Master cylinder

| Master cylinder |

| 1. |

Pushrod with primary piston

|

|

| 2. |

Pressure chamber (primary circuit)

|

|

| 3. |

Steel central valves

|

|

| 4. |

Secondary piston

|

|

| 5. |

Pressure chamber (secondary circuit)

|

|

| 6. |

Compression spring

|

|

The master cylinder consists of a tandem cylinder that is made of steel.

As the car as two independent brake circuits, it has a master cylinder with two independent pressure chambers. The master cylinder therefore incorporates two pistons: a primary piston (next to the brake pedal) and a secondary piston and also a return spring for these. The secondary piston has a steel centre valve that opens the ducts to the brake fluid reservoir in the brake off position.

Two pipes run from the master cylinder (primary/secondary) to the ABS-unit (valve block) that in turn supplies the wheel cylinders with brake fluid.

Brake fluid reservoir is fitted directly to the master cylinder.

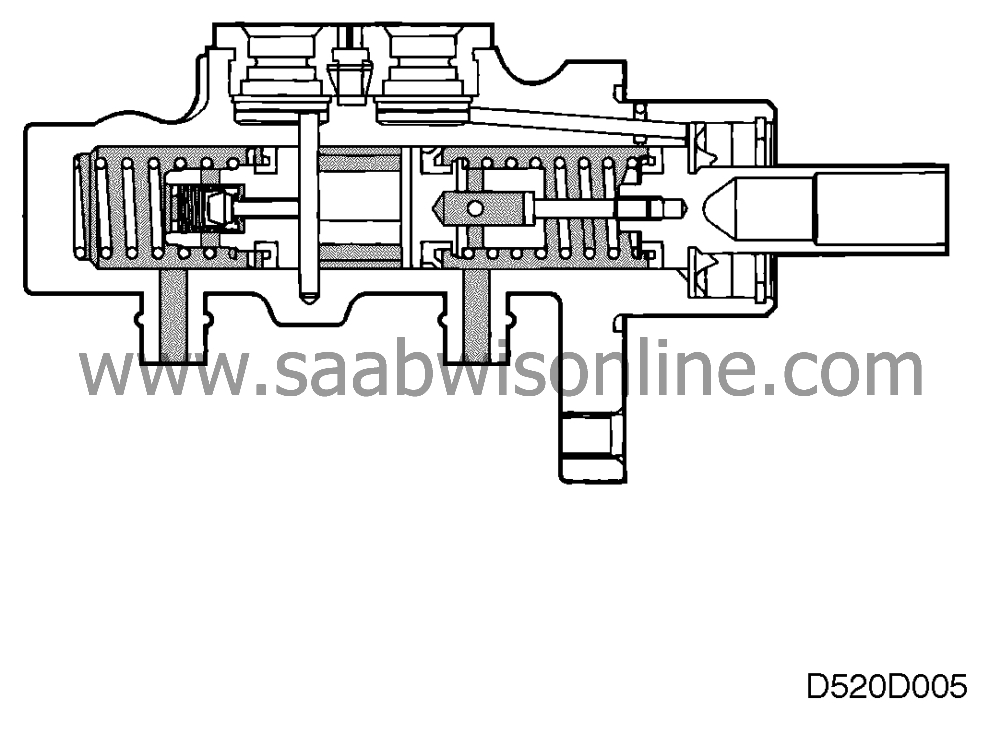

| Brake off |

Master cylinder, brake off position

Pressure-less

In the brake off position the return springs pistons press against the rear end position. In this position both return ducts are open and the brake system remains pressure- less. Backward movement is limited by a stop pin.

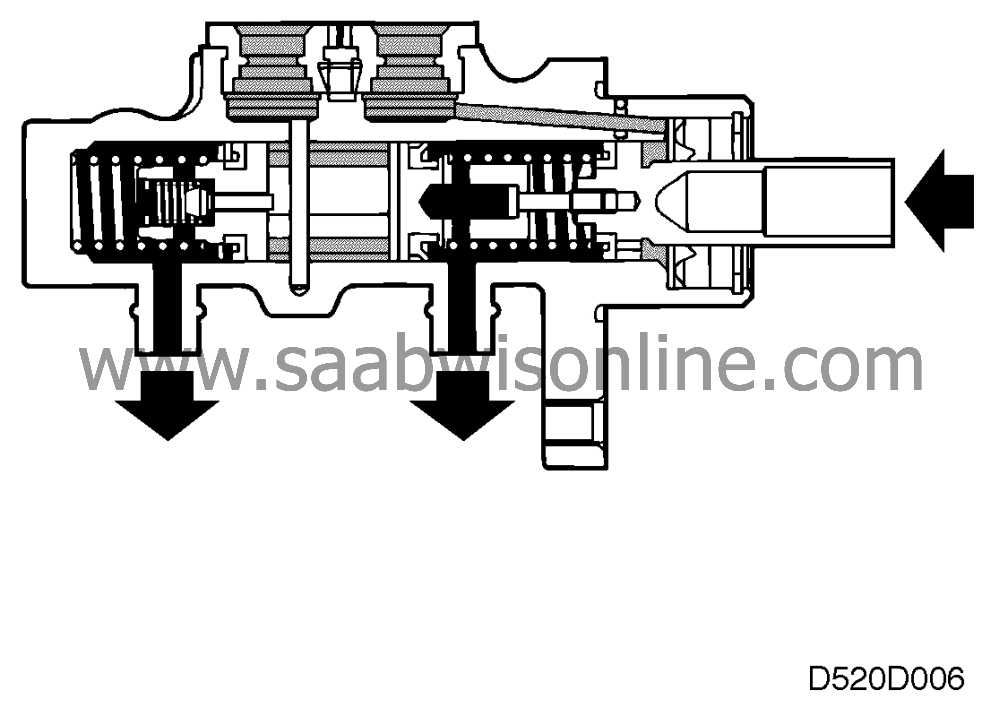

| Brake applied (both circuits in operation) |

Master cylinder, brake applied (both circuits in operation)

Pressure-less

Servo pressure

When the brake pedal is pressed down, the primary piston is pushed forwards by the pushrod.

The return duct to the brake fluid reservoir is closed and the pressure in front of the primary piston increases. The pressure also effects the secondary piston which is pushed forwards with the result that the secondary piston return duct is closed by the central valve. The hydraulic pressure in both brake circuits increases, and because the pistons are the same size, the pressures in both brake circuits are the same. The pressure is transmitted in the brake system and effects the brake piston in each brake housing. The brake pistons force the brake blocks against the brake discs.

When the brake pedal is released, the pistons in the master cylinder return and open the return ducts. The pressure ceases and the brake pistons in each brake cylinder are pushed back to the brake off position by the piston seals.

| Brake applied (one circuit out of operation) |

Master cylinder, Brake applied (one circuit out of operation)

Pressure-less

Servo pressure

When the brake pedal is depressed and there is for example a leak in the primary circuit, the primary piston is pressed forwards by the push rods until it mechanically effects the secondary piston. The secondary piston closes the return passage with the central valve and hydraulic pressure is built up in the secondary circuit only.

If there is a leak in the secondary circuit the secondary piston is pushed forwards and will touch bottom in the master cylinder. In both cases a longer pedal movement is required to accomplish the desired breaking action.