Knock control

| Knock control |

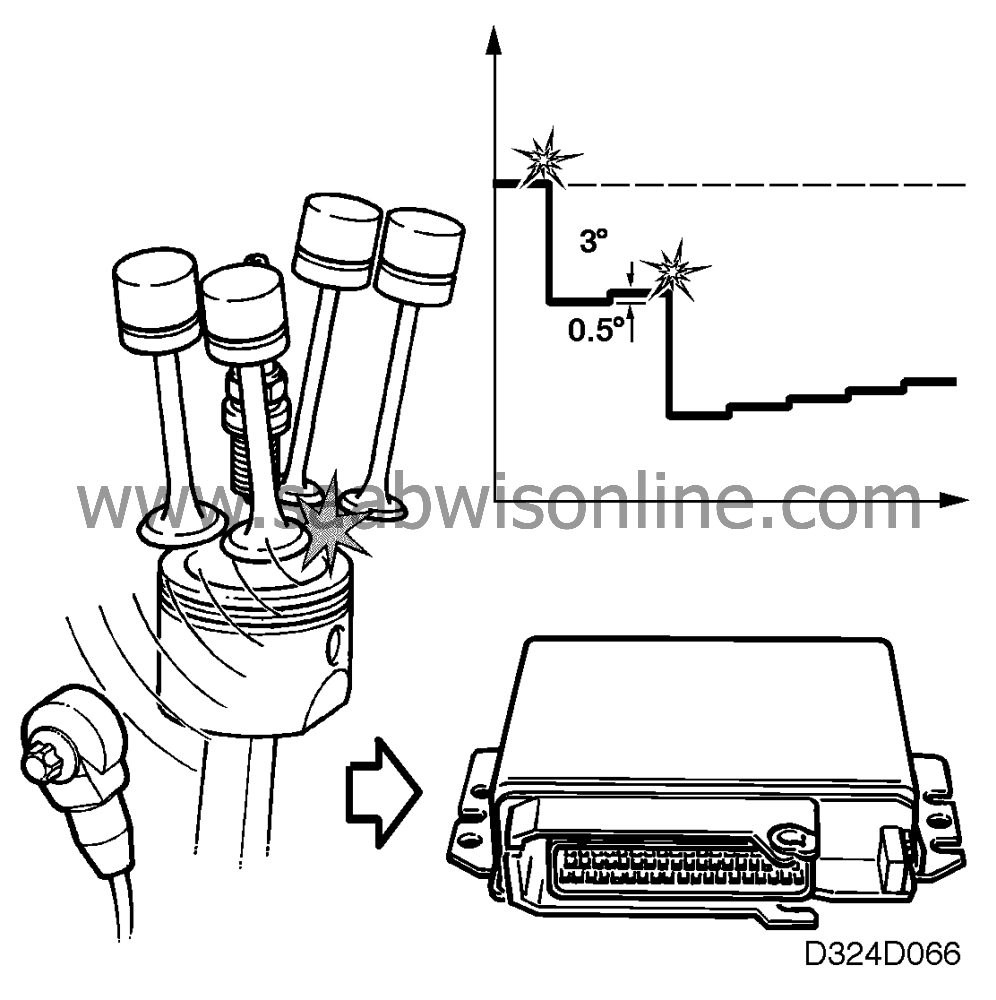

If knocking occurs in any of the cylinders, the relevant knock sensor sends a signal to the control module.

The control module notes the cylinder in which knocking occurs and retards the ignition in that cylinder by 3° (at engine speeds up to 1200 rpm the ignition is retarded by 2.25°).

If the knocking stops as a result of retarding the ignition, the timing will be restored in steps of 0.75° to what it was before.

On the other hand, if knocking persists in the same cylinder despite its ignition point being retarded by 3°, the control module will retard it an additionally step, and so on. However, the control module cannot retard the ignition by more than 13.5°.

At high intake air temperatures (above 50°C), the ignition is also retarded to counteract knocking. When the temperature drops, the ignition is restored to normal in steps of 0.75°.

When the throttle opens past a certain angle, the control module interprets it as full load and the ignition timing is obtained from another map (Kennfeld) with lower timing angles.

Should a break in continuity occur in any of the knock sensors or in any of the sensor circuits, the ignition will be retarded by up to 12° in both rows of cylinders (not at idling speed).