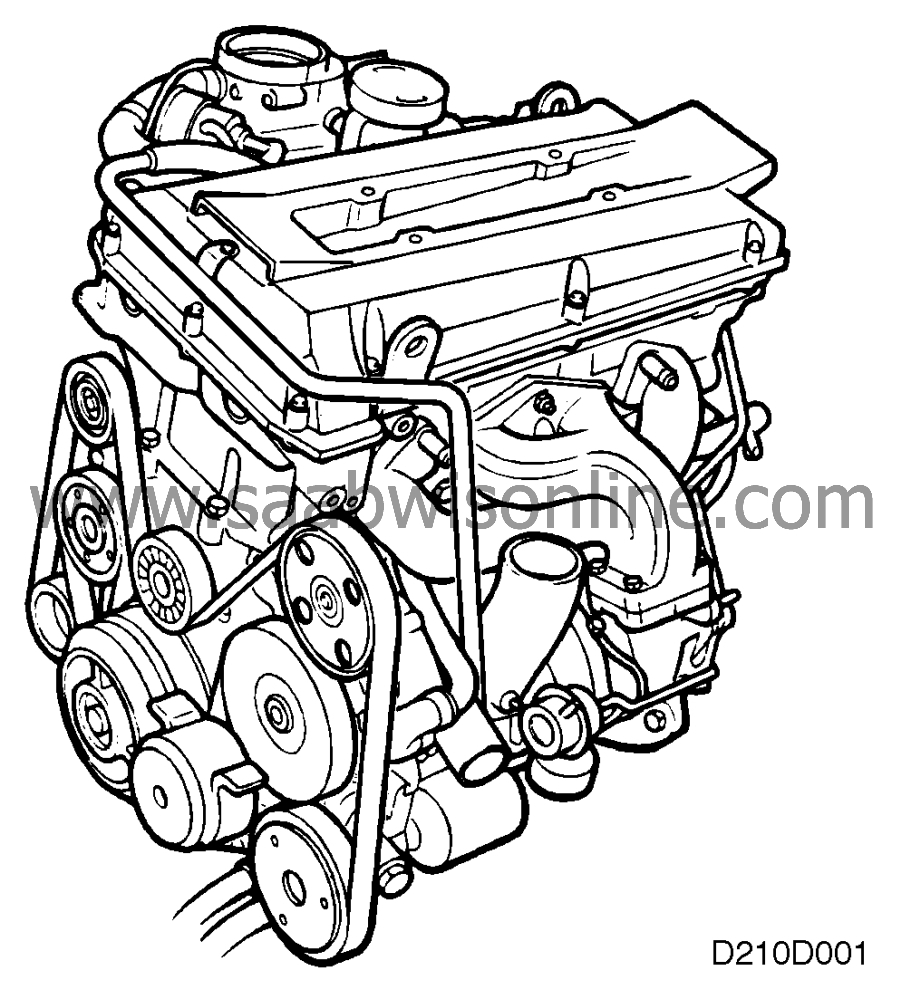

Engine block

| Engine block |

The engine is transversely mounted and inclined forwards at an angle of 8°.

The swept volume of 2.0 litres (B206i B204L) and 2.3 litres (B234i) helps to develop high torque even at low engine speeds, which is of particular benefit in normal driving conditions.

The balance shafts are designed to overcome vibration and the forces generated by the moving parts of the engine and at the same time reduce the level of unwanted engine noise.

| Cylinder block |

The block is a special one-piece casting with the cylinder bored in the block. Special oilways for the lubricating system are also drilled in the block.

Incorporated in the sides are the balance shafts, the inner journals of which run in aluminium bearing shells press- fitted in the block. These can be replaced without the need for any subsequent machining.

| Pistons |

The pistons are mode of light alloy and have grooves for two compression rings and one scraper ring.

The top compression ring is flat and coated with chromium or molybdenum. The second compression ring, which is slightly wider than the top one, also has an oil-scraper function. The scraper ring itself is in three parts.

| Connecting rods |

The connecting rods are forgings and incorporate bushes for the gudgeon pins. The gudgeon-pin bushes and big-end bearing shells are replaceable.

The gudgeon pins are of the fully-floating type, being free to turn in both piston and connecting rod. Axial movement of the pin is limited by circlips inside the piston boss.

| Crankshaft assembly |

The crankshaft is a forging and has ground journals, which are surface-treated by induction hardening. This provides a hard surface finish which is highly resistant to wear. There are five main bearings, with the middle bearing also serving to locate the crankshaft axially. Lubrication is provided for through drilled oilways in the shaft. All main bearing shells are replaceable.

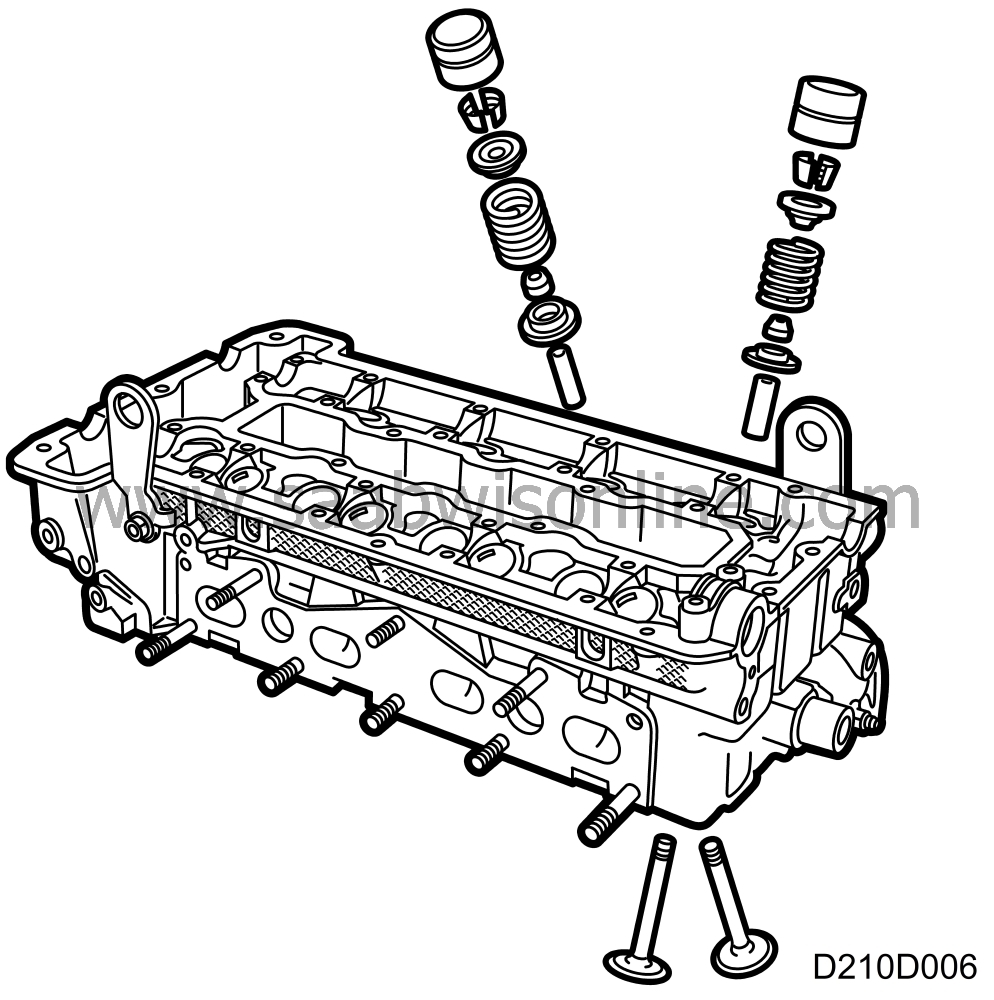

| Cylinder head |

The cylinder head, a light-alloy precision casting, is bolted onto the block. The combustion chambers are hemispherical with the spark plug in the centre, and there are four valves per cylinder. This design improves the flow of gases in the cylinders, ensuring effective combustion of the fuel-air mixture and so higher efficiency.

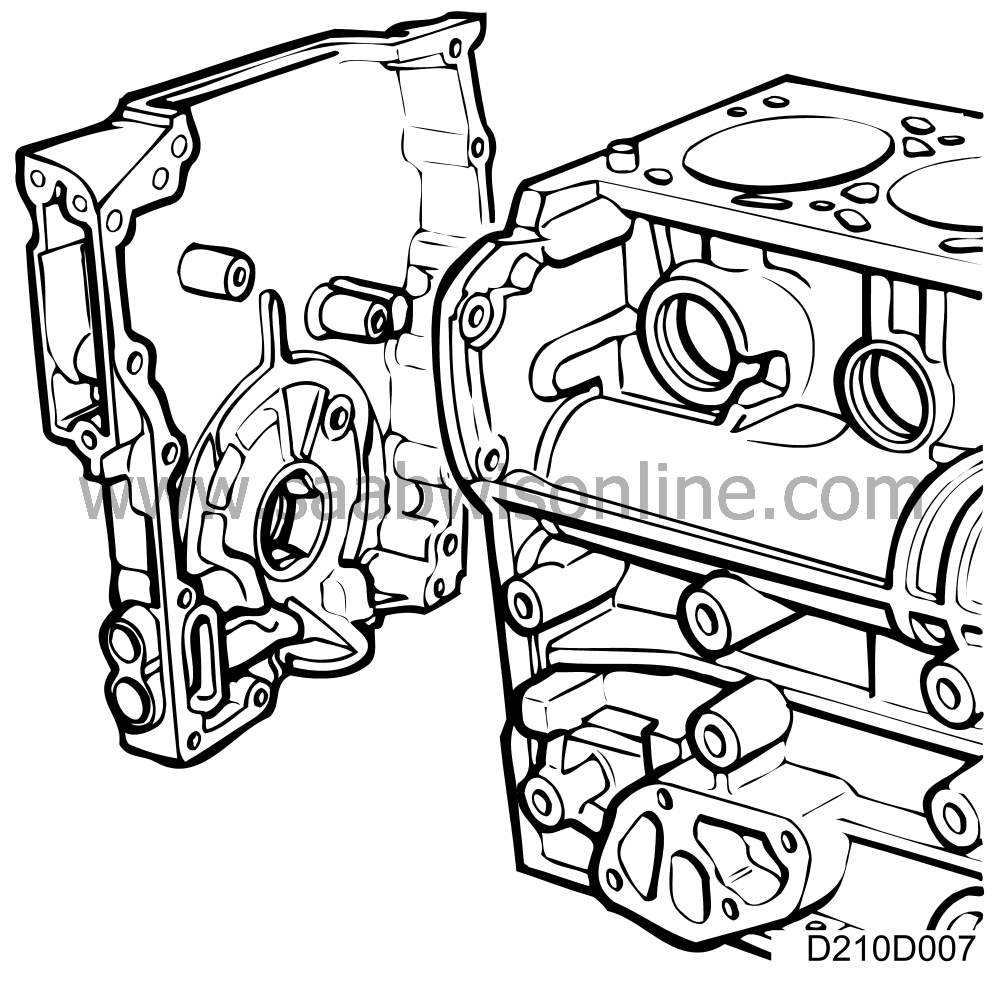

| Timing cover and end plate |

The timing cover and the end plate are both designed to match the shape of the cylinder block. The oil pump is mounted inside the timing cover. The timing cover and the end plate are both sealed against the block with flange sealant, part no. 93 21 795.