B pillar, five-door body

| B pillar, five-door body |

The sill is reinforced. This reinforcement must not be damaged when the B pillar is cut.

| Important | ||

|

Body reinforcement components should be cut and joined only if they are specifically covered in the description of methods. Unless otherwise stated, a damaged reinforcement component must be discarded and a new one fitted in its place. This is mandatory. |

||

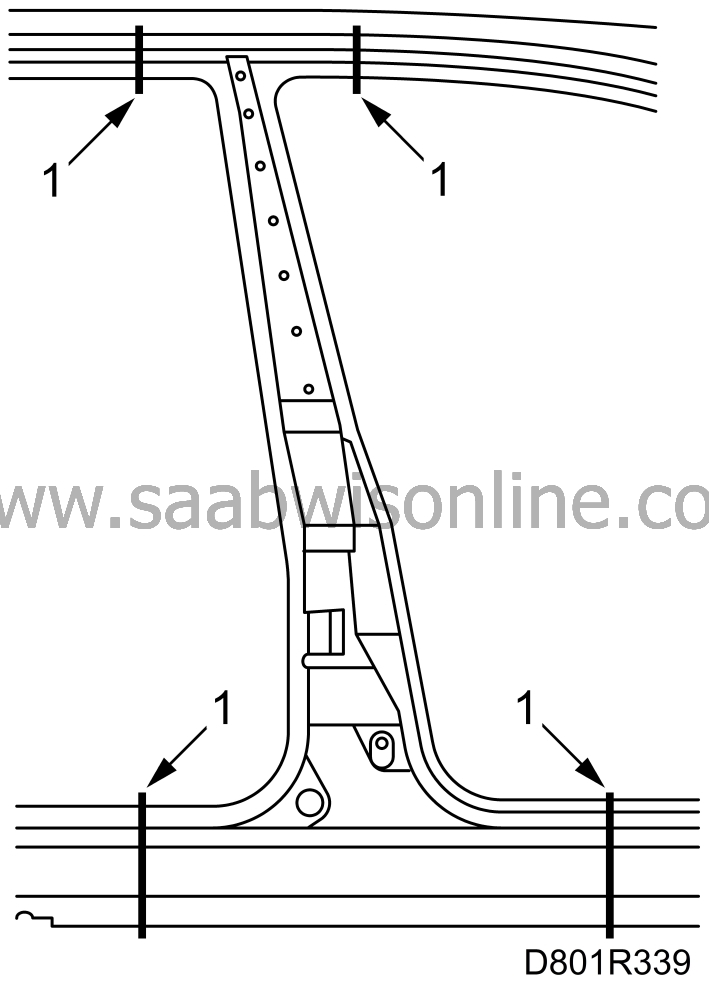

| 1. |

Cut away the B pillar. B pillar joints, see

Joints. Be careful that the underlying metalwork is not damaged.

Joints. Be careful that the underlying metalwork is not damaged.

|

|

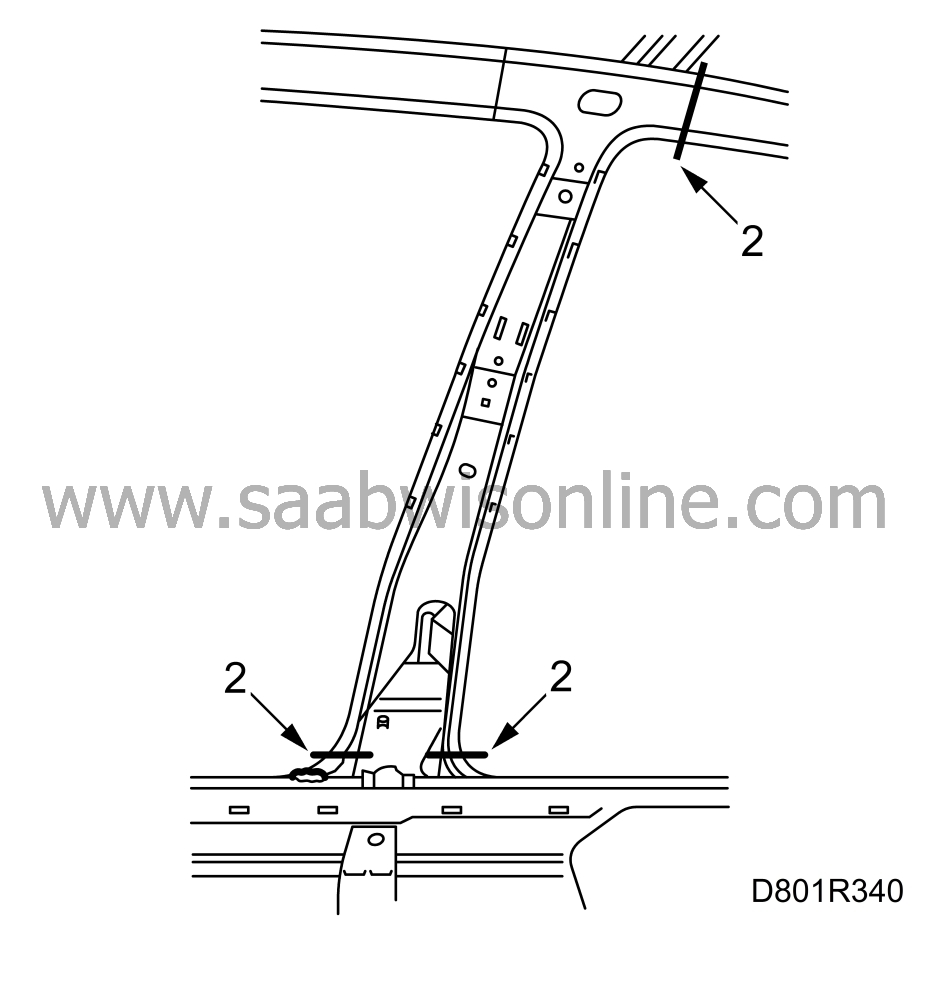

| 2. |

Cut the inner part of the B pillar above the seam welds at the lower end.

|

|

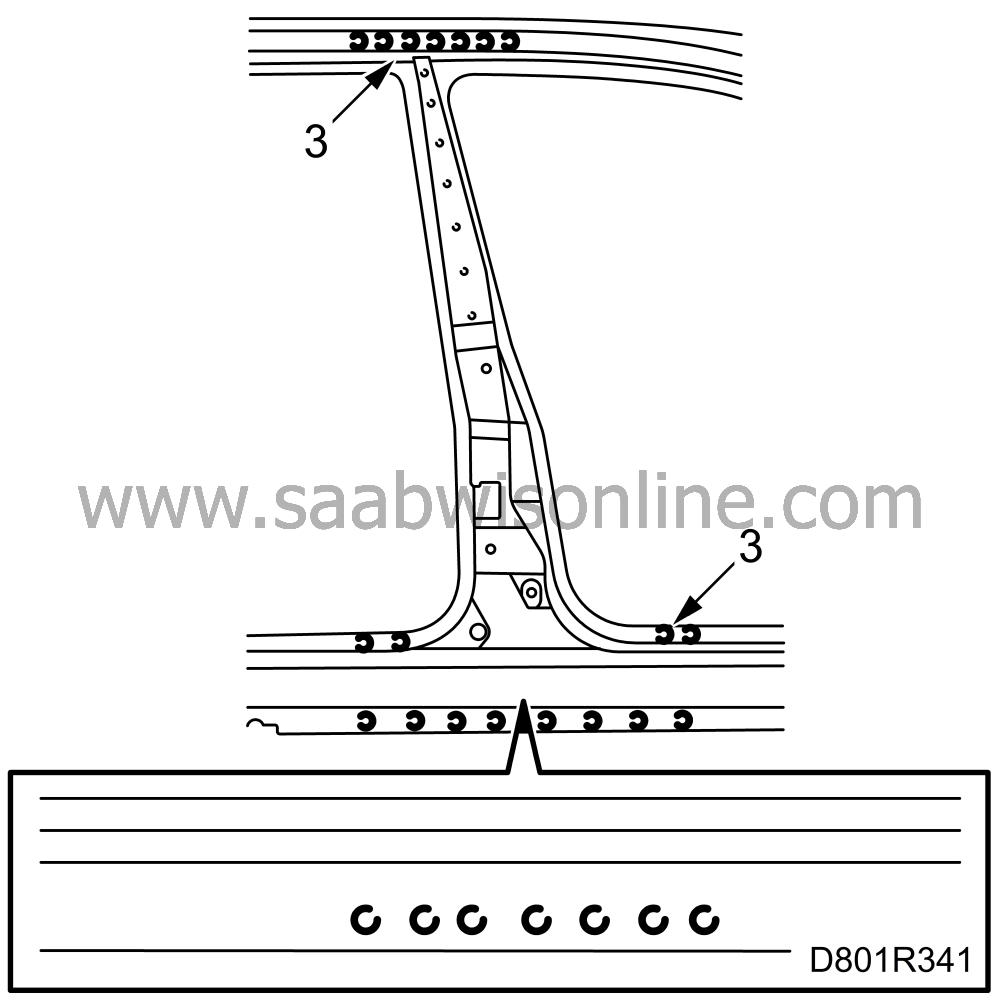

| 3. |

Drill out the spot welds.

|

|

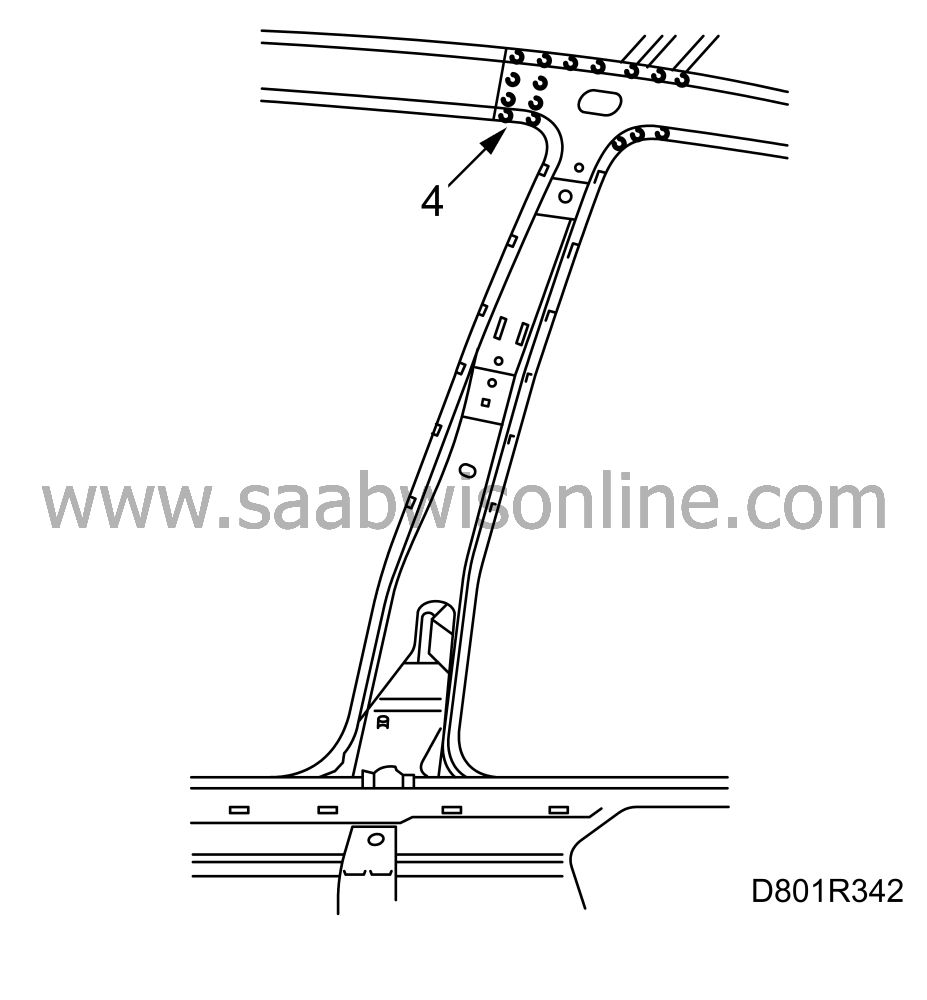

| 4. |

Drill out the spot welds in the inside of the B pillar at the upper end and remove the B pillar.

|

|

| 5. |

Realign any deformed metalwork.

|

|

| 6. |

Use a grinder to clean the areas on the new reinforcement and body that are to be welded.

|

|

| 7. |

Position the reinforcement component and fix it with a few welding clamps.

|

||||||||||

| 8. |

Cut the B-pillar's outer panel roughly to size so that it will overlap the joint by about three centimetres.

|

|

| 9. |

Drill holes for plug welding in the outer panel.

|

|

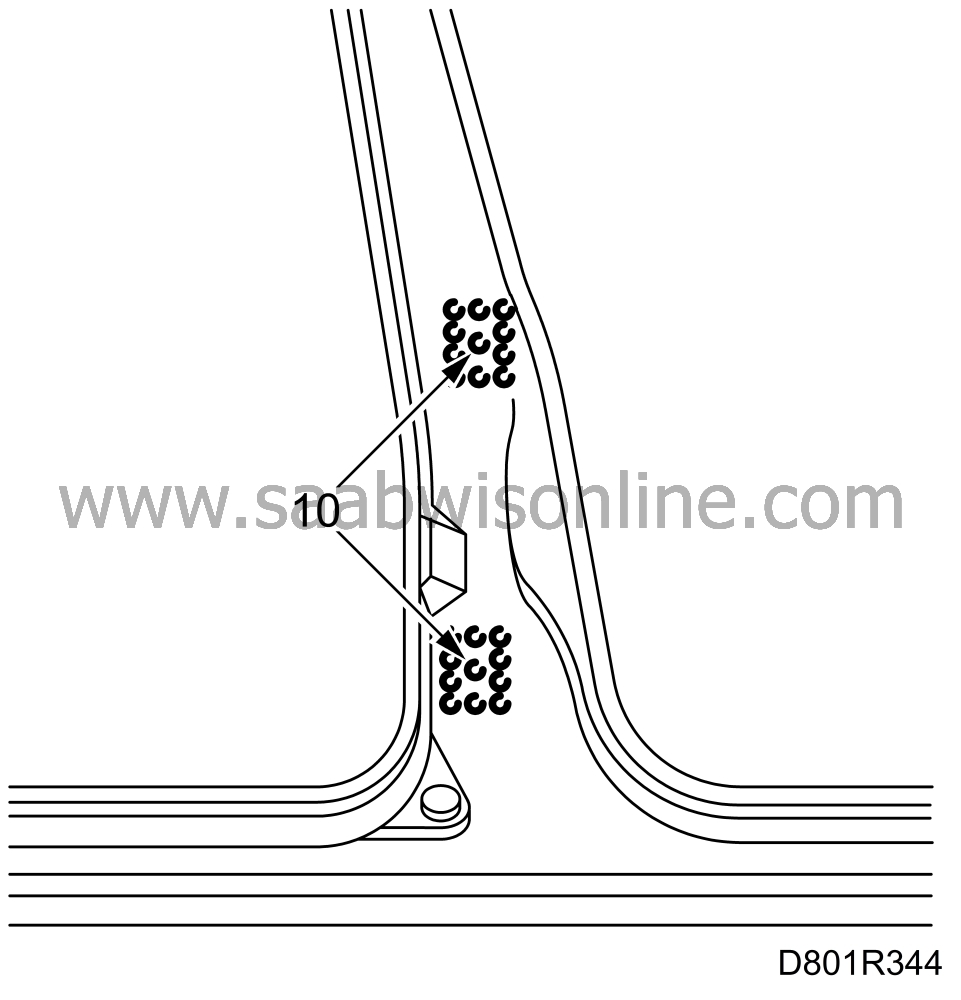

| 10. |

Drill holes for the hinge mountings at the pre-stamped punch marks in the outer panel.

|

|

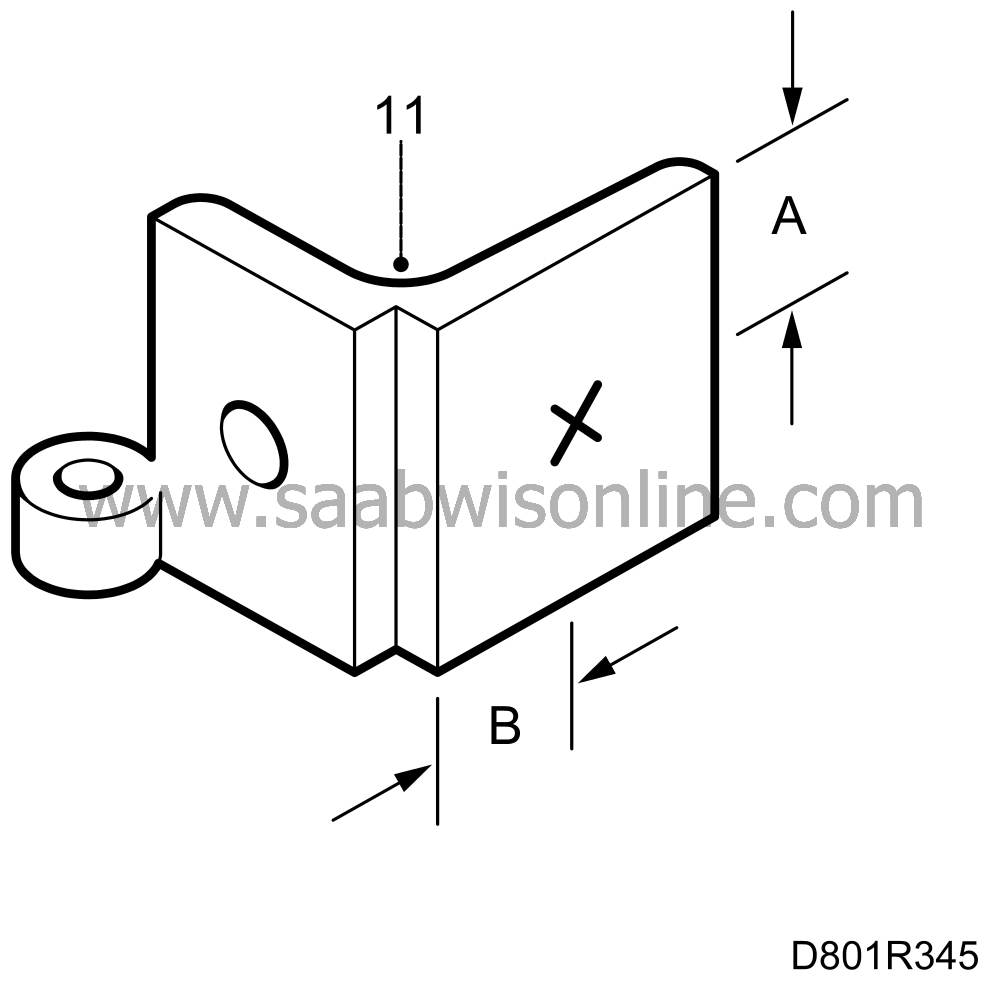

| 11. |

Drill holes for the hinges as shown.

Upper hinges: A = 24.1 mm, B = 30.2 mm Lower hinges: A = 25.1 mm, B = 30.2 mm |

|

| 12. |

Screw the hinges to the outer panel with nuts and bolts. Scratch round the hinge to mark its position on the outer panel.

|

|

| 14. |

Use a grinder to clean the areas on the outer panel and body that are to be welded.

|

|

| 15. |

Position the outer panel and fix it with a few welding clamps.

|

|

| 16. |

Roughly cut the B-pillar's new inner part.

|

|

| 17. |

Position the spare part and fix it with a few welding clamps. Cut through the rear edge of the spare part and roof member simultaneously so that the joint can be welded edge-to-edge.

|

|

| 18. |

Cut through the outer panels of the B pillar and door frame simultaneously so that the joints can be welded edge-to-edge.

|

|

| 19. |

Mark the positions where holes for plug welding are to be drilled in the inner part at the top.

|

|

| 20. |

Remove the spare part and drill holes for plug welding.

|

|

| 21. |

Use a grinder to clean the areas on the spare part and the body that are to be welded.

|

|

| 22. |

Apply welding primer to the surfaces which are to be spot and plug welded. Use Teroson Zinkspray.

|

|

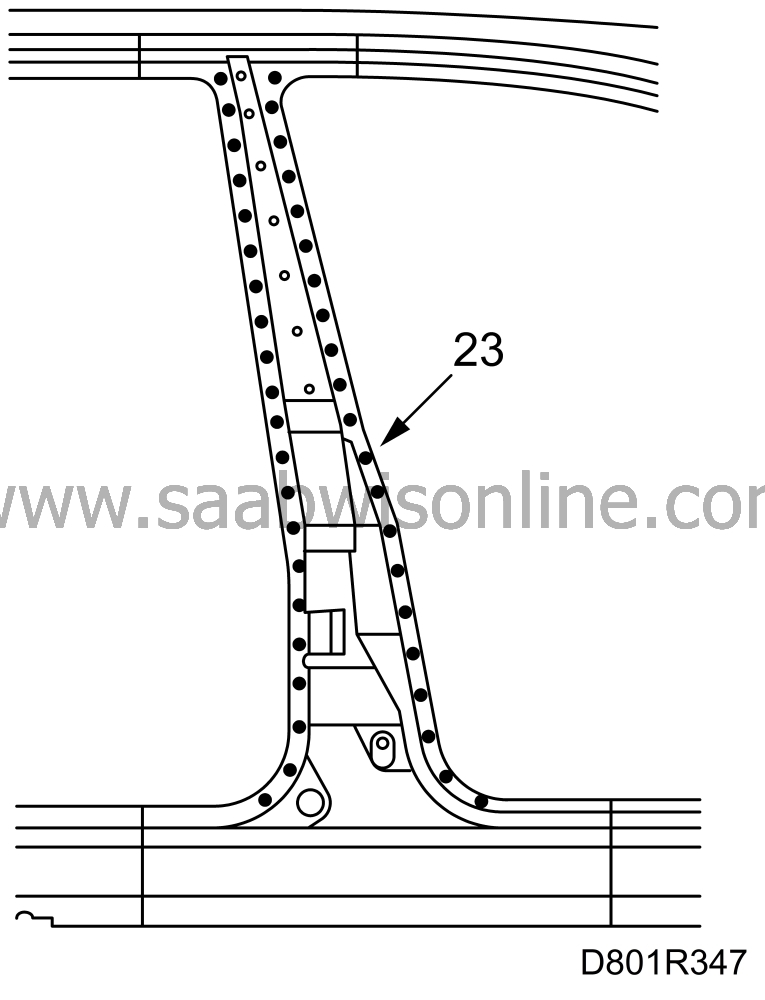

| 23. |

Position the spare part and fix it with a few welding clamps. Spot weld the inner part to the outer part and the reinforcement component.

|

|

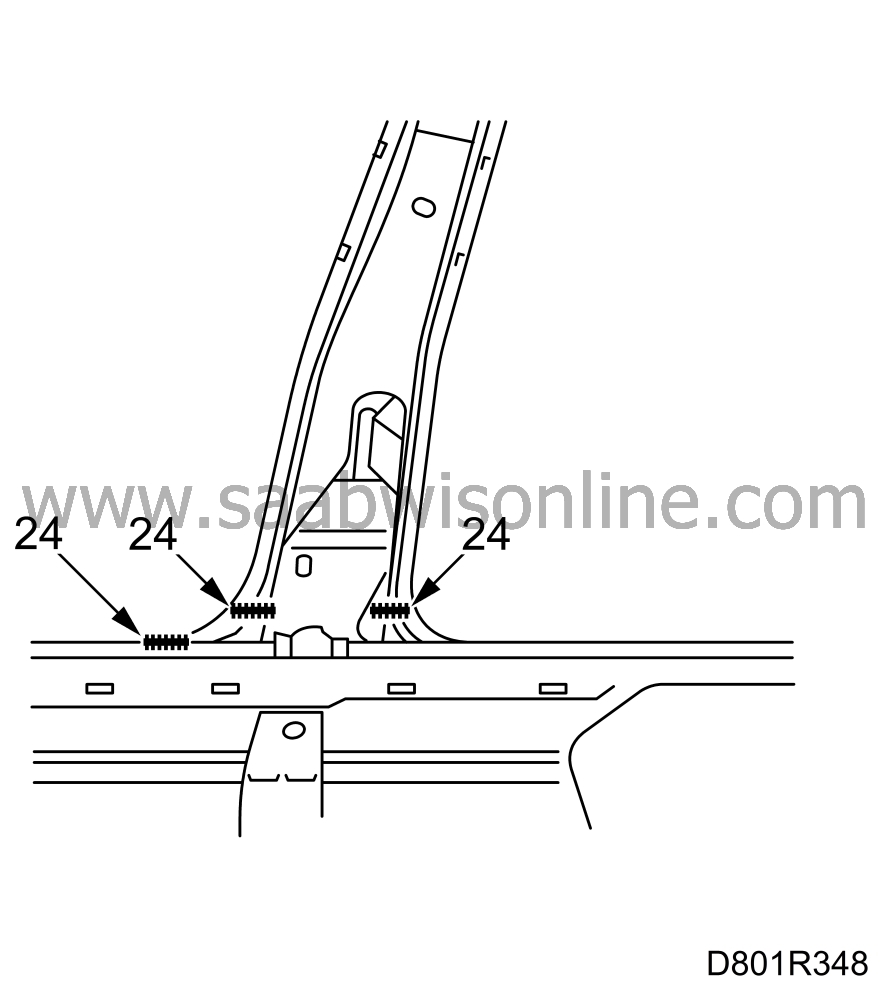

| 24. |

Weld the joint at the lower end of the inner part.

|

|

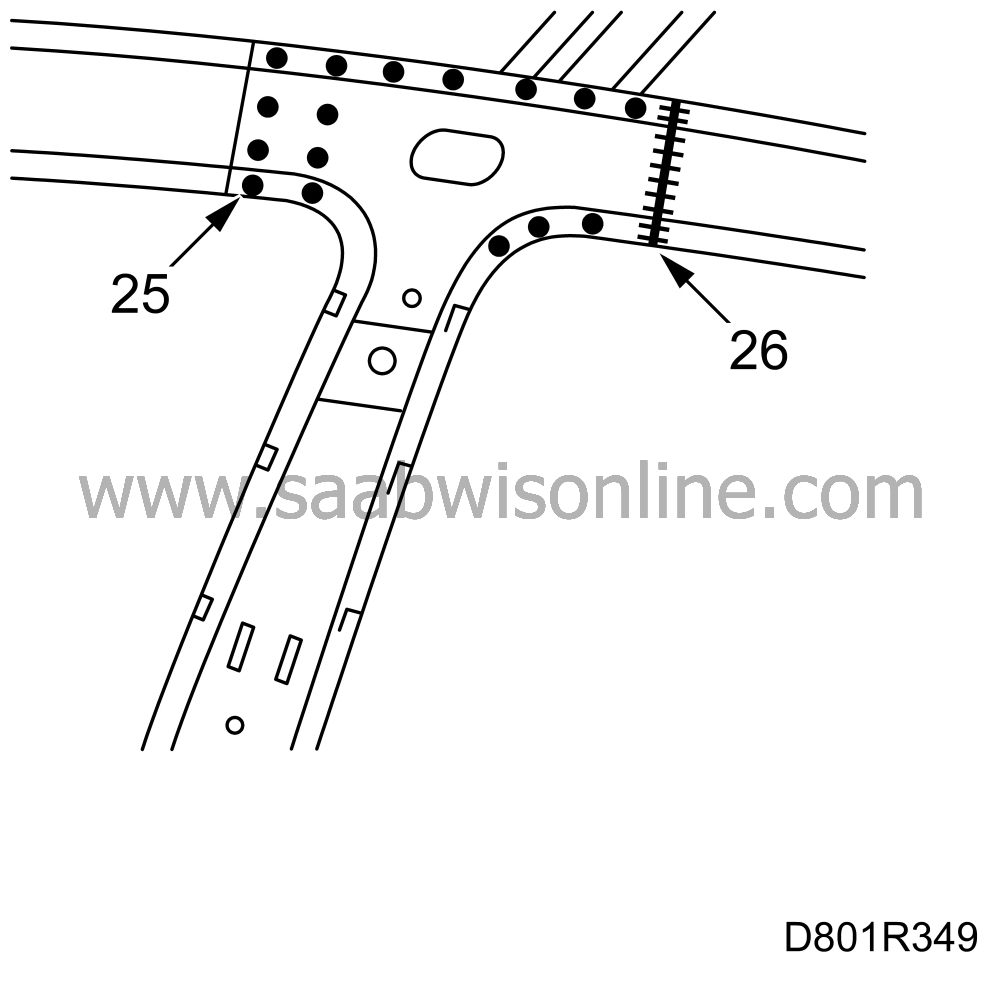

| 25. |

Plug weld the upper parts of the inner part and reinforcement to the roof member.

|

|

| 26. |

Weld the joint between the inner part and the roof member.

|

|

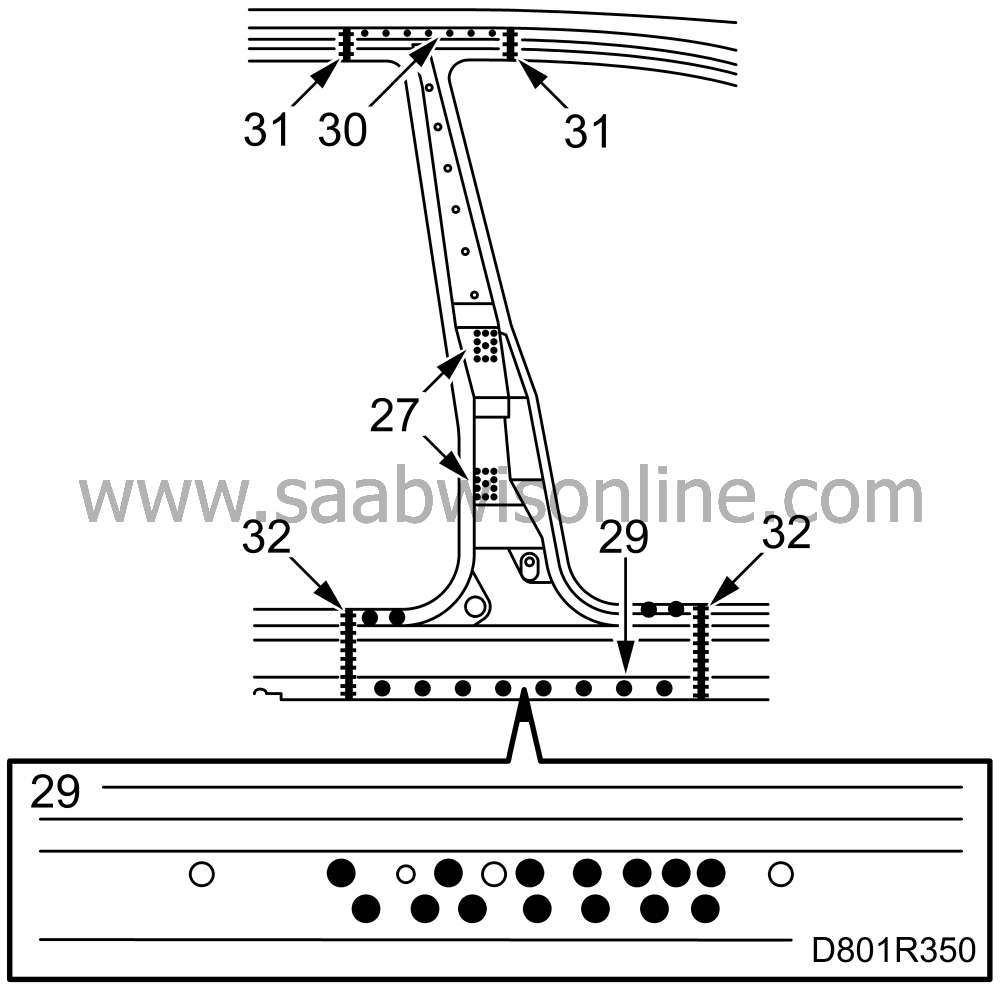

| 27. |

Plug weld the outer panel to the reinforcement.

|

|

| 28. |

Grind the welds clean.

|

|

| 29. |

Weld the lower end of the outer panel.

|

|

| 30. |

Spot weld the upper end of the B pillar in place.

|

|

| 31. |

Weld the roof member joints.

|

|

| 32. |

Weld the sill joints.

|

|

| 33. |

Apply welding primer to the surfaces which have been ground clean. Use Teroson Zinkspray.

|

|

| 34. |

Screw the hinges in place with nuts and bolts.

|

|

| 35. |

Hang the door on and check its fit. Adjust as necessary and then fix the hinges with a couple of tack welds.

|

|

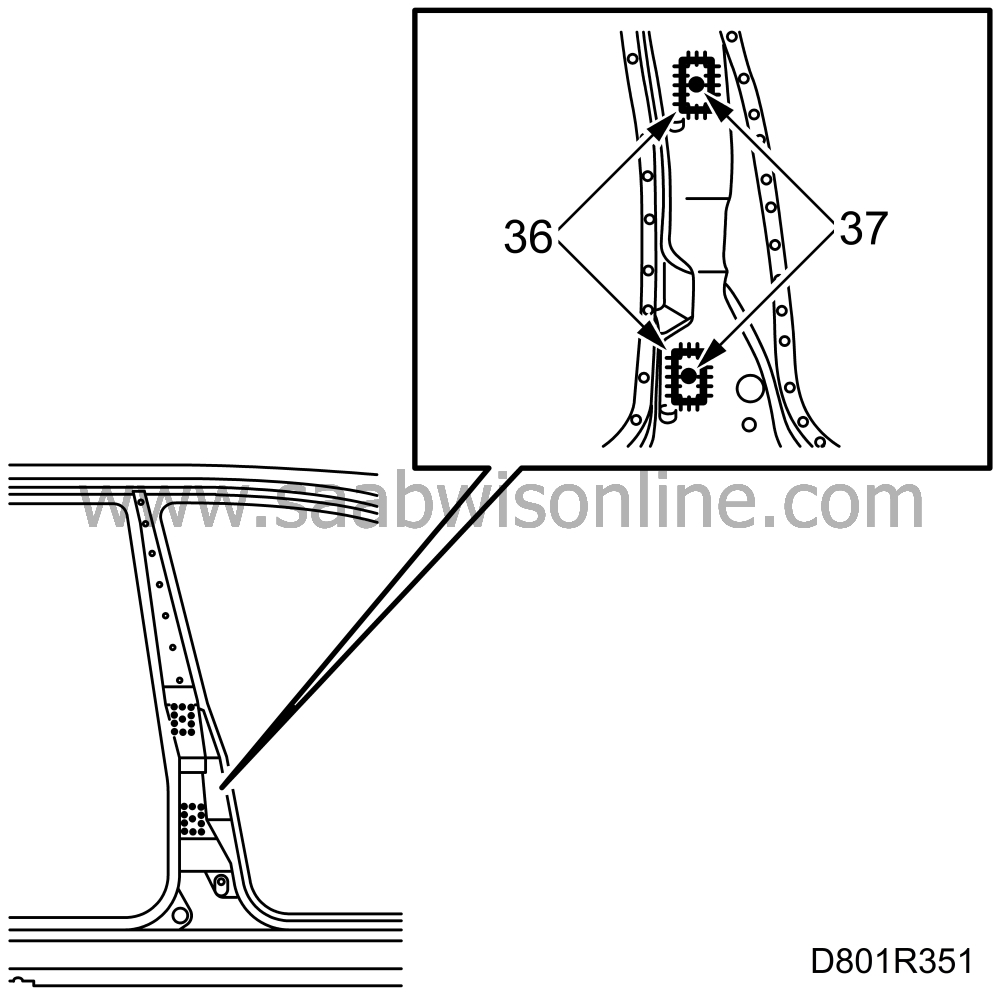

| 36. |

Weld the hinges in place.

|

|

| 37. |

Remove the nuts and bolts and weld up the holes in the hinges.

|

|

| 38. |

Grind the welds clean.

|

|

| 39. |

Wash off surplus welding primer. Welding primer makes for poorer adhesion of paint, filler and sealant.

|

|

| 40. |

Apply primer to all surfaces that have been ground clean. Use Standox 1K Füllprimer.

|

|

| 41. |

Seal joints and metal folds with putty. Use Terostat 1K-PUR.

|

|

| 42. |

Apply anti-corrosion agent to the lower end of the B pillar on the inside after painting. Use Terotex HV 400 or Mercasol 1.

|

|