Windscreen

| Windscreen |

| To remove |

| 1. |

Lower the soft top completely.

|

|

| 2. |

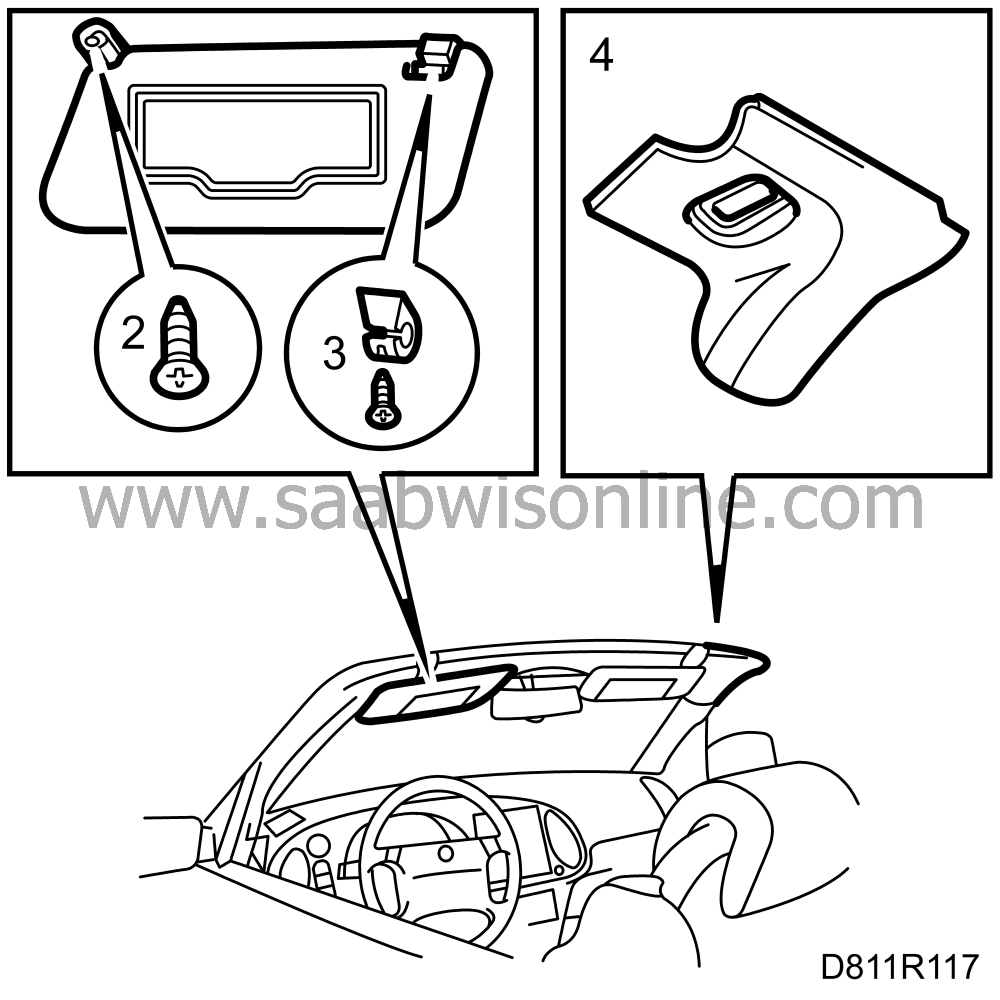

Remove the sun visor.

|

|

| 3. |

Remove the sun visor support.

|

|

| 4. |

Remove the cover on the top right-hand corner of the windscreen frame.

|

|

| 5. |

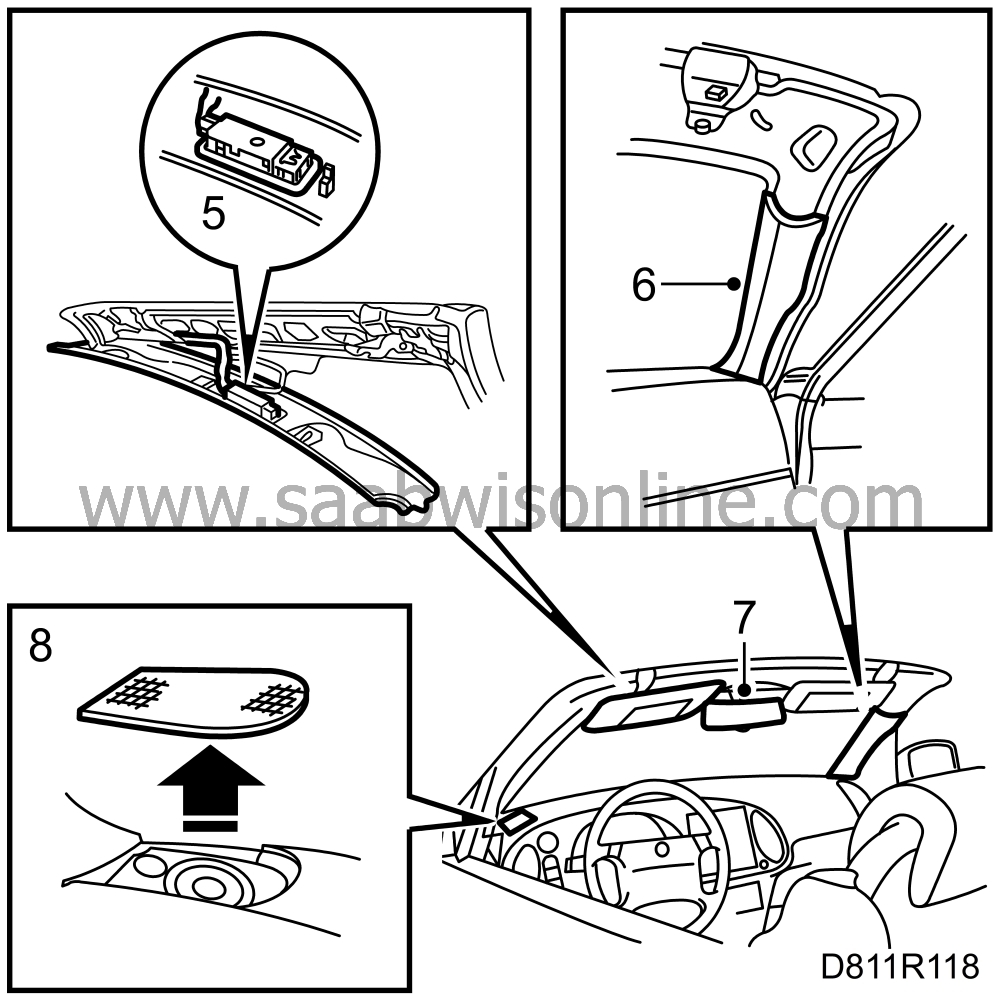

Loosen the cover along the top edge of the windscreen frame and unplug the electric connections to the interior lighting.

|

|

| 6. |

Remove the A-pillar trim.

|

|

| 7. |

Remove the rear view mirror.

|

|

| 8. |

Remove the loudspeaker grilles.

|

|

| 9. |

Remove the windscreen wipers.

|

|

| 10. |

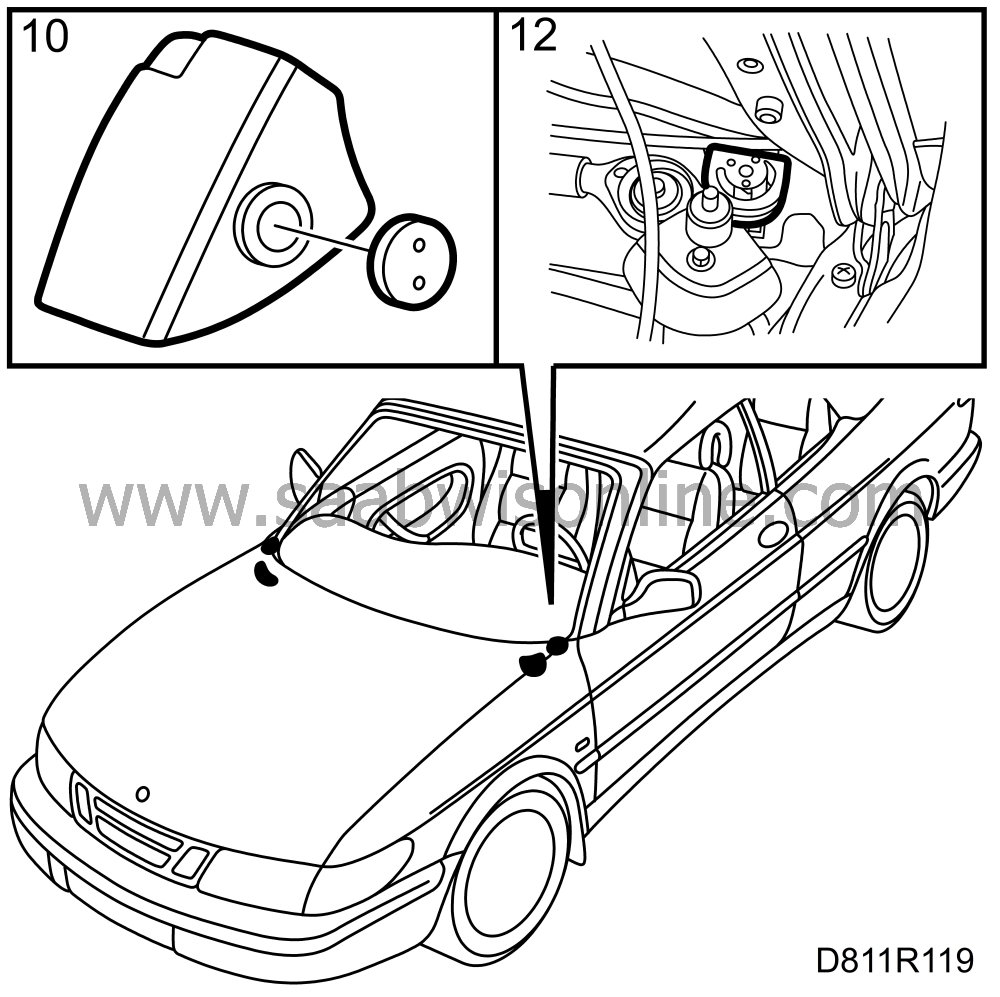

Remove the covers at the corners of the bulkhead partition cover.

|

|

| 11. |

Remove the cover over the bulkhead partition space.

|

|

| 12. |

Turn the eccentrics to open position.

|

|

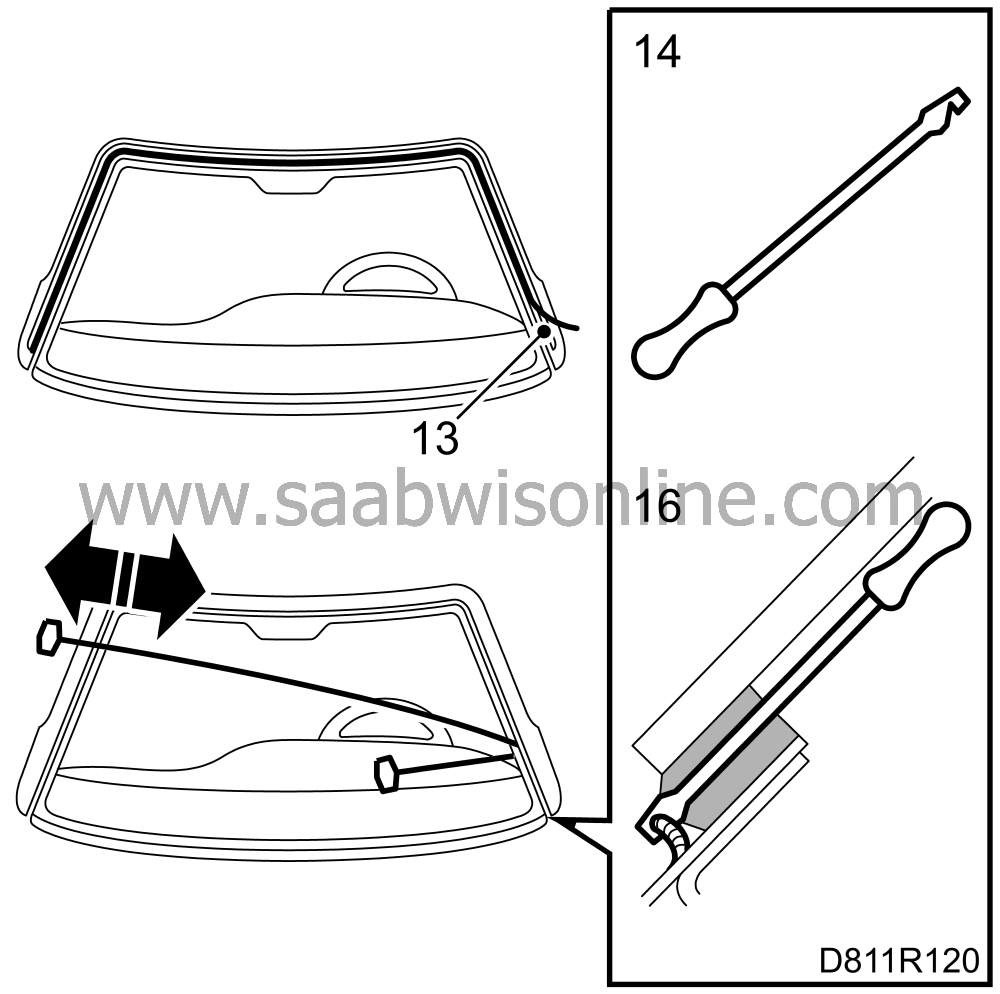

| 13. |

Remove the decor trim around the windscreen.

|

|

| 14. |

Make a special tool to quickly and easily pull the piano wire through the bead of adhesive by making a groove in a long, narrow screwdriver as illustrated.

|

|

| 15. |

Use the handle, special tool part no. (45) 30 14 099, together with the piano wire.

|

|

| 16. |

Press the screwdriver through the bead of adhesive from the inside of the windscreen at the bottom left-hand corner.

|

|

| 17. |

Hook one end of the piano wire over the groove on the screwdriver and pull the wire through the bead of adhesive into the compartment.

|

|

| 18. |

Attach the piano wire to the handle.

|

|

| 19. |

Saw round the windscreen with the help of an assistant.

|

|

| 20. |

Lift out the windscreen.

|

|

| To fit |

| Important | ||

|

It takes 4 hours at + 23 ° C and 50%% relative humidity for Betamate E 2400 to harden. To prevent the windscreen from coming loose or changing its position while the adhesive is hardening, the car must not be subjected to jolts or blows. Doors, boot lid and bonnet must not be slammed shut. The car must not be rocked or rolled. Neither must the windscreen be tensioned while the adhesive is hardening. |

||

The car must be standing on all four wheels on a level surface when the windscreen is being fitted. To obtain as good a result as possible, it is very important that all cleaned and primed surfaces are kept free from dirt during the procedure. The same applies to the adhesive after it has been applied. Therefore, once work has commenced it must continue without a break until the windscreen is fitted and the adhesive has begun to harden. The hardening process starts as soon as the contents in the two tubes are mixed. Therefore, the windscreen must be fitted within 5 minutes after starting to apply the adhesive. Note that steps 6-10 must be carried out absolutely in the order shown if a satisfactory result with maximum adhesion is to be obtained.

| 1. |

Cut down the adhesive on the windscreen flange to a height of max. 2 mm. If the old windscreen is to be refitted, the adhesive on the windscreen must also be cut down to a height of max. 2 mm. Old and well-cohered adhesive gives a good base for the new adhesive. Loose adhesive on the glass or metal must be removed.

|

|

| 2. |

Remove loose particles and dirt from the metal flange with a vacuum cleaner.

|

|

| 3. |

Make good any damage to the paintwork as follows:

|

|

| • |

Scrape off any loose flakes of paint with a knife.

|

| • |

Clean with Teroson Cleaner FL.

|

| • |

Apply primer. Use Standox 1K Füllprimer.

|

| • |

Apply the finish coat.

|

||||||||||

| 4. |

Apply body primer, part no. (45) 301 87 02, to any painted areas that have been touched up. Body primer must

not

be used on old, well-cohered adhesive.

|

|

| 5. |

Place the lifting handle on the outside of the windscreen and lay it on a stand with its inner surface face up.

|

|

| 6. |

Carefully wash the edge of the windscreen with the cleaning agent that came with the adhesive kit. Wet the edge thoroughly with a rag. Dry with the lint-free cloth that came with the adhesive kit. Avoid touching the cleaned surface.

|

||||||||||

| 7. |

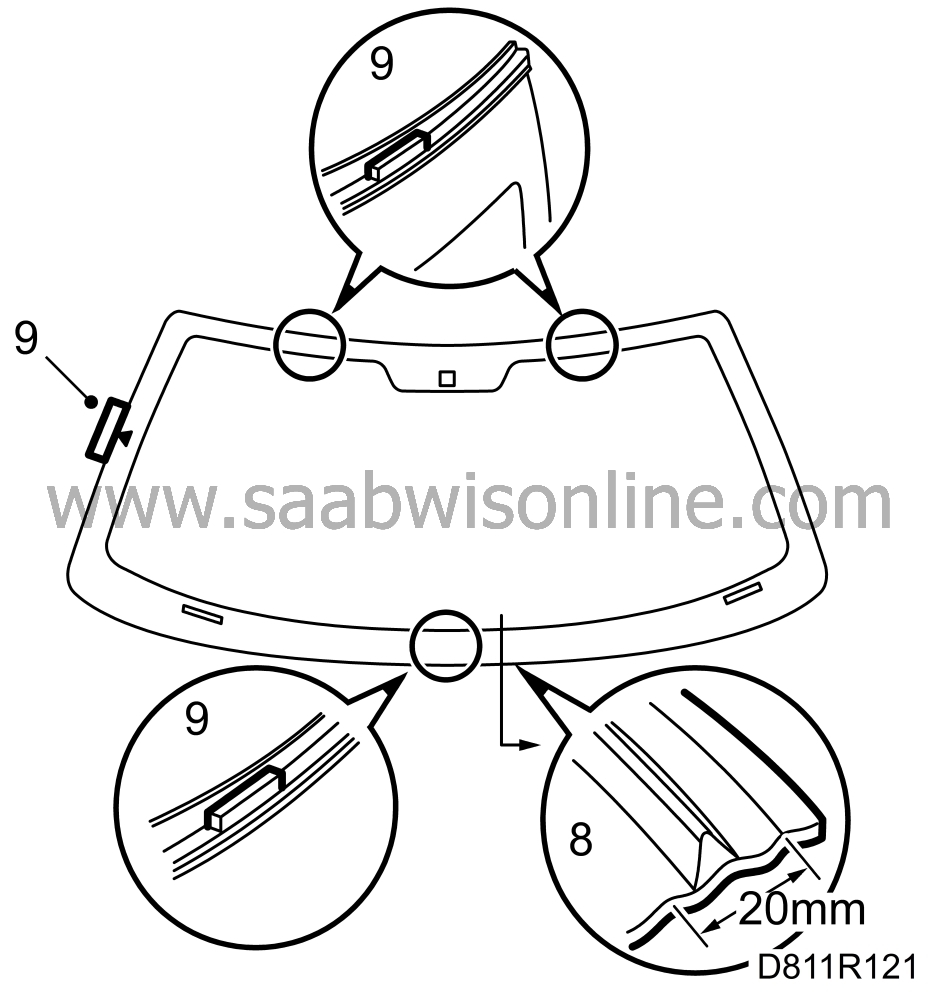

Press the retaining strip and the decor strip onto the windscreen.

|

|

| 9. |

Place the spacers on the windscreen. The marking in the blackening on the left side of the windscreen shows where the spacers are to be placed.

|

|

| 10. |

Apply the adhesive as follows:

|

|

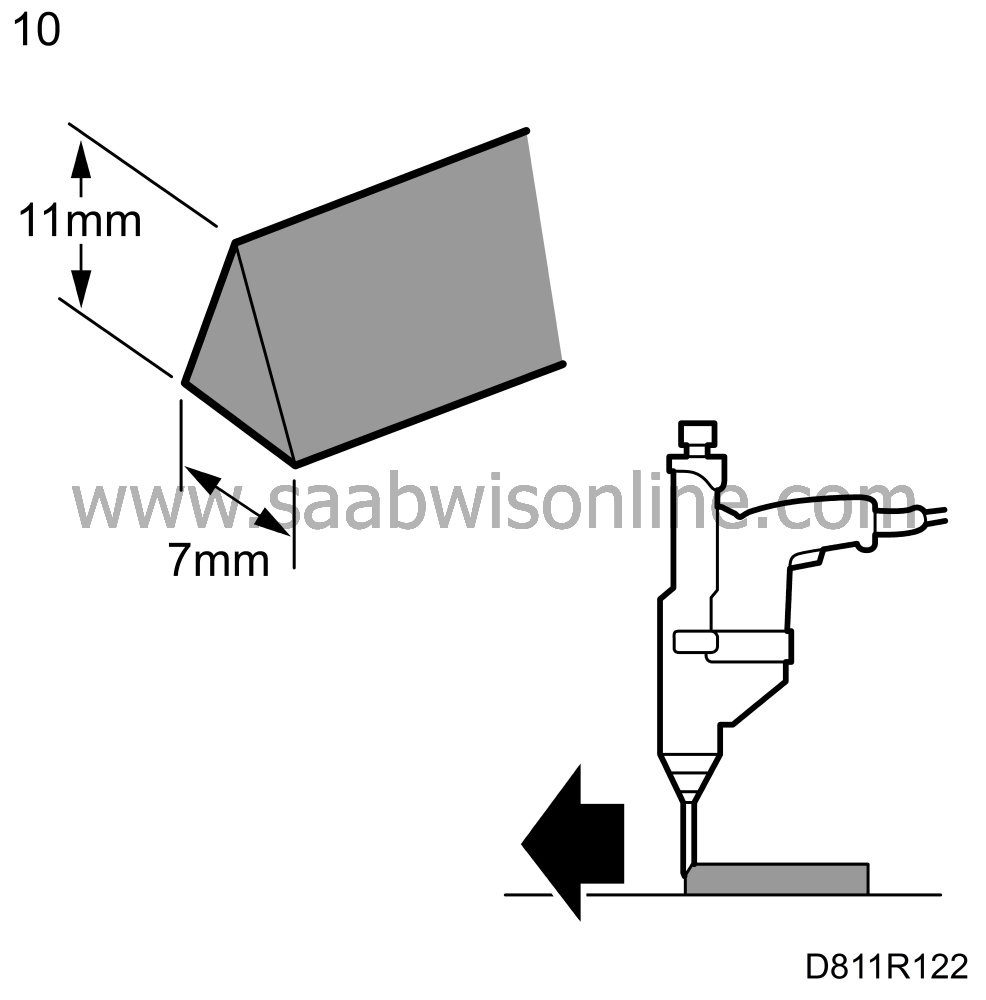

| • |

Cut 5 mm off the tip of the adhesive applicator nozzle. Heat the nozzle in hot water and adjust the opening to the size 7 x 11 mm.

|

| • |

Adjust the pressure of the adhesive gun to obtain a bead of adhesive measuring 7 x 11 mm.

|

| • |

Hold the gun at right-angles to the window and apply a bead of adhesive to the primed surface along the retaining strip. Start on the lower edge of the window. Make sure that there are no breaks in the adhesive bead.

|

| 11. |

Fit the windscreen in place.

|

|

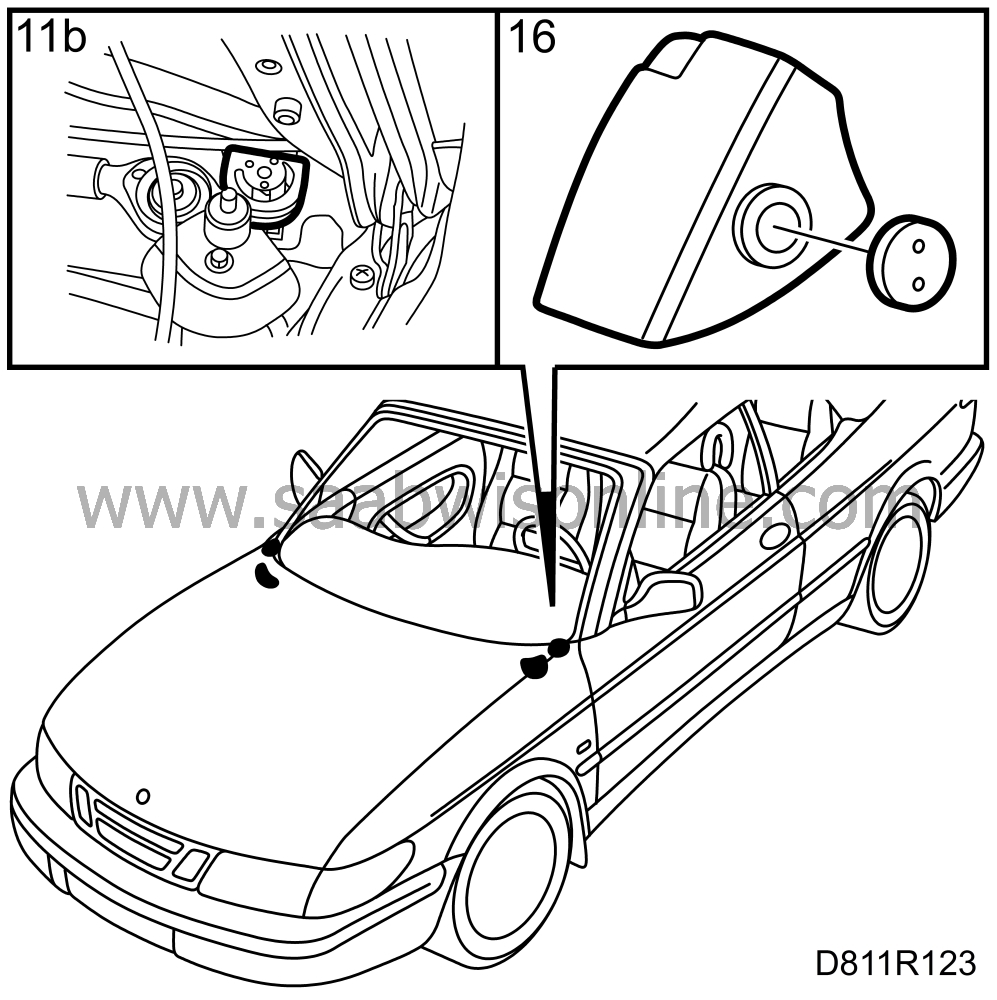

| 11.a. |

Adjust the windscreen to the left against the spacer.

|

| 11.b. |

Secure the windscreen in this position and turn the eccentrics so that they are lying against the windscreen.

|

||||||||||

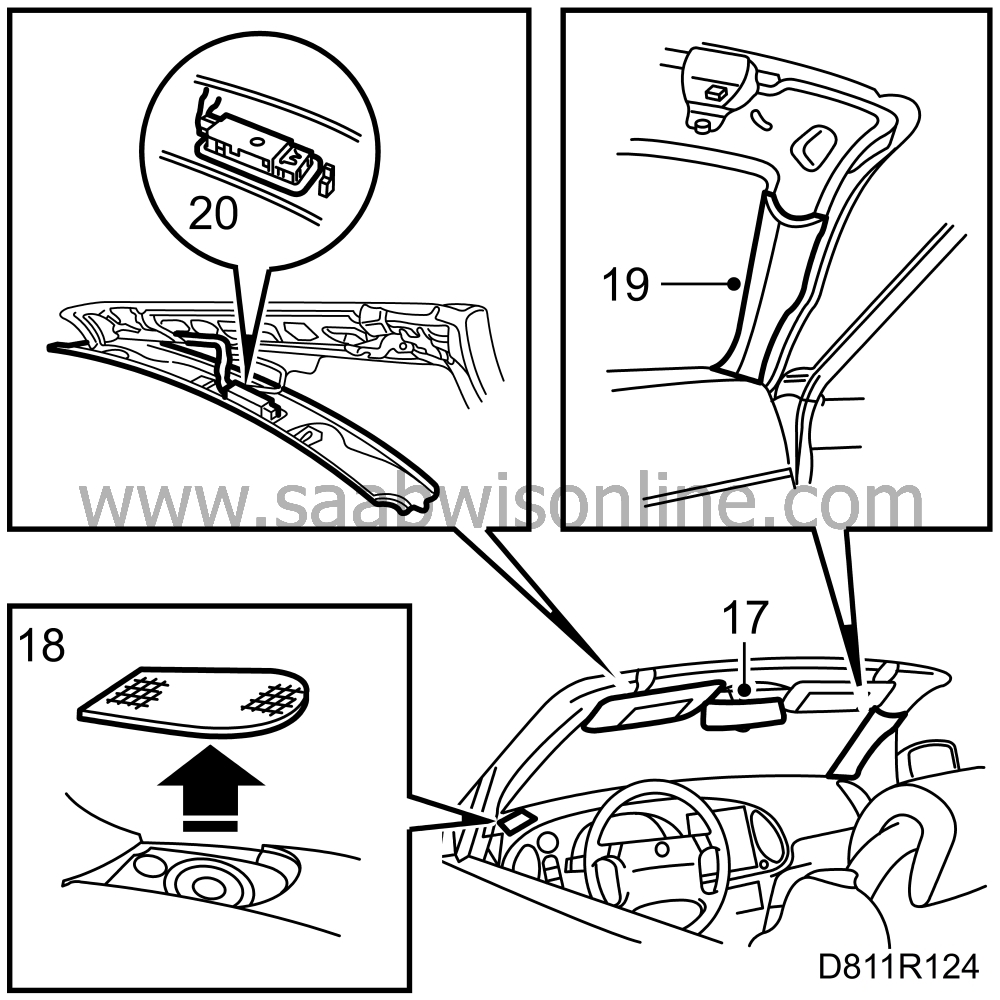

| 12. |

Lift the top of the decor strip slightly in the middle and pour on water. Check for leaks.

|

|

| 13. |

Allow the adhesive to harden before continuing. Betamate E 2400 hardens in 4 hours at + 23

°

C and 50%% relative humidity.

|

|

| 14. |

Put back the cover over the bulkhead space.

|

|

| 15. |

Put back the windscreen wipers.

|

|

| 16. |

Put back the covers on the corners of the bulkhead partition cover.

|

|

| 17. |

Refit the rear view mirror. If the mirror base is loose, it can be glued with glass adhesive, part no. (45) 30 06 830.

|

|

| 18. |

Refit the loudspeaker grilles.

|

|

| 19. |

Put back the A-pillar trim.

|

|

| 20. |

Plug in the electric connector for the interior lighting and put back the cover on the top edge of the windscreen.

|

|

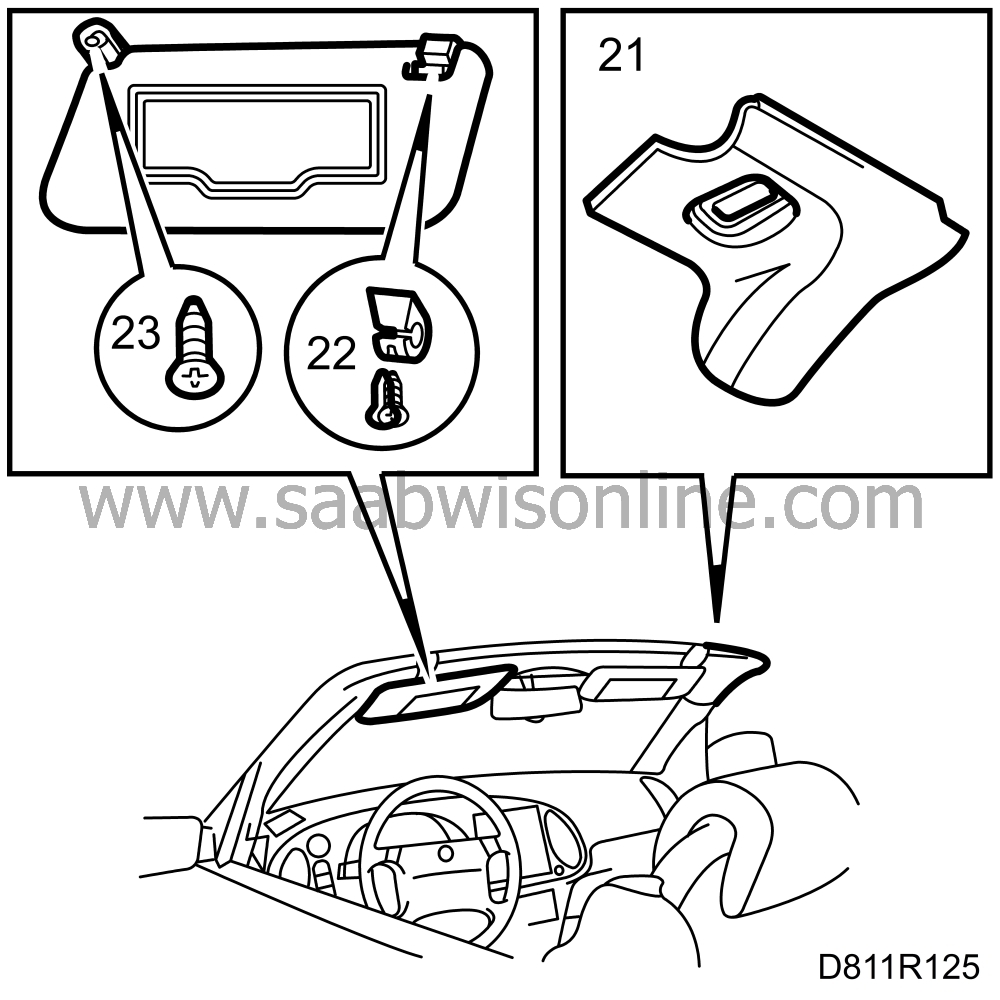

| 21. |

Put back the cover on the top right-hand corner of the windscreen.

|

|

| 22. |

Refit the sun visor support.

|

|

| 23. |

Refit the sun visor. Wind tape around the connectors to reduce the risk of them rattling.

|

|

| 24. |

Clean the windscreen inside and out.

|

|