Radio interference onAM

| SERVICE INFORMATION | |

| Bulletin Nbr: | 367-1713 |

| Date: ........... | FEBRUARY 1997 |

| Market: | CA GB IE |

| Radio interference on AM |

| Cars concerned |

Saab 900 M94-. For detailed information, see the relevant type of interference in point C.

| Background |

The action package in this SI has been produced for use in connection with customer concerns/complaints about interference or poor radio reception when listening to AM stations.

Always try to get the customer to describe the nature of the interference as precisely as possible, e.g. extraneous noise, tones, crackling, frying, motorboating, etc. and the circumstances in which the interference occurs.

| Materials |

|

47 11 214

(CA=30564136)

|

Processor card for main instrument display

|

|

48 72 677

(CA=30567465)

|

Interference suppression kit for ICE

|

|

|

containing:

|

|

|

Interference suppression capacitor

|

|

|

Crimp pin

|

|

48 72 685

(CA=30567466)

|

Interference suppression kit for Trionic

|

|

|

containing:

|

|

|

Interference suppression capacitor

|

|

|

Crimp pin

|

|

49 00 015

(CA=30567189)

|

Interference suppression kit for Motronic

|

|

|

containing:

|

|

|

Grounding braids (4)

|

|

Pressed thread screws (3)

|

|

|

|

Lock washers (8)

|

|

|

Hose clip

|

| Procedure |

| Note | ||

|

Only the system or systems which the following trouble-shooting procedures show are the cause of interference are to be rectified. |

If the car’s antenna/aerial is in poor condition, the radio will be less resistant to interference and radio reception in general will be substandard. Therefore, start fault diagnosis by inspecting the antenna/aerial.

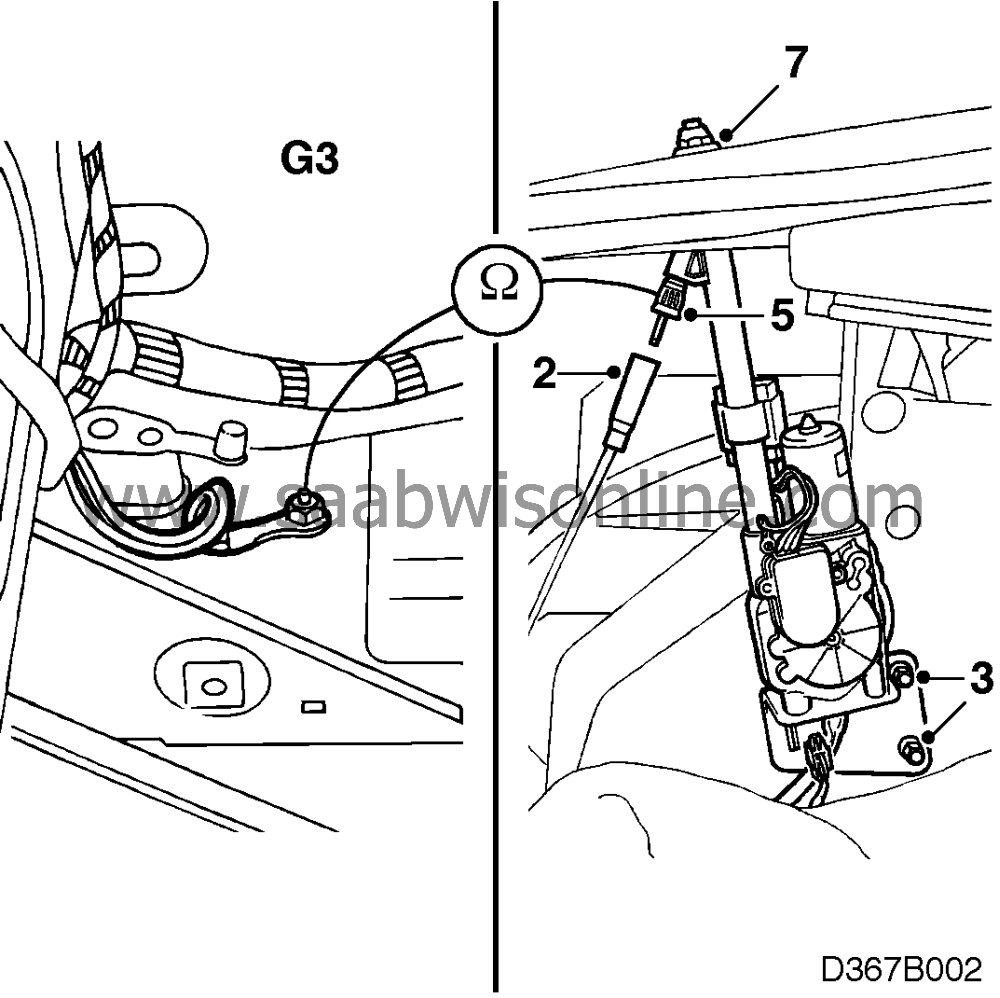

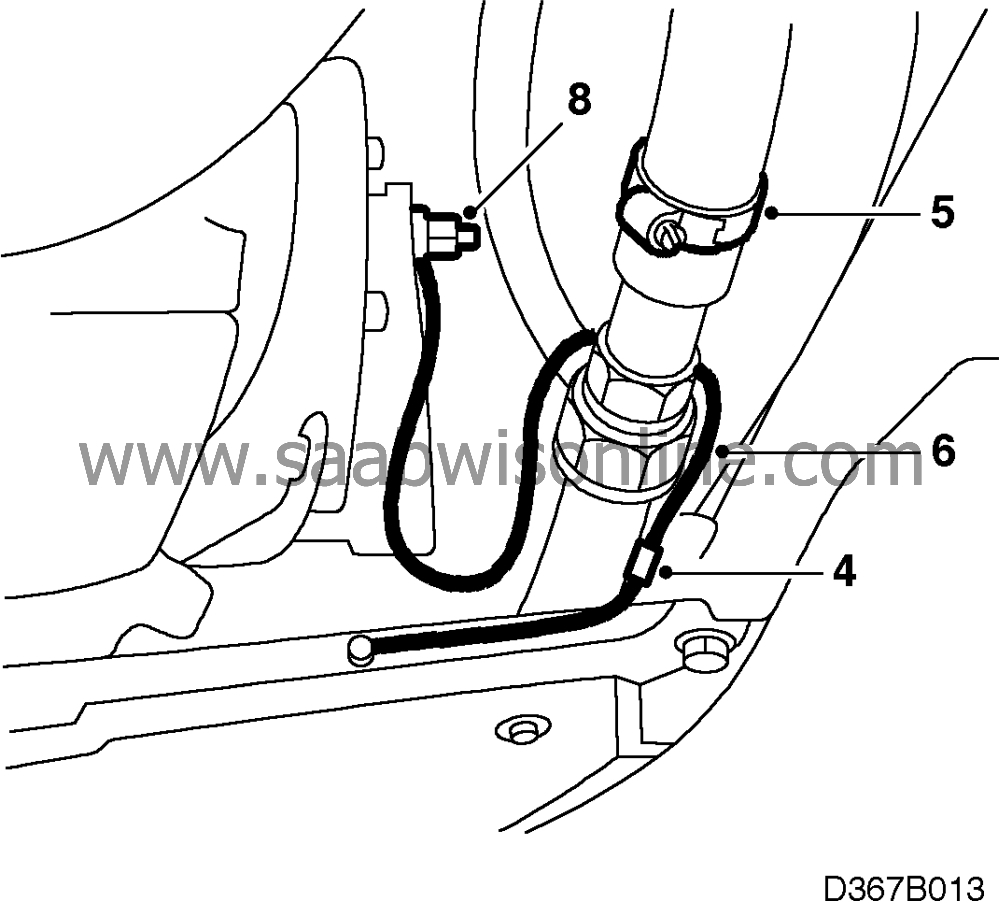

A. Antenna/aerial’s ground connection unsatisfactory.

It is extremely important for the antenna/aerial to be properly grounded. This can be checked as described below.| 1. |

Bend aside the luggage compartment

trim behind the left-hand wheel housing.

|

|

| 2. |

Disconnect the antenna/aerial cable.

|

|

| 3. |

Undo the two nuts securing the antenna/aerial.

|

|

| 4. |

Place a piece of insulating paper between the antenna/aerial

bracket and the car body.

|

|

| 5. |

Take a resistance reading across the antenna/aerial

connector’s screened plug and grounding point G3 below the left-hand rear light

cluster.

|

|

| 6. |

If the reading obtained is less than 10 ohms the ground connection is

OK. Remove the paper and continue with point B.

|

|

| 7. |

If the reading is above 10 ohms, adjust the lock washer until it is in

good contact with the body metal.

|

|

| 8. |

If the resistance reading obtained is less than 10 ohms after adjusting

the washer, remove the paper and continue with point B.

|

|

| 9. |

If it is greater than 10 ohms there may be an open circuit in the

antenna/aerial. Change the antenna/aerial and continue with point

C.

|

|

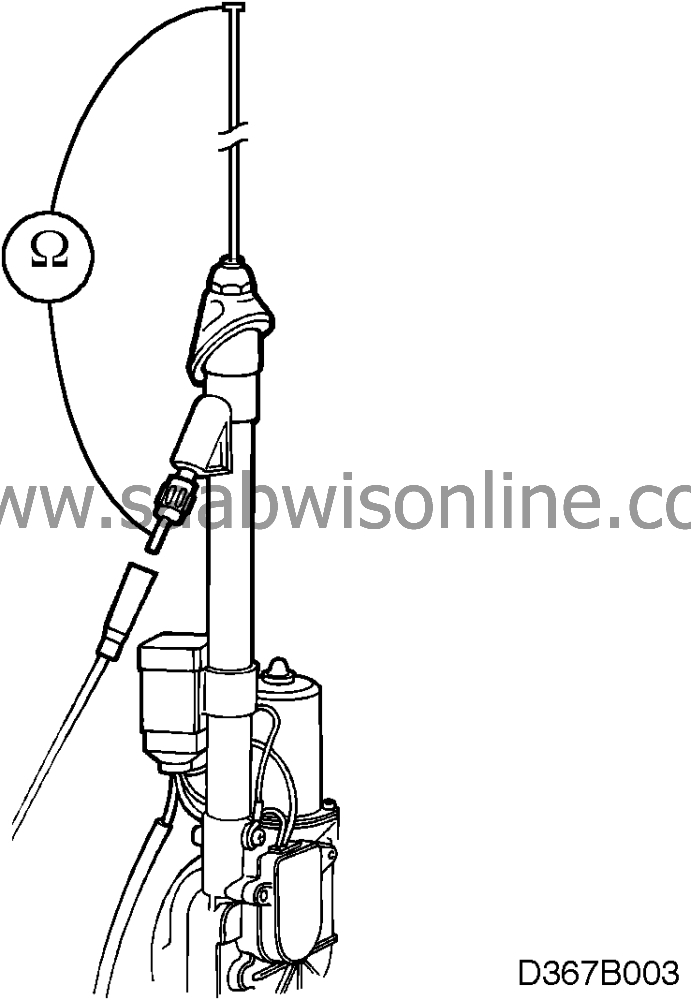

B. Free play in the antenna/aerial rod

Free play/poor contact between the various sections of the antenna/aerial rod may occur. Check this as described below:| 1. |

Switch on the radio and let the

antenna/aerial extend to its fullest height.

|

|

| 2. |

Take a resistance reading across the top of the antenna/aerial rod and the

centre pin of the antenna/aerial connector.

|

|

| 3. |

If the reading obtained is more than 30 ohms the antenna/aerial

rod should be changed.

|

|

| 4. |

Connect the antenna/aerial cable.

|

|

| 5. |

Tighten the nut at the base of the antenna/aerial (unless this has already

been done) and the two nuts securing the antenna/aerial.

|

|

| 6. |

Refit the luggage compartment trim.

|

|

| 7. |

If the antenna/aerial rod is dirty it can be wiped clean with a cloth

(do

lubricate it with wax or oil).

|

|

| 8. |

Continue as described in point C.

|

|

C. Interference

Interference may be caused by different systems in different cars. To determine which system or systems are the cause of the interference, the tests must be conducted outdoors so that they will not be affected by electrical equipment. etc. in the garage.Interference may be of three kinds:

| • |

Background noise, see point C1 on page

4.

|

|

| • |

Background tones, see point C2 on page 5.

|

|

| • |

Ignition system interference, see point C3 on page

8.

|

|

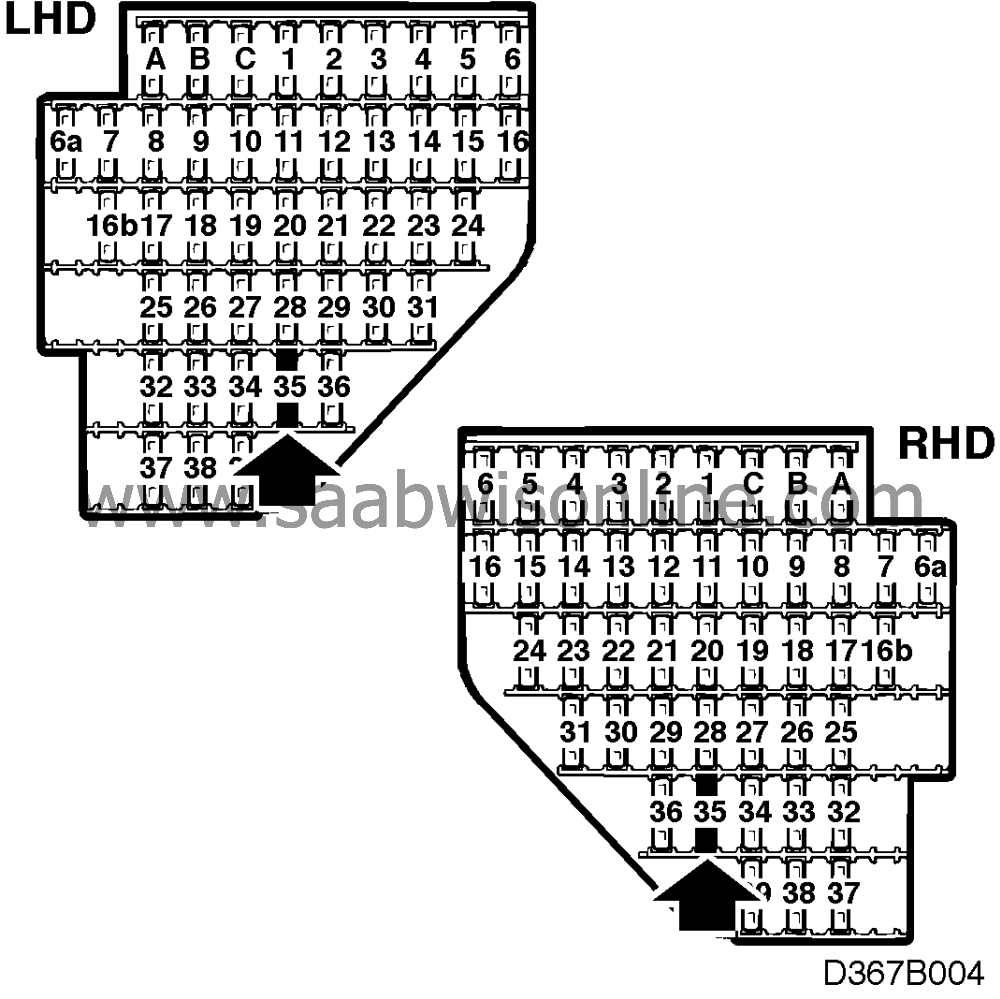

C1. Background noise

On M94 cars and up to and including M96 cars, the ICE may be the cause of background noise. Starting with M97 cars an interference suppressor has been introduced in the ICE.

To check

Turn the ignition switch to the OFF position and activate the radio. Tune in a weak station.

Remove fuse 35. This should result in a noticeable reduction of the noise.

Procedure

Fit interference suppression kit 48 72 677 (CA=30567465) as described below.

| 1. |

Remove the dashboard’s main fuse

board.

|

|

| 2. |

Remove the lower section of the dashboard on the driver’s

side.

|

|

| 3. |

Remove fuse 35 and extract the blue/black lead from the fuse

holder.

|

|

| 4. |

Cut the connector off the lead.

|

|

| 5. |

Cut the interference suppression capacitor’s lead to a length of

100 mm.

|

|

| 6. |

Twist it together with the blue/black lead in a new connector and

plug the connector into fuse holder 35.

|

|

| 8. |

Refit fuse 35, switch on the radio and check the result of the above

measures.

|

|

| 9. |

Refit all parts that have been removed.

|

|

C2. Background tone

A tone can be generated by three different systems. They are easy to distinguish from each other, depending on when the tone occurs.

| 1. |

The background tone varies between

different stations and it comes and goes according to the light intensity sensed by the

photodiode in the SID.

The fault can show up on M94 and later cars and is caused by the main instrument 2. An interference-suppressed processor card has been introduced on the types of instrument below with effect from the following chassis numbers: |

|

| - |

miles/turbo T2034392 and T7007538

respectively

|

| - |

miles/inj T2035029 and T7008509 respectively

|

| - |

km/turbo: not introduced at the time of this SI’s

publication

|

| - |

km/inj: not introduced at the time of this SI’s

publication

See section C2.1 for checking and rectification. |

| 2. |

A steady howling tone which disappears 5 seconds after the ignition is

switched off.

The fault occurs on cars equipped with Trionic M94-. See section C2.2 for checking and rectification. |

|

| 3. |

A tone occurs when the lights dim after the door has been

closed.

The fault is due to the ICE and occurs on M94- cars. See section C2.3 for checking and rectification. |

|

C2.1 Main instrument 2

Check whether the tone comes from the main instrument display’s PWM control of instrument lighting, as follows:

| 1. |

Set the instrument lighting rheostat to

max.

|

|

| 2. |

Shine a torch on the SID unit’s photodiode. The tone should

increase in intensity.

|

|

| 3. |

Cover the photodiode and the tone should stop.

|

|

The fault can be rectified by changing the processor card in the main instrument 2 and substituting an interference-suppressed card, part number 47 11 214 (CA=30564136).

This card is suitable with effect from the following chassis numbers (inclusive) :

| - |

miles/turbo R2011902

|

|

| - |

miles/inj R2015393

|

|

| - |

km/turbo R2018927

|

|

| - |

km/inj R2015980

|

|

See group 3 “Main instrument 2” for repair instructions.

C2.2 Trionic

Check whether the tone comes from the PWM control of the idle air control valve, as follows:

| 1. |

Start the engine and switch on the

radio.

|

|

| 2. |

Unplug the connector from the idle air control valve in the engine bay.

The tone should now disappear.

|

|

The fault can be rectified by fitting interference suppression kit 48 72 685 (CA=30567466) as described below:

| 1. |

Remove the Trionic control module as

described in group 2 “Trionic”.

|

|

| 2. |

Unplug the connector and extract the socket at position 49 (red/blue

lead).

|

|

| 3. |

Cut off the connector.

|

|

| 4. |

Cut all but 200 mm off the interference suppression capacitor’s

lead.

|

|

| 5. |

Twist the red/blue lead together with the interference suppression

capacitor’s lead in a new connector.

|

|

| 6. |

Refit the socket in position 49 of the connector.

|

|

| 7. |

Plug in the connector.

|

|

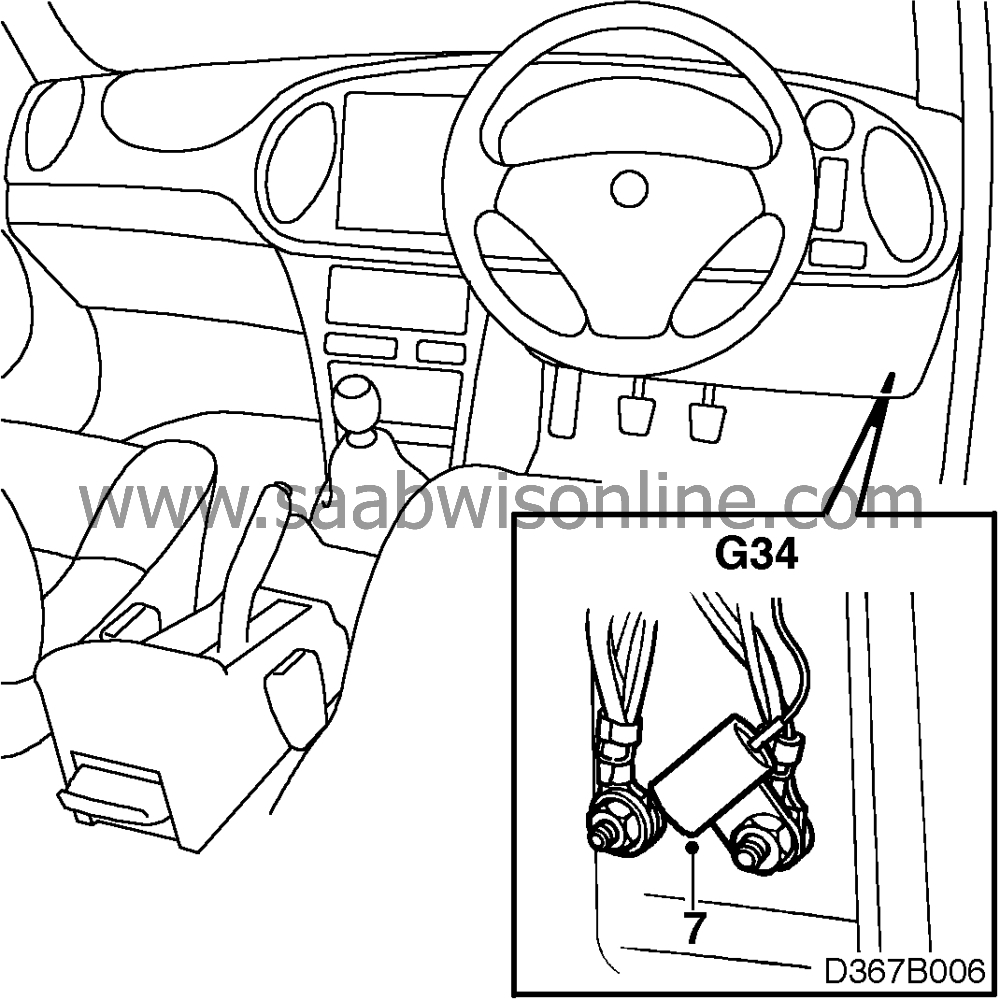

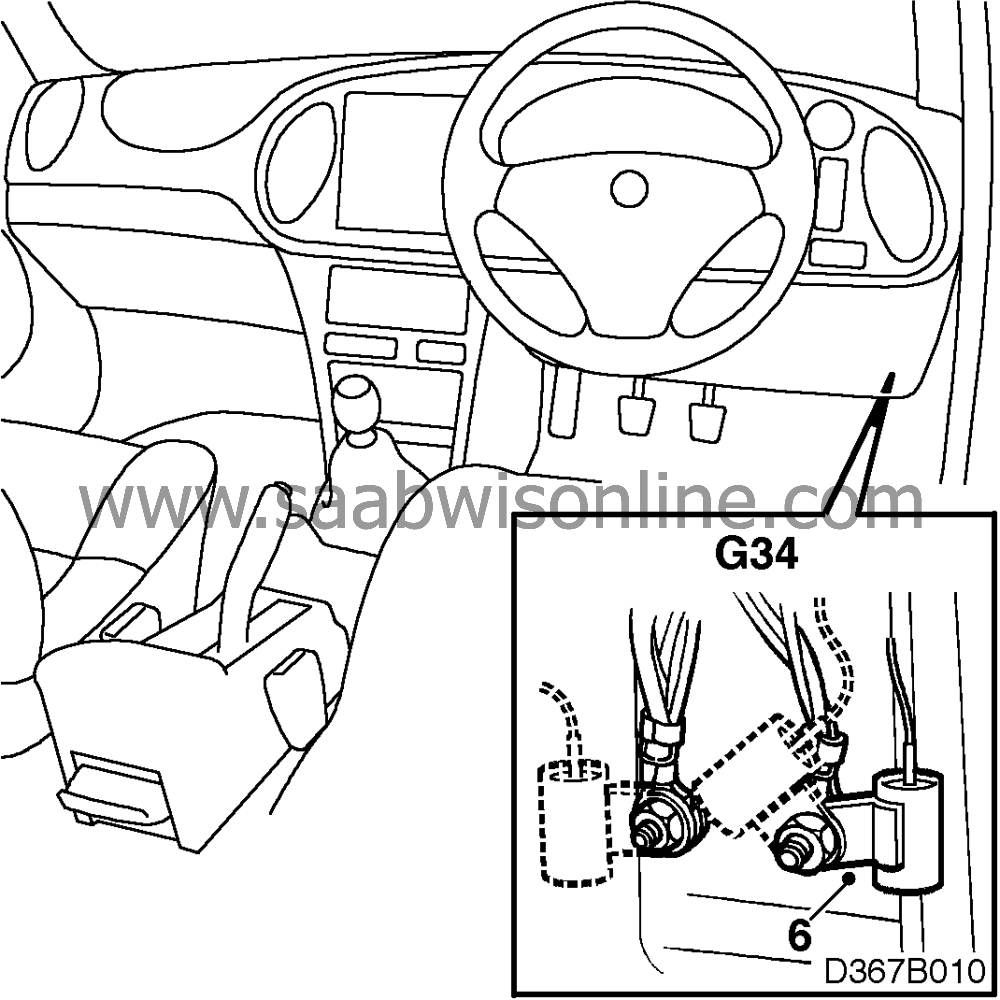

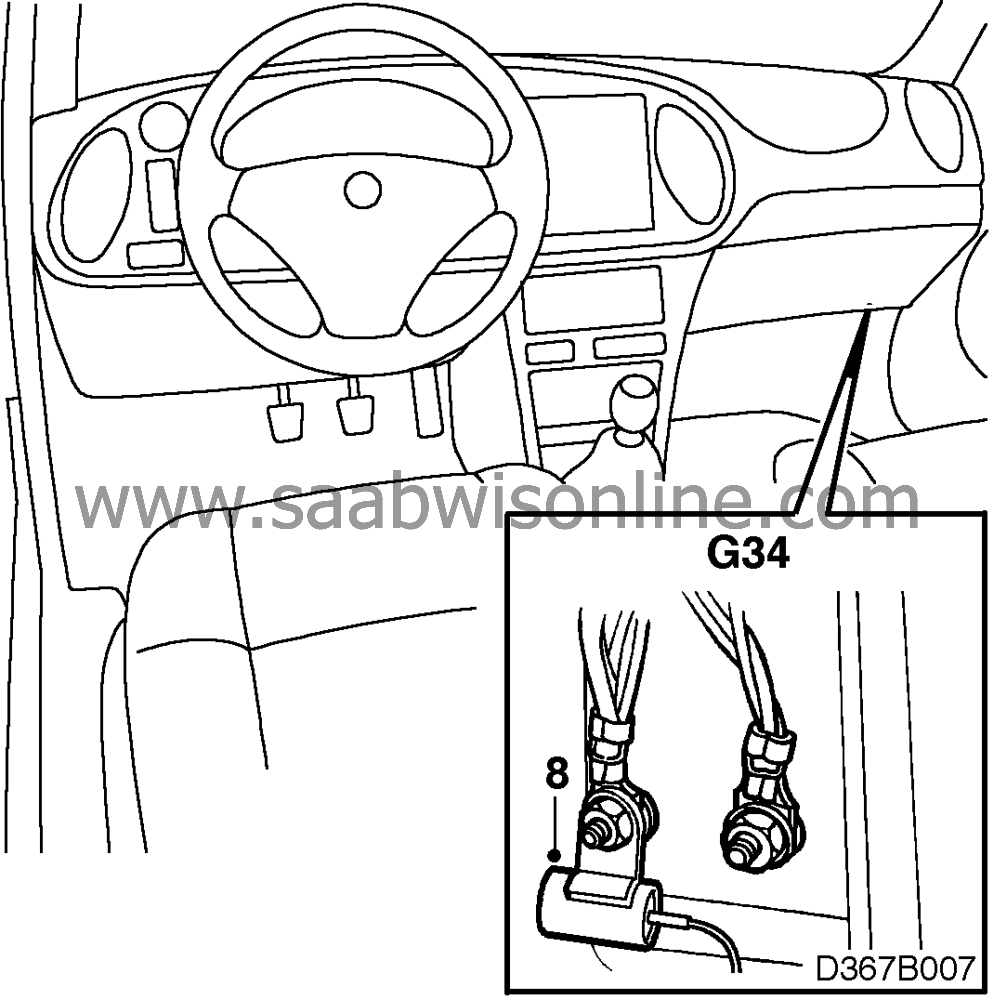

| 8. |

Mount the capacitor on the left-hand screw at grounding point

G34.

|

|

| 9. |

Check the result of the above measures by starting the car and

switching on the radio.

|

|

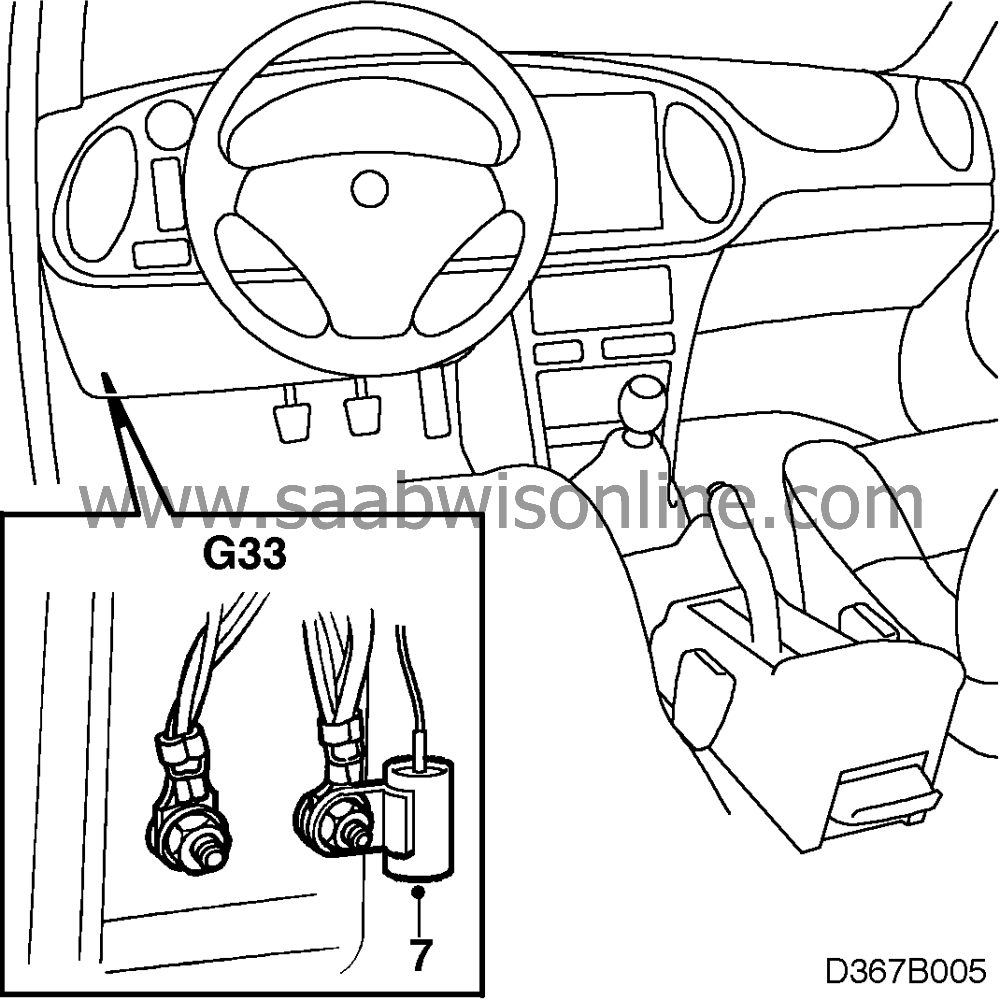

C2.3. ICE

Check whether the tone comes from the PWM control of interior lighting dimming when the door is closed.

| 1. |

Switch on the radio.

|

|

| 2. |

Open a door and close it again. A tone is heard while dimming of the

interior lighting takes place.

|

|

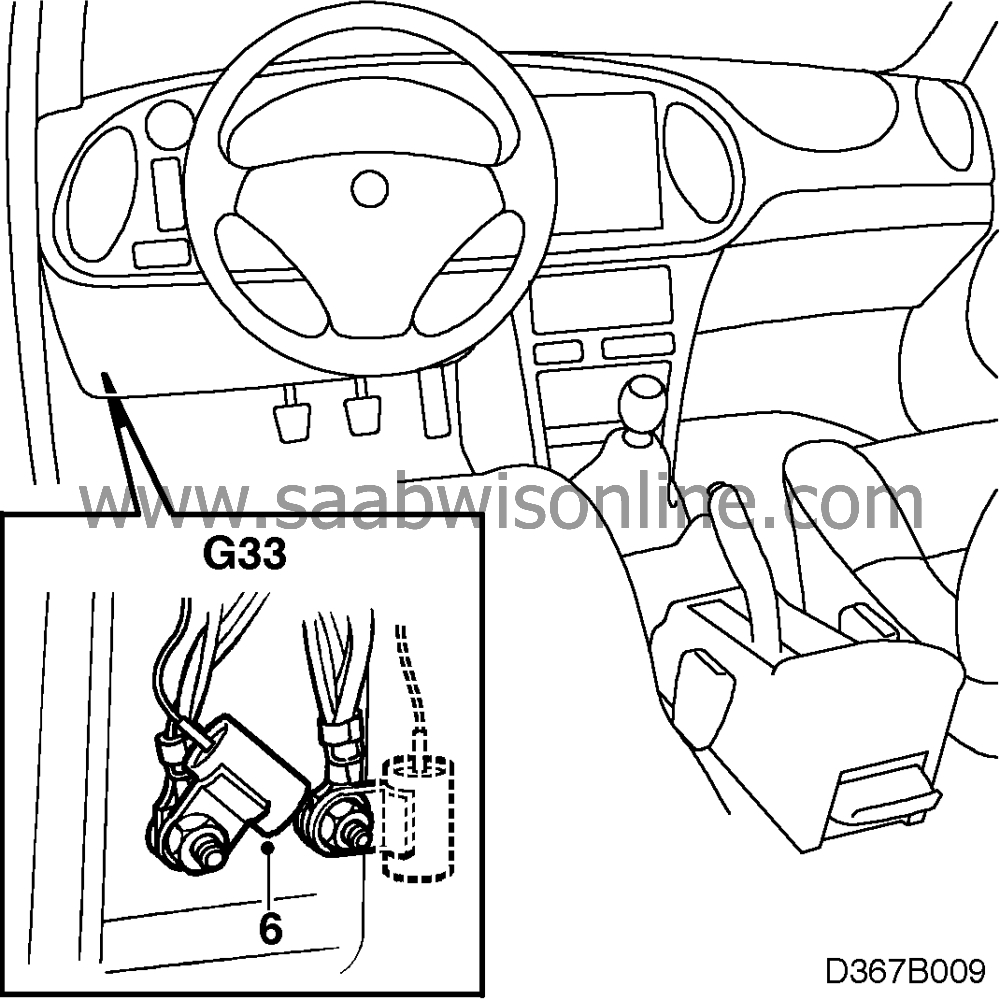

The fault can be rectified by fitting interference suppression kit 48 72 677 (CA=30567465) as described below:

| 1. |

Remove the ICE control module as

described in group 3 “Electrical system - ICE”.

|

|

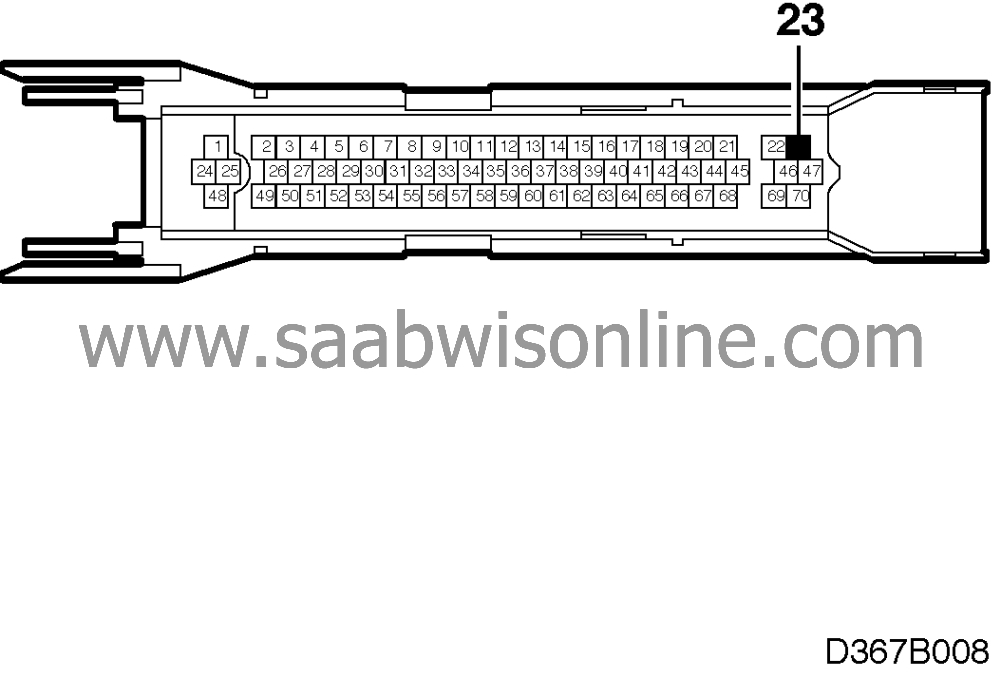

| 2. |

Unplug the connector and extract the socket at position 23 (grey/green

lead).

|

|

| 3. |

Cut off the connector.

|

|

| 4. |

Twist the grey/green lead together with the capacitor’s lead

in a new connector.

|

|

| 5. |

Refit the contact socket in position 23 and plug in the

connector.

|

|

| 7. |

Check the result of the above measures by opening and

closing the door when the radio is switched on.

|

|

| 8. |

Refit all parts that have been removed.

|

|

C3. Ignition system interference

Ignition system interference can occur on 4-cylinder cars equipped with the Motronic engine management system. The “ticking” sound is heard at its loudest when the engine is idling and diminishes with increasing engine rpm.

The fault can be rectified by fitting interference suppression kit 49 00 015 (CA=30567189) (4 grounding braids) as described below:

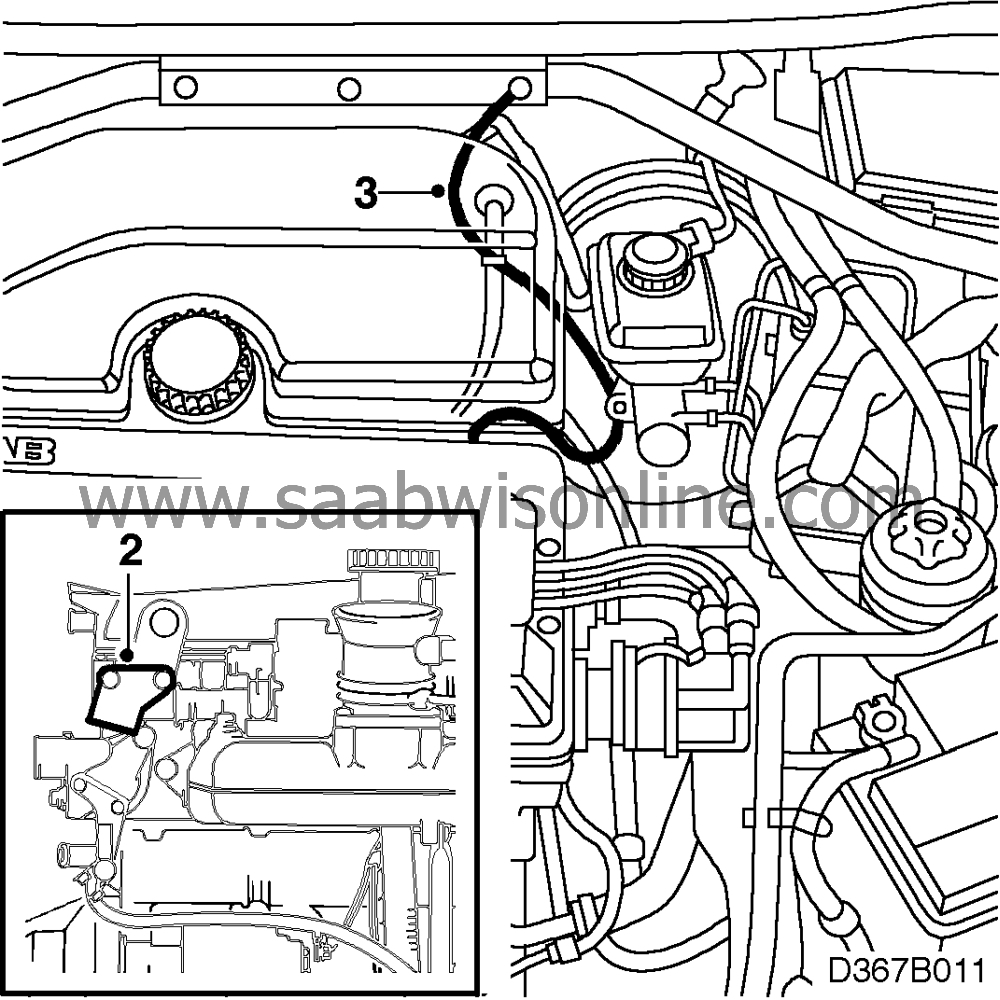

Braid 1, between engine block and cross- member

| 1. |

Remove the engine’s resonating

chamber.

|

|

| 2. |

Fit the grounding braid between left-hand side of the engine block and

the cross-member, as shown.

|

|

| 3. |

Secure the braid to the throttle cable by means of a cable tie. The braid

should be slack between the engine and the cable tie.

|

|

| 4. |

Refit the resonating chamber.

|

|

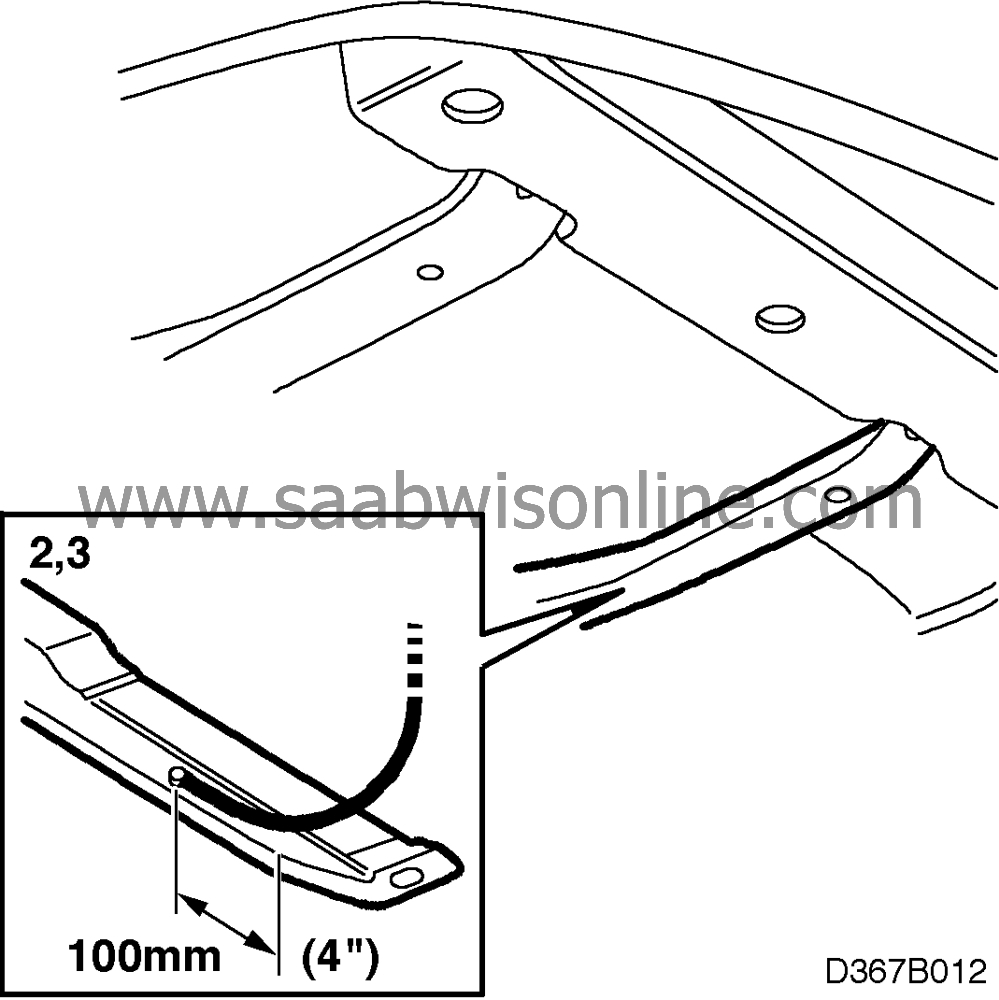

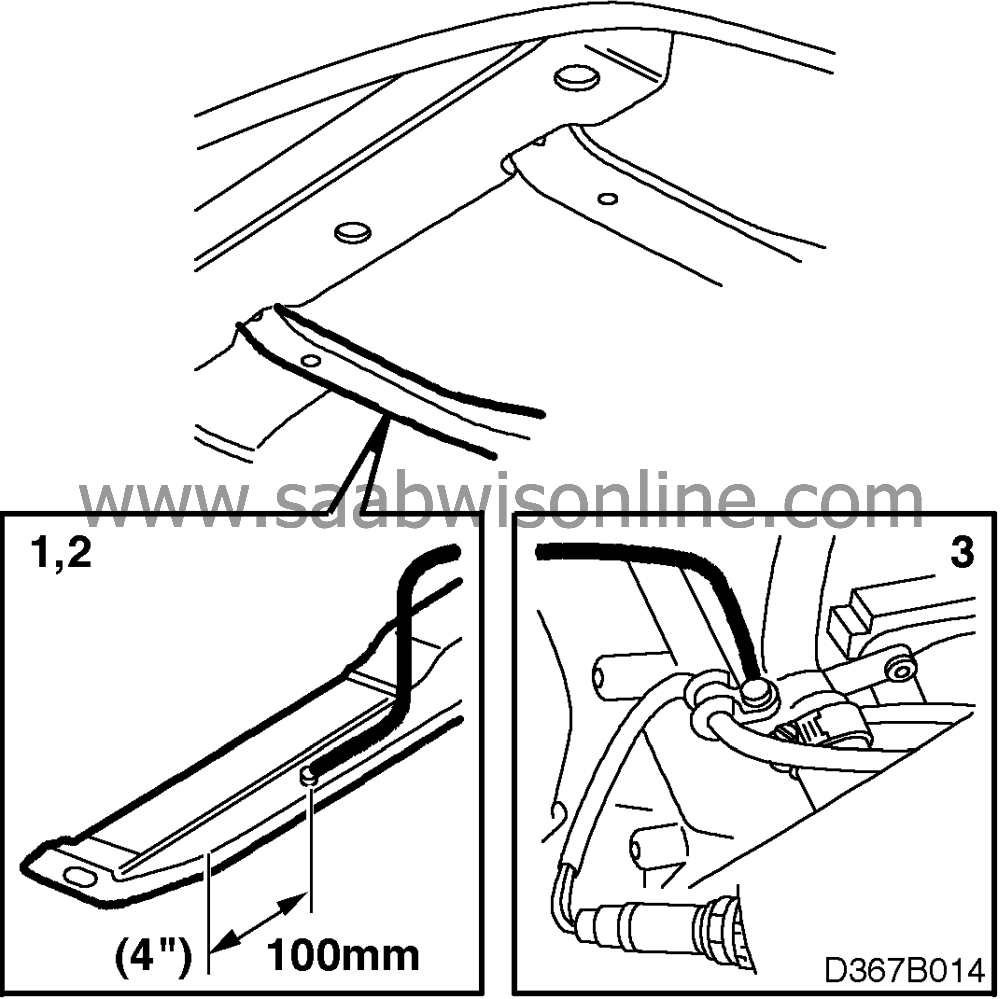

Braid 2, between A/C pipe and left-hand part of subframe

| 1. |

Raise the car.

|

|

| 2. |

Drill a hole with a 3.5 mm bit in the left-hand part of the subframe about

100 mm (4”) from the bend at the front, see illustration.

|

|

| 3. |

Secure one end of the braid by means of a self-tapping screw.

Seal with anti-corrosion agent. |

|

| 4. |

Run the braid along the subframe and fasten it under the A/C pipe’s

plastic clamp.

|

|

| 5. |

Fit the hose clip in place at the A/C pipe’s joint on the

compressor side.

|

|

| 6. |

Run the braid between the A/C pipes and position it round the

bright-polished metal nut (compressor side).

|

|

| 7. |

Pull it tight and fasten it securely with the hose clip.

|

|

| 8. |

Secure the loose end of the braid to the gearbox’s grounding

point. Make sure that the braid has sufficient slack to take up movements of the

engine.

|

|

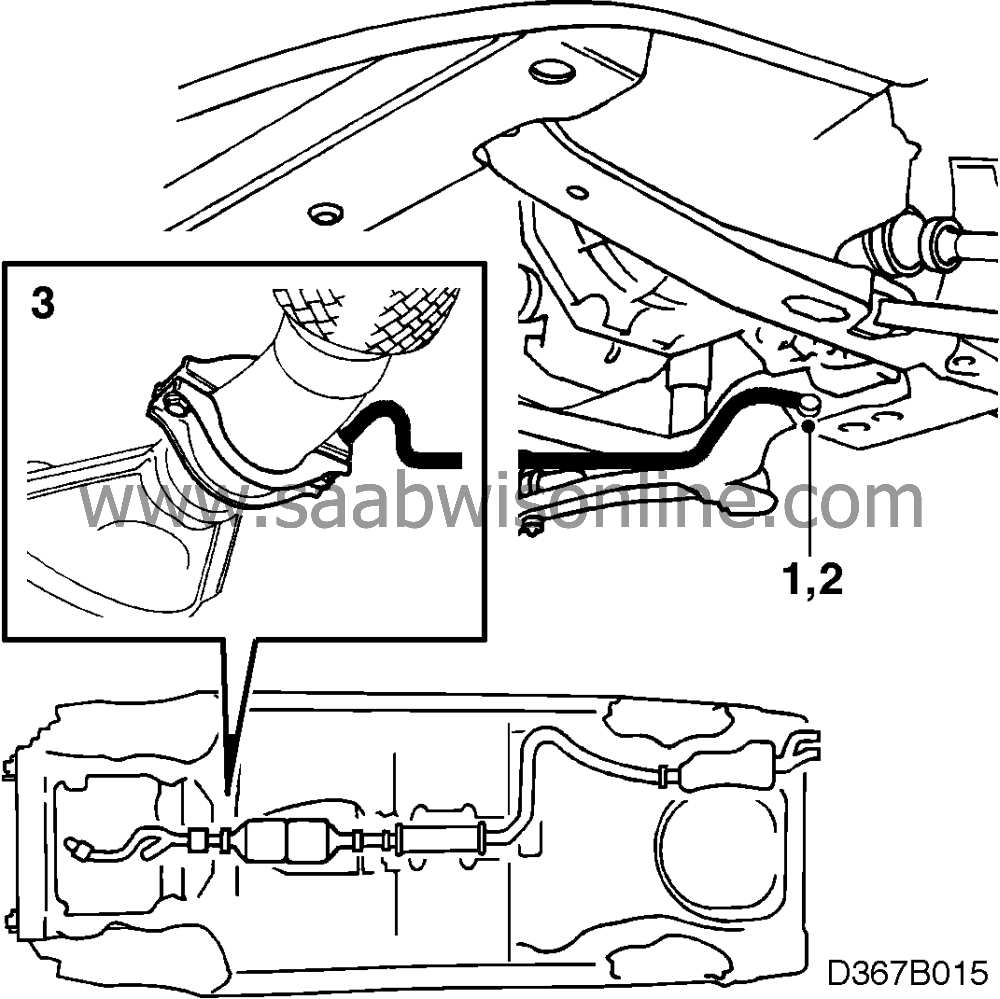

| 1. |

Drill a hole with a 3.5 mm bit in the right-hand

part of the subframe about 100 (4”) mm from the bend at the front, see

illustration.

|

|

| 2. |

Secure one end of the braid by means of a self-tapping screw.

Seal with anti-corrosion agent. |

|

| 3. |

Pull up the braid and fasten the other end with the screw securing the clamp for

the oxygen sensor’s lead.

|

|

| 4. |

Secure the braid with a cable tie round the compressor bracket’s

mounting lug. Make sure it has sufficient slack to take up the movements of the

engine.

|

|

Braid 4, between catalytic converter and subframe

| 1. |

Drill a 3.5 mm hole in the rear part of the

subframe, see illustration.

|

|

| 2. |

Screw the braid in place.

Seal with anti-corrosion agent. |

|

| 3. |

Fasten the other end to the exhaust pipe clamp next to the catalytic converter by

means of the nut supplied.

|

|

| 4. |

Lower the car to the floor.

|

|

| Standard time information |

Object code: 36741 (CA=R0440)

Fault code: 68

|

|

Check

|

Change

|

|

Localization code

|

09

|

09

|

|

Action code

|

08

|

01

|

|

Time in hours

|

0.1

|

0.2

|

Object code: 36743 (CA=R0420)

Fault code: 68

|

|

Check

|

Change

|

|

Localization code

|

09

|

09

|

|

Action code

|

08

|

01

|

|

Time in hours

|

0.1

|

0.1

|

Checking/fitting interference suppression kit

Object code: 36568 (CA=R0710)

Fault code: 68

|

|

Checking

|

Fitting

|

|

Localization code

|

09

|

09

|

|

Action code

|

08

|

10

|

|

Time in hours

|

0.1

|

0.3

|

Check/change processor card

Object code:38111/38112 (CA=N4180)

Fault code: 68

|

|

Check

|

Change

|

|

Localization code

|

09

|

09

|

|

Action code

|

08

|

01

|

|

Time in hours

|

0.1

|

0.8

|

Checking/fitting interference suppression kit

Object code: 24810 (CA=R0710)

Fault code: 68

|

|

Checking

|

Fitting

|

|

Localization code

|

09

|

09

|

|

Action code

|

08

|

10

|

|

Time in hours

|

0.1

|

0.4

|

Checking/fitting interference suppression kit

Object code: 36568 (CA=R0710)

Fault code: 68

|

|

Checking

|

Fitting

|

|

Localization code

|

09

|

09

|

|

Action code

|

08

|

10

|

|

Time in hours

|

0.1

|

0.4

|

Checking/fitting grounding braids

Object code: 36710 (CA=J4560)

Fault code: 68

|

Localization code

|

09

|

|

Action code

|

10

|

|

Time in hours

|

0.5

|

| Warranty information |

Regular warranty rules apply.