Noise from soft top cover drive unit/soft top cover will not open

|

MODIFICATION INSTRUCTION

|

|

Bulletin Nbr:

|

811-2172

|

|

Date:

...........

|

September 1999

|

|

Market:

|

AU

|

|

|

Noise from soft top cover drive unit/soft top cover will not open

|

Cars in stock must be remedied before delivery.

Cars already delivered must be rectified in connection with a scheduled visit to the garage for service or repairs.

Saab 900 CV M95 -M98

Deformation of the drive unit gearcase or the aluminium plate securing the motor to the gearcase has occurred on certain occasions, especially on cars where the soft top is operated frequently. This can increase the clearance between the gears on the motor and the gearcase. If the clearance becomes too great, the gears will be damaged and noise will occur. The motor may also be ”disengaged” completely, preventing the soft top from being operated.

Perform this procedure after a customer complaint.

The addition of these reinforcing brackets can make a soft top (Tonneau) cover drive unit operable again and prevent further deterioration.

30 04 561 Grease

46 13 519 Reinforcement kit, soft top cover drive unit, consisting of:

Angle bracket (2 pcs.)

Pin (1 pc.)

Circlip (2 pcs.)

Screw (2 pcs.)

82 93 177 Gauge for adjusting soft top cover

|

1.

|

Remove the soft top cover drive unit, see ”8. Convertible, Adjustment and replacement, Soft top cover motor”

.

.

|

|

2.

|

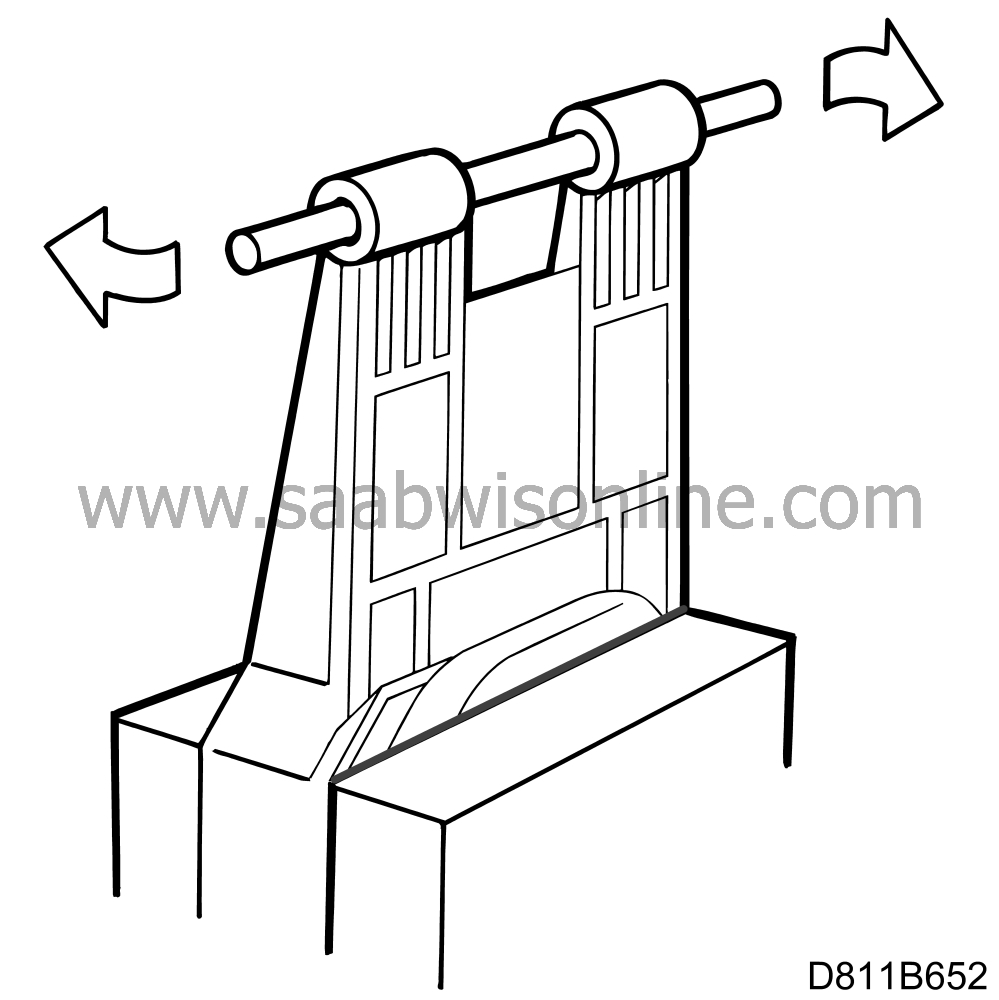

Place the drive unit on a workbench.

|

|

3.

|

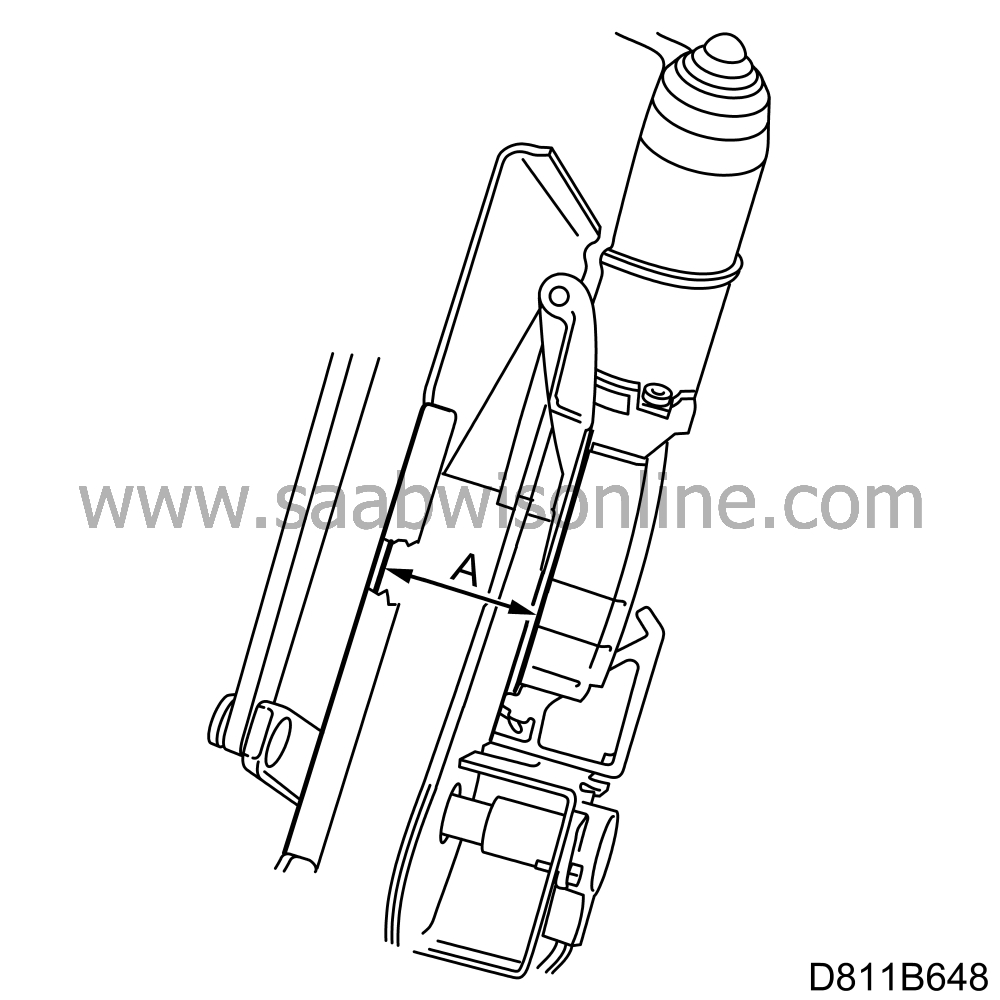

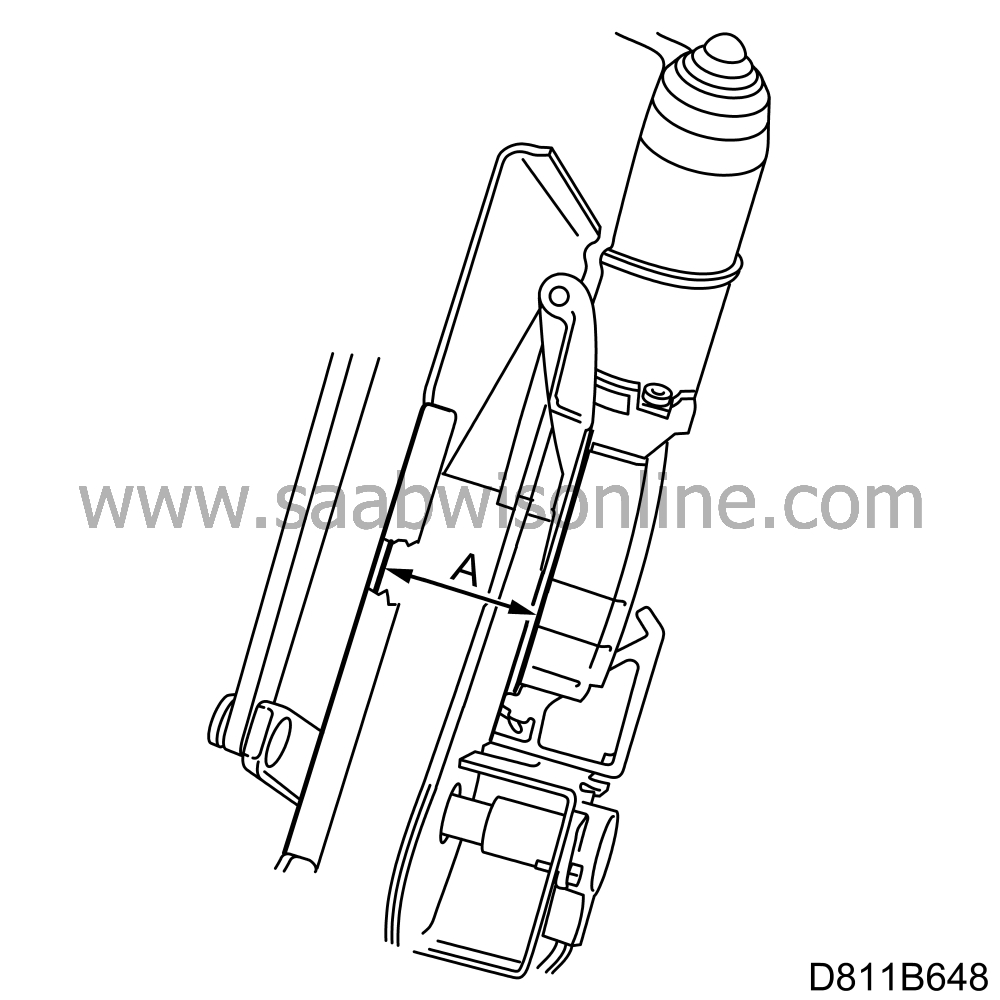

Make sure the motor is connected correctly to the gearbox mechanically and check the distance A in the illustration.

If A exceeds 36 mm, the drive unit must be modified in accordance with this Service Information unless any of the following damage has occurred.

|

|

4.

|

Open the catch and tilt the motor all the way from the gearcase. (Some catches may be bent to one side and must be straightened to restore correct operation and before they will open fully.)

Check:

|

|

|

•

|

that the gears are not damaged

|

|

|

•

|

that the catch is not damaged

|

|

|

•

|

that there are no fractures in the gearcase. A certain deformation of the bracket securing the spindle for the motor’s aluminium plate is acceptable, however. Any realigning can be carried out in connection with the modification.

|

If any of the above damage has occurred, the soft top cover drive unit must be replaced with a new one, see ”8. Convertible, Adjustment and replacement, Soft top cover motor”

.

.

|

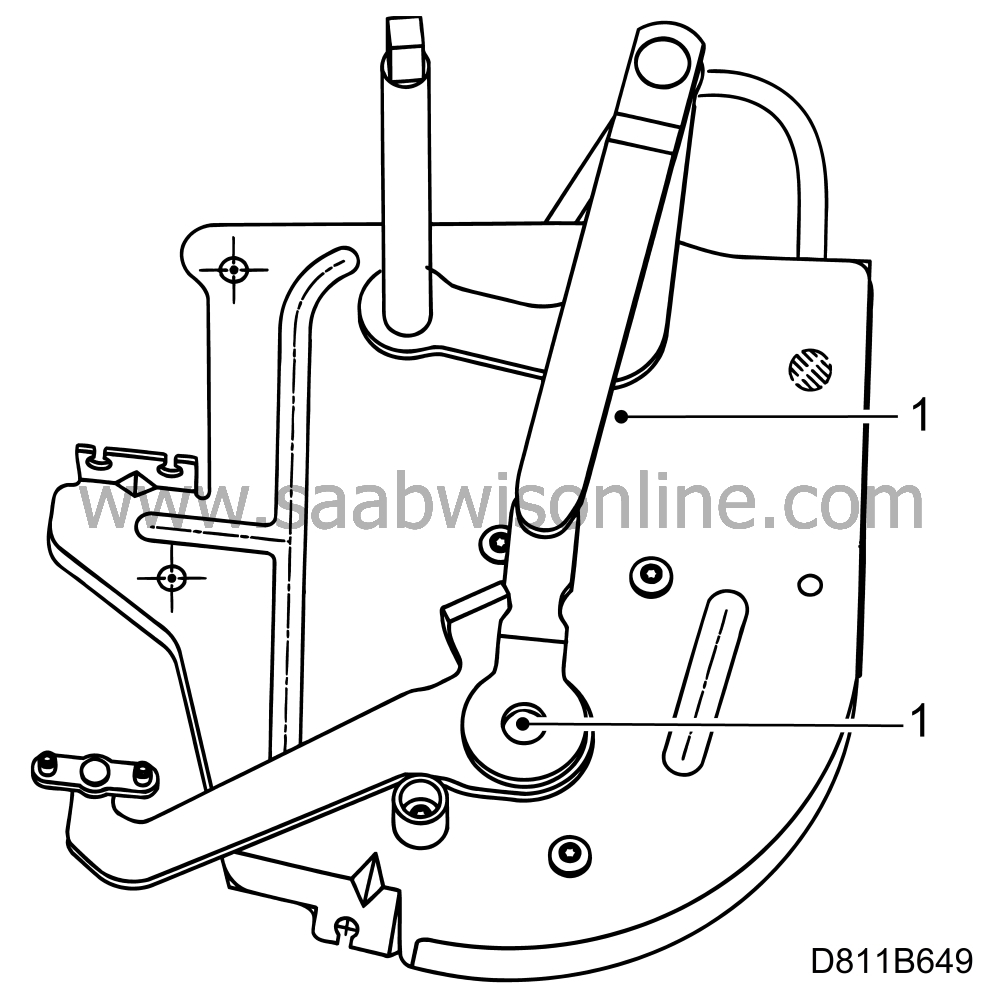

1.

|

Remove the screw securing the link arm and remove the link arm from the drive unit.

|

|

2.

|

Remove the gearcase from the drive unit’s plate bracket (four screws).

|

|

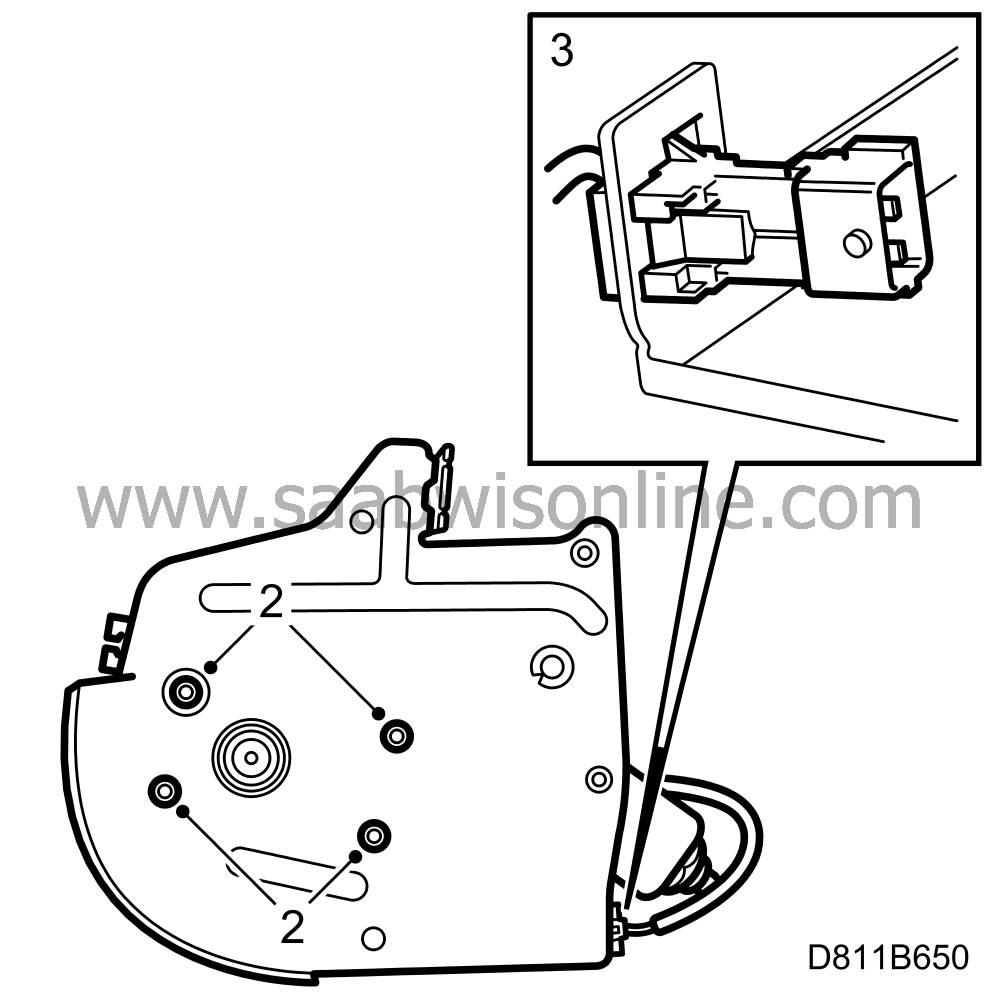

3.

|

Release the motor connector from the mounting plate.

|

|

4.

|

Open the catch fully. (Some catches must be straightened before they can be opened fully.)

|

|

5.

|

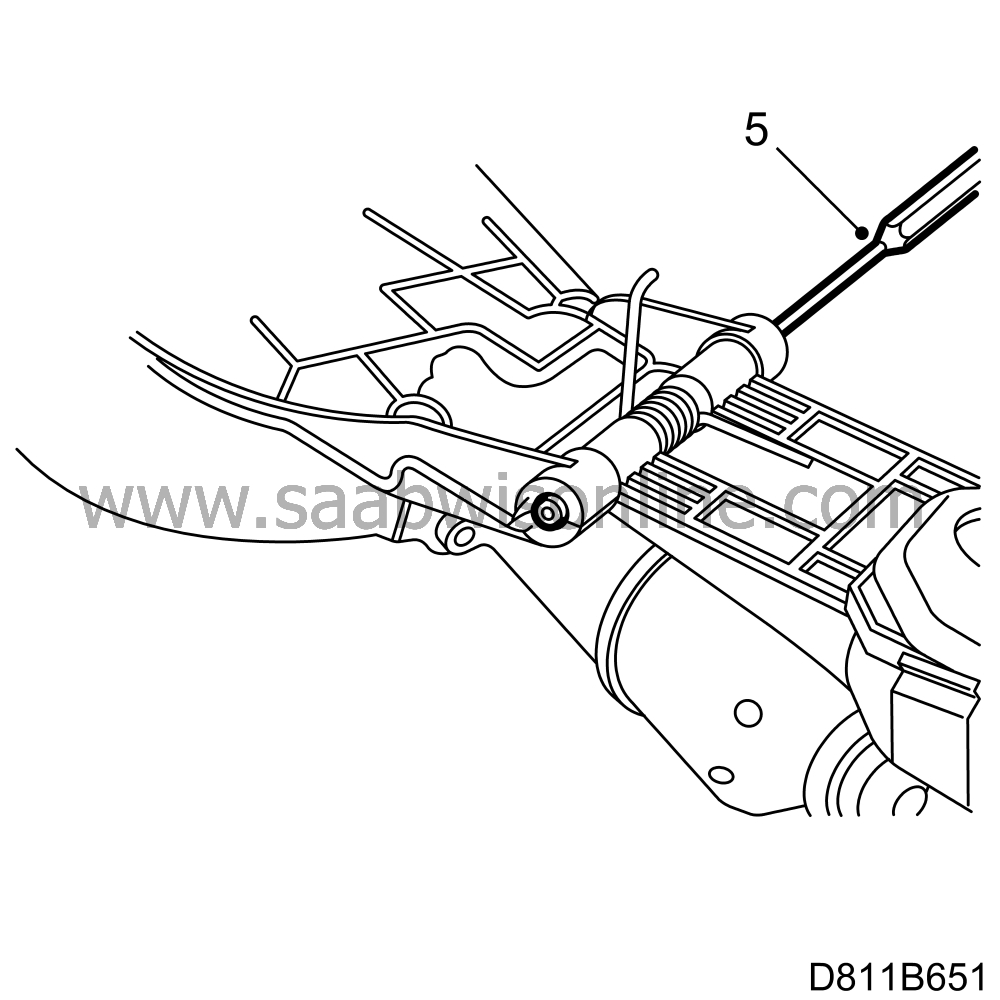

Remove the hinge pin with a drift. Apply the drift to the end of pin without splines. Remove the motor from the gearcase.

|

|

6.

|

If the gearcase has been deformed it can be aligned in the following way:

Refit the pin into the gearcase. Support the gearcase in a vice and align it to its original shape by twisting with a pipe wrench or large adjustable pliers.

|

|

7.

|

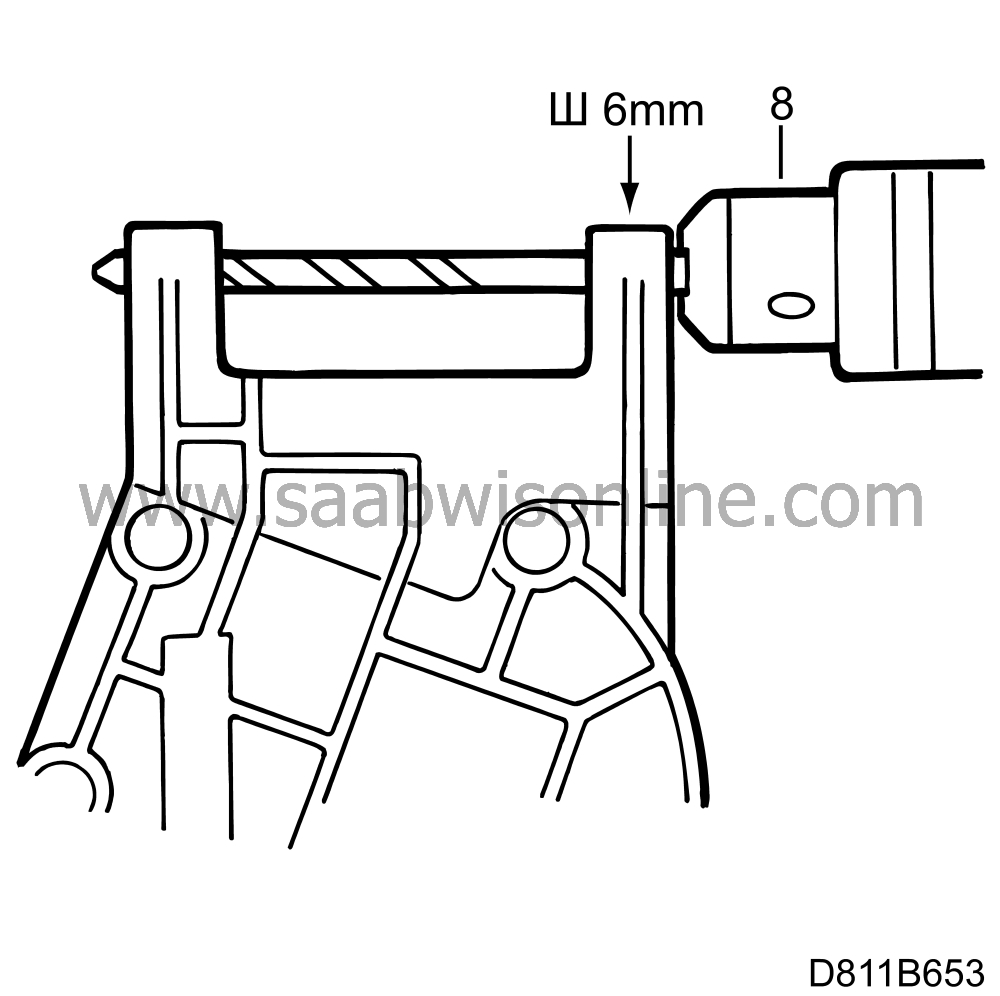

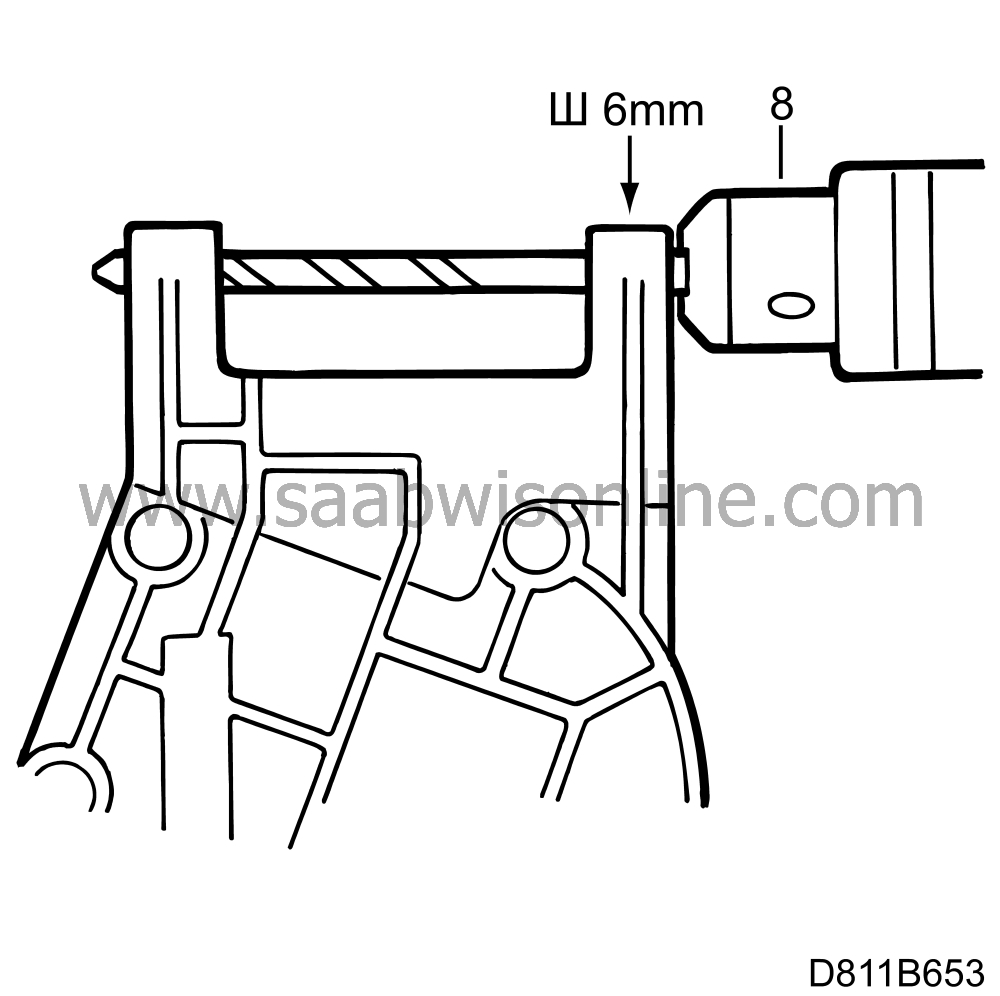

Replace the motor and make sure the gap A is 36 mm as illustrated. Repeat the alignment if necessary until the measurement is 36 mm. Remove the old pin.

|

|

8.

|

Drill out the holes for the new pin in the motor’s aluminium plate with a 6 mm bit. Drill from the side where the hole is already 6 mm. Protect the gears from cuttings.

|

|

9.

|

Align the motor’s aluminium plate to its original shape if necessary. Remove the motor from the aluminium plate if it is to be aligned.

|

|

10.

|

Make sure there are no cuttings on the motor gear (in the grease). This may occur if the motor gear has been in contact with the edge of the opening in the gearcase. Clean the gear where appropriate and apply new grease, part no. 30 04 561.

|

|

11.

|

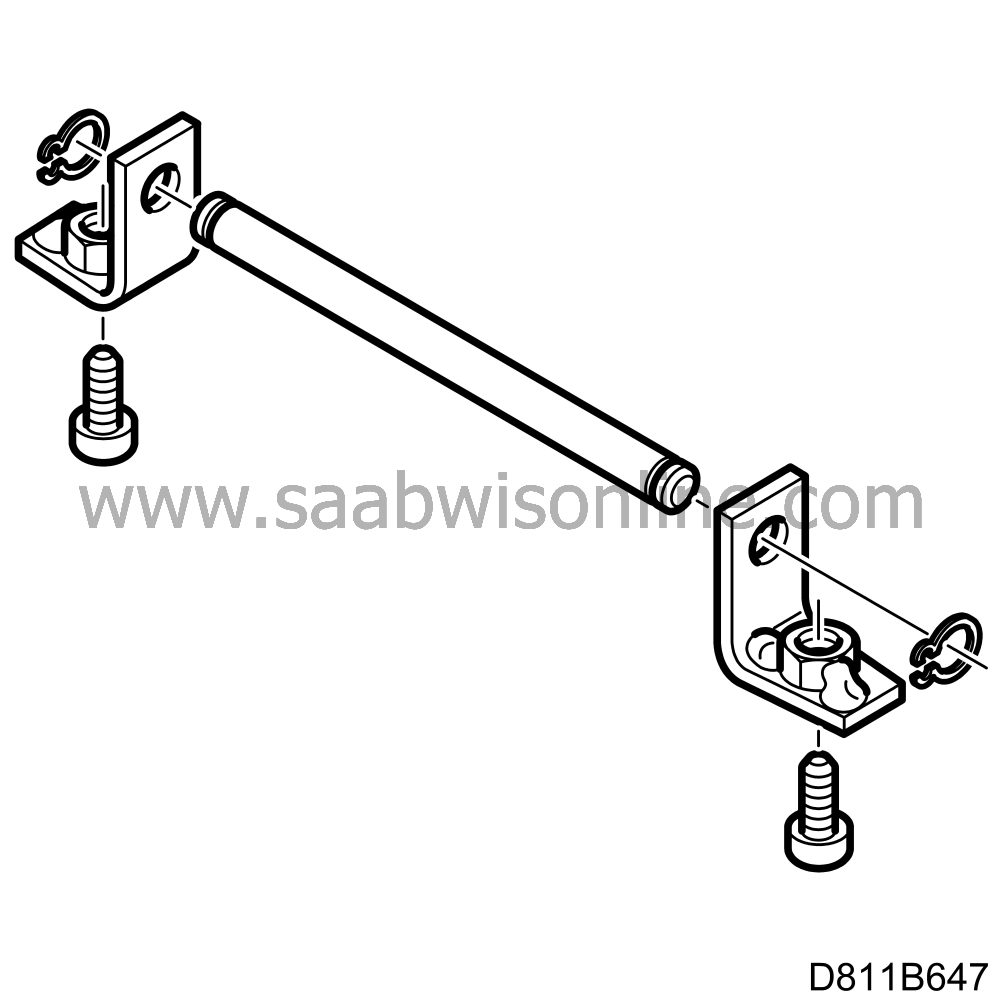

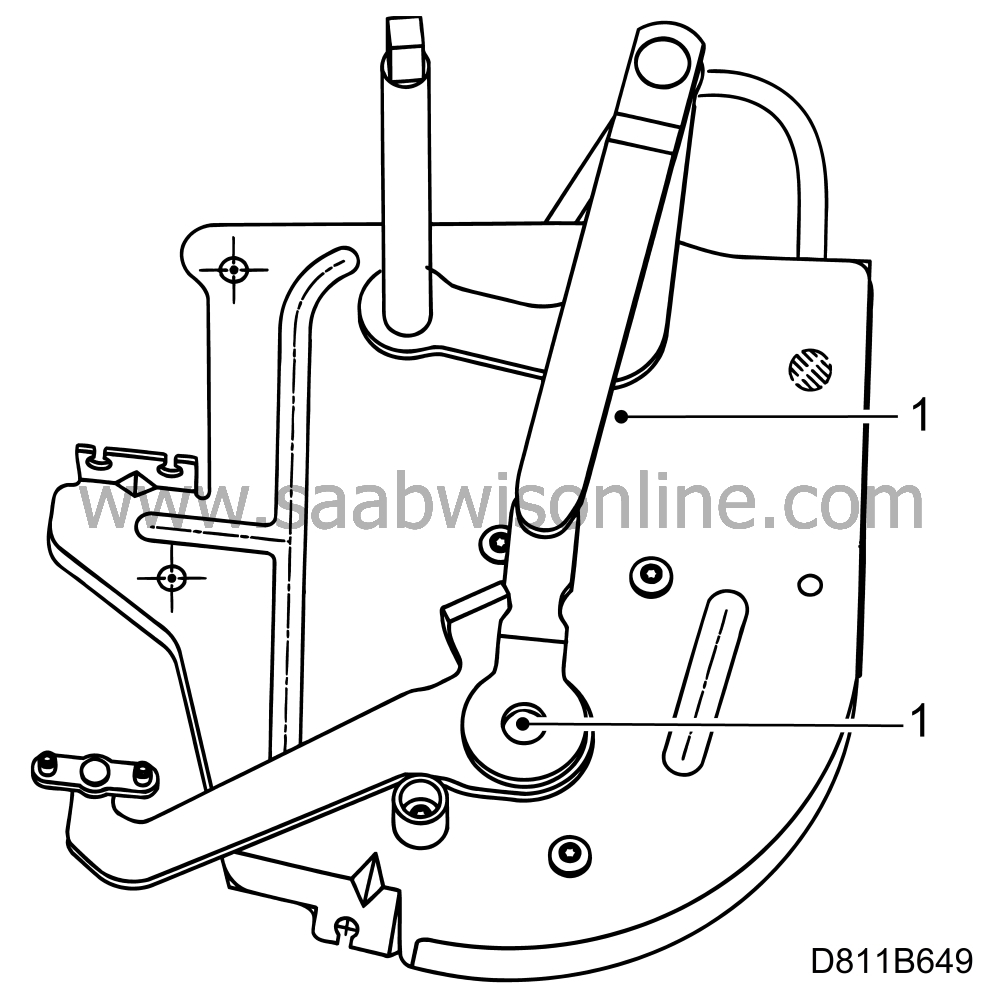

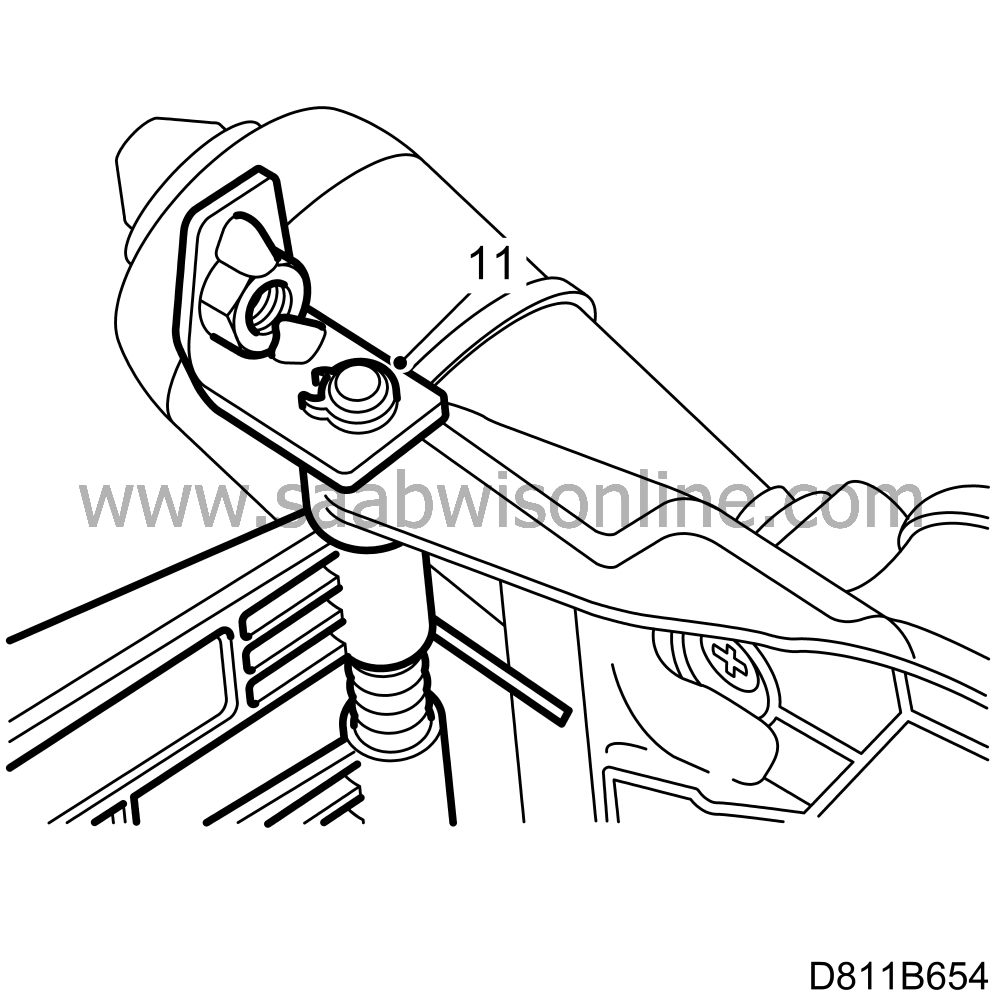

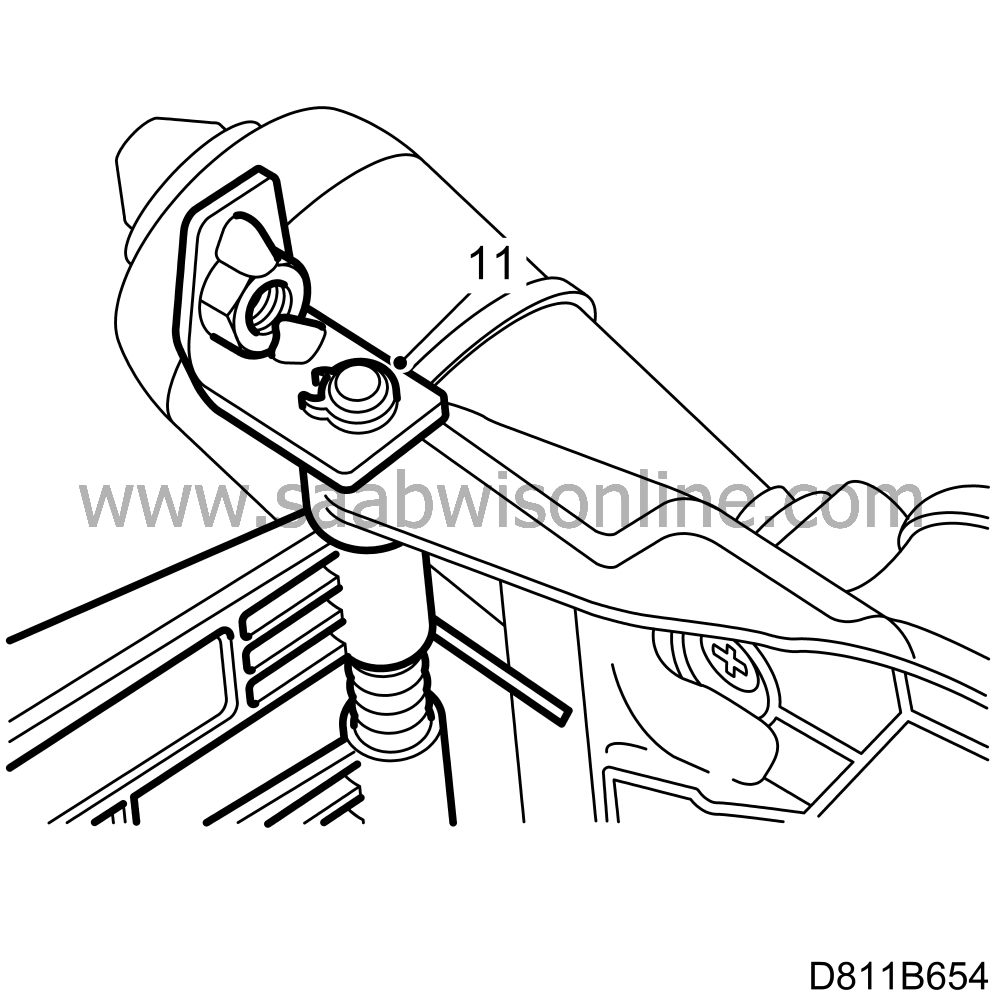

Assemble the motor’s aluminium plate, gearcase and spring with the new pin in the two angle brackets. Fit the circlips on the ends of the spindle.

|

|

12.

|

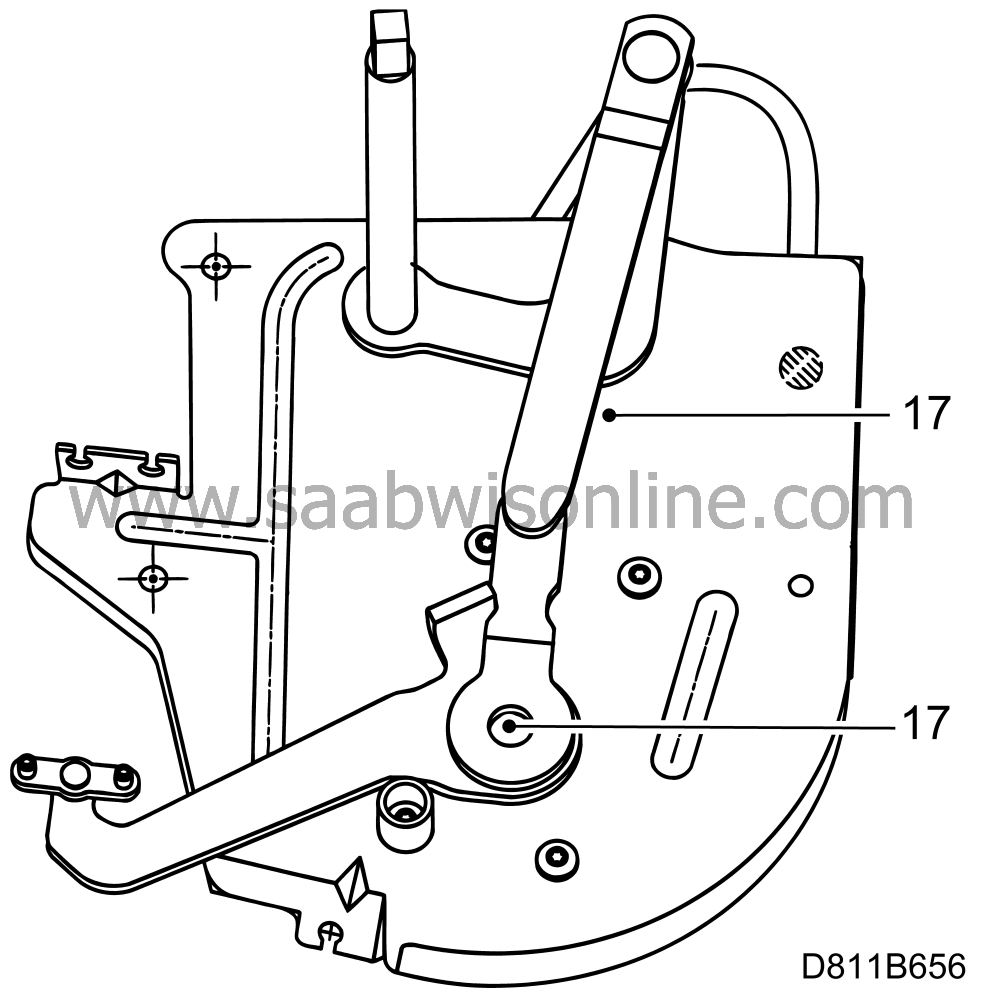

Fit the gearcase on the drive unit’s plate bracket. Mark the position of the holes for the angle brackets in the drive unit’s plate.

|

|

13.

|

Remove the gearcase. Center punch the marks and drill two holes with a 7.5 mm bit.

|

|

14.

|

Fit the gearcase to the drive unit’s plate and fasten on the two angle brackets.

|

|

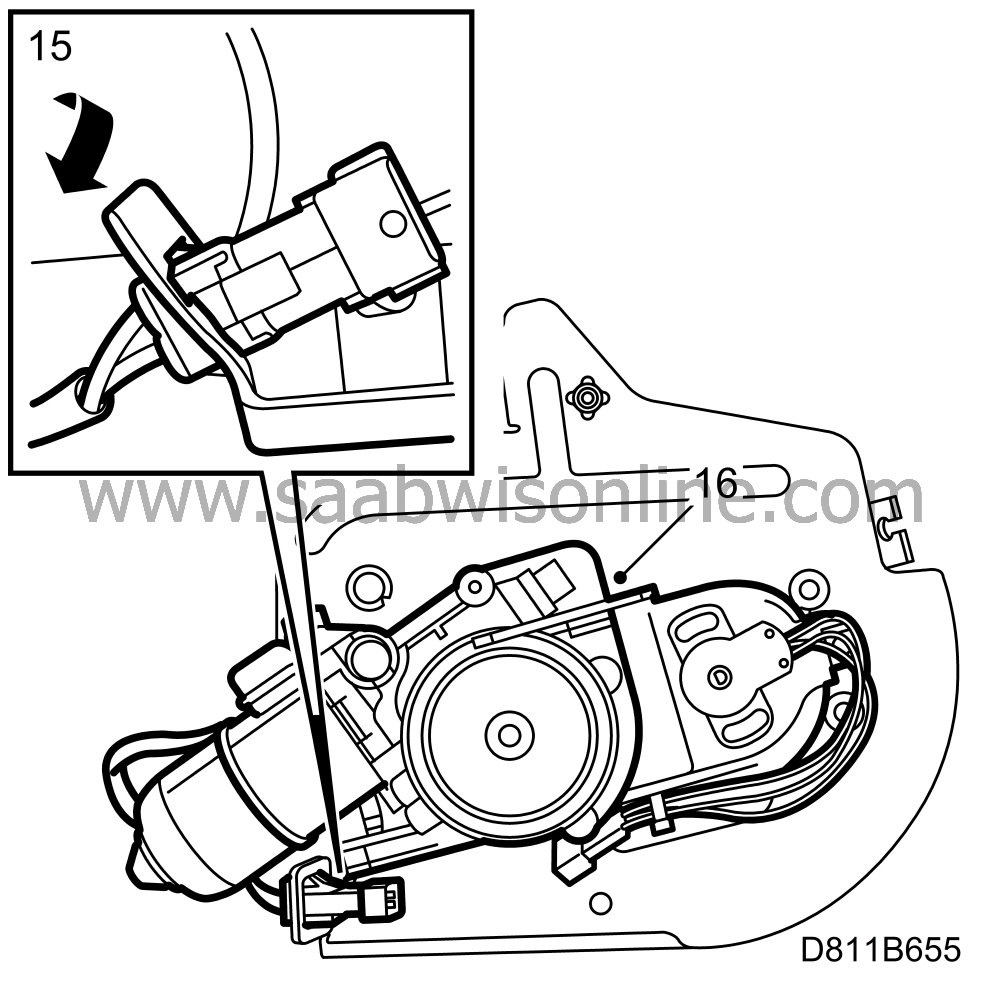

15.

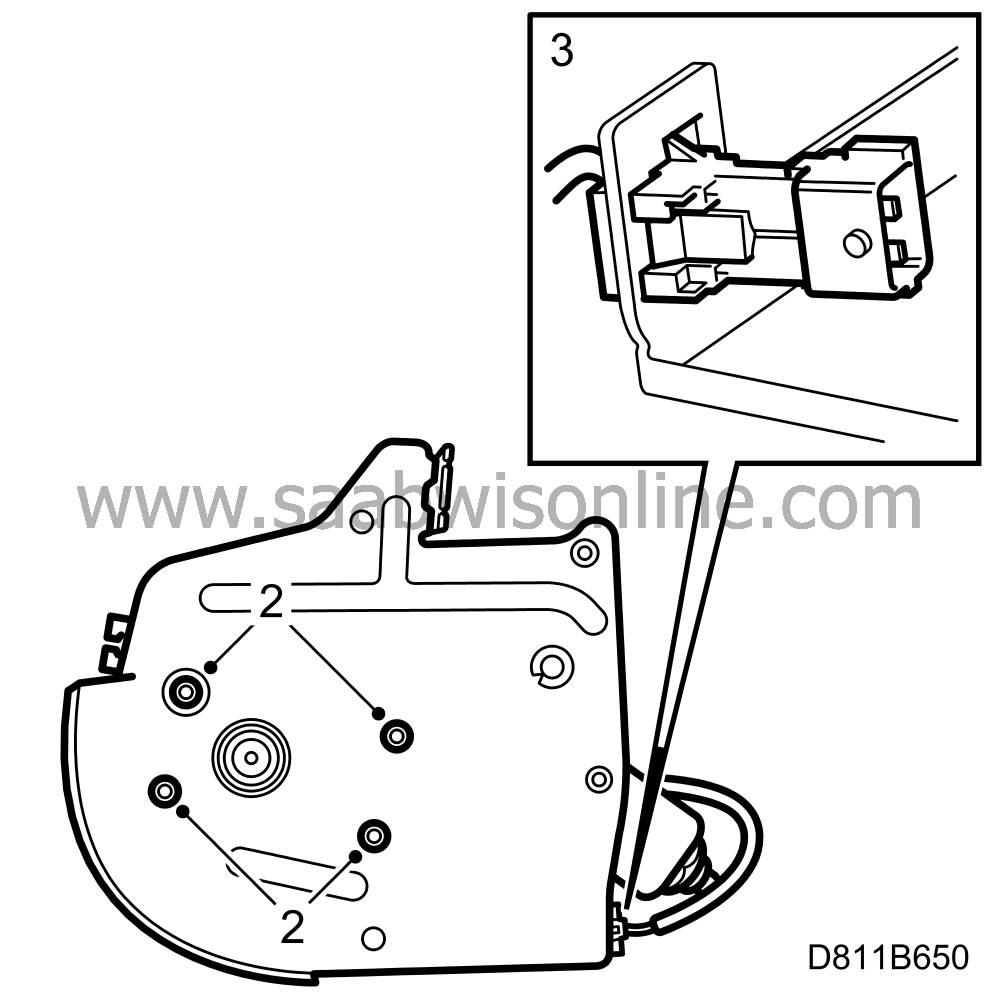

|

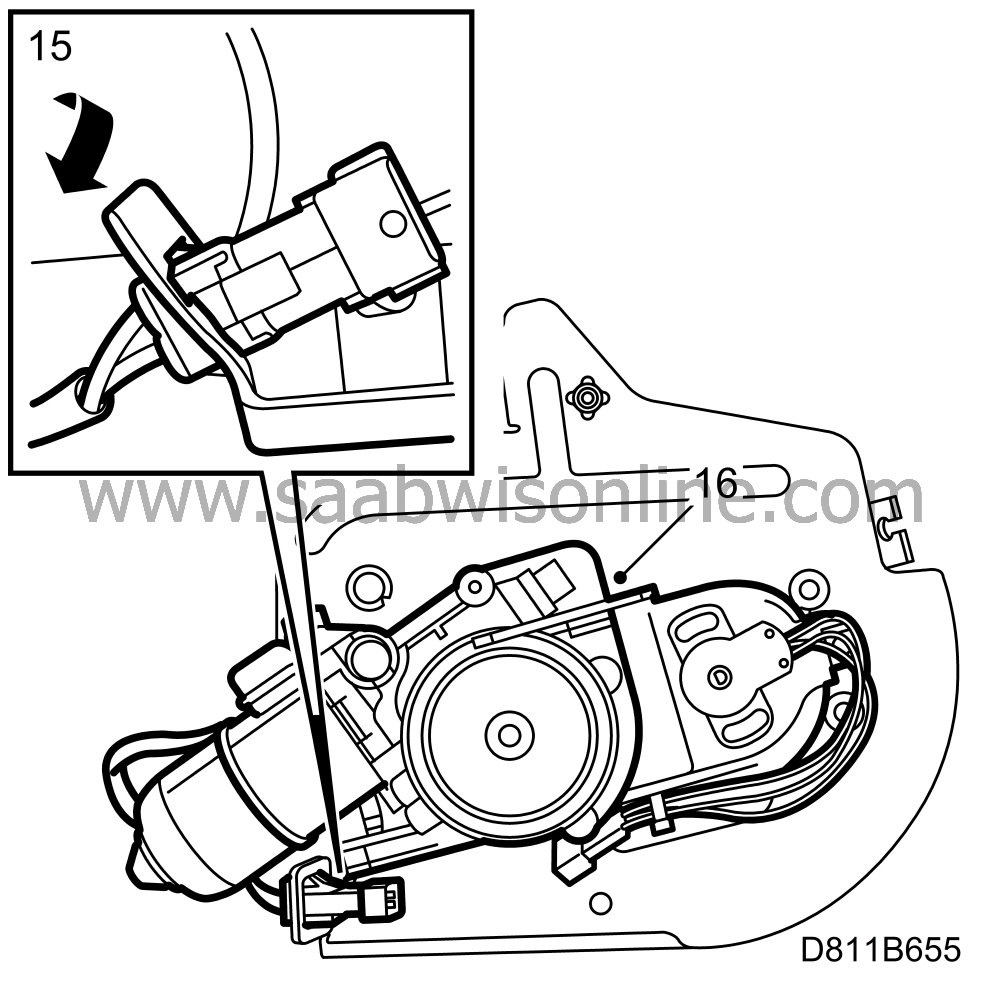

If the drive unit’s plate has a bracket for the connector, it must be bent to one side and backwards 10 °. Fit the connector to the bracket. If there is no bracket, the connector must be secured with cable ties.

|

|

16.

|

Make sure the catch works with the reinforcement kit fitted. The spring must be able to tilt out the motor once the catch has been released.

|

|

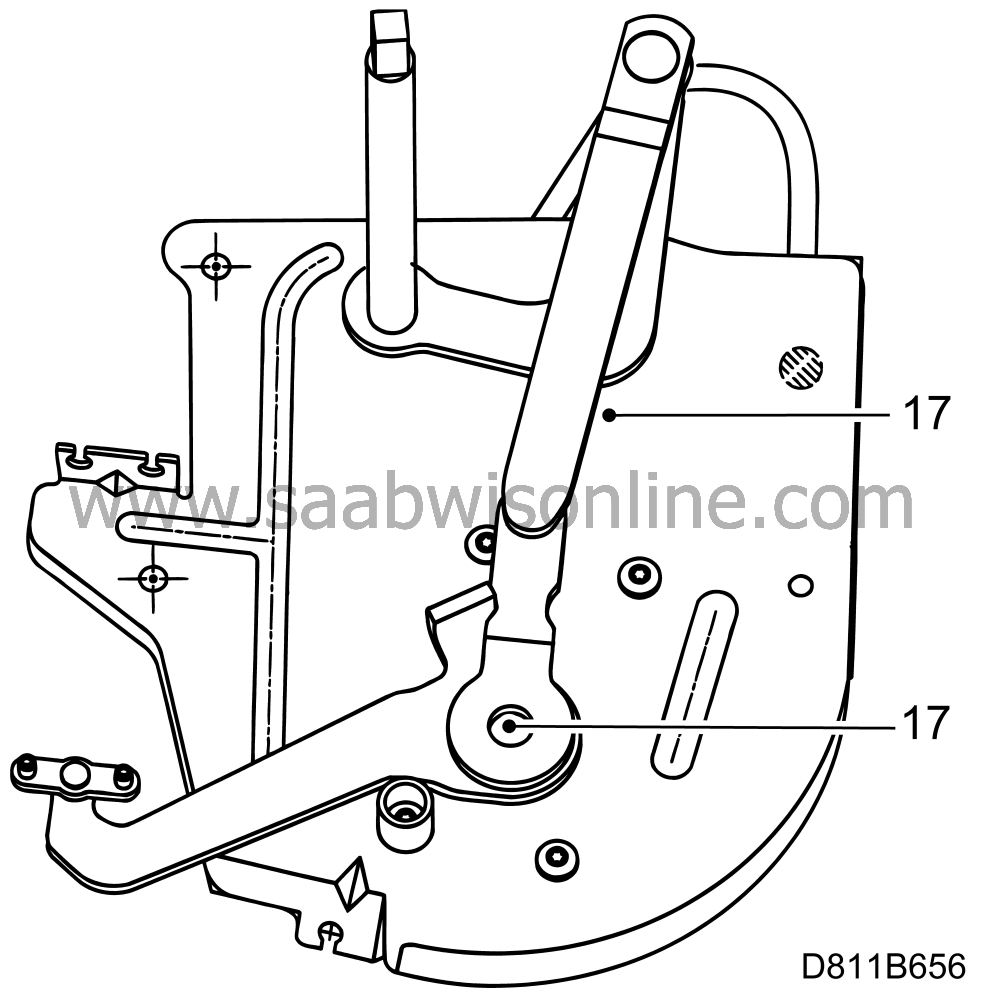

17.

|

Fit the link arm to the drive unit.

|

|

18.

|

Fit the soft top cover drive unit, see ”8. Convertible, Adjustment and replacement, Soft top cover motor”.

|

|

19.

|

After fitting the reinforcement kit, the front soft top cover latches must be checked and adjusted as necessary.

|

|

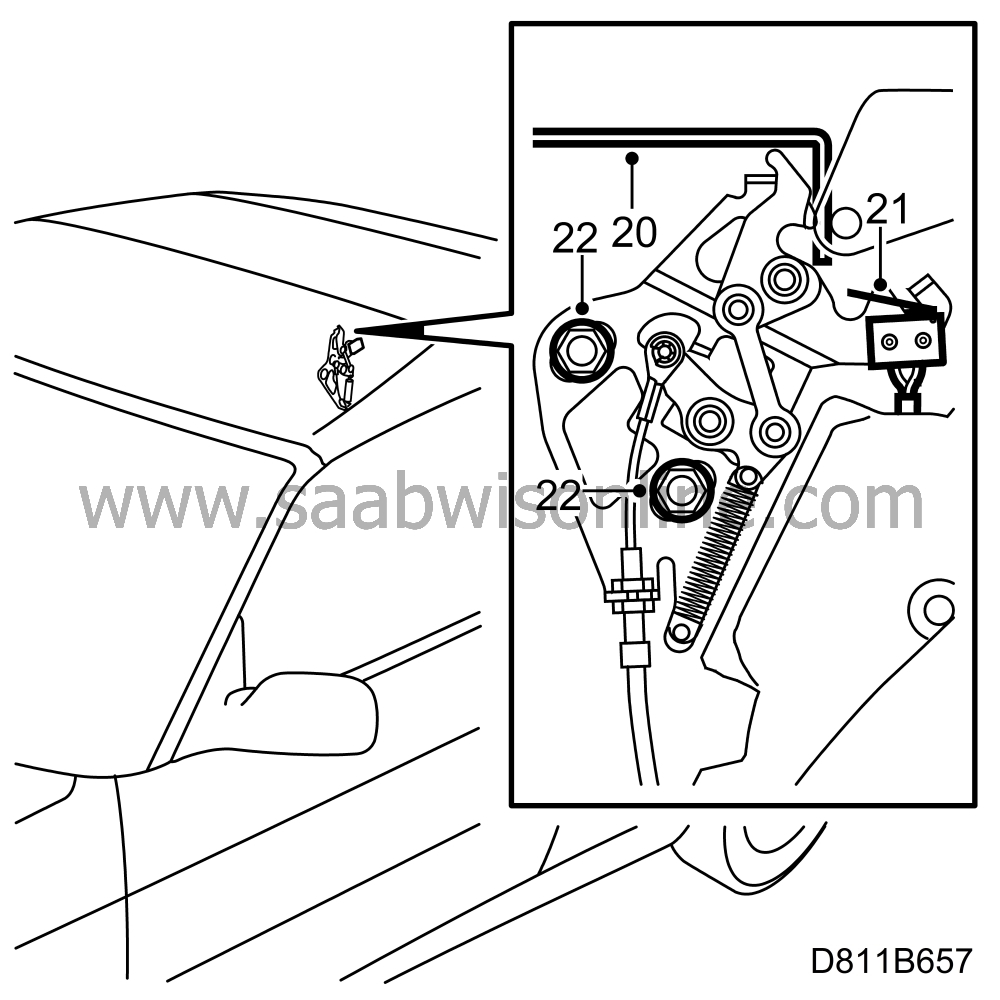

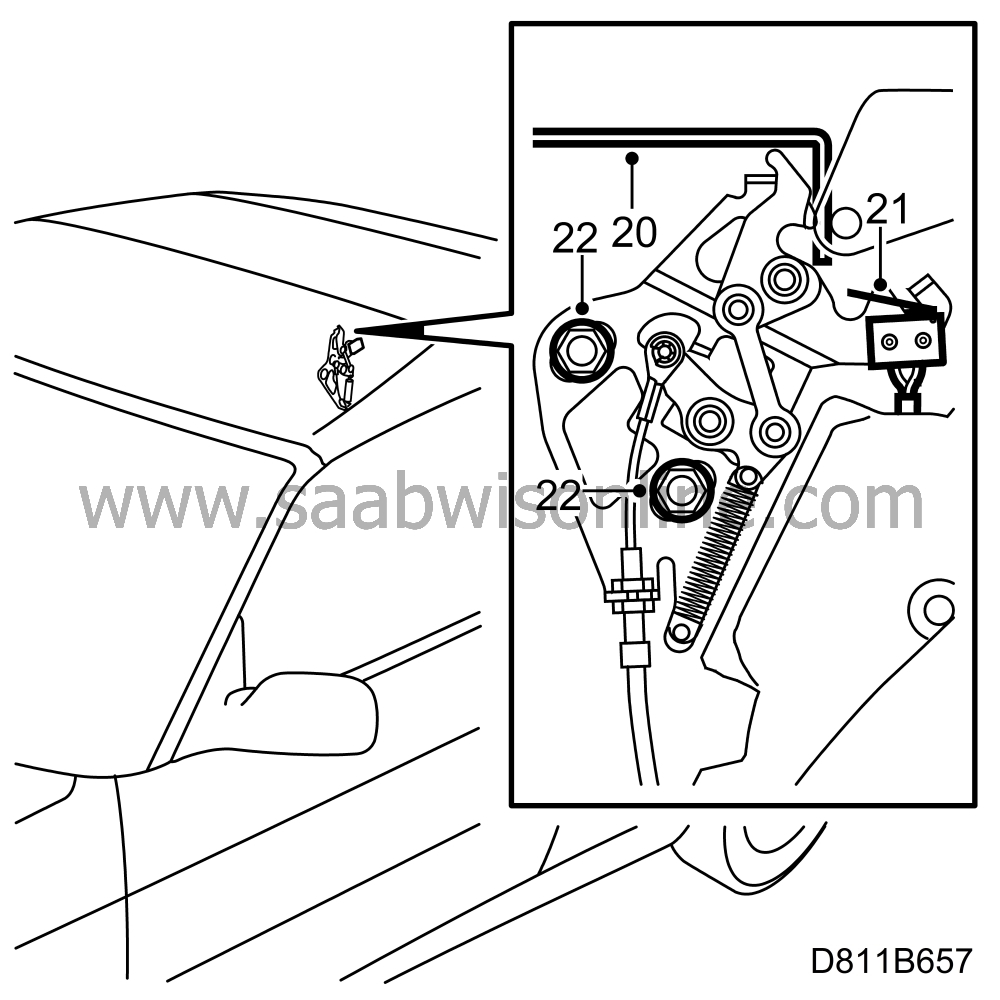

20.

|

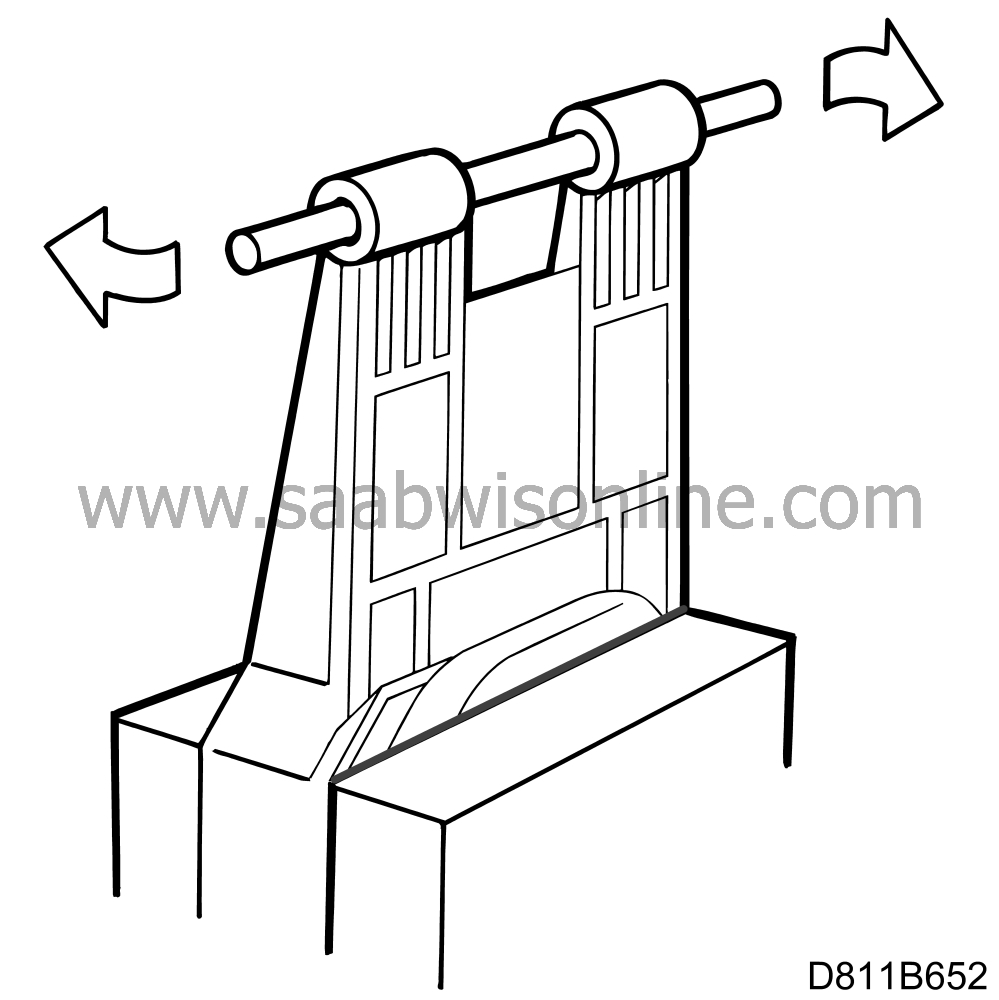

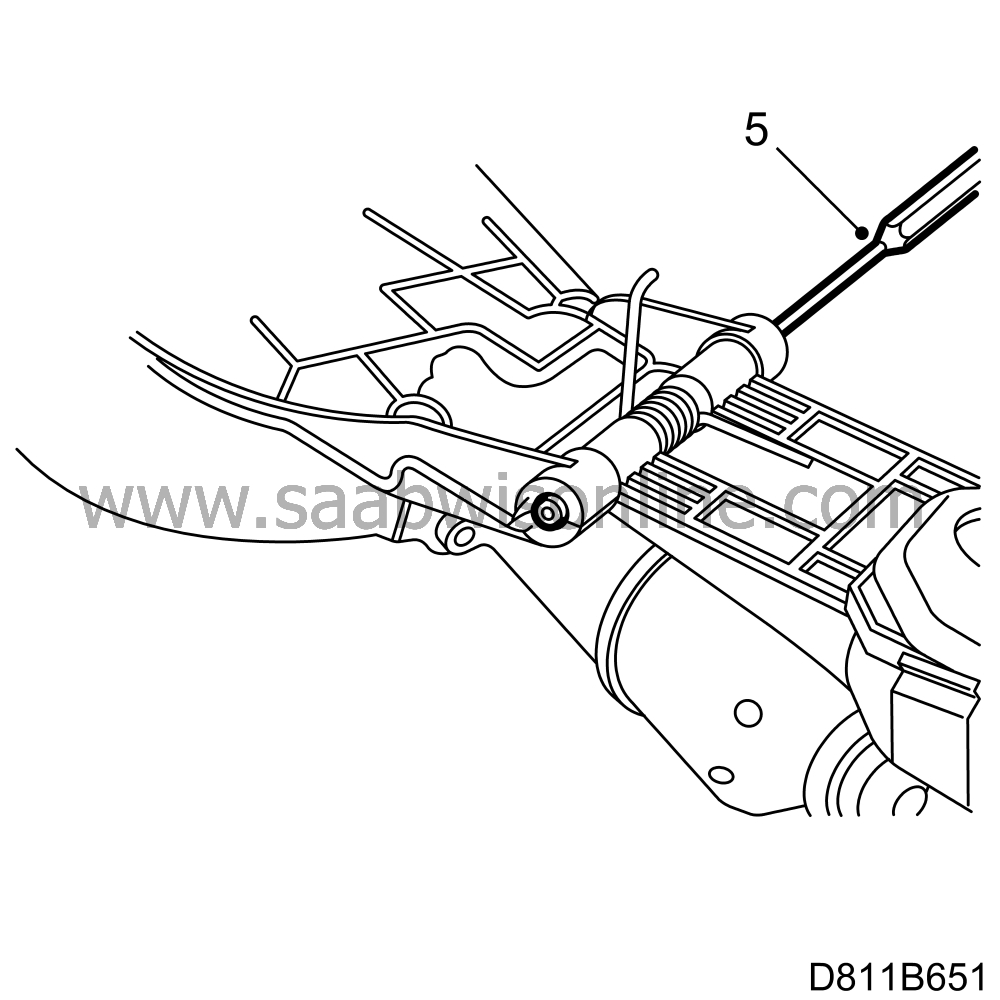

Raise the soft top cover until special tool 82 93 177 can be located as illustrated.

|

|

21.

|

Make sure the soft top cover latch striker goes freely into the latch without touching the tool. Listen for a ”clicking” sound when the microswitch is activated. If the latch striker touches the tool, the latch must be adjusted towards the front of the car.

|

|

22.

|

Adjustment:

Remove the relevant side trim. See ”8. Convertible, Adjustment and replacement, Rear side trim”

.

.

Loosen the two nuts securing the latch and adjust the latch forwards. Tighten the nuts.

Return to step 21 and check the adjustment.

When being closed, the soft top cover can ”knock” against the latch. In this is the case, adjust the latch slightly so that the seals buffer the soft top cover.

Refit the rear side trim. See ”8. Convertible, Adjustment and replacement, Rear side trim”

.

.

|

|

23.

|

Connect the diagnostic tool, clear any diagnostic trouble codes and then program the control module. See ”8. Convertible, Fault diagnosis, general, Programming the control module”

.

.

|

|

Warranty/Time Information

|

See separate information.

.

.

.

.

.

.