Fault diagnosis strategy for electronic systems

|

|

Fault diagnosis strategy for electronic systems

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

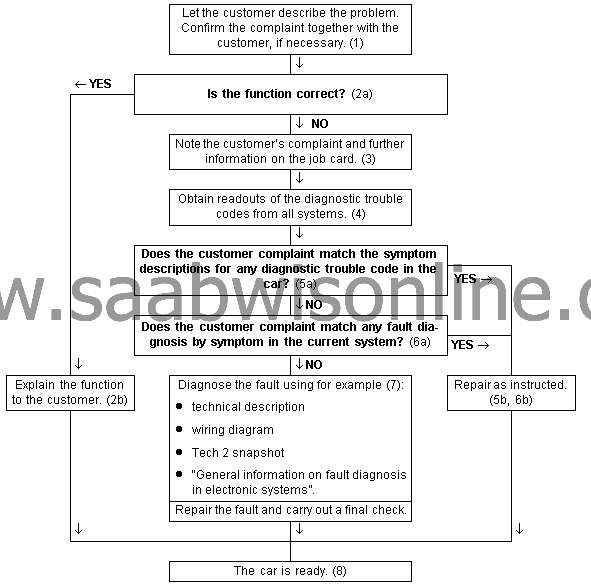

Let the customer report the problem.

Check the complaint together with the customer if necessary. (1)

|

|

|

|

|

|

|

|

|

|

|

↓

|

|

|

|

|

|

|

|

←

YES

|

Is the function OK?

(2a)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

↓

NO

|

|

|

|

|

|

|

|

|

|

Note the customer's complaint on the job sheet together with any additional information. (3)

|

|

|

|

|

|

|

|

|

|

|

↓

|

|

|

|

|

|

|

|

|

|

Obtain readouts of diagnostic trouble codes from all systems. (4)

|

|

|

|

|

|

|

|

|

|

|

↓

|

|

|

|

|

|

|

|

|

Does the customer complaint match the symptom descriptions for any diagnostic trouble code in the car?

(5a)

|

|

|

|

|

|

|

|

YES

→

|

|

|

|

|

|

|

|

|

↓

NO

|

|

|

|

|

|

|

|

|

Does the customer's complaint match any fault diagnosis based on symptoms in the present system?

(6a)

|

|

|

|

|

|

|

|

YES

→

|

|

|

|

|

|

↓

|

|

|

↓

NO

|

|

|

|

|

|

|

Explain the function to the customer. (2b)

|

|

Carry out fault diagnosis, using for example (7):

|

•

|

“General information on fault diagnosis in electronic systems”.

|

|

|

Repair as per instructions. (5b, 6b)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Repair the fault and carry out a final check.

|

|

|

|

|

|

|

|

↓

|

|

|

↓

|

|

|

↓

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The car is ready. (8).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

|

The customer's description of the problem constitutes a basis for the fault diagnosis strategy.

If necessary, the customer must demonstrate the trouble on the car to avoid misunderstandings.

|

|

2.

|

In certain cases, the function may be correct.

|

|

|

2.a.

|

Good product knowledge is required to decide this.

|

|

|

2.b.

|

If the function is correct, this must be explained to the customer.

|

|

3.

|

If the function is considered faulty, the car should be repaired.

Saab's fault diagnosis strategy assumes that the technician is familiar with the customer's description of the problem. So note the customer's complaint and any other observations on the job sheet.

|

|

4.

|

The technician obtains a readout of the diagnostic trouble codes from

all

systems.

A malfunction in one system can often be caused by a fault in another system.

|

|

5.

|

The car may contain diagnostic trouble codes which are secondary faults or which have been incorrectly generated.

|

|

|

5.a.

|

Compare the customer's complaint with the symptom descriptions for the various diagnostic trouble codes. EPSI has a fast search path for this.

|

|

|

5.b.

|

If the symptom description for a diagnostic trouble code matches the customer's complaint, this diagnostic trouble code is probably caused by the primary fault.

Repair as per instructions.

|

|

6.

|

If there is no match with the diagnostic trouble codes, fault diagnosis on the basis of symptoms can be carried out.

|

|

|

6.a.

|

In EPSI, search under fault diagnosis on the basis of symptoms in the system where the fault has occurred.

|

|

|

6.b.

|

If the symptom description in the current system matches the complaint, the right fault diagnosis description has probably been found.

Repair as per instructions.

|

|

7.

|

If there is no match with diagnostic trouble codes or symptoms, the technician must diagnose the fault himself.

A final check must be carried out after the repair.

Good technical product knowledge is required to solve this type of problem.

|

|

General information on fault diagnosis in electronic systems

|

Electronic control modules

When the electronic control module is supplied with current, the processor in it is tripped. The processor then reads the instructions stored in the electronic control module's memory.

The control module is programmed to read the inputs and activate the outputs. If the control module's program is faulty, the diagnostic trouble code “Internal control module fault” will be generated.

The electronic control module must be powered up if the system is to operate. When the electronic control module is powered up and the processor has been tripped, the diagnostic tool will be able to communicate with the electronic control module.

Outputs

The purpose of the system is to control a number of functions by means of various actuators, e.g. an injector or a lamp. For the system to be capable of performing its functions, it must be possible to activate the actuators. For this reason the actuators must be connected to the electronic control module and have a proper power supply or ground connection.

Inputs

A condition for the electronic control module's capability of controlling its actuators is that the system's sensors supply the electronic control module with correct values.

The diagnostic tool can be used to check the performance of the sensors.