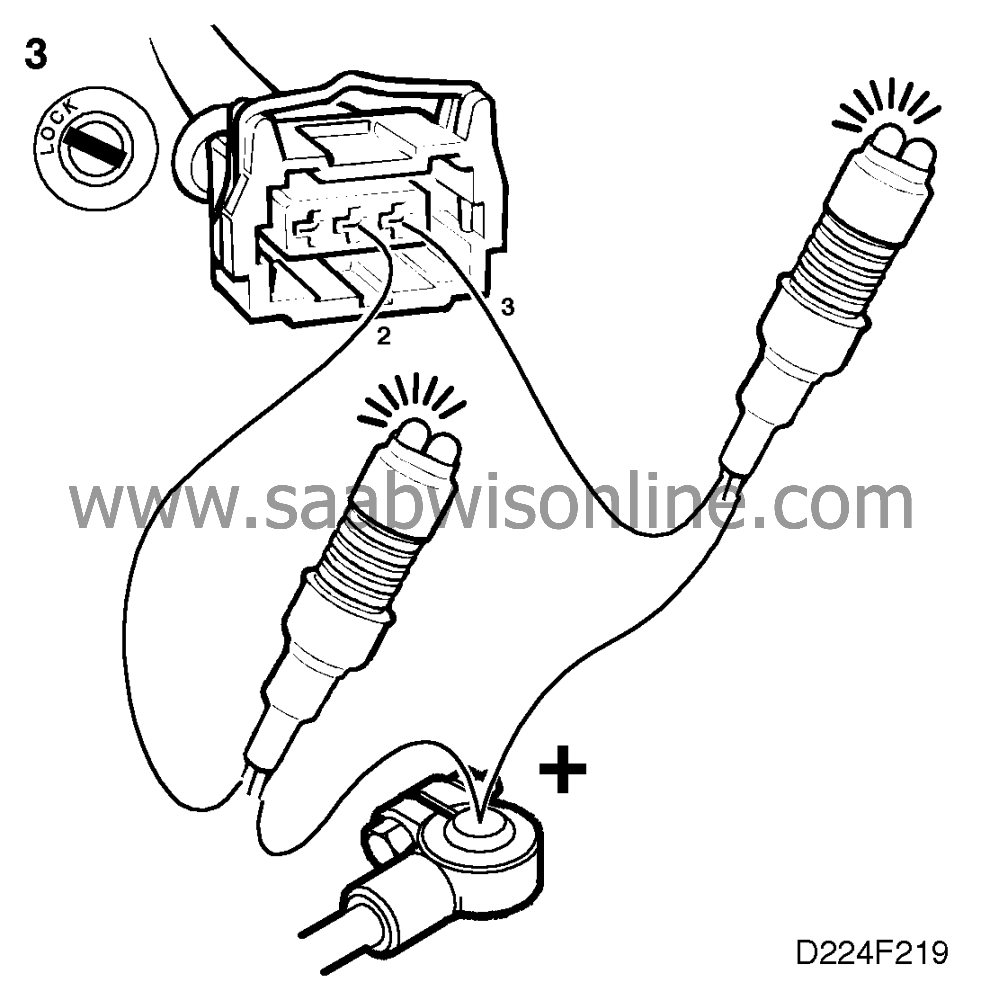

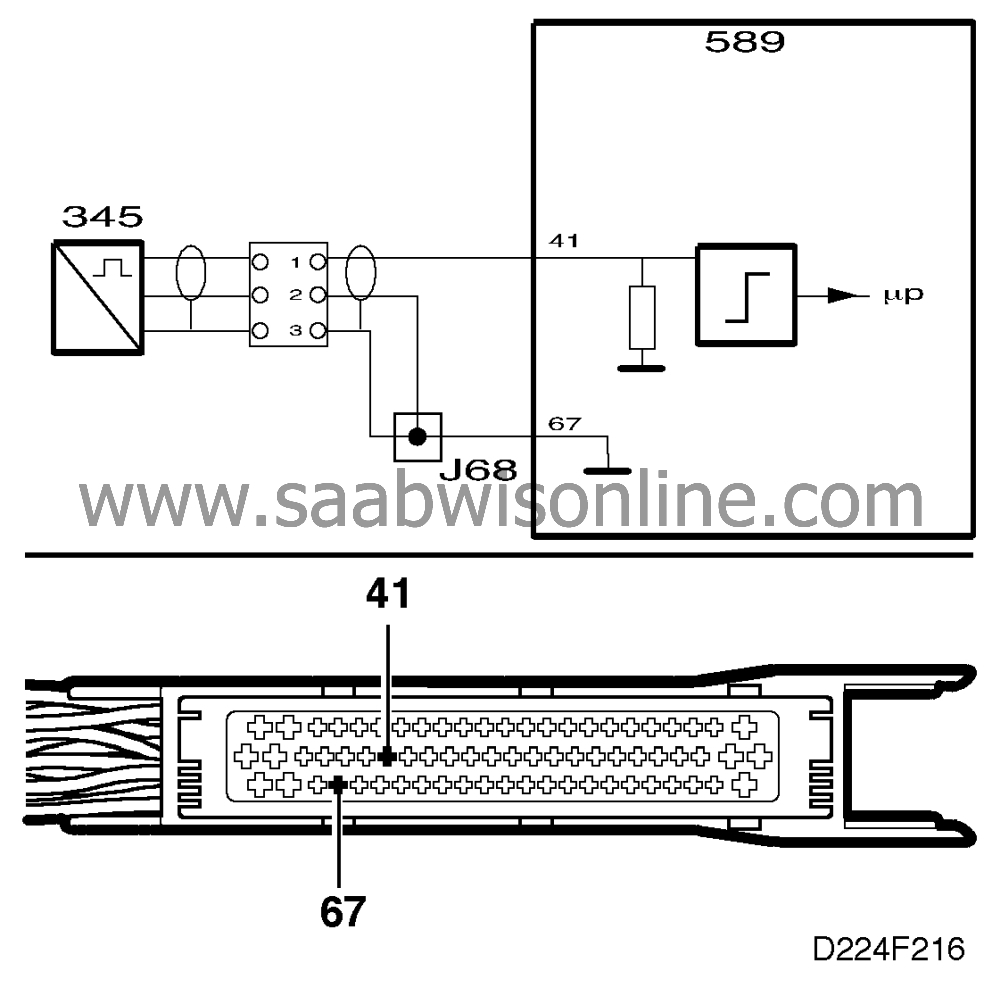

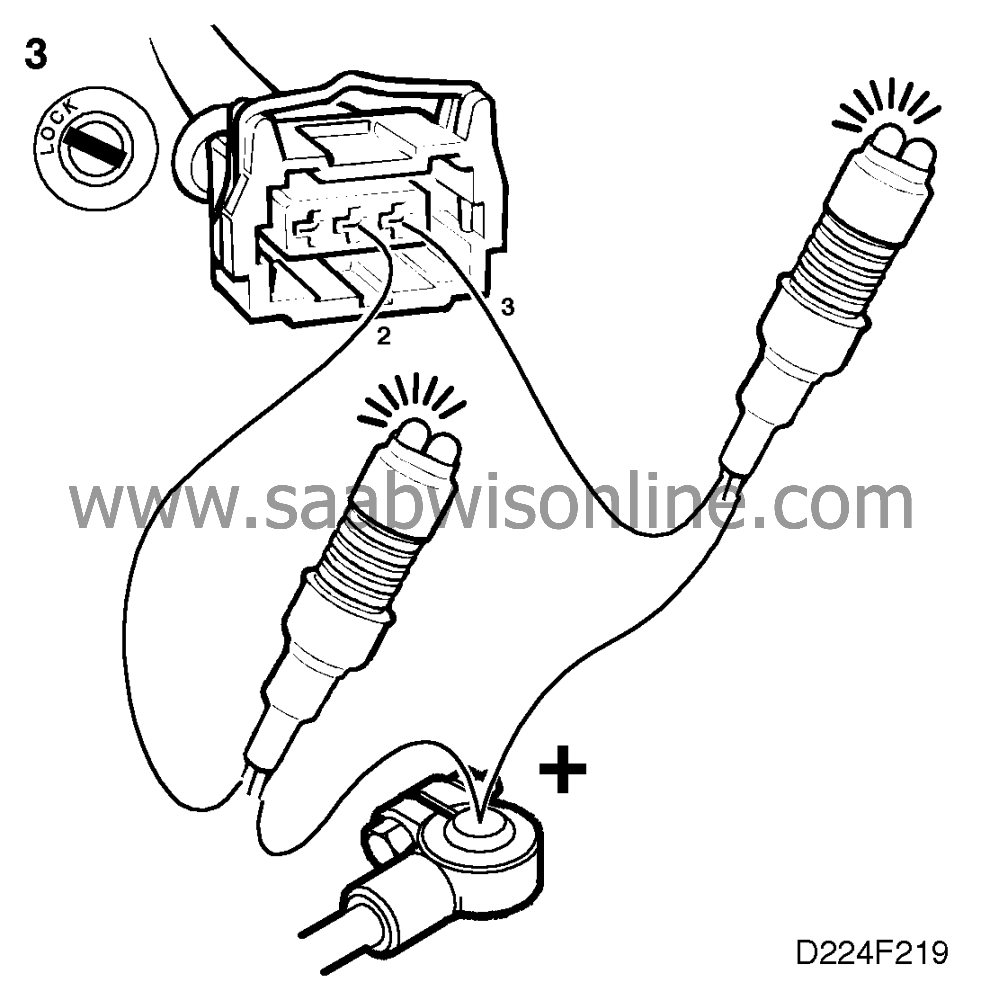

3. Check the crankshaft position sensor's

ground and screen connections

|

-

|

Connect the test lamp

to:

|

Does the test lamp light up in both cases?

Continue with point 4.

Repair or replace the appropriate lead between:

• pin 2 and crimped connection J68

• pin 3 and crimped connection J68.

Then continue with point 5.

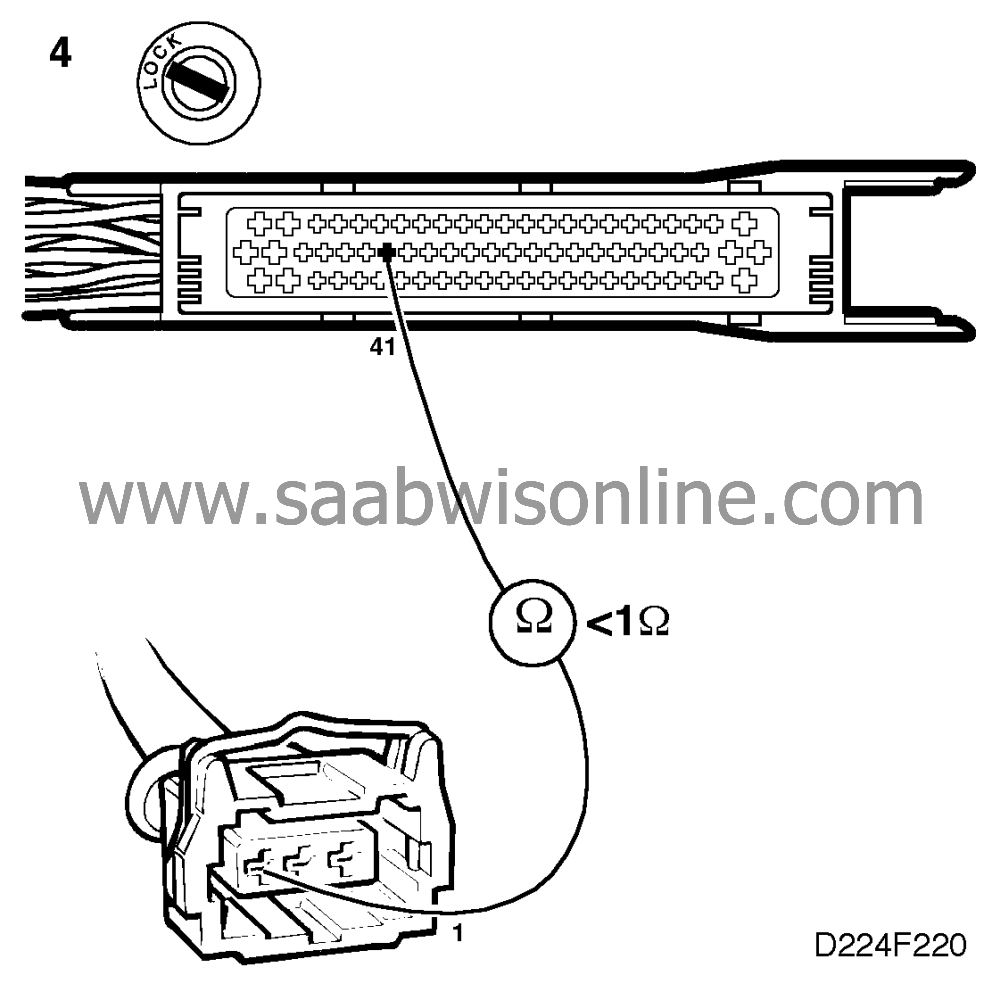

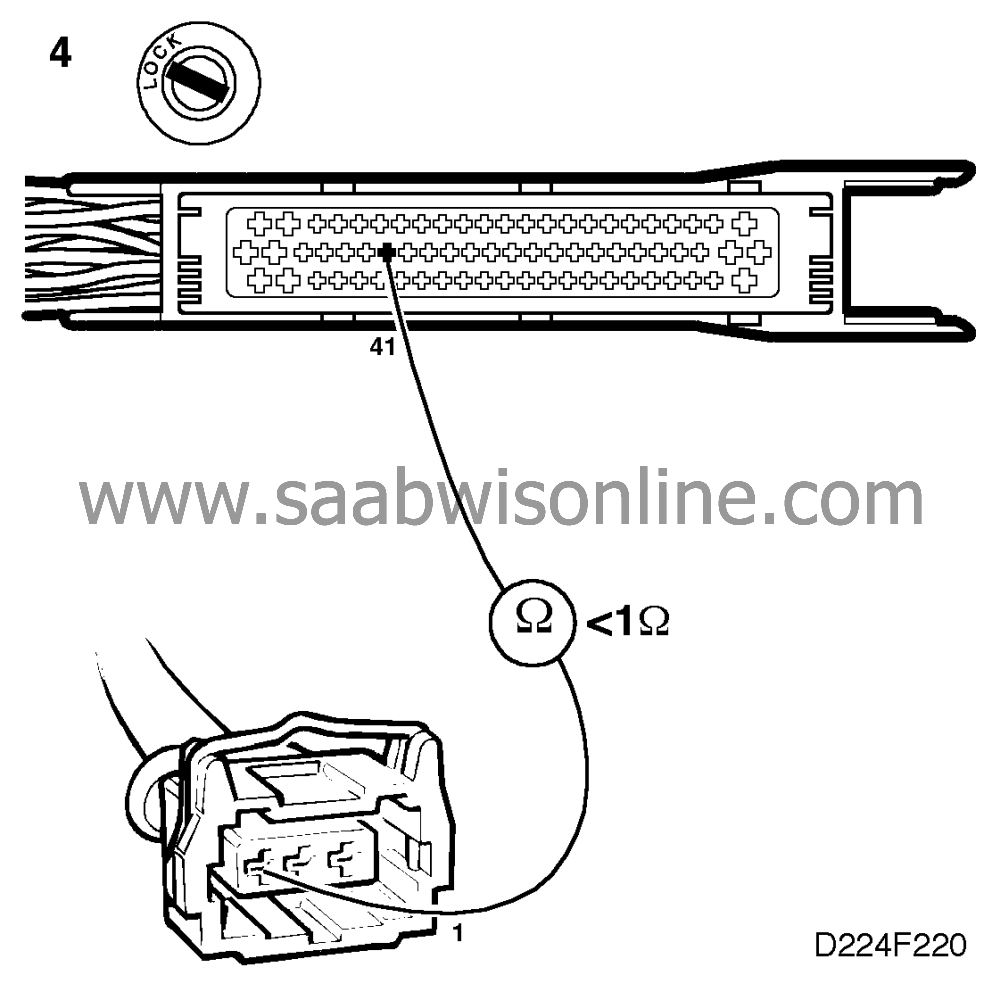

4. Check the control module sensor

input

|

-

|

Check the lead between pin 1 of

the connector and pin 41 of the control module.

|

Is the lead OK?

Change the crankshaft position sensor and then continue with point

5.

Repair or replace the lead and then continue with point 5.

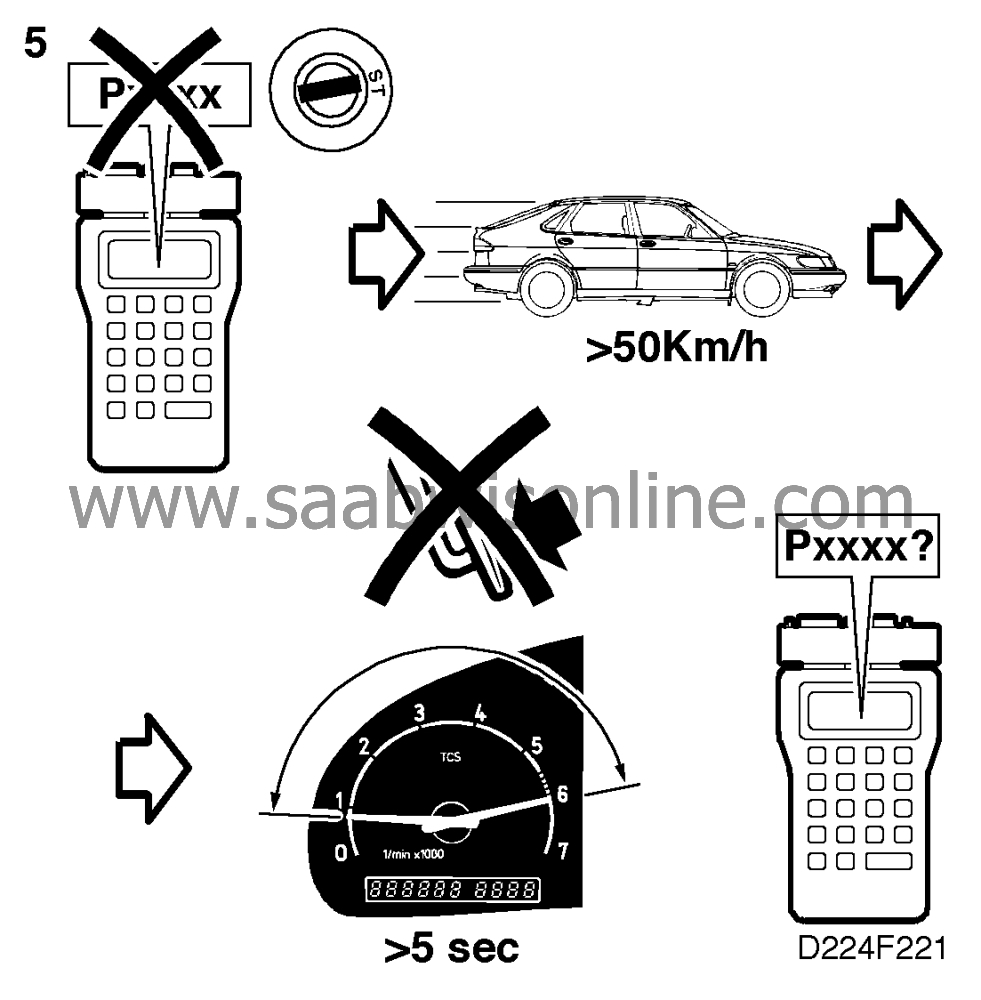

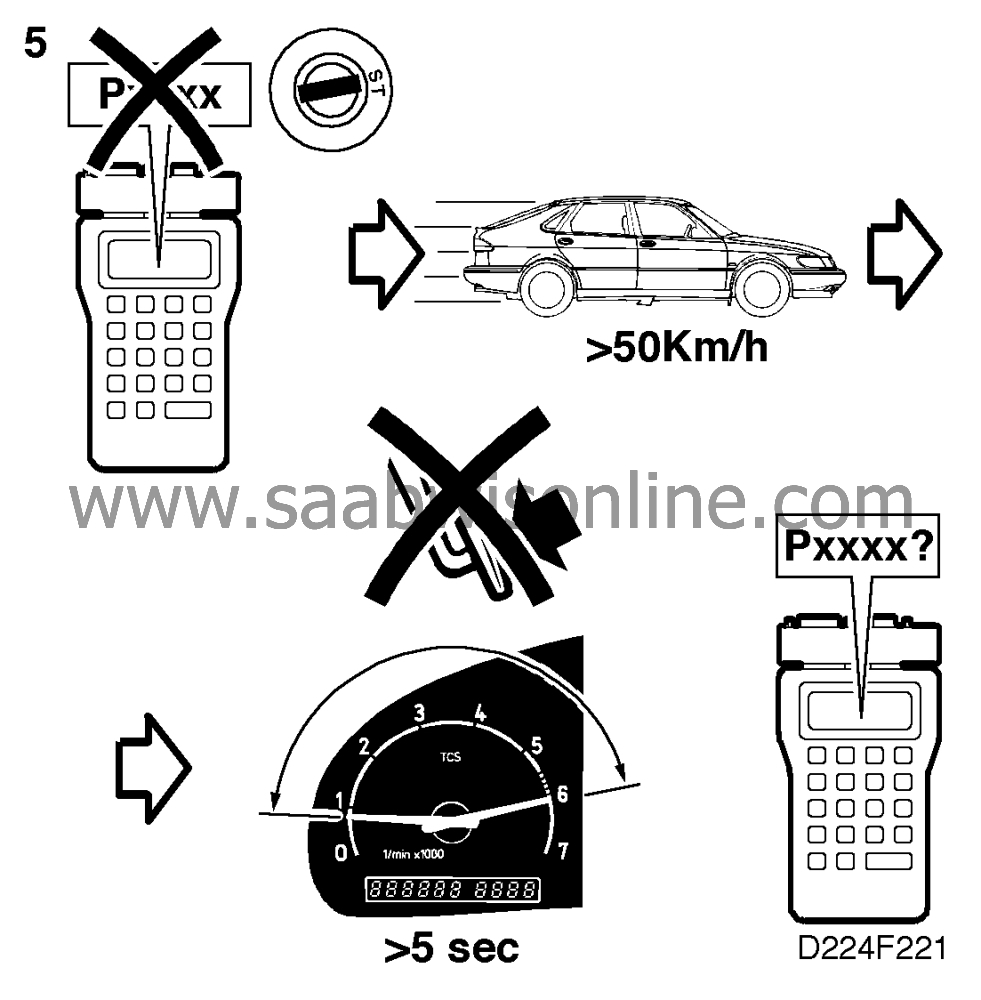

5. Final check

|

-

|

Clear the diagnostic trouble

code.

|

|

-

|

Implementation of driving

cycle:

|

|

|

•

|

Drive the car at a higher speed

than 50 km/h.

|

|

|

•

|

Rev up the engine to maximum rpm for

at least 5 seconds without touching the brake pedal.

|

|

-

|

Evaluation of driving cycle: Check

whether the diagnostic trouble code has recurred.

|

Has the diagnostic trouble code recurred?

Proceed to

.

.

The remedial measure taken was correct.