Principle of operation, idle air control

| Principle of operation, idle air control |

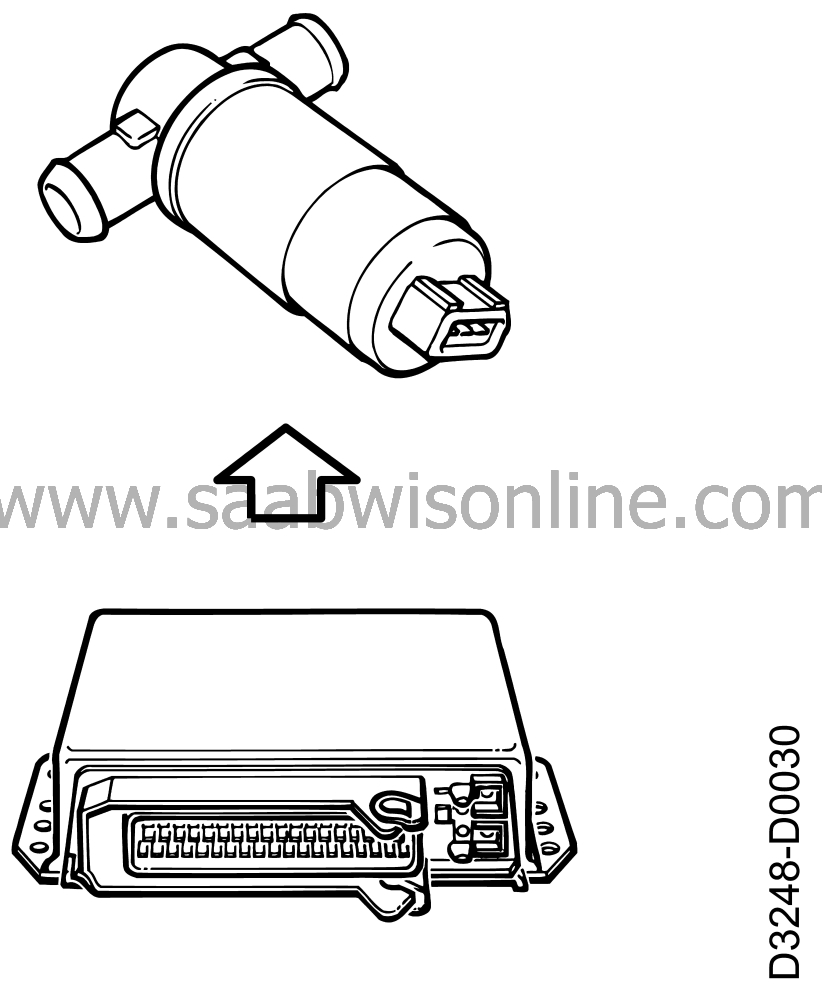

| Idle air control valve (IAC) |

When the accelerator is in the rest position and the throttle butterfly closed, air for the fuel-air mixture is obtained only from the IAC valve.

The control module regulates the degree of opening of the valve in order to maintain idling speed constant. In consequence, the valve opens on engagement of the A/C or on shifting into Drive, for instance, to compensate for the drop in idling speed which would otherwise occur.

The IAC valve, which has two windings, receives its power supply from the main relay.

A signal from pin 4 of the control module opens the valve by activating one of the windings and another signal from pin 22 of the control module closes the valve by activating the other winding.

The interaction between these two signals controls the opening of the IAC valve so that idling speed is always maintained at the correct level when the speed of the car is less than 3 km/h.

The increase in the mass air flow through the valve, on engagement of the

| • |

DRIVE position, is about 1.1

grammes per second

|

|

| • |

A/C compressor, is about 1.4 grammes per second

|

|

| • |

Radiator fan, is about 0.4 grammes per second

|

|

| • |

Secondary air injection pump, is about 0.8 grammes per

second.

The signals are 100 Hz PWM signals which at idling speed are: |

|

| • |

pin 4 aprox. 2-5 V

|

|

| • |

pin 22 aprox. 7-10 V

|

|

In the event of a break in the circuit, the opening of the valve is set by a spring so that idling speed will be at least 1000 rpm.