Principle of operation, Lambda control

| Principle of operation, Lambda control |

| Oxygen sensor |

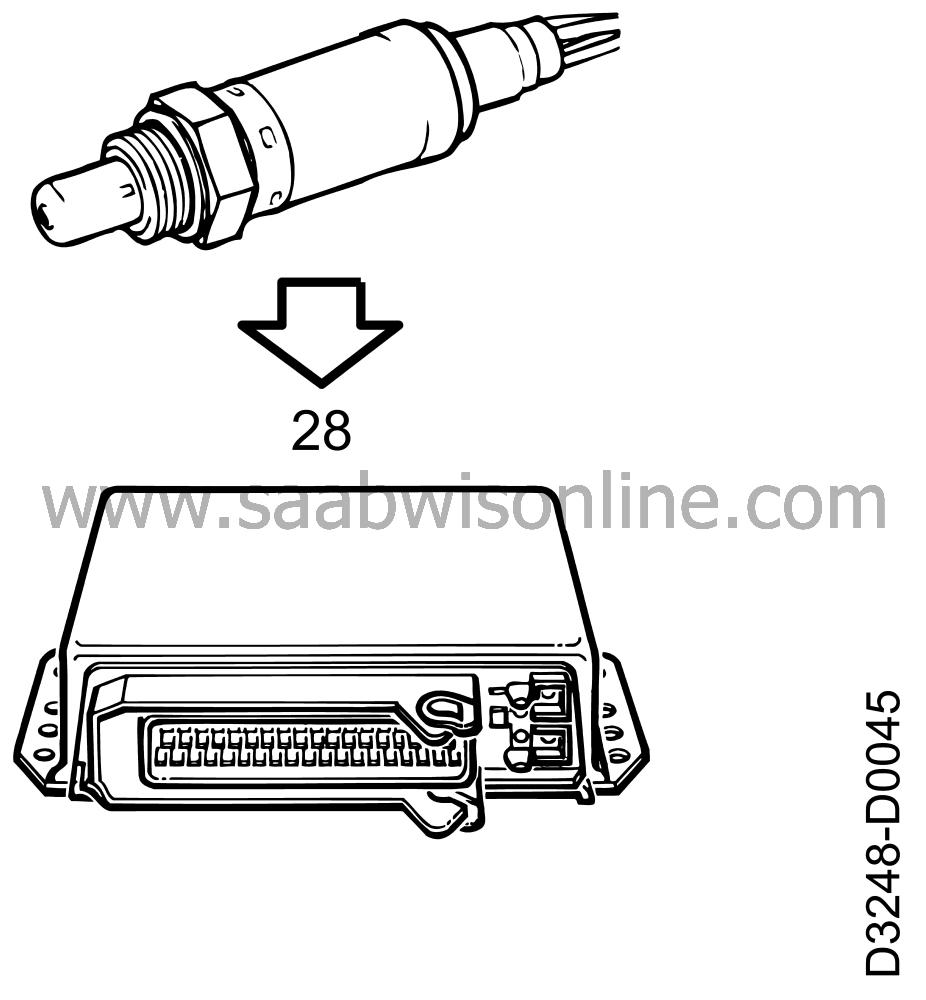

The oxygen sensor is mounted in the exhaust pipe at the front end just behind the exhaust manifold. Its purpose is to provide the control module with information on the composition (oxygen content) of the exhaust gas.

The sensor consists of a primary cell and a solid ceramic electrolyte.

The inside of the ceramic element is in contact with the surrounding air while the outside is in contact with the exhaust gases.

When the oxygen content of the exhaust gases rises, the pressure on the ceramic element increases and it produces an electric current.

Information on the oxygen content of the exhaust gases is sent by the oxygen sensor to pin 28 of the control module. The control module processes the information instantly, as it is one of the most important factors for determining the amount of fuel.

If the engine runs on a rich mixture, i.e. with a low oxygen content, the oxygen sensor produces a signal of up to about 1 V. In the case of a lean mixture, the signal voltage will be extremely low or equal to zero (0 V).

To operate efficiently the sensor must be hot. To attain working temperature as quickly as possible it is fitted with a heating element which receives current from the fuel pump relay and is grounded at grounding point G7P.

When measured with a voltmeter, the signal voltage will normally vary between 0.1 and 0.9 V.

In the event of a break in the sensor circuit, the control module will set the voltage at 0.5 V, which corresponds to lambda = 1.

| Markets with leaded petrol |

In markets with variants adapted for leaded petrol, the cars are fitted with an rpm relay which interrupts the oxygen sensor's preheater circuit when the RPM output on pin 6 of the control module indicates an engine speed in excess of 3000 rpm. This is to prevent overheating of the oxygen sensor by the effect of the powerful 18-watt preheater.