Test readings, control module connections

| Test readings, control module connections |

| Scope |

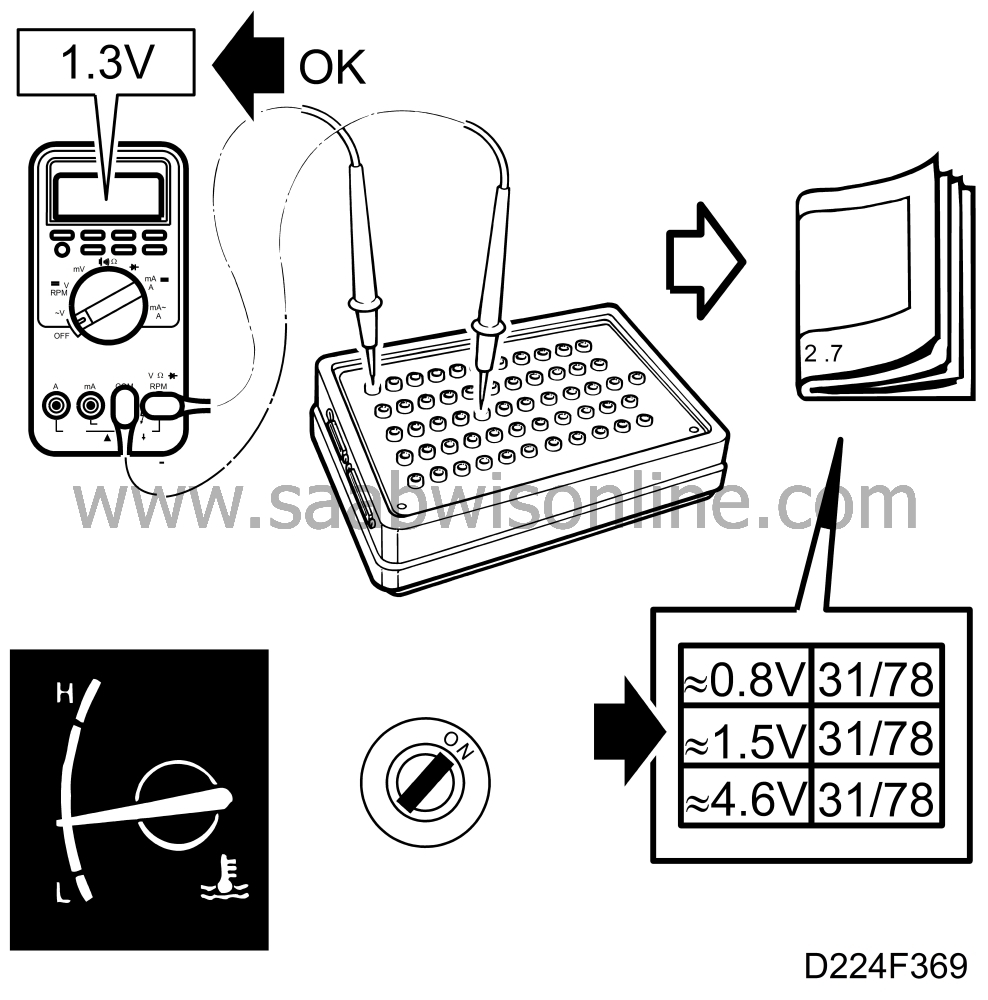

Test readings and directions for measuring signals and signal levels on the Trionic control module are given in the following pages.

| Some important points to remember: |

| • |

Readings should be taken with a

Breakout Box (BOB) connected between the control module and the control module's

connector.

|

|

| • |

Several voltage levels should be regarded as guiding values. Your common

sense should tell you whether a reading is correct or not.

|

|

| • |

If any test reading is obviously incorrect, use the wiring diagram to trace the

leads, connectors or components which you consider ought to be checked more thoroughly.

|

|

| • |

The pages referred to in the table contain a description of the relevant

signal's function and a fault diagnosis schedule with detailed, step-by-step instructions

explaining the diagnostic procedure to be followed.

|

|

| • |

All test readings are for a warmed-up engine.

|

|

| • |

Unless otherwise stated, the ignition should be switched on.

|

|

| • |

The test readings are in respect of a calibrated FLUKE 88/97.

|

|

>= greater than; < = less than; » = approximately equal to; ∼ = alternating current Pins without further comments are not used. (LP: LOGIC PROBE P = select pulse; p = visible pulses.)

|

Pin

|

Colour

|

Component/Function

|

In/Out

|

Test

conditions

|

Across + -

|

Test

reading

|

|

1

|

PK/WH

|

+30

|

in

|

900+50 rpm

|

B+ to 1

|

<0.5 V

|

|

2

|

GN/BK

|

Boost pressure control valve

|

out

|

900 ± 50 rpm

|

2 - 25

|

90 Hz

17.5%%

(-) 1.9 ms

(-) (LP HI LO)

|

|

3

|

GN/WH

|

Injector 1

|

out

|

900 ± 50 rpm

|

3 - 25

|

7.5 Hz

2.5-4.5 ms (-)

(LP

HI

LOp)

|

|

4

|

BU/WH

|

Injector 2

|

out

|

900 ± 50 rpm

|

4 - 25

|

7.5 Hz

2.5-4.5 ms (-)

(LP

HI

LOp)

|

|

5

|

VT/WH

|

Injector 3

|

out

|

900 ± 50 rpm

|

5 - 25

|

7.5 Hz

2.5-4.5 ms (-)

(LP

HI LOp)

|

|

6

|

GY/WH

|

Injector 4

|

out

|

900 ± 50 rpm

|

6 - 25

|

7.5 Hz

2.5-4.5 ms (-)

(LP

HI LOp)

|

|

7

|

|

|

|

|

|

|

|

8

|

|

|

|

|

|

|

> = greater than; < = less than; = » approximately equal to; ∼ = alternating current

|

Pin

|

Colour

|

Component/Function

|

In/Out

|

Test

conditions

|

Across + -

|

Test

reading

|

|

9

|

OG/BK

|

Trigger 1

|

out

|

900 ± 50 rpm

|

9 - 25

|

7.5 Hz

8.3 %% (-)

11 ms (-)

(LP

HI LOp)

|

|

10

|

GN/YE

|

Trigger 2

|

out

|

900 ± 50 rpm

|

10 - 25

|

7.5 Hz

8.3 %% (-)

11 ms (-)

(LP

HI LOp)

|

|

11

|

BU/RD

|

Trigger 3

|

out

|

900 ± 50 rpm

|

11 - 25

|

7.5 Hz

8.3 %% (-)

11 ms (-)

(LP

HI LOp)

|

|

12

|

GY/RD

|

Trigger 4

|

out

|

900 ± 50 rpm

|

12 - 25

|

7.5 Hz

8.3 %% (-)

11 ms (-)

(LP

HI LOp)

|

|

13

|

OG/ WH

|

Engine torque

limitation

|

in

|

|

13 - 25

|

B+

|

|

Shifting

|

13 - 25

|

0 V

|

||||

|

14

|

BK/WH

|

DRIVE

|

in

|

P, N

|

14 - 25

|

0 V

|

|

R, D, 1, 2, 3

|

14 - 25

|

B+

|

||||

|

15

|

VT

|

Switch, brake

lights

|

in

|

brake pedal not

depressed

|

15 - 25

|

0 V

|

|

brake pedal depressed

|

15 - 25

|

B+

|

||||

|

16

|

|

|

|

|

|

|

|

17

|

YE/BN

|

Combustion cyl. 1+2

|

in

|

900 ± 50 rpm

|

17 - 25

|

15-30 Hz

(LP

LO HIp)

|

|

18

|

BN/RD

|

Combustion cyl. 3+4

|

in

|

900 ± 50 rpm

|

18 - 25

|

15-30 Hz

(LP

LO HIp)

|

|

19

|

|

|

|

|

|

|

|

20

|

PK

|

Manifold absolute pressure

signal

|

out

|

|

20 - 67

|

1.0 V *)

|

|

21

|

BU

|

M96: EVAP canister purge valve

Diagnosis

|

in

|

900 ± 50 rpm, warm engine

and >1 min. since starting.

|

21 - 25

|

1.3 V

8 Hz

10%% (-)

12 ms (-)

(

HI

LOp)

|

|

BU

|

M96 1/2: Tank pressure

sensor

|

in

|

Undo the tank filler cap.

|

21 - 25

|

0 kPa =

2.5 V

see also technical data

|

|

|

22

|

BU/BN

|

Manifold absolute pressure sensor

|

in

|

|

22 - 67

|

100 kPa =

1.9 V

see also technical data

|

*) A somewhat lower reading may be obtained at high altitudes.

> = greater than; < = less than; = » approximately equal to; ∼ = alternating current

|

Pin

|

Colour

|

Component/Function

|

In/Out

|

Test

conditions

|

Across + -

|

Test

reading

|

|

23

|

GN

|

Front heated oxygen sensor (oxygen

sensor 1)

|

in

|

900 ± 50 rpm, warm engine

and >1 min. since starting

|

23 - 47

|

0.1-0.9 V

|

|

24

|

BK

|

Main ground

|

in

|

900 ± 50 rpm

|

24 - B-

|

<0.1 V

|

|

25

|

BK

|

Main ground

|

in

|

900 ± 50 rpm

|

25 - B-

|

<0.1 V

|

|

26

|

BU

|

Boost pressure control

valve

|

out

|

1000-1500 rpm

|

1 - 26

|

2.3 V

|

|

1000-1500 rpm

|

|

90 Hz

17.5%% (-)

1.9 ms (-)

(LP P HI LO)

|

||||

|

27

|

M96: BU M96 1/2:

YE/GY

|

EVAP canister purge

valve

|

out

|

900 ± 50 rpm and engine

warm

|

27 - 25

|

1.3 V

8 Hz

10%% (-)

12 ms (-)

(

HI

LOp)

|

|

28

|

GN

|

Shut-off valve,

evaporative emission canister

|

out

|

900 ± 50 rpm

|

28 - 25

|

B+

|

|

In connection with EVAP

diagnostics.

|

28 - 25

|

0 V

|

||||

|

29

|

|

|

|

|

|

|

|

30

|

|

|

|

|

|

|

|

31

|

BU/GY

|

Main

relay

|

out

|

|

31 - 25

|

B+

|

|

start the engine

|

31 - 25

|

<0.5 V

|

||||

|

32

|

YE/GN

|

CHECK

ENGINE

|

out

|

|

32 - 25

|

<0.5 V

|

|

engine running and CHECK ENGINE

lamp (MIL) out

|

32 - 25

|

B+

|

||||

|

33

|

GY/BK

|

Diagnosis

|

in/out

|

ISAT scan tool not

connected

|

33 - 25

|

»

6.5 V

|

|

ISAT scan tool

connected

|

33 - 25

|

B+

|

||||

|

34

|

|

|

|

|

|

|

|

35

|

|

|

|

|

|

|

|

36

|

BU/GN

|

Cruise

Control

|

in

|

|

36 - 25

|

»

10 V

|

|

CC active

|

36 - 25

|

<0.5 V

|

||||

|

37

|

|

|

|

|

|

|

> = greater than; < = less than; = » approximately equal to; ∼ = alternating current

|

Pin

|

Colour

|

Component/Function

|

In/Out

|

Test

conditions

|

Across + -

|

Test

reading

|

|

38

|

YE

|

Low fuel

level

|

in

|

low fuel warning lamp in main

instrument display panel on

|

38 - 25

|

<0.5 V

|

|

low fuel warning lamp in main

instrument display panel out

|

38 - 25

|

B+

|

||||

|

39

|

PK/BK

|

Vehicle speed signal

|

in

|

raise RH front wheel, rotate 1/2

turn/sec.

|

39 - 25

|

15 Hz

50%%

(LP HIp LOp)

|

|

40

|

|

|

|

|

|

|

|

41

|

YE

|

Crankshaft position

sensor

|

in

|

900 ± 50 rpm

|

41 - 67

|

5-10 V∼

»

870 Hz (LP HI LO)

|

|

42

|

WH/BK

|

Throttle position sensor

|

out

|

|

42 - 67

|

5 V

|

|

43

|

GY

|

Pressure sensor

|

out

|

|

43 - 67

|

5 V

|

|

44

|

OG

|

Knock signal

|

in

|

900 ± 50 rpm

|

44 - 25

|

50-100 mV∼ (LP P LO)

|

|

45

|

GN/BN

|

Throttle position sensor

|

in

|

|

45 - 67

|

idling

»

0.5 V see also technical data

|

|

46

|

WH/BK

|

Intake air temperature

sensor

|

in

|

40°C (104°F)

|

46 - 67

|

1.5 V

see also technical data

|

|

47

|

BK

|

Heated oxygen sensor, reference

ground

|

in

|

900 ± 50 rpm

|

47 - 67

|

0-1 V

|

|

48

|

PK/WH

|

+30

|

in

|

900 ± 50 rpm

|

B+ - 48

|

<0.5 V

|

|

49

|

BU/VT

|

Idle air control valve

|

out

|

A/C and all electrical equipment

switched off

|

49 - 25

|

500 Hz

25-50%%

0.5-1.0 ms

(LP HI LO)

|

|

50

|

BK/WH

|

Front heated oxygen

sensor, heating

|

out

|

900 ± 50 rpm

|

50 - 25

|

»

0.5 V

|

|

remove fuse 38

|

50 - 25

|

0 V

|

||||

|

51

|

BK/WH

|

Rear heated oxygen

sensor, heating

|

out

|

900 ± 50 rpm, coolant temp

>50°C (122°F)

|

51 - 25

|

»

0.5 V

|

|

remove fuse 38

|

51 - 25

|

0 V

|

> = greater than; < = less than; = » approximately equal to; ∼ = alternating current

|

Pin

|

Colour

|

Component/Function

|

In/Out

|

Test

conditions

|

Across + -

|

Test

reading

|

|

52

|

|

Vacuum pump, brake

system

|

out

|

P, N

|

52 - 25

|

B+

|

|

R, D, 1, 2, 3

|

52 - 25

|

<0.5 V

|

||||

|

53

|

|

|

|

|

|

|

|

54

|

RD/WH

|

A/C out

|

out

|

900 ± 50 rpm, A/C

On

|

54 - 25

|

<0.5 V

|

|

900 ± 50 rpm, A/C

OFF

|

54 - 25

|

B+

|

||||

|

55

|

BU/YE

|

SHIFT

UP

|

out

|

when ignition switch turned to

ON

|

55 - 25

|

<0.5 V

|

|

After 3 sec.

|

55 - 25

|

B+

|

||||

|

56

|

WH

|

Fuel pump

relay

|

out

|

|

56 - 25

|

B+

|

|

900 ± 50 rpm

|

56 - 25

|

<0.5 V

|

||||

|

57

|

GN/OG

|

Throttle position signal

|

out

|

900 ± 50 rpm

|

57 - 25

|

100 Hz 9 %% (+) 0.9 ms (+) (LP

LO HI)

|

|

58

|

GN/RD

|

Engine speed signal

|

out

|

900 ± 50 rpm

|

58 - 25

|

30 Hz

(LP

LO HIp)

|

|

59

|

GN/GY

|

A/C in

|

in

|

900 ± 50 rpm, A/C

On

|

59 - 25

|

B+

|

|

900 ± 50 rpm, A/C

OFF

|

59 - 25

|

0 V

|

||||

|

60

|

YE/GY

|

+15

|

in

|

|

B+ - 60

|

<0.5 V

|

|

61

|

BU/GN

|

CHECK ENGINE

request

|

in

|

ON

|

61 - 25

|

B+/0 V

(2 Hz)

(LP HIp LOp)

|

|

OFF

|

61 - 25

|

0 V

|

||||

|

62

|

BK/WH

|

For production only

|

|

|

|

|

|

63

|

BN

|

For production only

|

|

|

|

|

|

64

|

|

|

|

|

|

|

|

65

|

YE

|

For production only

|

|

|

|

|

|

66

|

BK

|

Reference ground, engine coolant

temperature sensor

|

in

|

|

66 - 25

|

<0.05 V

|

|

67

|

BK

|

Sensor ground

|

out

|

|

67 - 25

|

<0.05 V

|

|

68

|

YE/WH

|

Engine coolant temperature

sensor

|

in

|

90°C (194°F)

|

68 - 66

|

0.41 V

see also technical data

|

|

69

|

|

|

|

|

|

|

|

70

|

GN

|

Rear heated oxygen sensor (oxygen sensor

2)

|

in

|

900 ± 50 rpm

|

70 - 47

|

0.1-0.9 V

|